A fully automatic casting and welding process and production line for lead-acid batteries

A lead-acid battery and production line technology, applied in foundries, manufacturing tools, foundry equipment, etc., can solve the problems of short connection time and inability to connect closely with cutting and brush work, so as to achieve short connection time, improve lead immersion effect, and ensure smoothness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

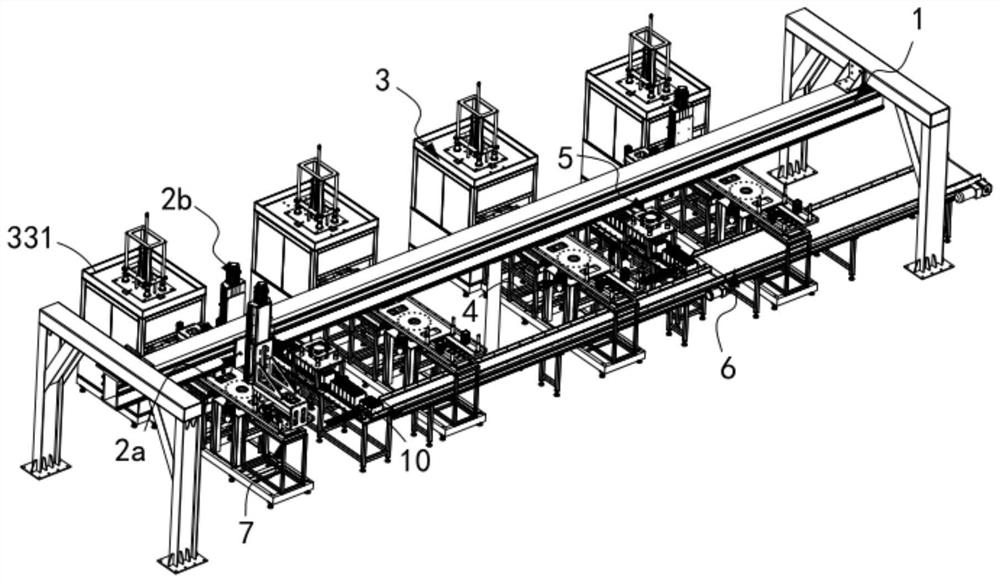

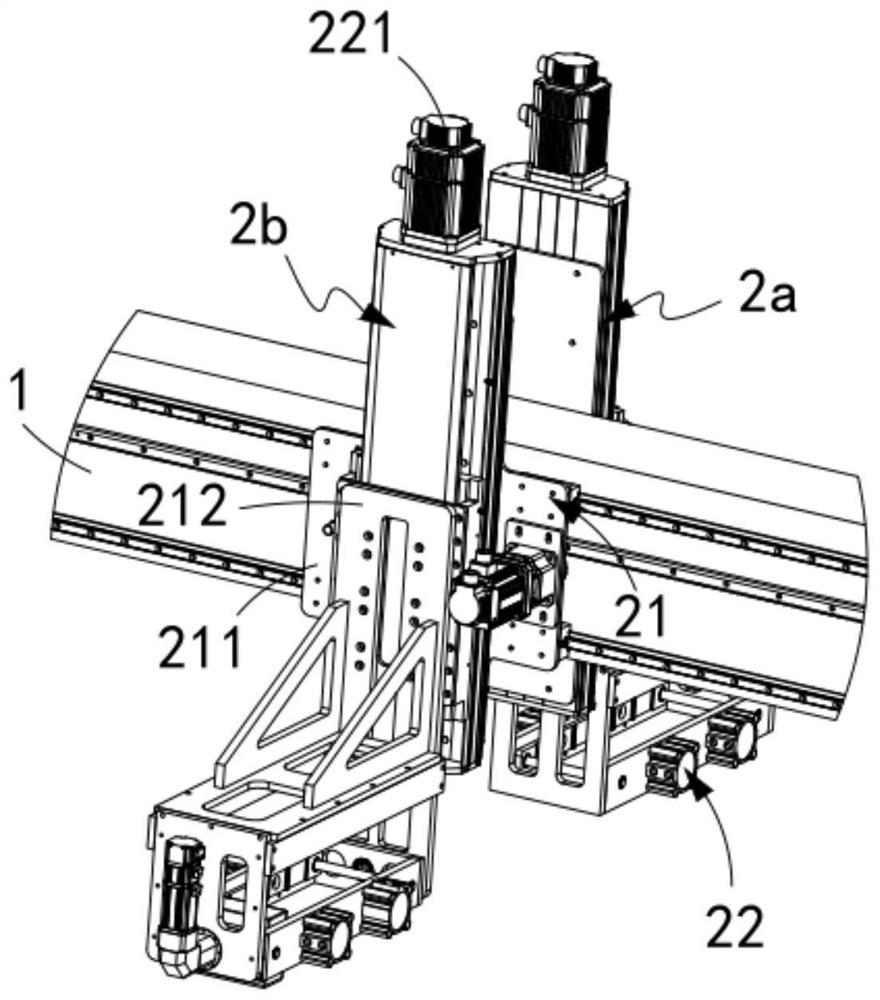

[0064] Such as figure 1 As shown, a full-automatic casting and welding production line for lead-acid batteries includes a gantry 1, a loading hand 2a that is slidably arranged on the gantry 1 along the length direction of the gantry 1, and a There is at least one set of processing lines in the length direction;

