Patents

Literature

40results about How to "Good coating stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Substrate Coated With A Hydrophilic Elastomer

ActiveUS20110319848A1Improve hydrophilicityGood coating stabilitySynthetic resin layered productsPretreated surfacesElastomerPolymer science

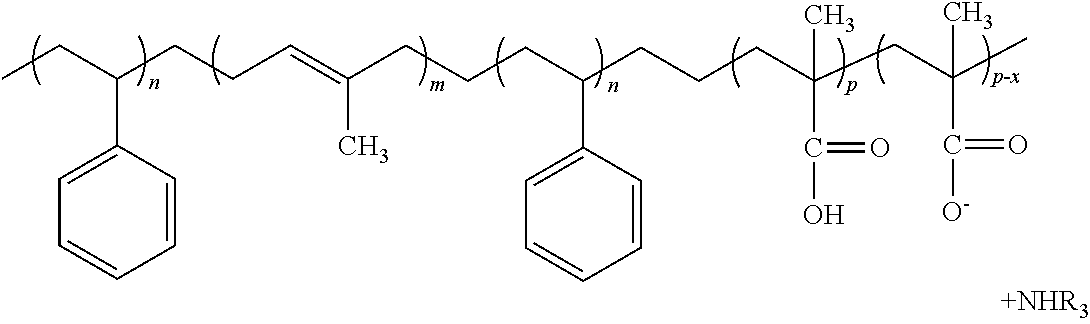

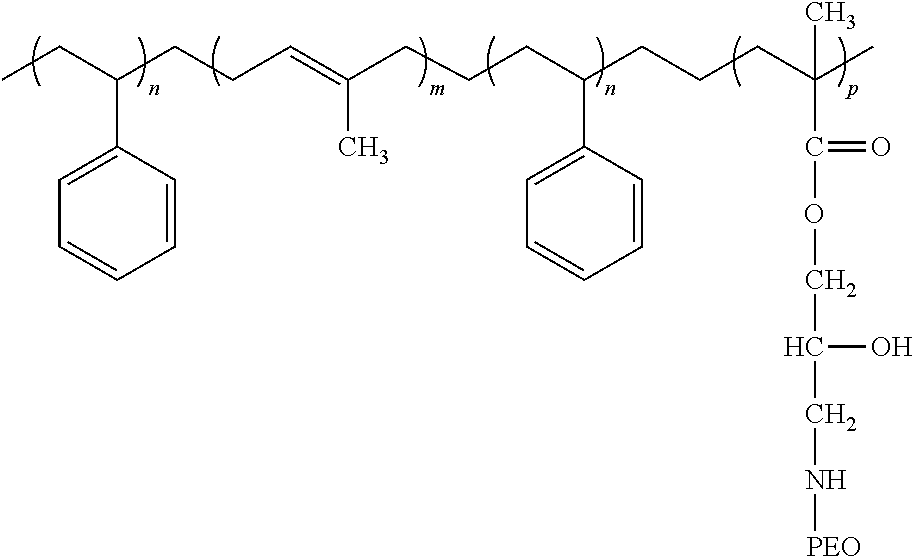

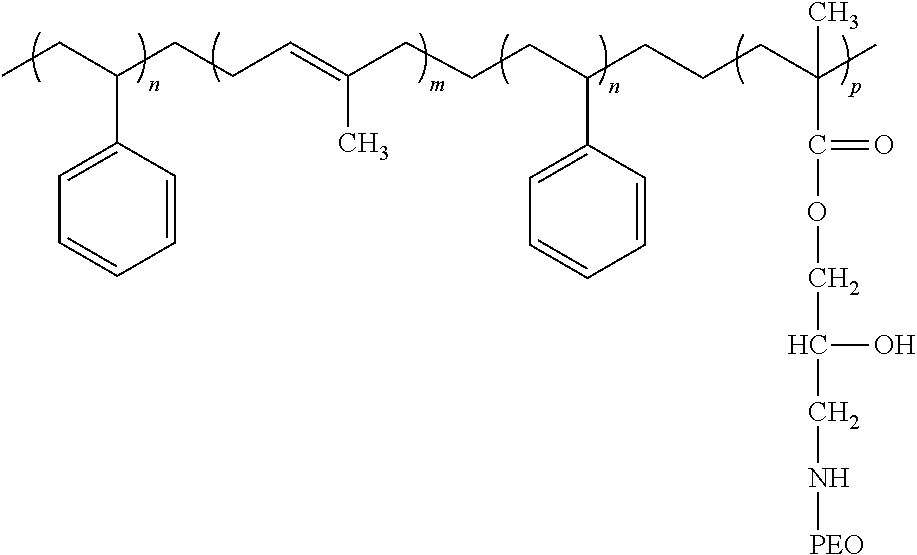

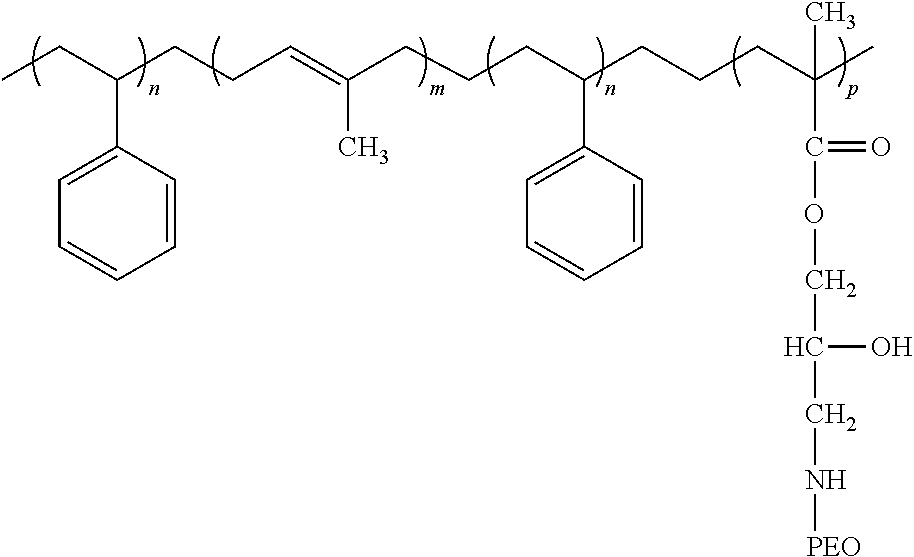

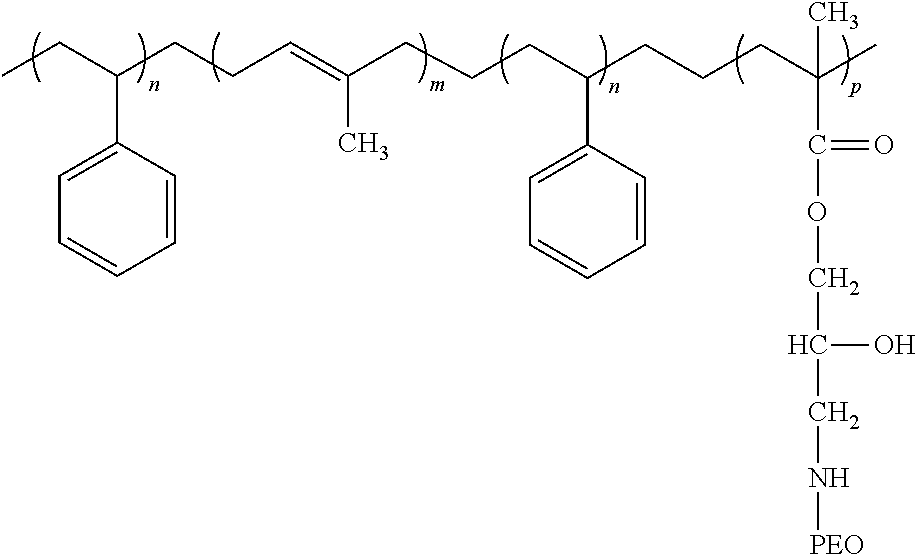

Substrates, coated with a block copolymer comprising at least four blocks being at least two hard blocks, one soft block and one hydrophilic block, wherein a the soft block is sandwiched between the hard blocks.

