Torsional vibration damper, elastomer member therefor, and manufacturing method thereof

A technology of torsional vibration dampers, elastomers, used in household components, vibration suppression adjustment, springs/shock absorbers, etc., can solve problems such as undesired, leakage and failure, unsightly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Reference is now made in detail to the description of the embodiments illustrated in the accompanying drawings. While several embodiments have been described using these figures, there is no intent to limit the present disclosure to the embodiments or embodiments disclosed herein. On the contrary, the intention is to cover all alternatives, modifications and equivalents.

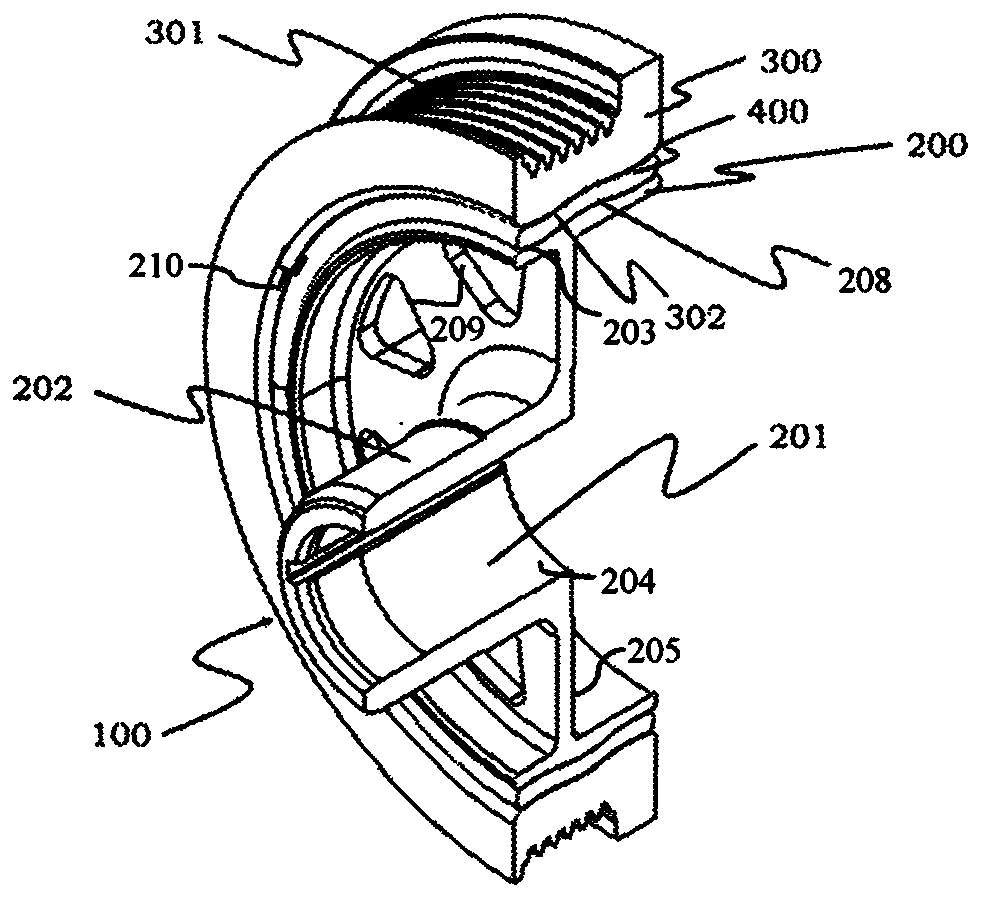

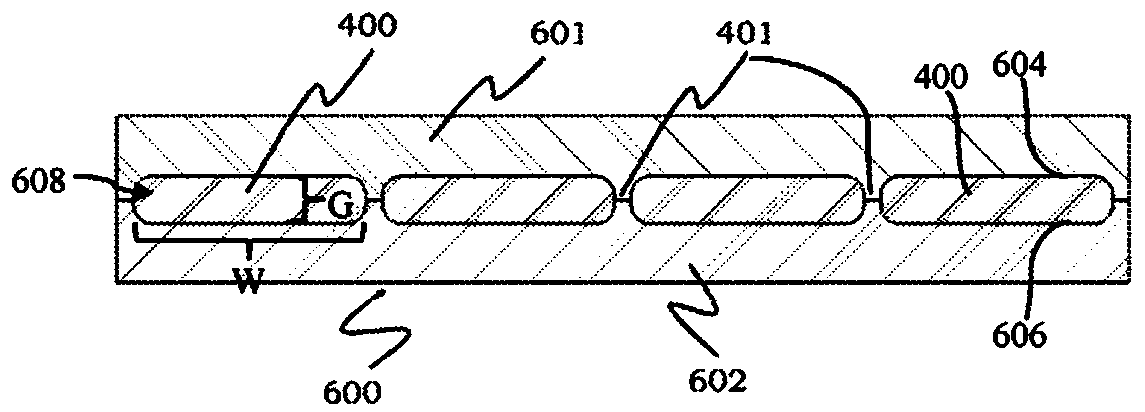

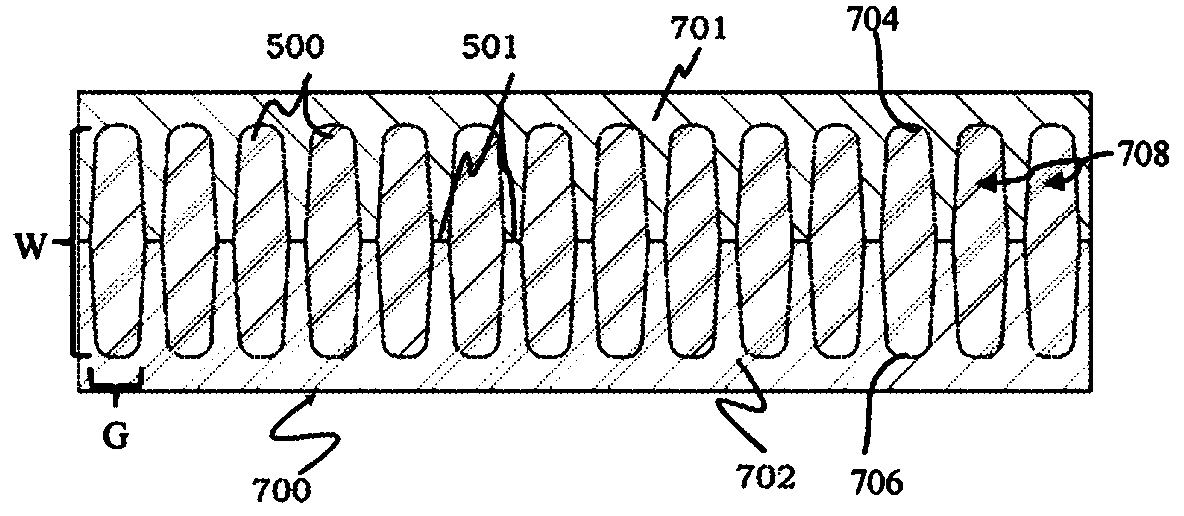

[0040] In Figure 1, Figure 7 and Figure 8 A TVD is generally indicated by the reference numeral 100 in FIG. 1 , and includes a hub 200 defining a generally centrally located bore 201 having an inner cylindrical surface 204 and an outer cylindrical surface 202, the inner cylindrical surface 204 accommodating a motor such as an IC motor. Vibrating shaft of the crankshaft, the outer cylindrical surface 202 receives the front engine seal. Hub 200 also includes an outermost radial surface 203 spaced radially outward from bore 201 by plate 205 . Plate 205 may define one or more holes or open windows 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com