Novel water-cooled cooling device

A cooling device, water-cooled technology, applied in the direction of casting molding equipment, cleaning/processing machinery of casting mold materials, metal processing equipment, etc., can solve problems such as increasing costs, achieve high work efficiency, increase production output, and adaptability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

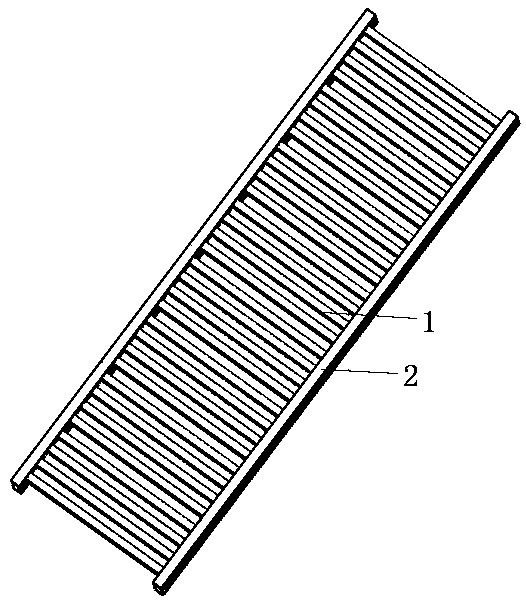

[0012] Aiming at the technical problems existing in the existing mixer, the present invention proposes a novel cold-water cooling device, comprising a ladder frame 1, a cooling pipeline 2, two ladder frames, and the two ladder frames are placed in parallel, so that There are multiple cold water pipes, and the cold water pipes are vertically connected between two ladder frames. The ladder frames are in the shape of a rectangular thin plate, and the cold water pipes are long cylindrical hollow tubes. The cold water pipes are Installed in separate rows on the ladder frame, in which the upper and lower rows of cold water pipes are installed side by side on the ladder frame. When in use, the cooling water flows from the ladder frame into the hollow pipe and the cooling pipe to play a circulating cooling function and improve cooling efficiency. Improve the production output per unit time, high work efficiency, energy saving and emission reduction, and better adaptability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com