Owner:THE PROCTER & GAMBLE COMPANY

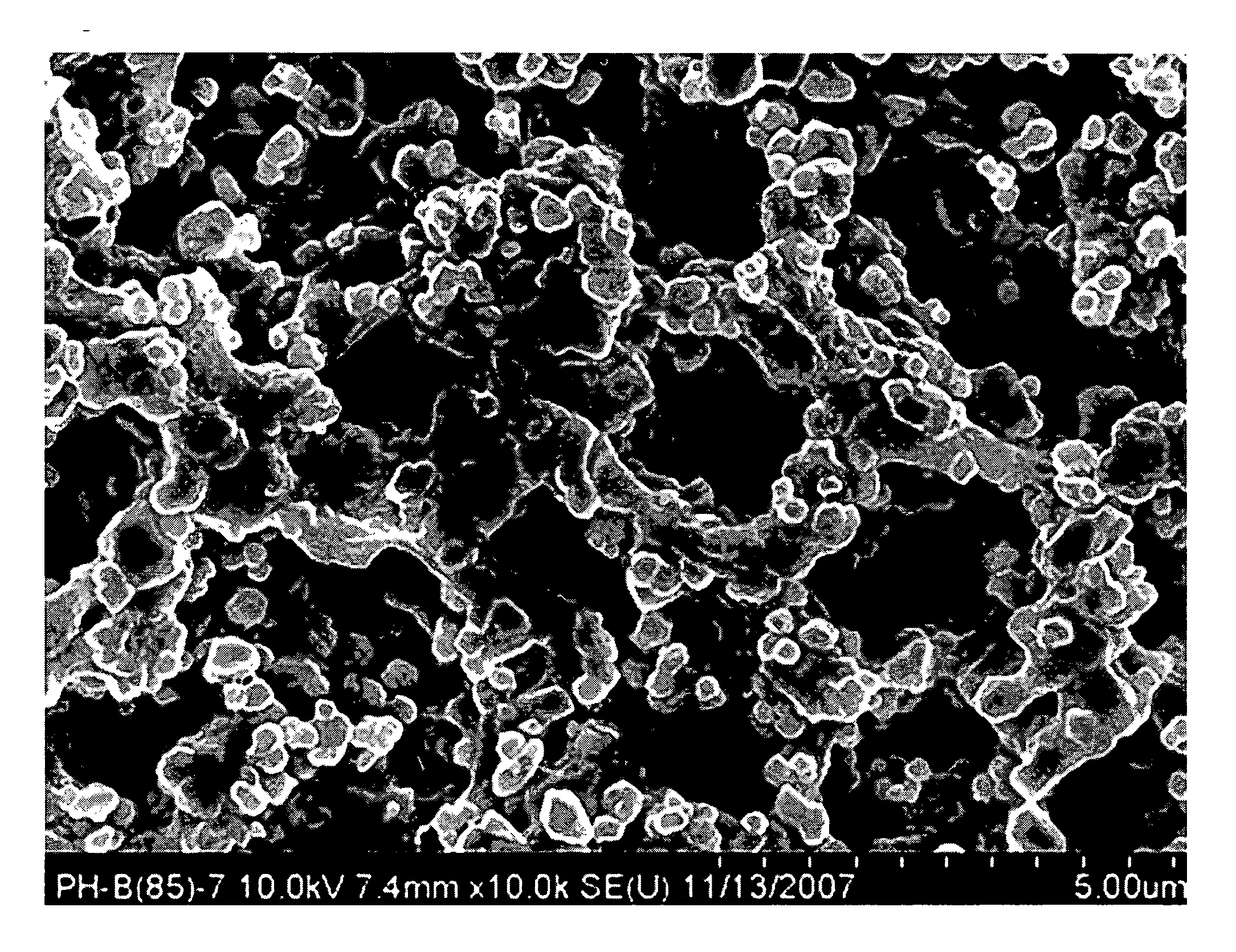

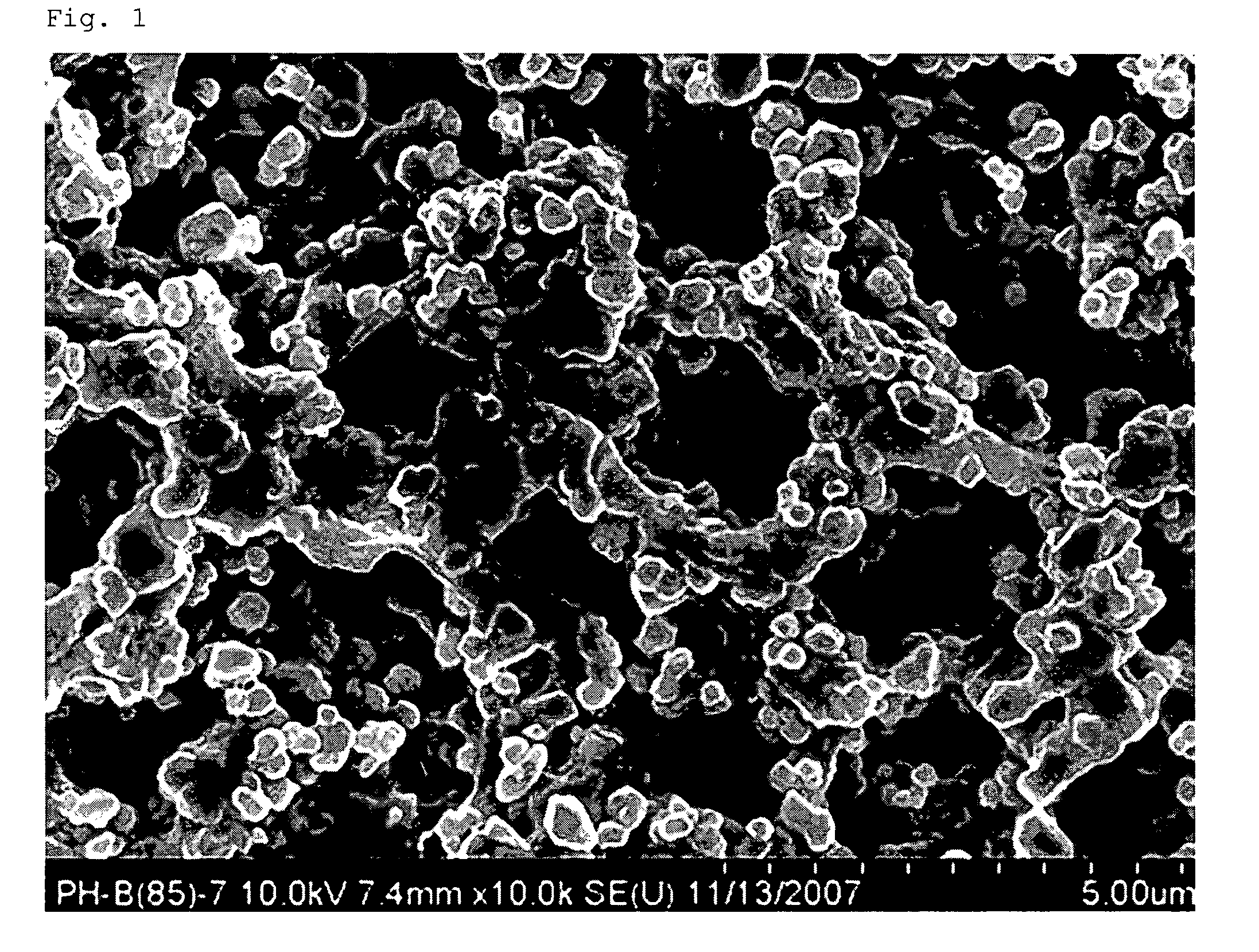

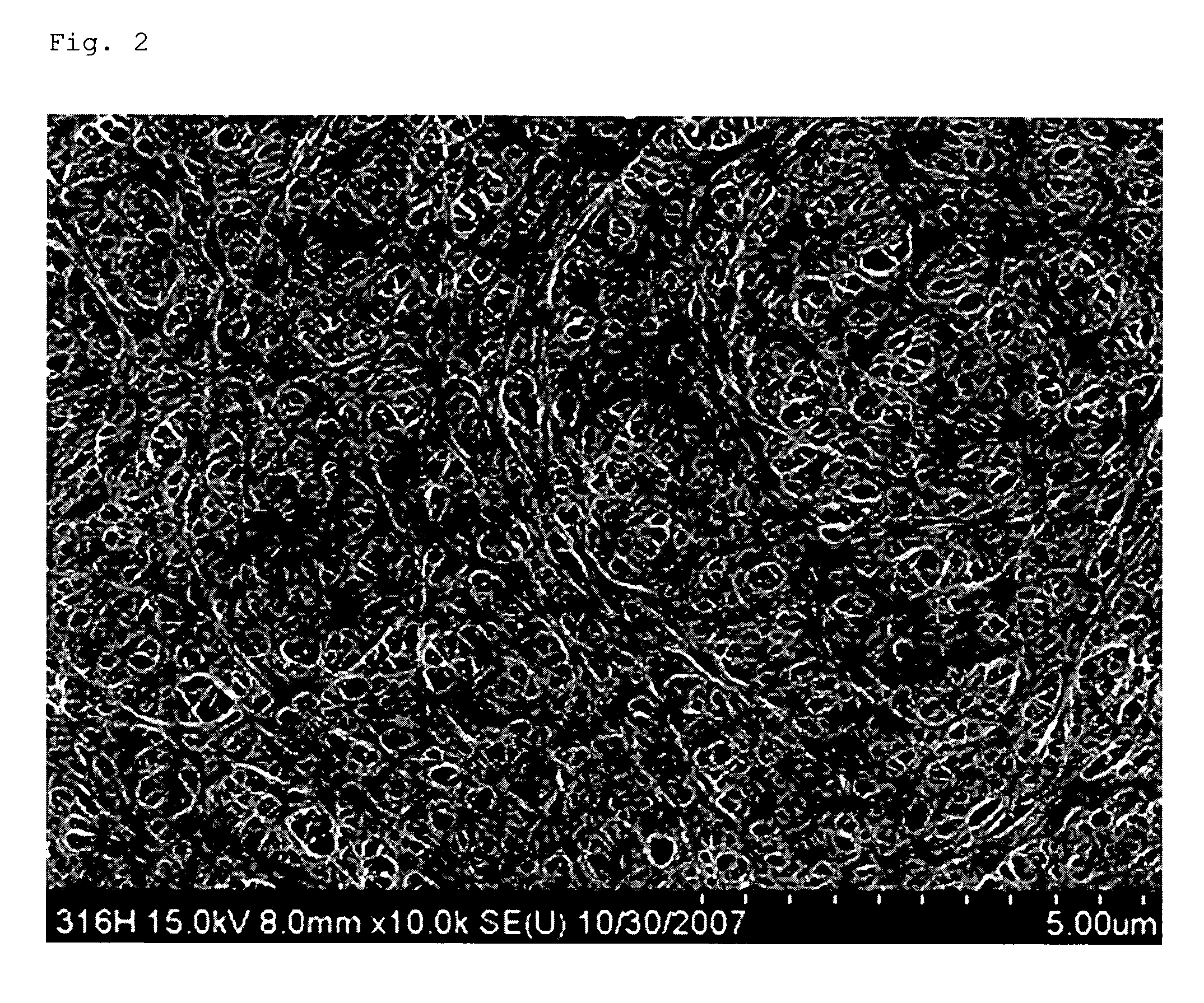

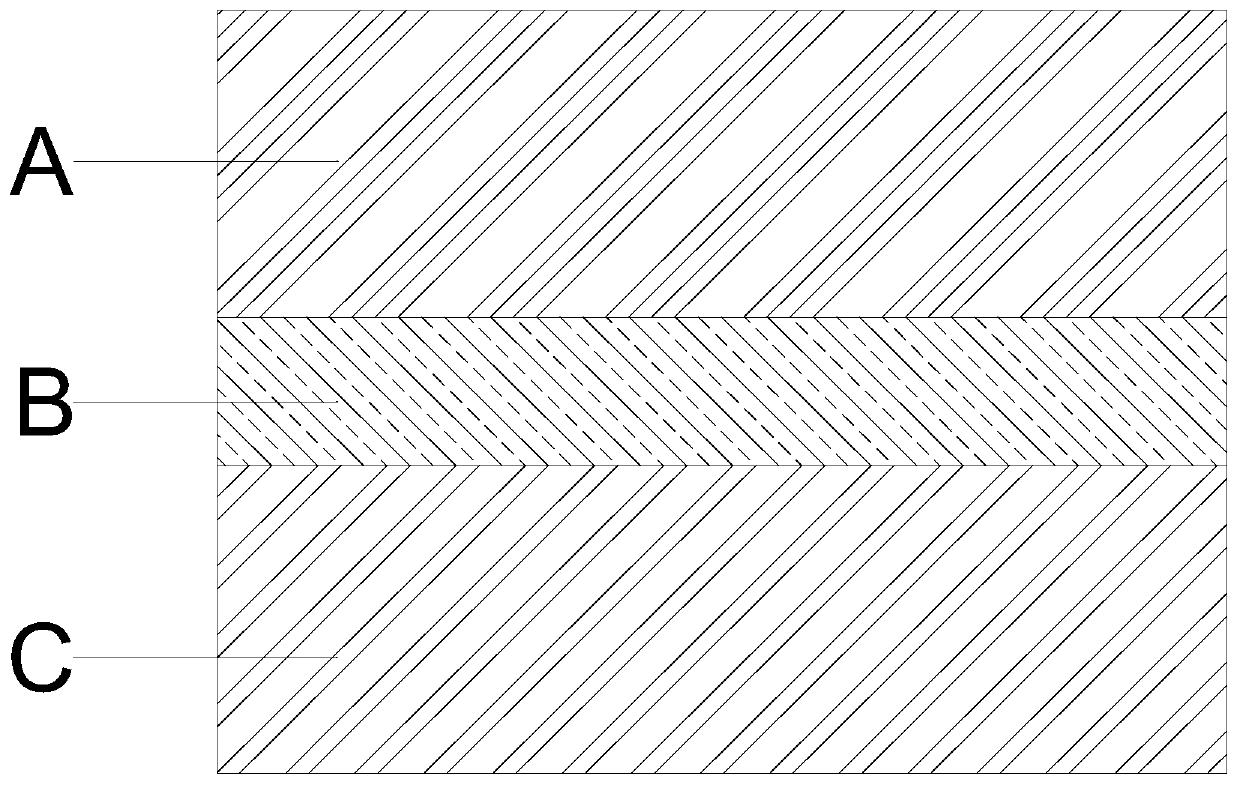

Method of manufacturing the microporous polyolefin composite film with a thermally stable layer at high temperature

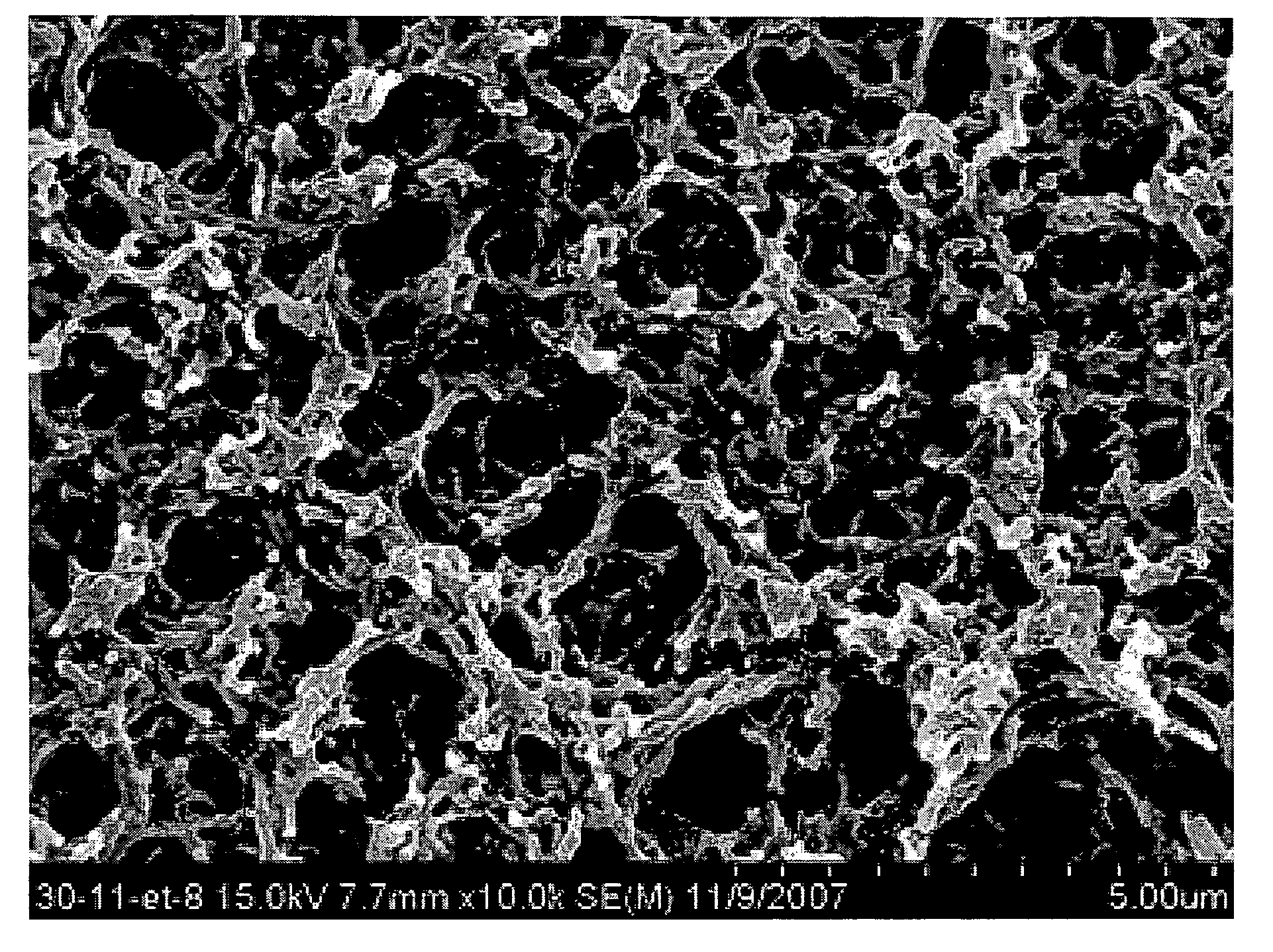

InactiveUS20110033743A1Improve breathabilityLow shrinkageSemi-permeable membranesLi-accumulatorsPolyolefinPolymer science

Provided is a method of manufacturing a microporous polyolefin composite film with a thermally stable porous layer at high temperature, particularly, to a method of manufacturing a microporous polyolefin composite film with a thermally stable porous layer at high temperature, comprising preparing a polyolefin microporous film using a composition containing a polyolefin resin; coating a solution, in which a high heat-resistant resin is dissolved in a solvent, on one surface or both surfaces of the polyolefin microporous film; phase-separating the polyolefin microporous film coated with the solution by contacting with a nonsolvent after the coating; and drying the polyolefin microporous film so as to remove the solvent and nonsolvent remained after the phase-separating, and thus forming the thermally stable layer at high temperature.

