Bioelectrode formed by three-dimensional ordered porous oxide modified conductive film and preparation method of bioelectrode

A porous oxide, three-dimensional ordered technology, applied in the field of biosensors, to achieve the effect of improving diffusion ability, good immobilization effect and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] a. Preparation of conductive film

[0044] After the glass substrate was cleaned and dried, the titanium bonding layer, the gold thin film layer, the titanium bonding layer and the silicon dioxide insulating layer were sequentially deposited by the ion plating method. The thickness of the bonding layer was 5nm, the thickness of the conductive metal layer was 50nm, and the thickness of the insulating layer was 300nm. . That is, a conductive film is obtained;

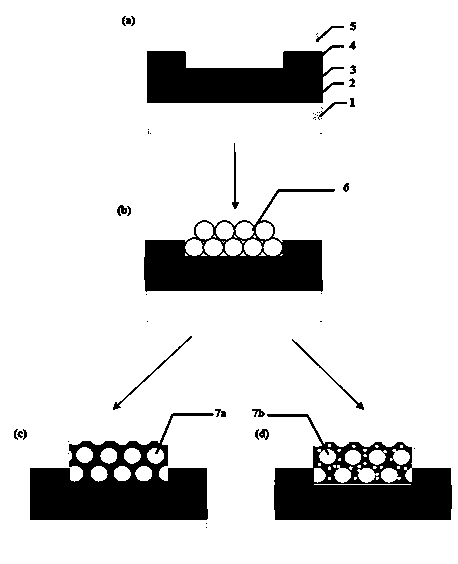

[0045] b. Preparation of three-dimensional ordered porous oxide modified conductive film

[0046] Preparation of silica sol containing mesoporous structure directing agent, the mass ratio of the mixture is: tetramethyl orthosilicate: P123: ethanol: water: hydrochloric acid = 1: 0.3: 0.1: 0.5: 0.001, fully Hydrolysis reaction. On the conductive film, use mechanical vibration assisted solvent casting process to drip the polystyrene colloidal ball suspension containing 1% by mass on the surface of the conductive fi...

Embodiment 2

[0051] a. Preparation of conductive film

[0052] After the quartz substrate was cleaned and dried, a tantalum bonding layer, a gold thin film layer, a tantalum bonding layer and a silicon dioxide insulating layer were sequentially deposited by sputtering coating method. The thickness of the bonding layer was 25nm, the thickness of the conductive metal layer was 100nm, and the thickness of the insulating layer was 500nm. That is, a conductive film is obtained;

[0053] b. Preparation of three-dimensional ordered porous oxide modified conductive film

[0054] Preparation of silica sol without mesoporous structure directing agent, the mass ratio of the mixture is: tetramethyl orthosilicate: isopropanol: water: sulfuric acid = 1: 10: 50: 0.5, fully hydrolyzed at 10 °C reaction. On the conductive film, the mechanical shock-assisted solvent casting process is used to drip the polystyrene colloidal ball suspension containing 5% by mass on the surface of the conductive film, and m...

Embodiment 3

[0059] a. Preparation of conductive film

[0060] After the silicon substrate with the silicon oxide layer is cleaned and dried, the titanium bonding layer, the platinum thin film layer, the titanium bonding layer and the silicon dioxide insulating layer are sequentially deposited by the evaporation coating method, the thickness of the bonding layer is 50nm, and the thickness of the conductive metal layer is 300nm , The thickness of the insulating layer is 1000nm. That is, a conductive film is obtained;

[0061] b. Preparation of three-dimensional ordered porous oxide modified conductive film

[0062] The alumina sol containing the mesoporous structure directing agent was prepared, and the mass ratio of the mixture was: aluminum nitrate: P123: methanol: water: nitric acid = 1: 0.1: 0.5: 1: 0.1, and a sufficient hydrolysis reaction occurred at 20 °C. On the conductive film, use mechanical vibration assisted solvent casting process to drop the polymethyl methacrylate crystal b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com