Continuous analyte sensors and methods of making same

a technology of analyte sensors and sensors, applied in the field of continuous analyte sensors, can solve the problems of increasing the concentration of glucose and property variations among the sensors produced, and achieve the effect of minimizing the variation among the sensors produced and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

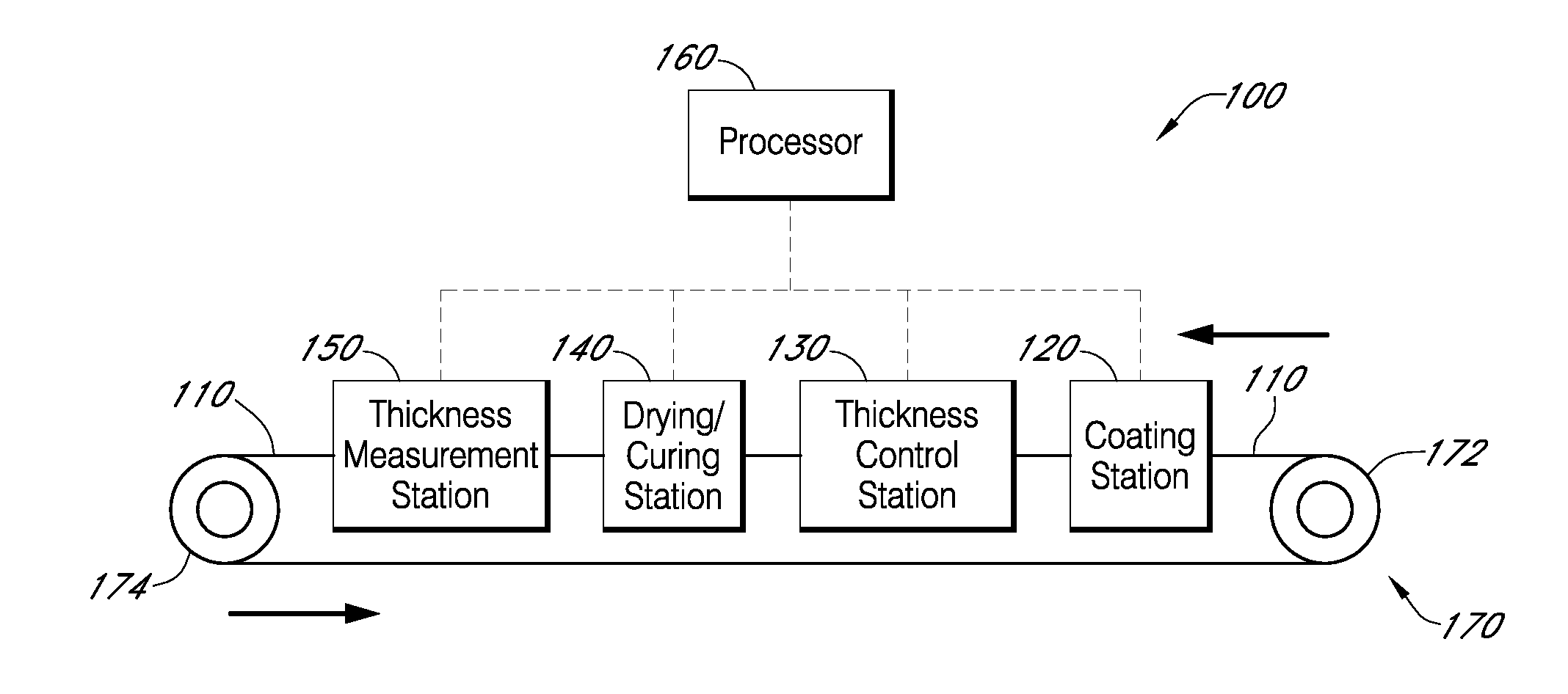

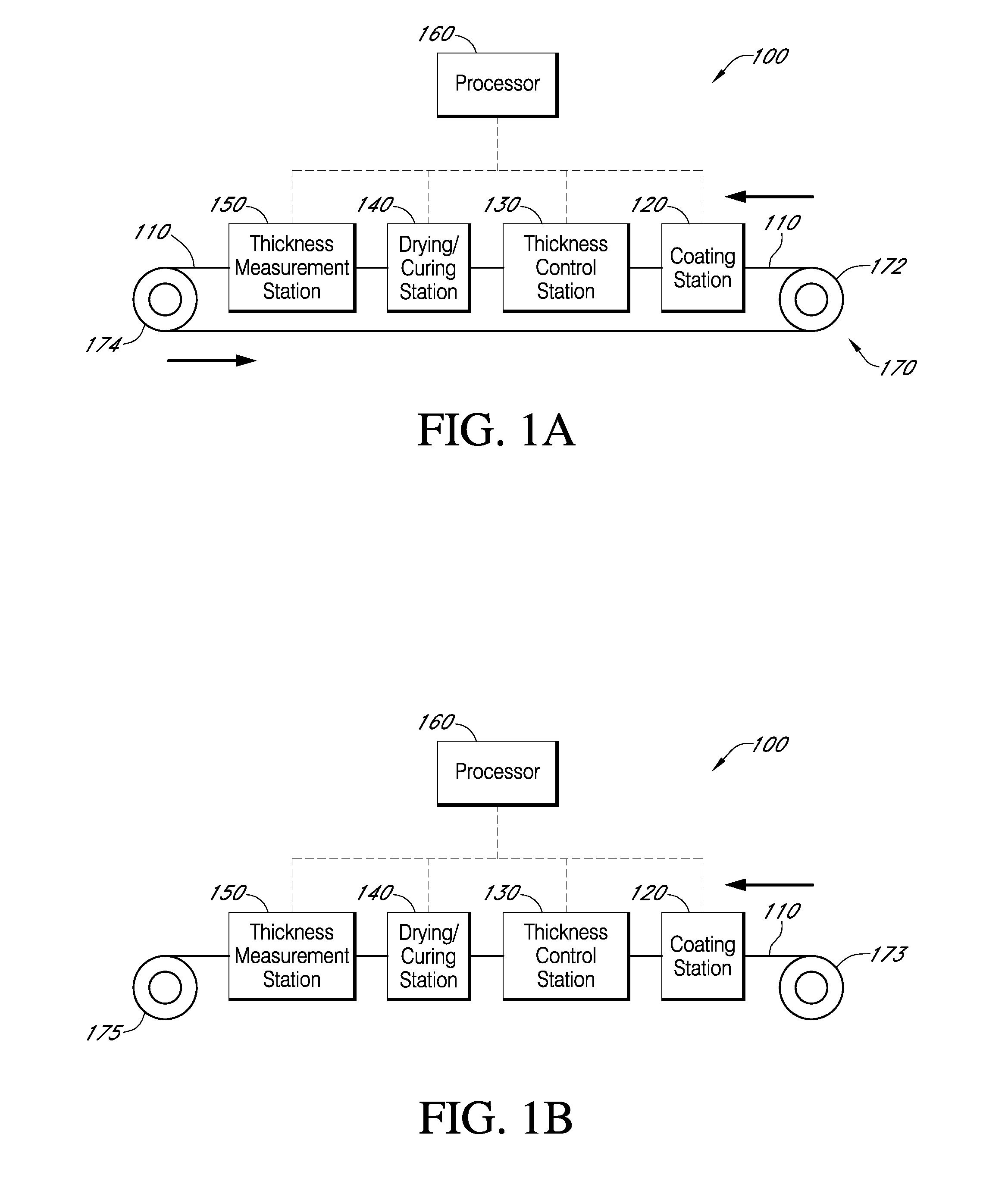

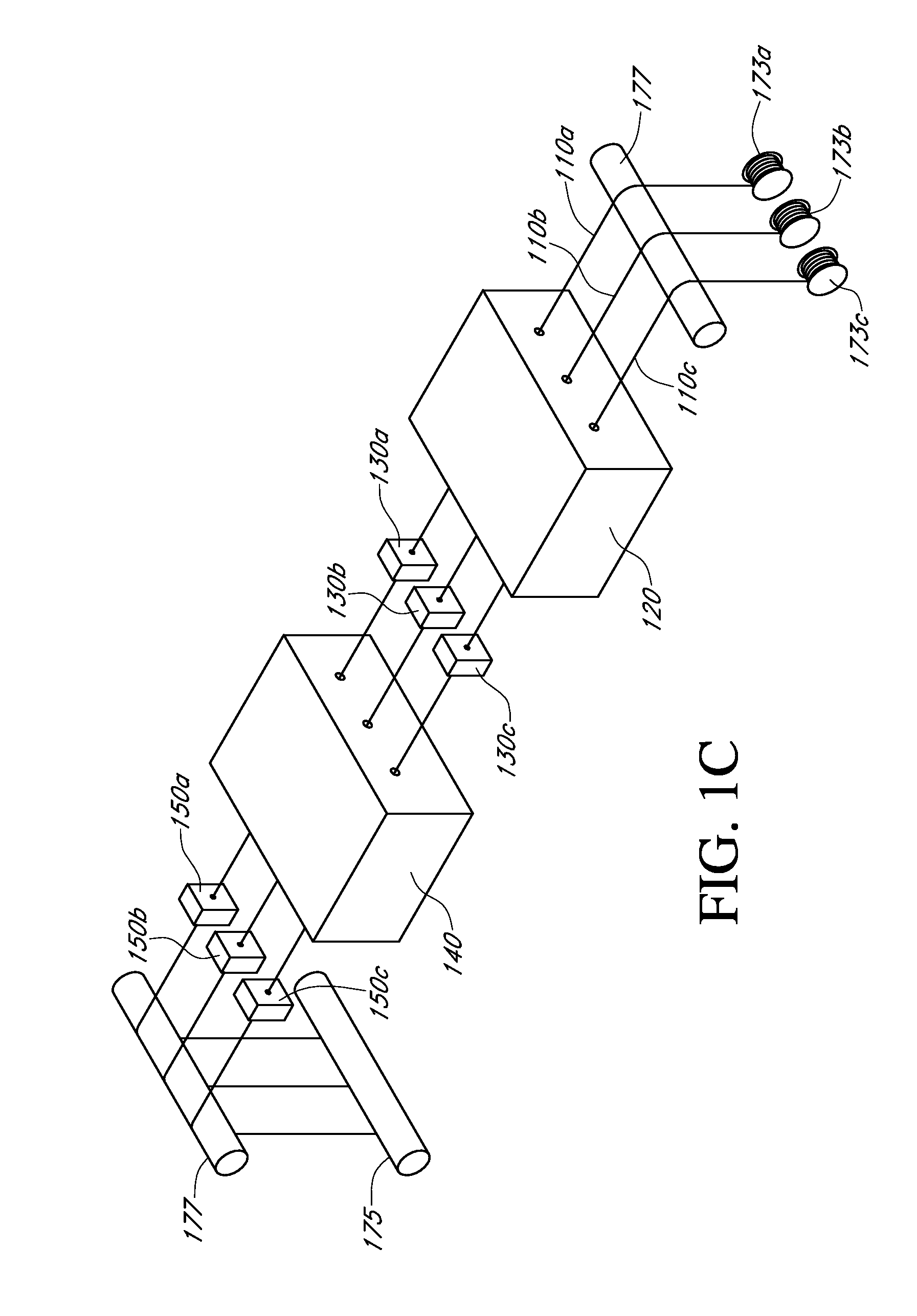

Image

Examples

Embodiment Construction

The following description and examples describe in detail some exemplary embodiments of systems and methods for manufacturing continuous analyte sensors. It should be understood that there are numerous variations and modifications of the systems, methods, and devices described herein that are encompassed by the present invention. Accordingly, the description of a certain exemplary embodiment should not be deemed to limit the scope of the present invention.

Definitions

In order to facilitate an understanding of the devices and methods described herein, a number of terms are defined below.

The term “analyte,” as used herein, is a broad term, and is to be given its ordinary and customary meaning to a person of ordinary skill in the art (and is not to be limited to a special or customized meaning), and refers without limitation to a substance or chemical constituent in a biological fluid (for example, blood, interstitial fluid, cerebral spinal fluid, lymph fluid, urine, sweat, saliva, etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com