Owner:SK INNOVATION CO LTD

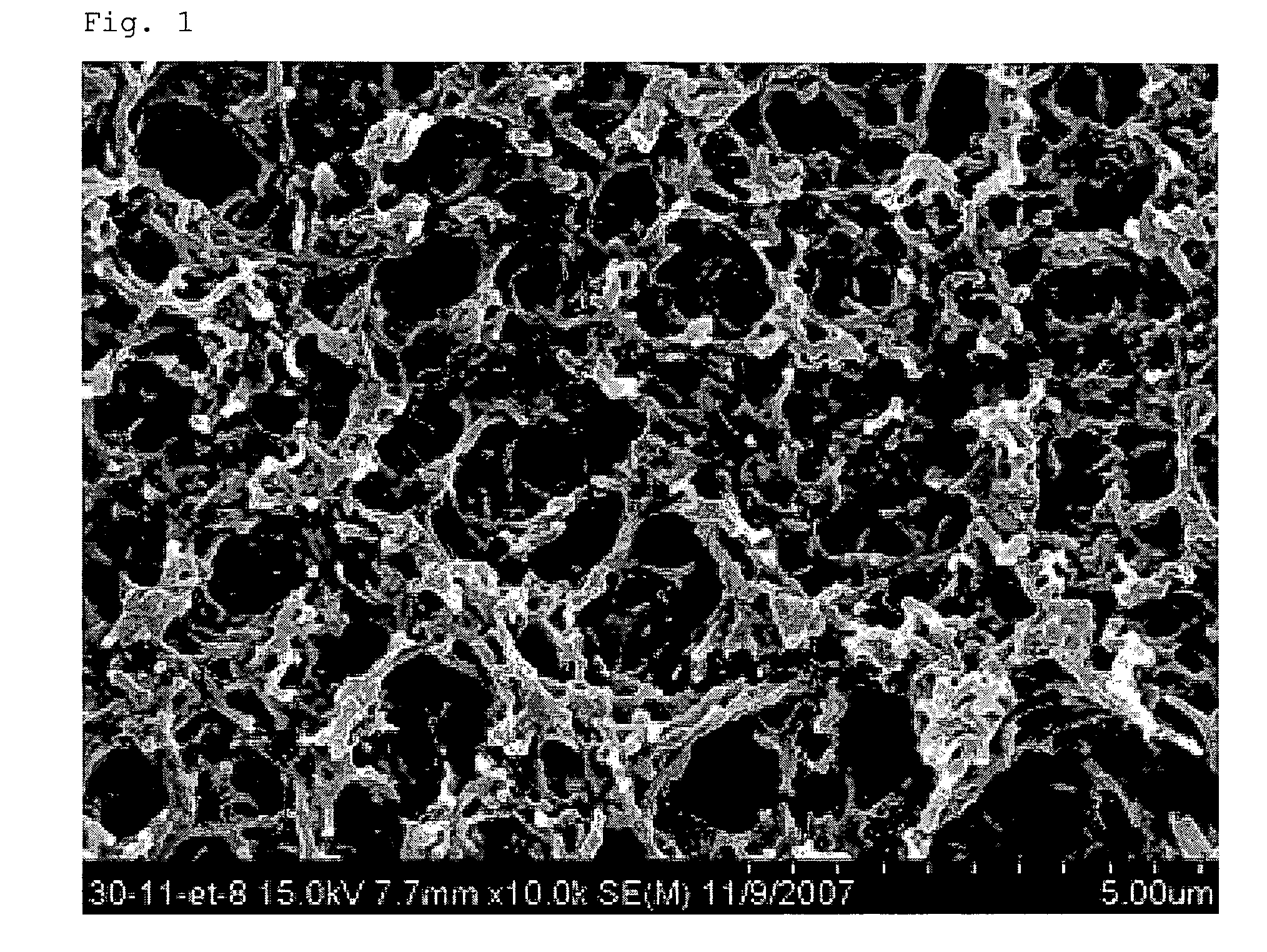

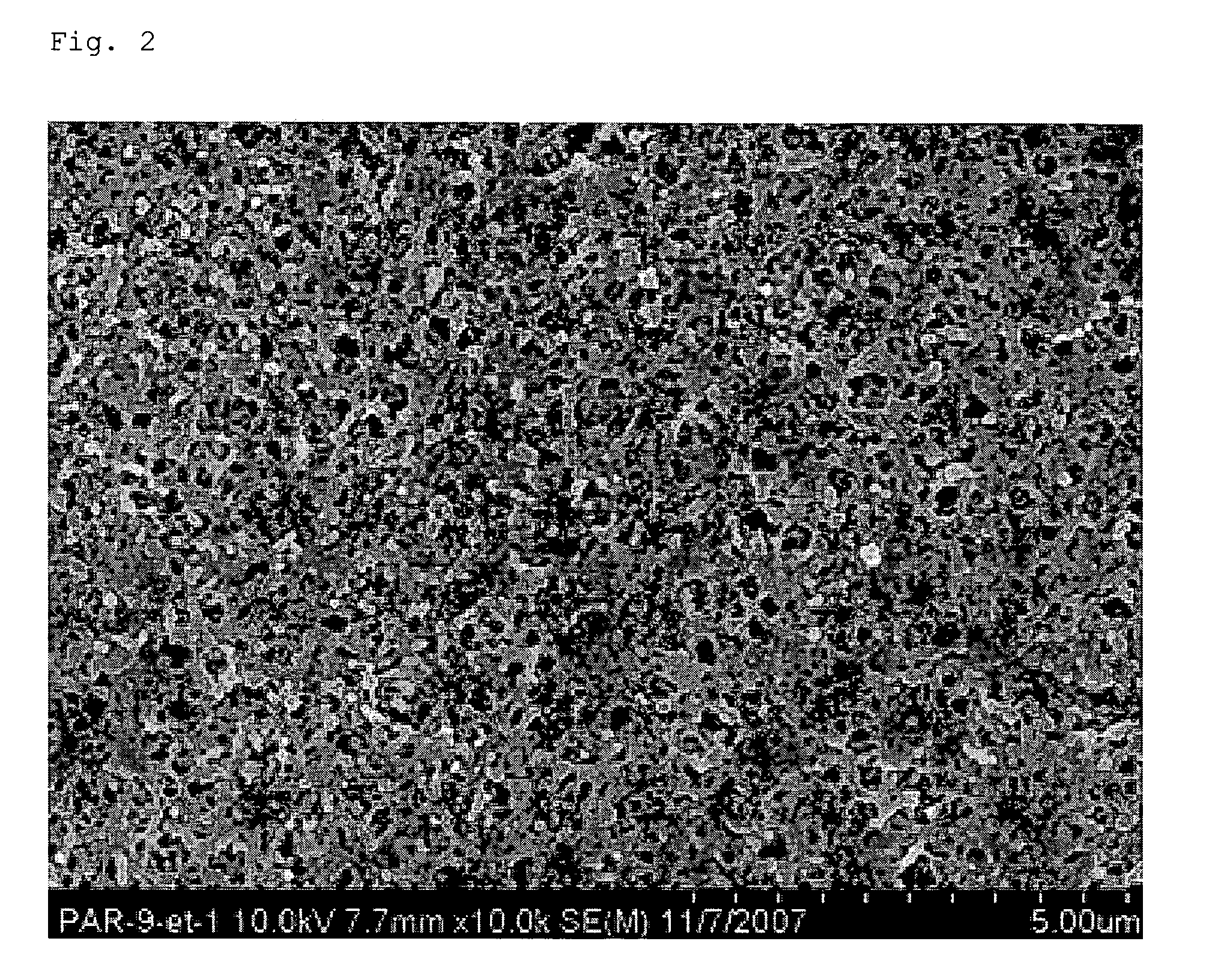

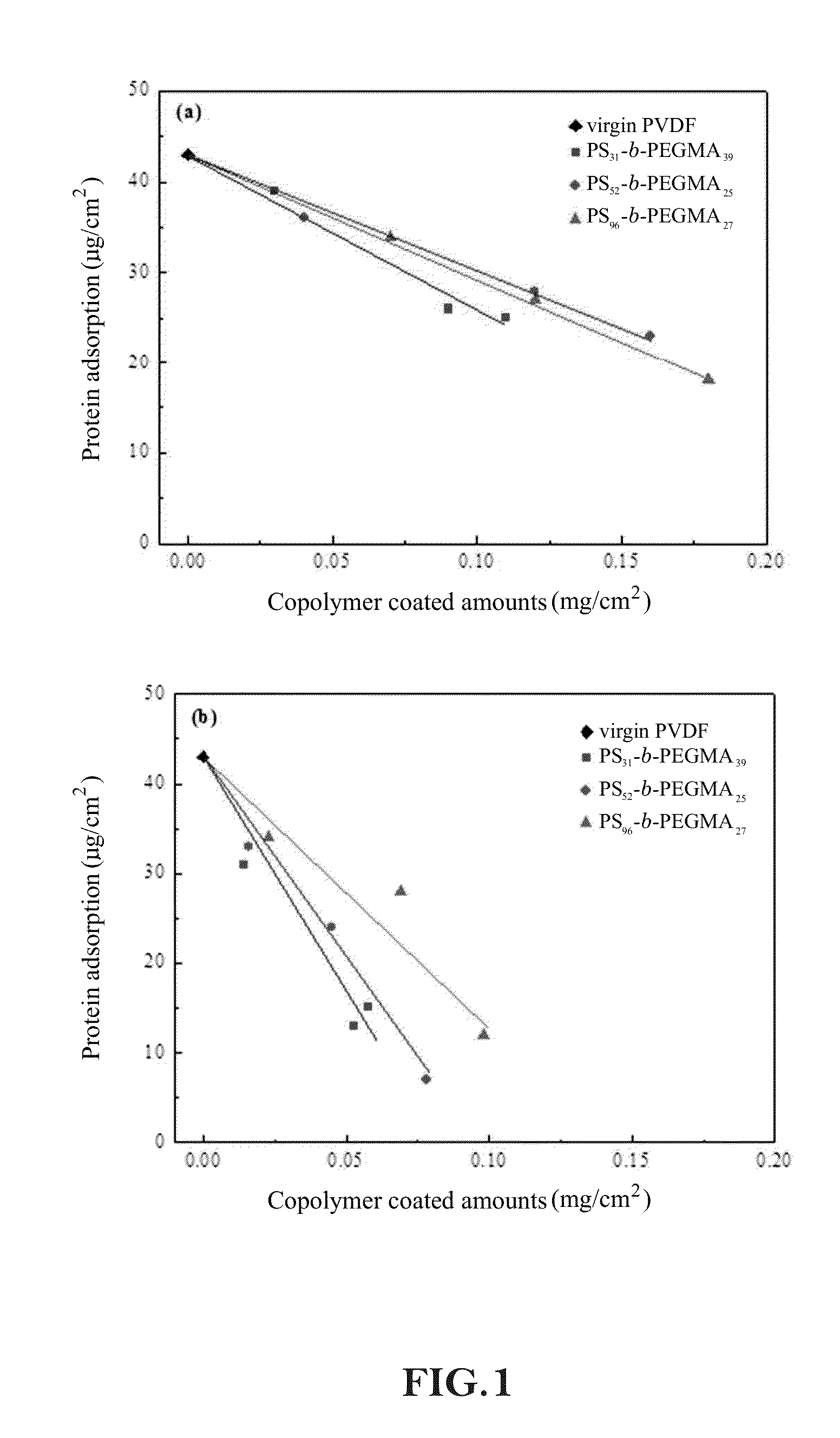

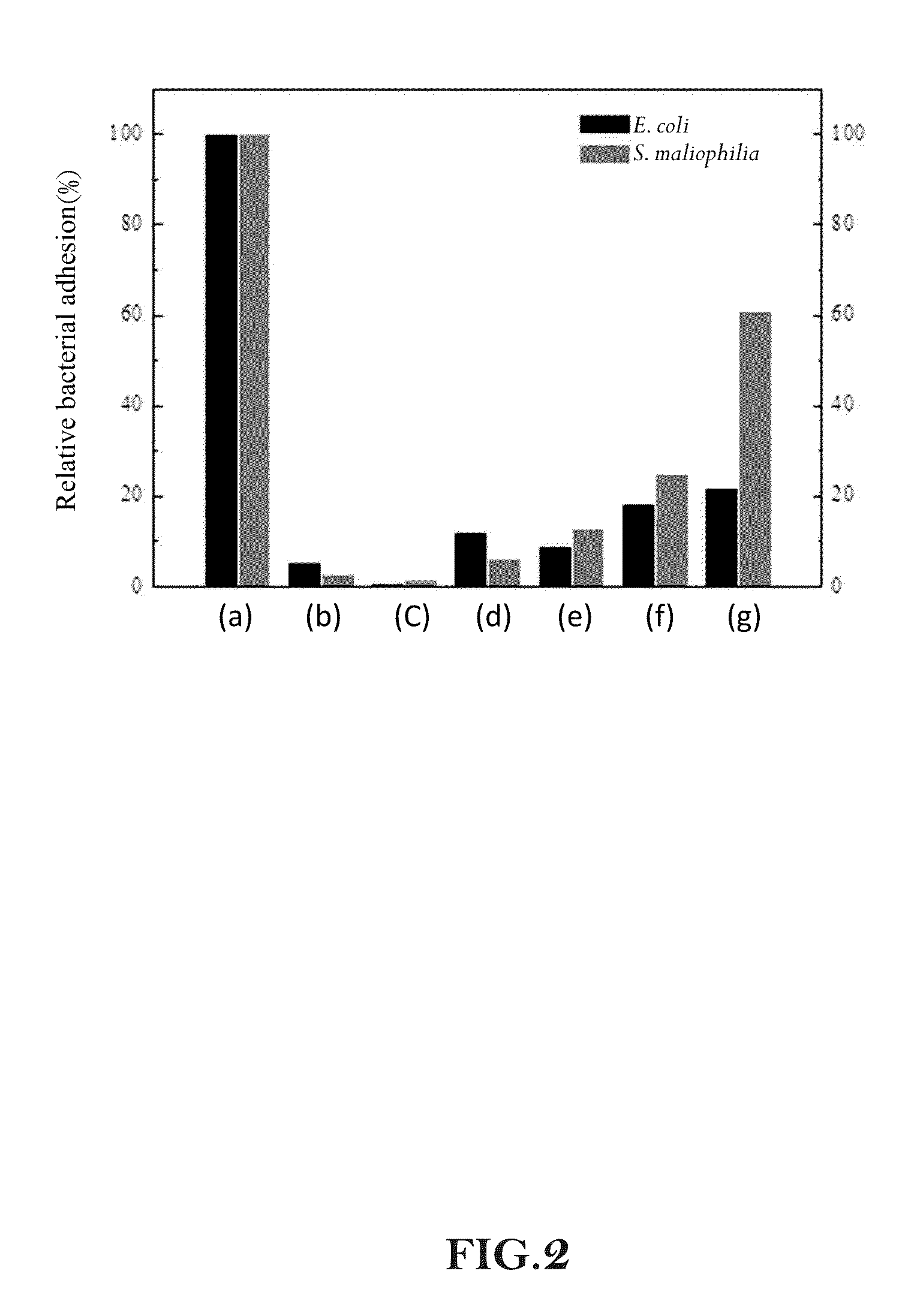

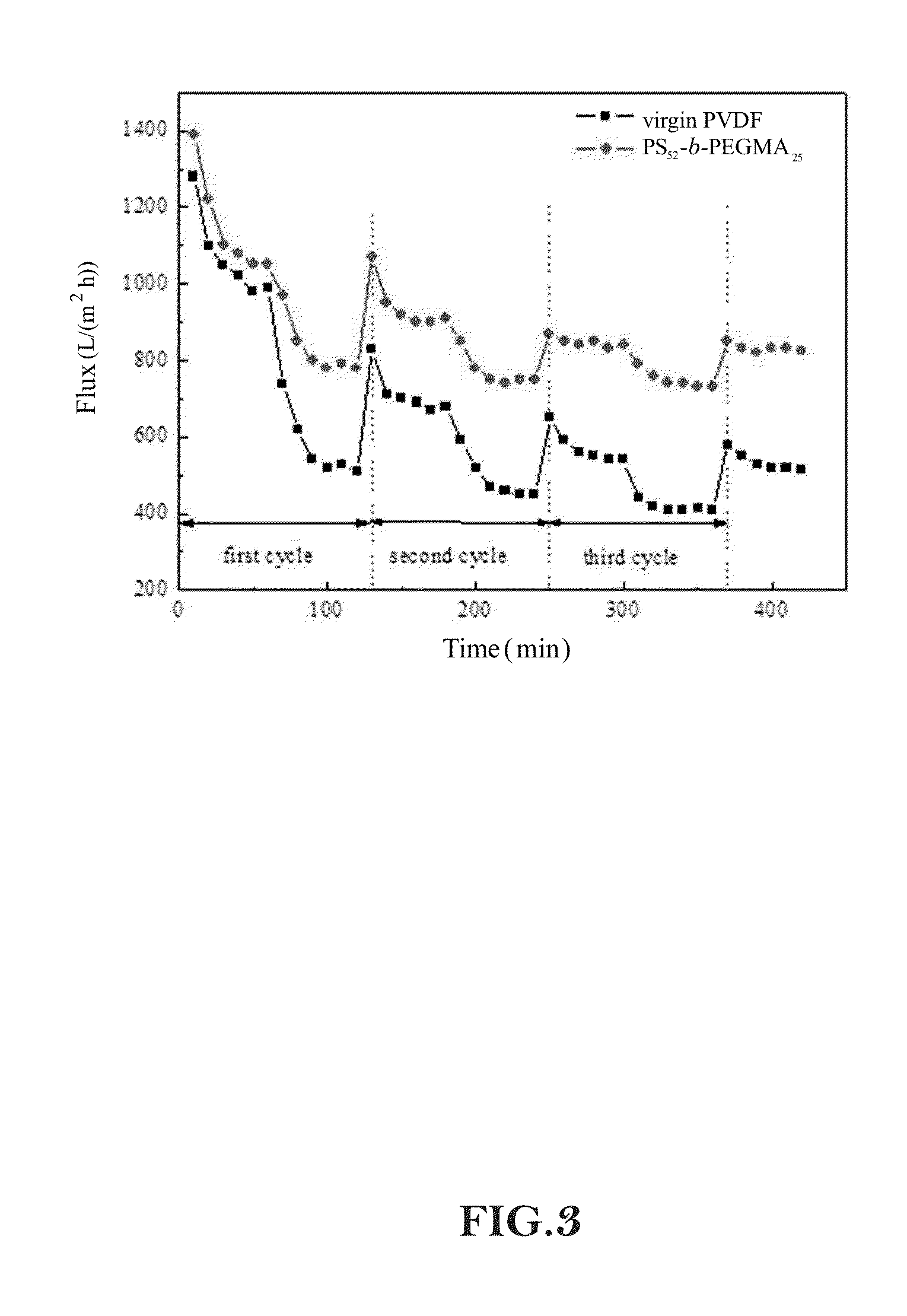