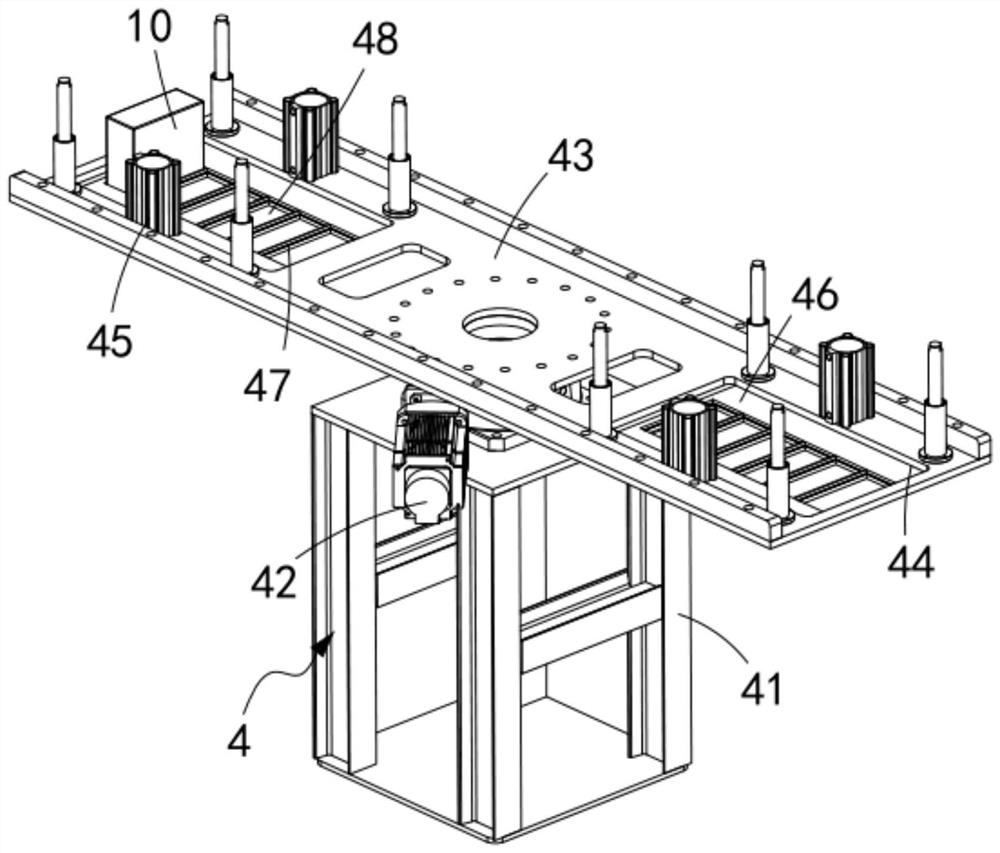

[0065] The processing line includes an unloading hand 2b that is slidably arranged on the other side of the gantry 1 relative to the loading hand 2a, a casting and welding machine 3 located below the unloading hand 2b, and a welding machine 3 arranged on the gantry. 1 below the station switching machine 4 and the slotting machine 5 arranged on one side of the casting and welding machine 3, the two ends of the station switching machine 4 are respectively provided with a feeding station 401 and a processing station 402, so The processing station 402 is located above the output end of the casting and welding machine 3, and the casting and welding machine 3 includes a le...

Embodiment 2

[0096] Such as Figure 4 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0097] further, such as Figure 4 As shown, the slotting machine 5 includes a frame b51 and a pressing assembly 52;

[0098] The press-down assembly 52 includes a seventh flat-push cylinder 521 installed above the frame b51. The telescopic end of the seventh flat-push cylinder 521 is set vertically downward, and its telescopic end direction is provided with a lead-acid battery pack. 10 matches the set jacking block 522;

[0099] The frame b51 is provided with a guide groove 53 along its length direction, and the frame b51 is provided with a pusher assembly, which includes a third guide rail 541, which is slidably ...

Embodiment 3

[0105] Such as Figure 18 Shown, the production technology of described a kind of lead-acid storage battery full-automatic cast welding production line, comprises:

[0106] Step 1, brush cutting work, the lugs on the lead-acid battery pack 10 are driven by the brush cutting machine to complete the ear cutting work, ear brushing work and ear trimming work in sequence;

[0107] Step 2, feeding, the feeding hand 2a extracts the lead-acid battery pack 10 that has completed the cutting and brushing work and puts it on the receiving plate 46 of the feeding station 401;

[0108] Step 3: After the lead-acid battery pack 10 enters the receiving plate 46 with soldering flux, the sixth horizontal push cylinder 45 drives the receiving plate 46 down to the liquid dipping mechanism 7, and the lugs enter the soldering liquid box 72 to complete the slime work;

[0109] Step 4: Take the lead liquid, and the casting and welding mold 326 enters the lead furnace 331 through the mold transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com