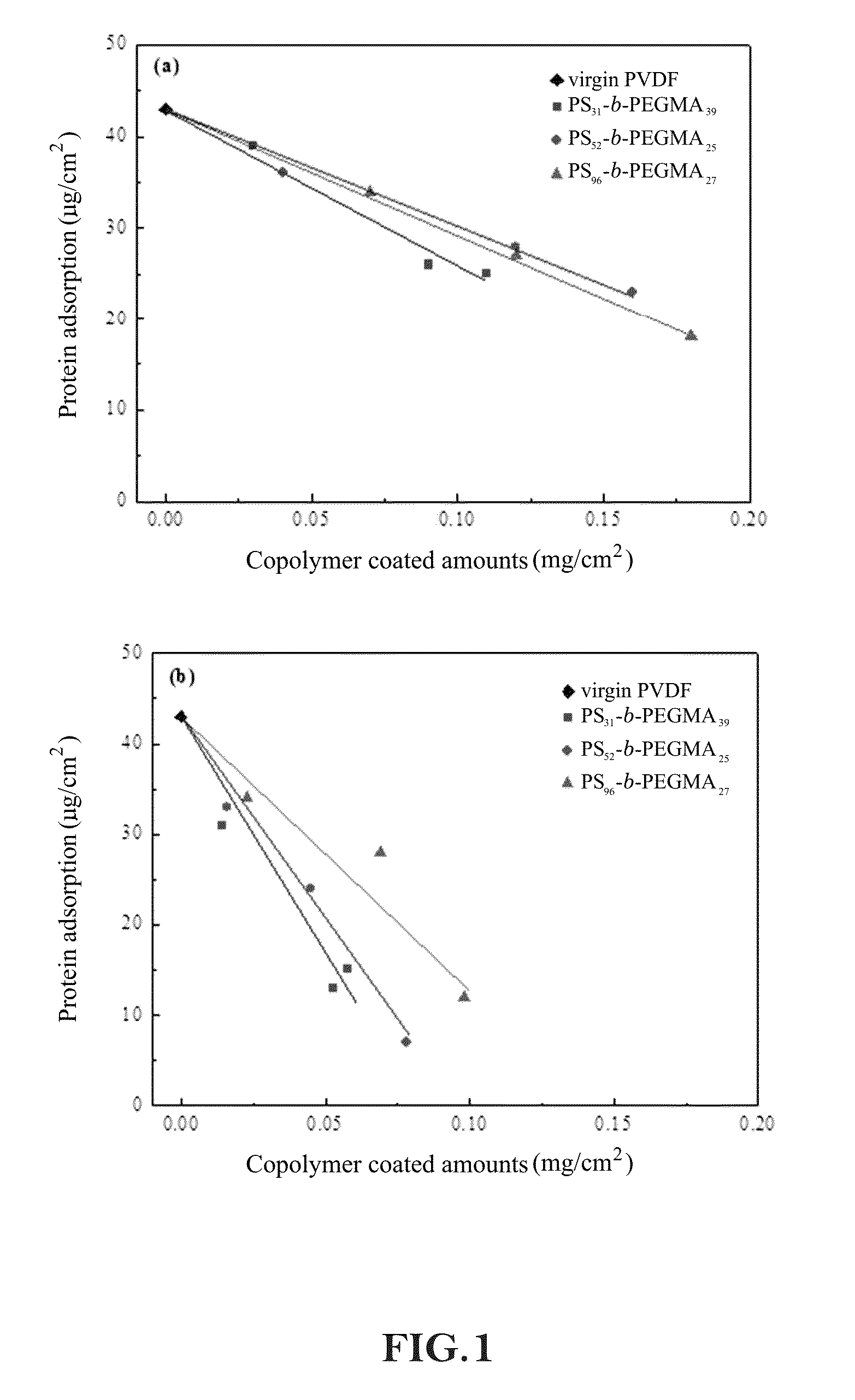

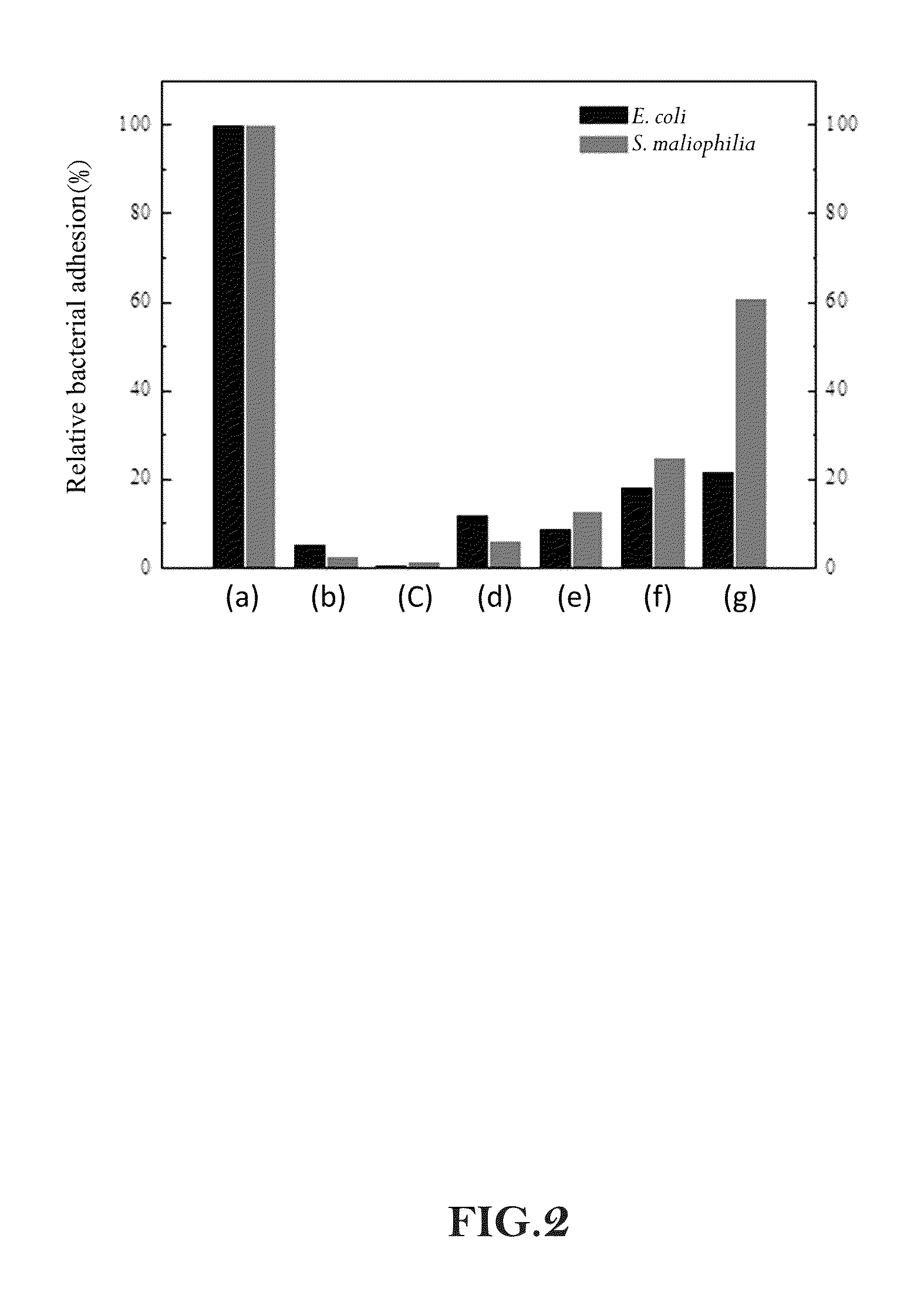

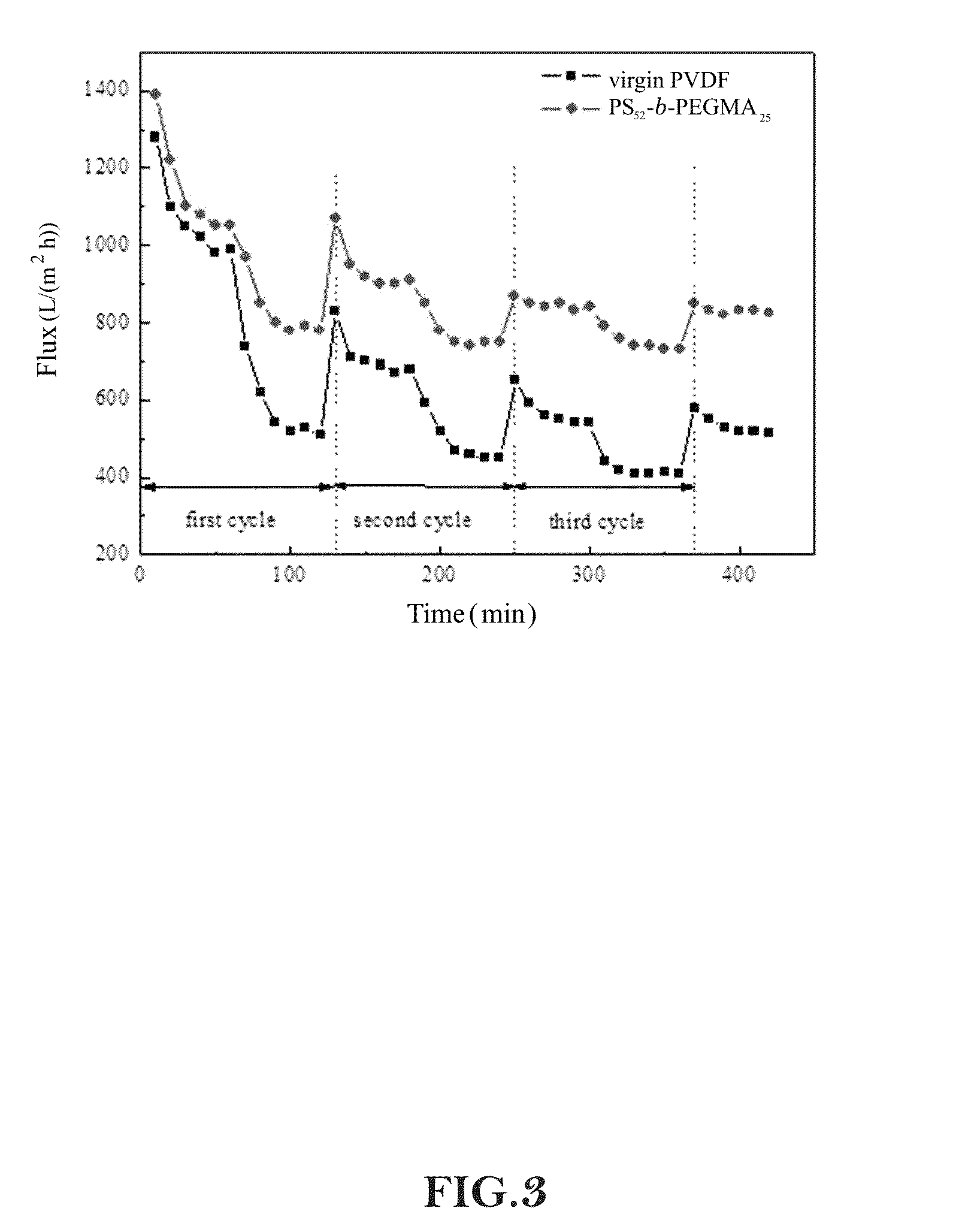

Antibiofouling Composition, Antibiofouling Membrane And Method For Forming The Same

ActiveUS20130228511A1Improve featuresSimple treatmentMembranesSemi-permeable membranesSolventPolymer chemistry

The present invention provides an antibiofouling composition, an antibiofouling membrane and a method for forming the same. The antibiofouling composition comprises a copolymer and at least one solvent. The copolymer comprises at least one hydrophobic segment and at least one antibiofouling segment where the hydrophobic segment comprises a plurality of hydrophobic moieties and the antibiofouling segment comprises a plurality of antibiofouling moieties. The molar ratio of the total of hydrophobic moieties to the total of the antibiofouling moieties is 0.5˜6.0.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

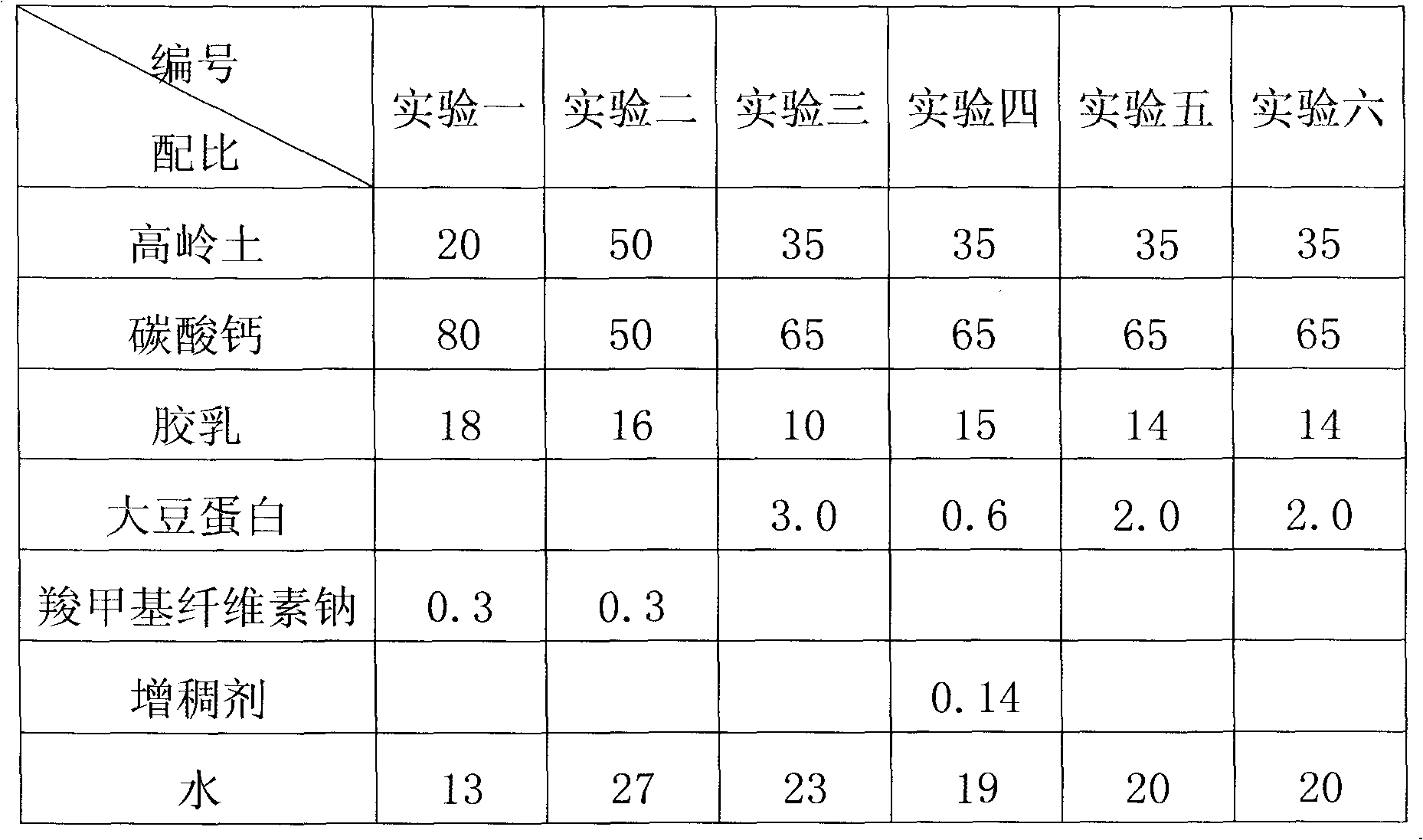

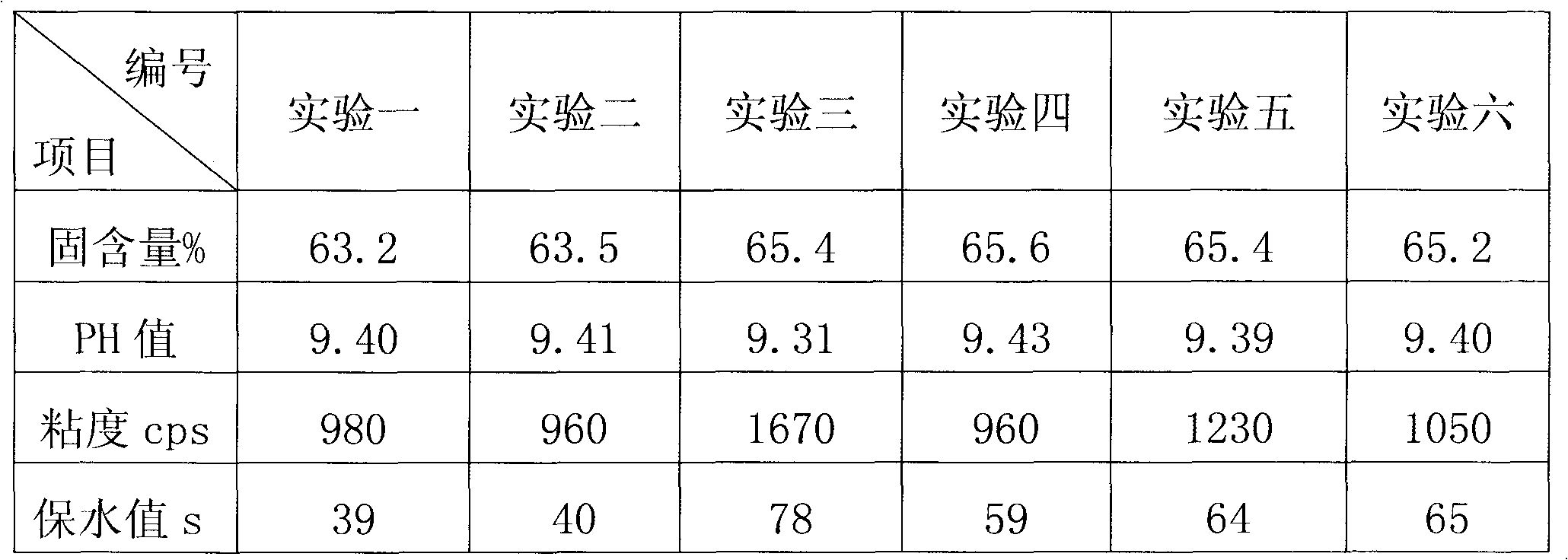

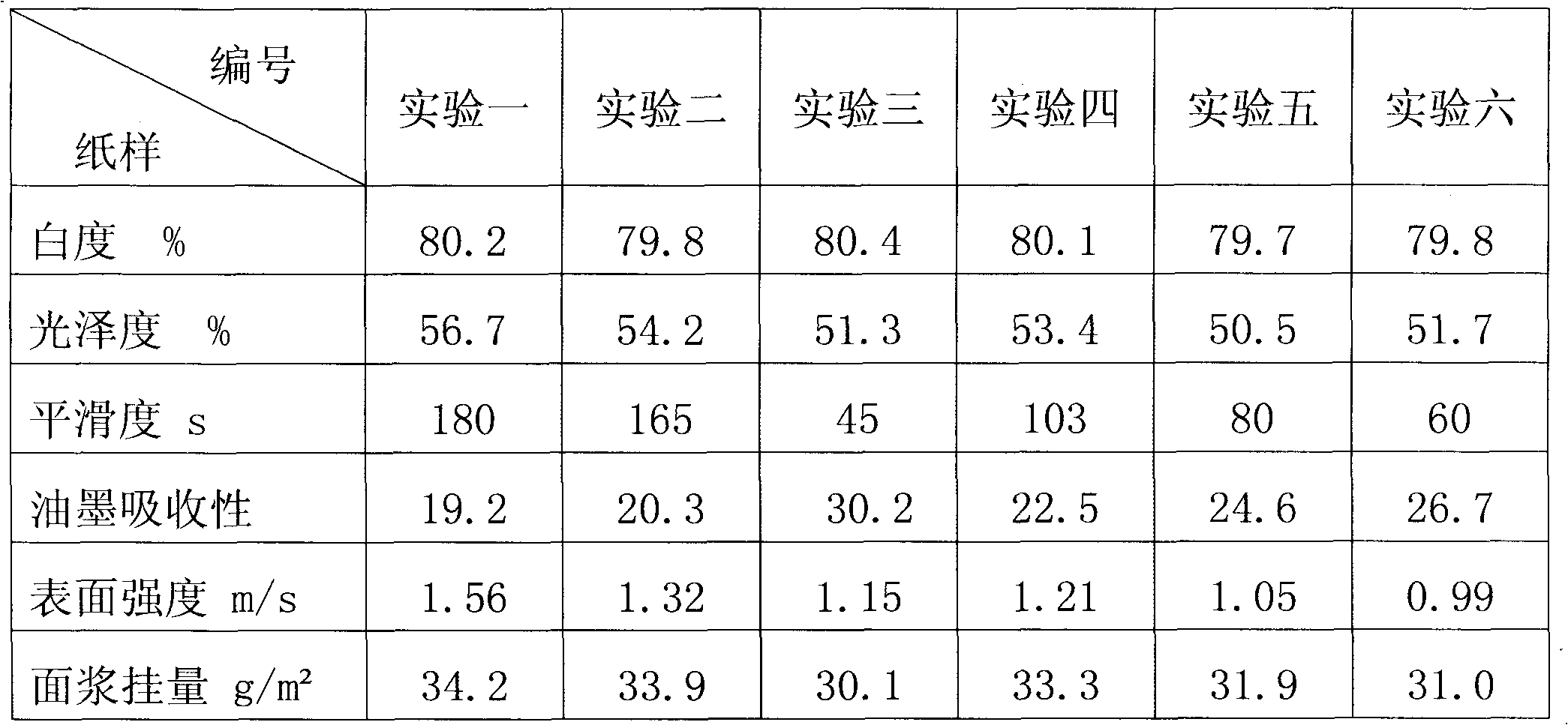

Top coating for coating layer of double-sided coating white board as well as preparation method and application thereof

The invention discloses a top coating for a coating layer of a double-sided coating white board as well as a preparation method and application thereof. As the top coating, the double-sided coating white board after being applied and coated by a coating machine not only is suitable for high-grade printing but also is suitable for vacuum forming. The top coating comprises the following components in parts by mass: 20 to 50 parts of kaolin, 50 to 80 parts of calcium carbonate, 10 to 18 parts of latex and 25 to 35 parts of water. The top coating also contains the components of a dispersant, a lubricant, a water repellent agent, a bactericide, a pH regulator and a functional assistant of 0.6 to 3.0 parts by mass of PC4200 soybean protein. By adding the functional assistant, the closure property of the coating layer can be opened, the covering property of the coating is enhanced, the use quantity of wood pulp is reduced, the smoothness of finished paper is lowered, and the infiltration of vacuum forming oil is benefited. The coating is applied and coated on a paperboard by the coating machine, can enable the paperboard to have favorable printing ink acceptance, improves the covering property of a paper face greatly and has lower smoothness and roughness and favorable printing adaptability.

Owner:YUANTONG PAPER SHANDONG

Superabsorbent Polymer Particles Coated With A Hydrophilic Elastomer And Absorbent Article Comprising Such Particles

ActiveUS20110319847A1Easy to transportGood coating stabilityLiquid surface applicatorsBaby linensElastomerPolymer science

Superabsorbent polymer particles, coated with a block copolymer comprising at least four blocks being at least two hard blocks, one soft block and one hydrophilic block, wherein a the soft block is sandwiched between the hard blocks.

Owner:THE PROCTER & GAMBLE COMPANY

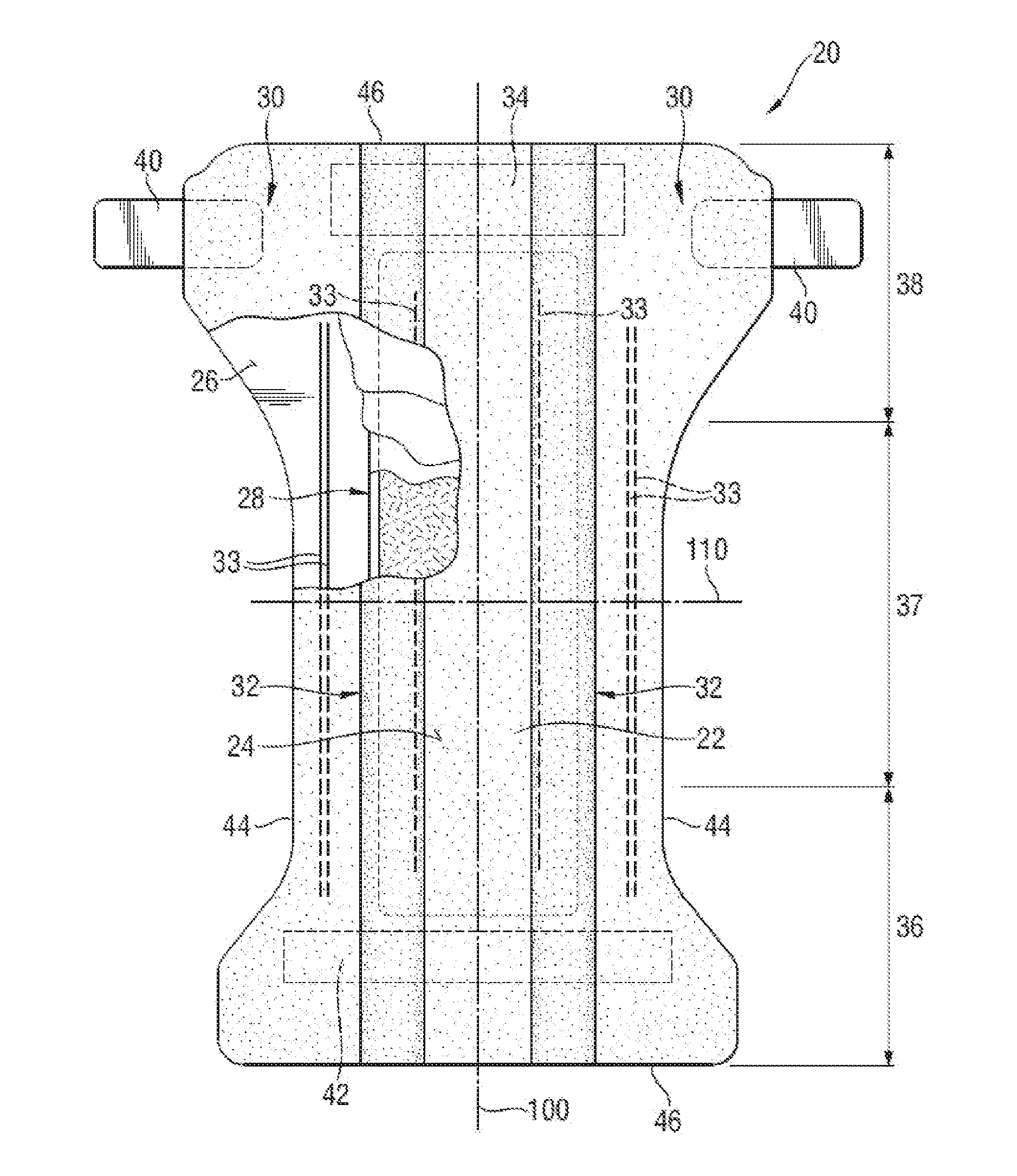

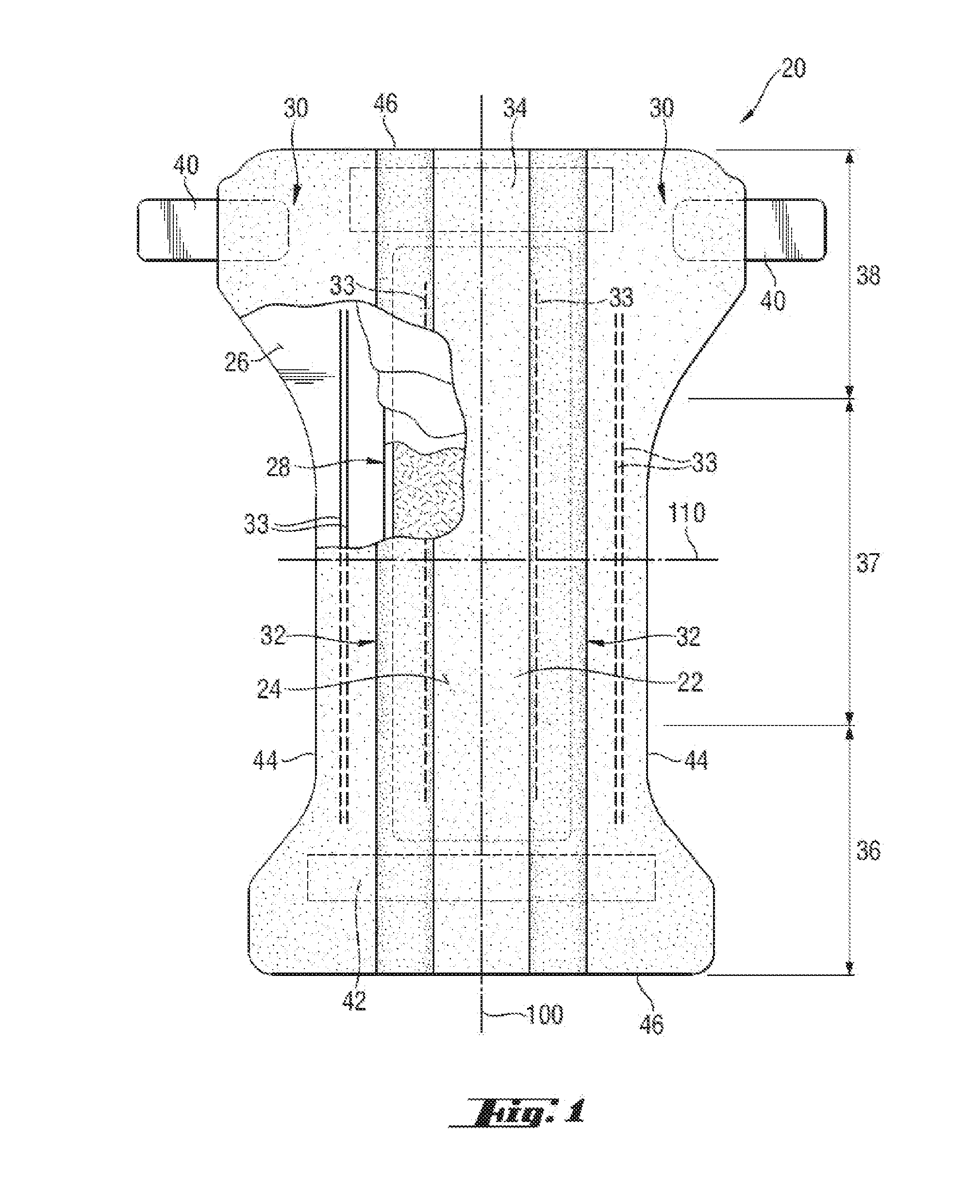

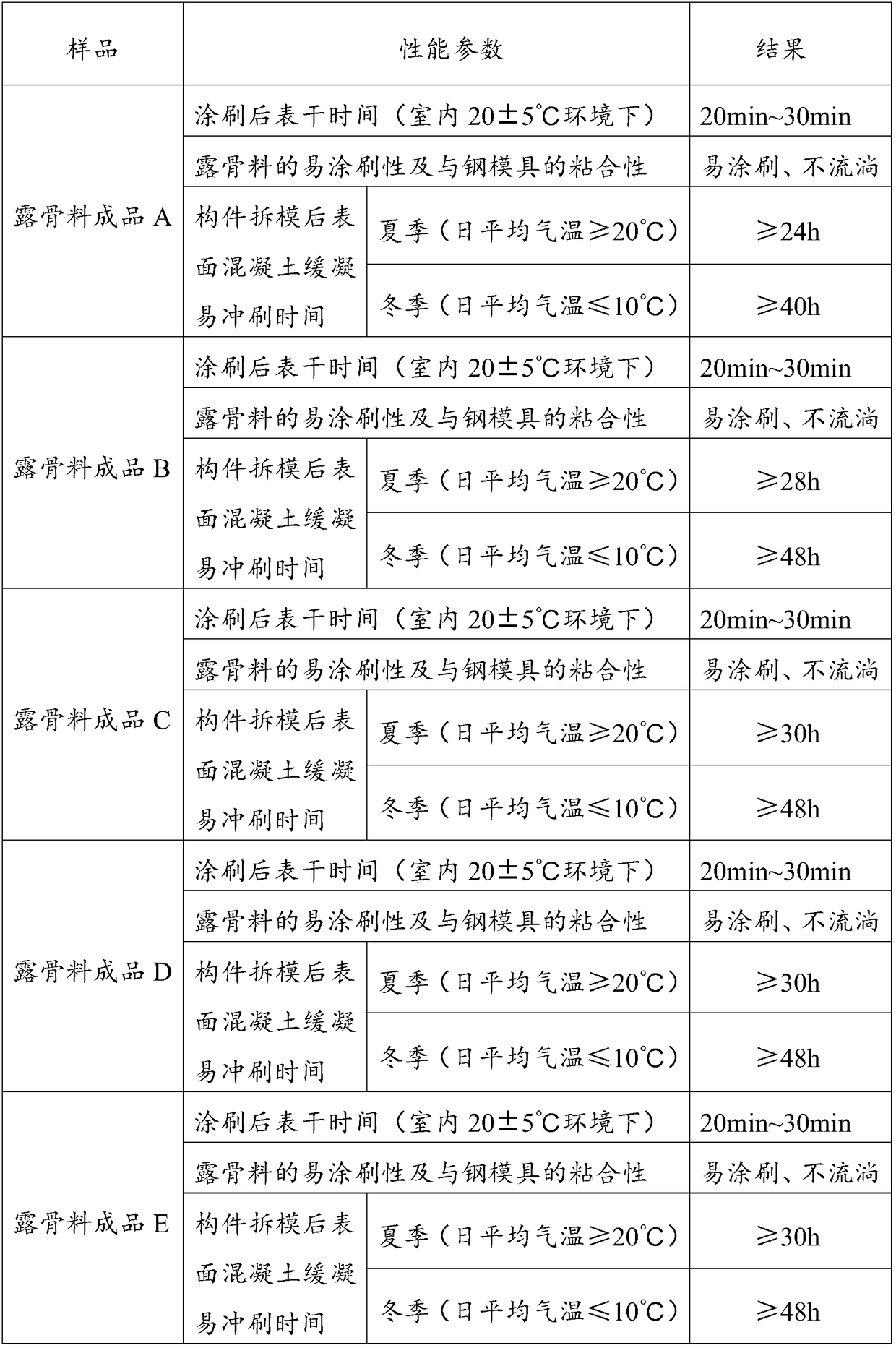

Precast concrete component exposed aggregate and preparation method thereof

The invention relates to the technical field of precast concrete components, discloses precast concrete component exposed aggregate and solves the problems that exposed aggregate in the prior art hascomplex ingredients, high production cost and high selling price. The precast concrete component exposed aggregate is prepared from the following raw materials in mass percent: 7.5% to 10% of sodium gluconate, 0.8% to 1.2% of thickening agent, 0.1% to 0.5% of preservative and 88.3% to 91.6% of water, wherein the raw materials are evenly mixed to prepare the precast concrete component exposed aggregate. The precast concrete component exposed aggregate has the advantages of simple ingredients, low cost, easiness in being painted, no fluidity and good use effect. The invention further discloses apreparation method of the exposed aggregate. All the ingredients are mixed according to steps to obtain a finished product of the exposed aggregate, and the preparation method is simple.

Owner:西安建工绿色建筑集团有限公司

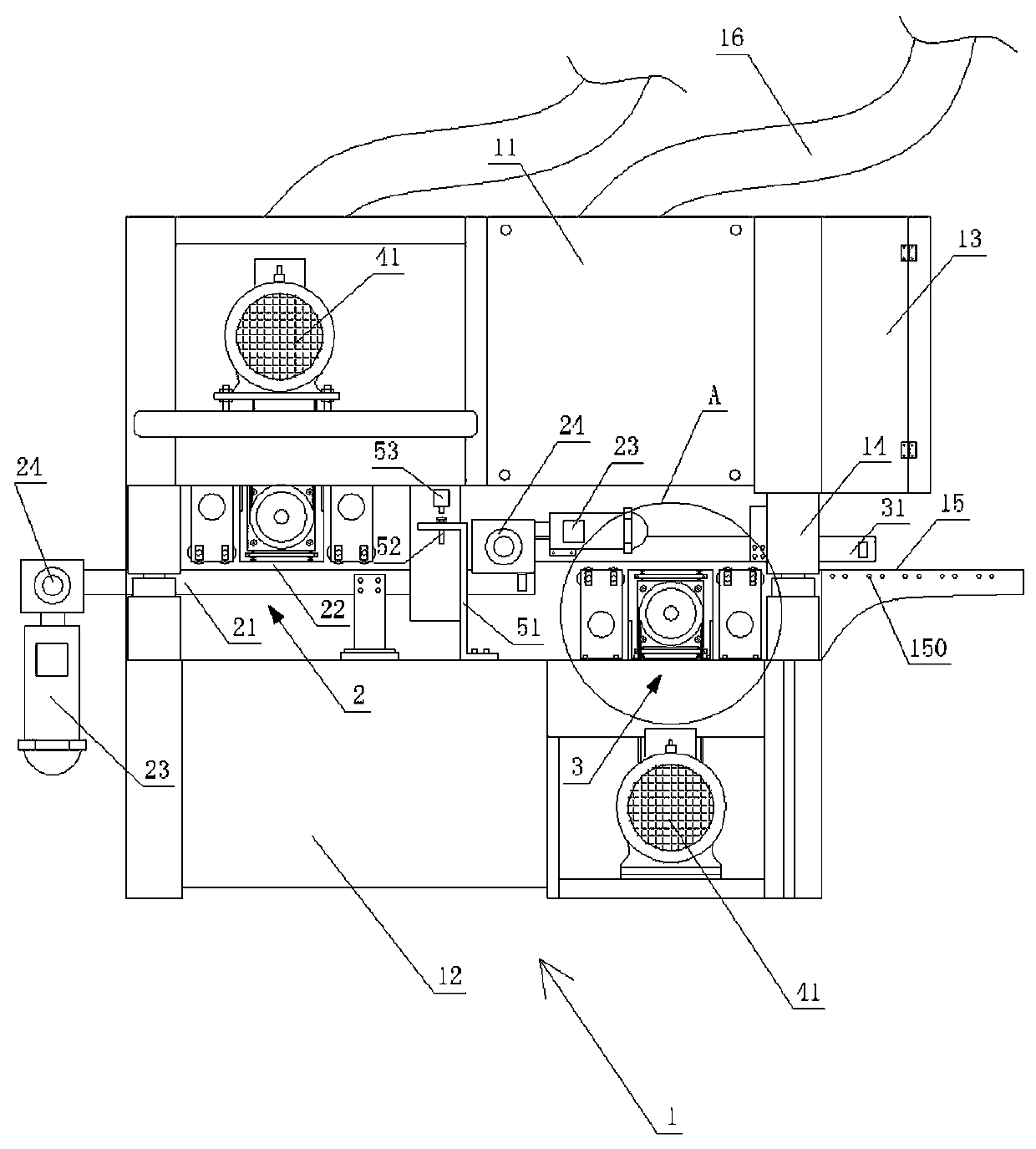

Solid wood batten coating and sanding process

ActiveCN107457656AEfficient designImprove sanding effectBelt grinding machinesAdhesive application devicesSolid woodMetallurgy

The invention discloses a solid wood batten coating and sanding process. The solid wood batten coating and sanding process comprises the following steps: 1) natural woods are pretreated as blanks; 2) first paint pulp is uniformly coated on the blanks to form first coating layers on the outer surfaces of the blanks; and the thicknesses of the first coating layers are controlled within 0.4-0.6 mm; 3) the primary asynchronous automatic sanding treatment is performed; 4) second paint pulp is uniformly coated on the first coating layers to form second coating layers on the outer surfaces of the blanks; and the thicknesses of the second coating layers are controlled within 0.1-0.3 mm; and 5) the secondary asynchronous automatic sanding treatment is performed. The coating and sanding process is more ideal in design; the quality of the coating layers on the surfaces of solid wood battens is high; and in the sanding operation process, the front surfaces and the back surfaces of the blanks are sanded in sequence, so that the quality of products is greatly improved.

Owner:福建省尤溪县红树林木业有限公司

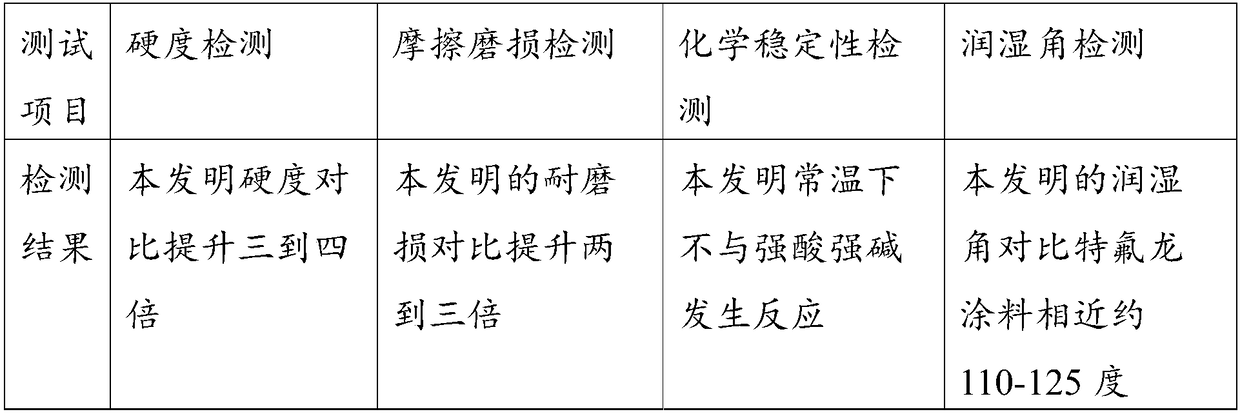

Preparation method of non-stick pan coating layer for cookware

InactiveCN108103496AEnsure environmental protection and non-toxicityThe production process is simpleCooking-vessel materialsMetallic material coating processesBond coatingBoron nitride

The invention provides a preparation method of a non-stick pan coating layer for cookware. The preparation method specifically comprises the following steps that (1), a boron nitride material with thepurity being 99. 5%, namely a coating is prepared for standby application, wherein the boron nitride material comprises, by weight percentage, 43% of boron, 0.1% of diboron trioxide, 0.03% of carbonand the balance water; and (2), the prepared coating is melted and clad on a substrate, namely the inner surface of the cookware by adopting a laser cladding process so as to form the non-stick pan coating layer, wherein the parameters of the laser cladding process are characterized in that the laser power is 1500-3500 W, the scanning speed is 3-12 mm / S, and the powder feeding rate is 6-20 g / min.The preparation method has the advantages that the manufacturing process is relatively simple and easy to operate, and the cost is low; and the prepared non-stick pan coating layer for the cookware isprovided with a fluoride-free metallurgical bonded coating, does not react with acid and alkali, has good chemical stability, has high-temperature resistance and a high wetting angle, and is non-toxic and safe.

Owner:FUJIAN UNIV OF TECH

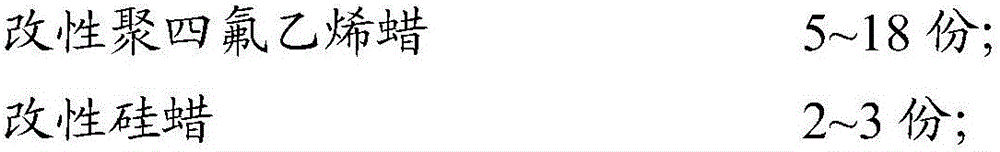

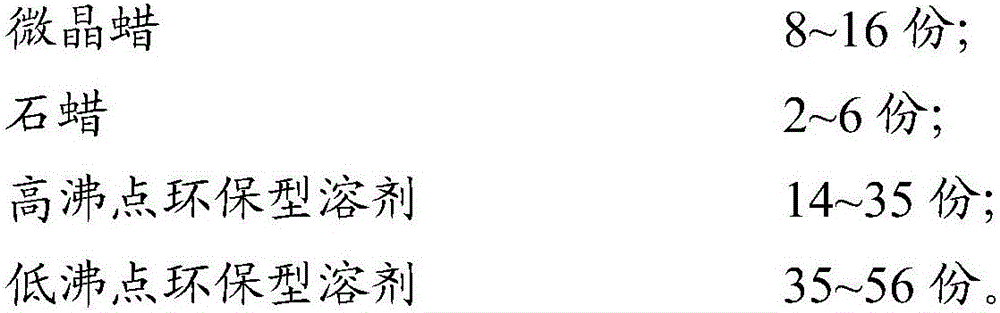

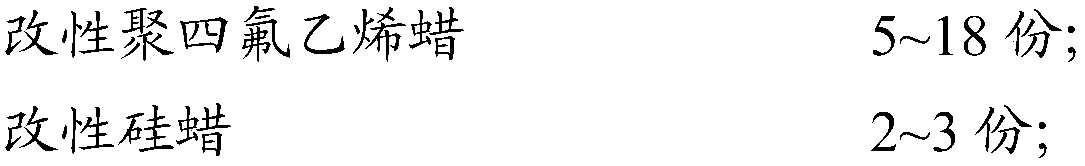

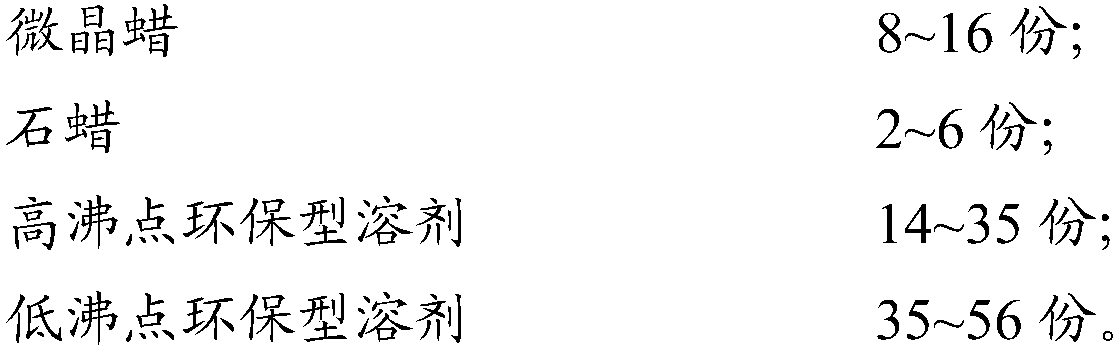

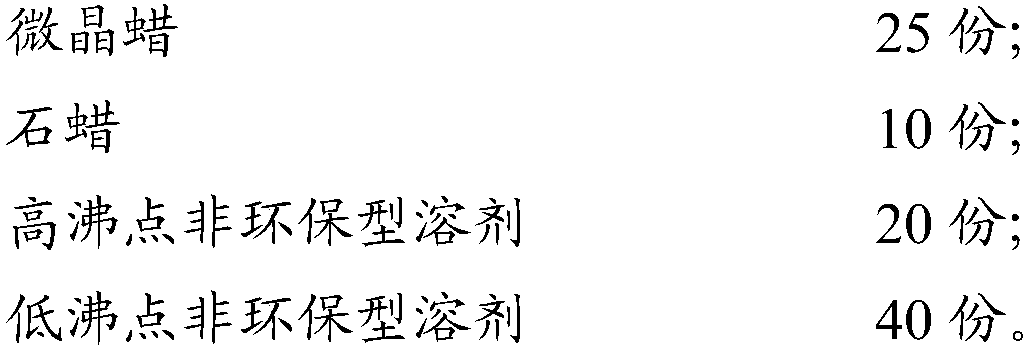

Solvent type wax release agent and preparation method thereof

ActiveCN106346653AImprove high temperature resistanceSmooth disengagementMicrocrystalline waxBoiling point

The invention relates to the field of release agents and discloses a solvent type wax release agent and a preparation method thereof. The solvent type wax release agent is prepared from, by weight, 5-18 parts of modified polytetrafluoroethylene wax, 2-3 parts of modified silicon wax, 8-16 parts of microcrystalline wax, 2-6 parts of paraffin, 14-35 parts of a high-boiling-point environment-friendly solvent and 35-56 parts of a low-boiling-point environment-friendly solvent. The preparation method includes steps: 1) dissolving a solid wax mixture at a high temperature; 2) adding the high-boiling-point environment-friendly solvent under a condition of high-temperature low-speed stirring, and cooling and adding the low-boiling-point environment-friendly solvent under a condition of low-speed stirring; 3) after low-speed stirring for cooling, discharging, packaging, and cooling to the room temperature to obtain a product. The solvent type was release agent has excellent high temperature resistance and coating performances. The preparation method of the solvent type wax release agent is simple in process, low in cost and beneficial for industrial production.

Owner:GUANGDONG UNIV OF TECH

Microporous polyolefin composite film with a thermally stable porous layer at high temperature

ActiveUS8795826B2Improve breathabilityIncrease temperatureSemi-permeable membranesLayered productsVitrificationPolymer science

Provided is a microporous polyolefin composite film with a thermally stable porous layer at high temperature, particularly, to the microporous polyolefin composite film in which the thermally stable porous layer at high temperature, which contains organic or inorganic particles and heat-resistant polymer having aromatic ring in main chain and also having a melting temperature or a glass transition temperature of 170 to 500° C., is formed on one surface or both surfaces of a polyolefin microporous film by a phase separation, wherein the composite film with the porous layer has a permeability of 1.5×10−5 to 20.0×10−5 Darcy, a meltdown temperature of 160 to 300° C., a MD / TD shrinkage of 1 to 40% at a temperature of 150° C. for 60 minutes.

Owner:SK INNOVATION CO LTD +1

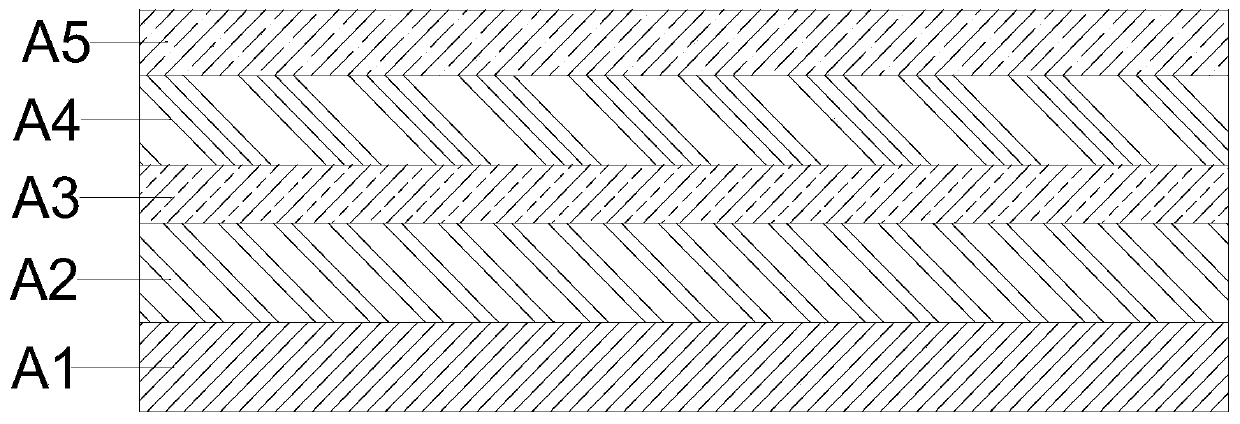

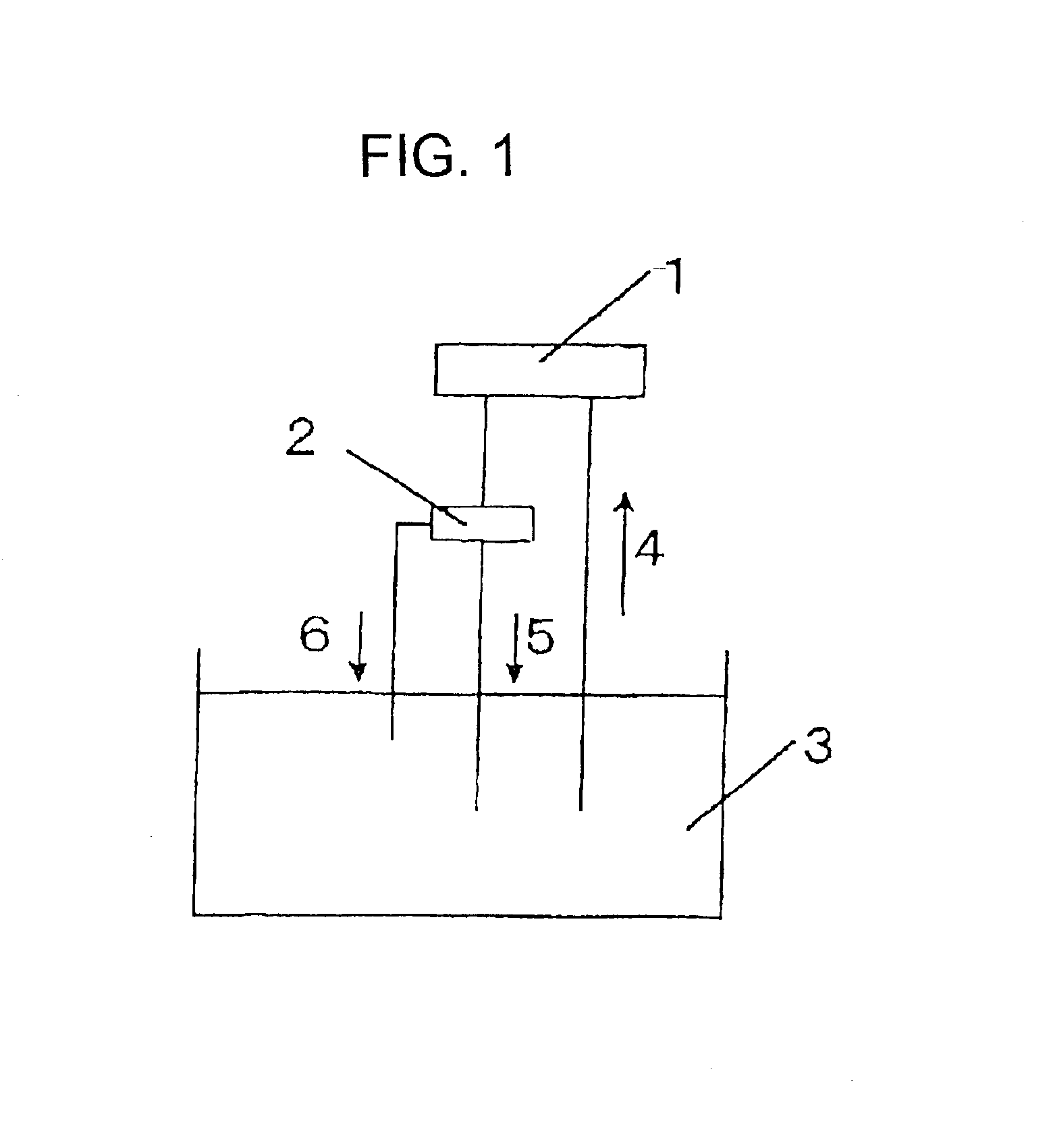

Method for manufacturing near-infrared reflective film and near-infrared reflective body provided with same

InactiveUS20130114132A1Good value for moneyGood film uniformityMirrorsOptical filtersRefractive indexViscosity

Disclosed is a method for manufacturing a near-infrared reflective body in which a near-infrared reflective film is manufactured that has excellent manufacturing cost performance, is capable of being employed over a large area, and has excellent application stability and resistance to refractive index unevenness in the surface. A method for manufacturing a near-infrared reflective film in which a high refractive index layer and a low refractive index layer are alternately laminated on a support, wherein the difference in the refractive index of adjacent high refractive index layers and low refractive index layers is at least 0.3, and the near-infrared reflective film is formed using a coating liquid for a high refractive index layer and a coating liquid for a low refractive index layer, if the viscosity of the high refractive index layers and low refractive index layers at 15° C. is η15 and at 45° C. is η45, the viscosity ratio (η15 / η45) in each case is at least 2.0.

Owner:KONICA MINOLTA INC

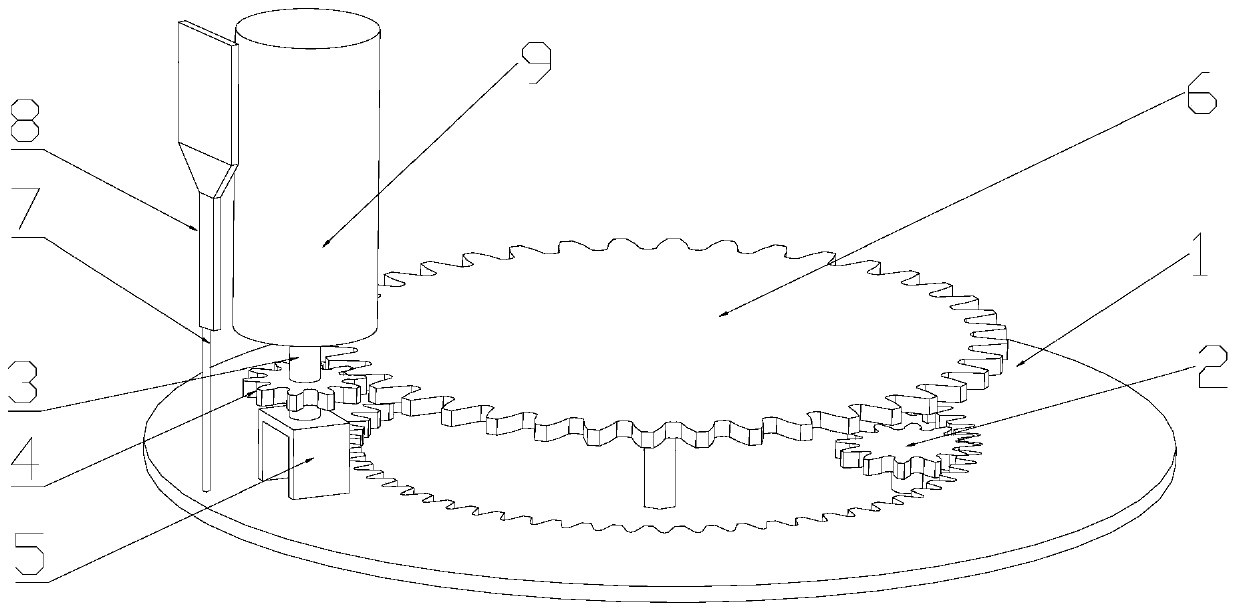

Gradient color solar cell module, coating device and method thereof

ActiveCN110556434AImprove aestheticsHigh photon transmittanceVacuum evaporation coatingSputtering coatingTransmittanceSolar cell

The invention discloses a gradient color solar cell module, a coating device and a method thereof. A composite transparent dielectric film with gradient colors is plated on a solar cell so that the color of the cell is not limited to black, blue and the like, the cell still keeps higher photon transmittance under the condition of a high aesthetic degree, and efficiency of the cell is higher. In the coating device, a correction plate is arranged between a magnetic control target and a coated sample substrate, a thickness of the film is flexibly controlled through a width of the correction plate, coating stability is good, operation is convenient, and working efficiency is high.

Owner:JINLING INST OF TECH

Novel electrically conductive and controllable heating electrothermal coating and preparation method thereof

InactiveCN110373090ASimple recipeLow costEpoxy resin coatingsElectrically-conductive paintsEmulsionCarbon nanotube

The invention relates to the field of electrothermal coating, and provides a novel electrically conductive and controllable heating electrothermal coating. The raw materials at least contain: conductive materials, resin binding materials and water; the raw materials of the conductive materials include graphite powder, carbon nano tubes and graphene; and the weight ratio of an emulsion A, the graphite powder, the carbon nano tubes and the graphene is 1: (0.05 to 0.1): (0.5 to 1): (0.01 to 0.1).

Owner:上海想呗科技有限公司

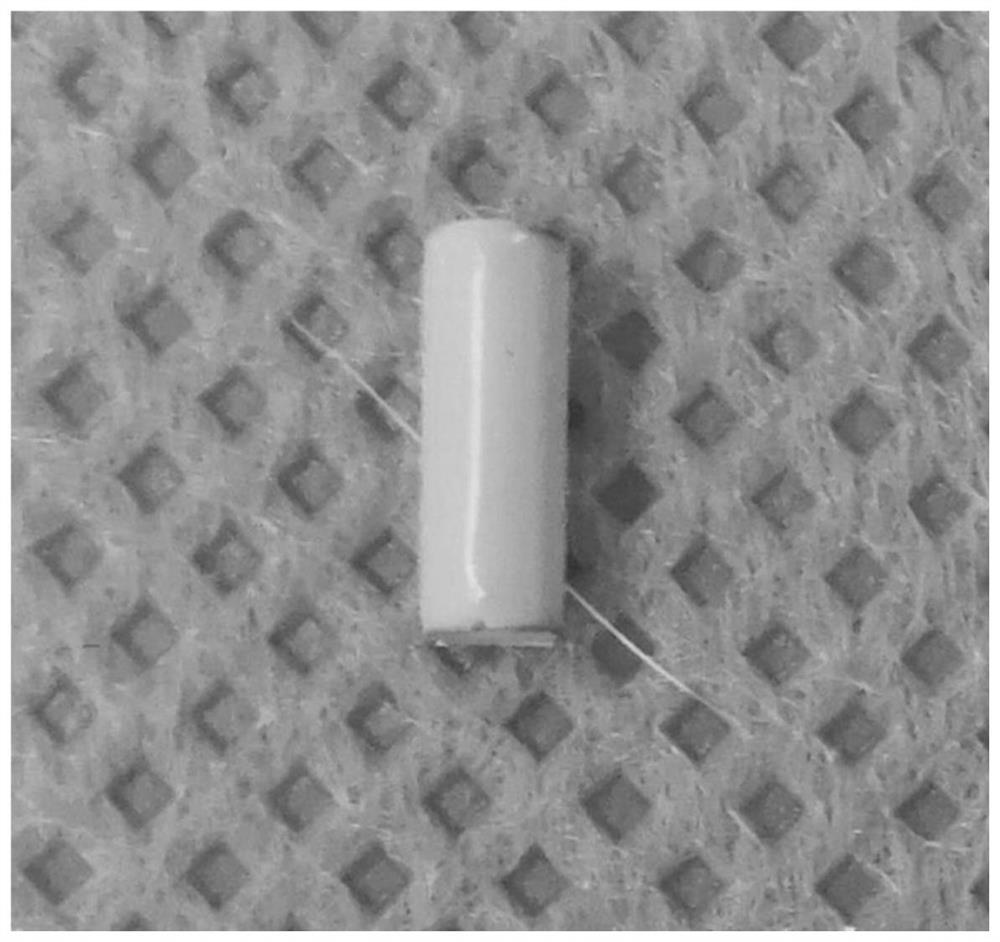

Titanium implant with bionic electro-active coating and preparation method thereof

PendingCN112791231AAvoid under-bondingImprove long-term stabilitySurface reaction electrolytic coatingTissue regenerationFerroelectric polymersTitanium surface

The invention relates to a titanium implant with a bionic electro-active coating and a preparation method, and solves the technical problem that an existing titanium implant coating is insufficient in biological activity or harmful to a human body, the titanium implant with the bionic electro-active coating is provided with the coating, the coating contains a filler and a polymer matrix, the filler is piezoelectric ceramic nano-particles, the matrix is a ferroelectric high-molecular polymer, the piezoelectric ceramic particles are uniformly dispersed in the ferroelectric polymer, and the invention also provides a preparation method of the titanium implant, so that the bionic electro-active coating can be firmly combined with the titanium surface. The method can be applied to the field of surface functional design and preparation of titanium implant materials.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY +1

Wear-resisting oxford fabric

The invention relates to a wear-resisting oxford fabric comprising a shell fabric layer and at least one layer of sizing agent coating, wherein the shell fabric layer is interweaved by 150-350D polyester filament yarn; and the sizing agent coating is composed of the following components in parts by weight: 60-80 parts of organic silicon resin, 5-10 parts of silane coupling reagent, 3-6 parts of cross-linking agent, 4-8 parts of alumina silicate fiber, 6-10 parts of copper oxide powder and 10-15 parts of solvent. The wear-resisting oxford fabric provided by the technical scheme is high in strength, firm, wear-resisting and firm in handfeel, has good coating stability and can be used as a material of products of cases, traveling bags, tent bottoms, and the like.

Owner:NANTONG QUANJI TEXTILE COATING

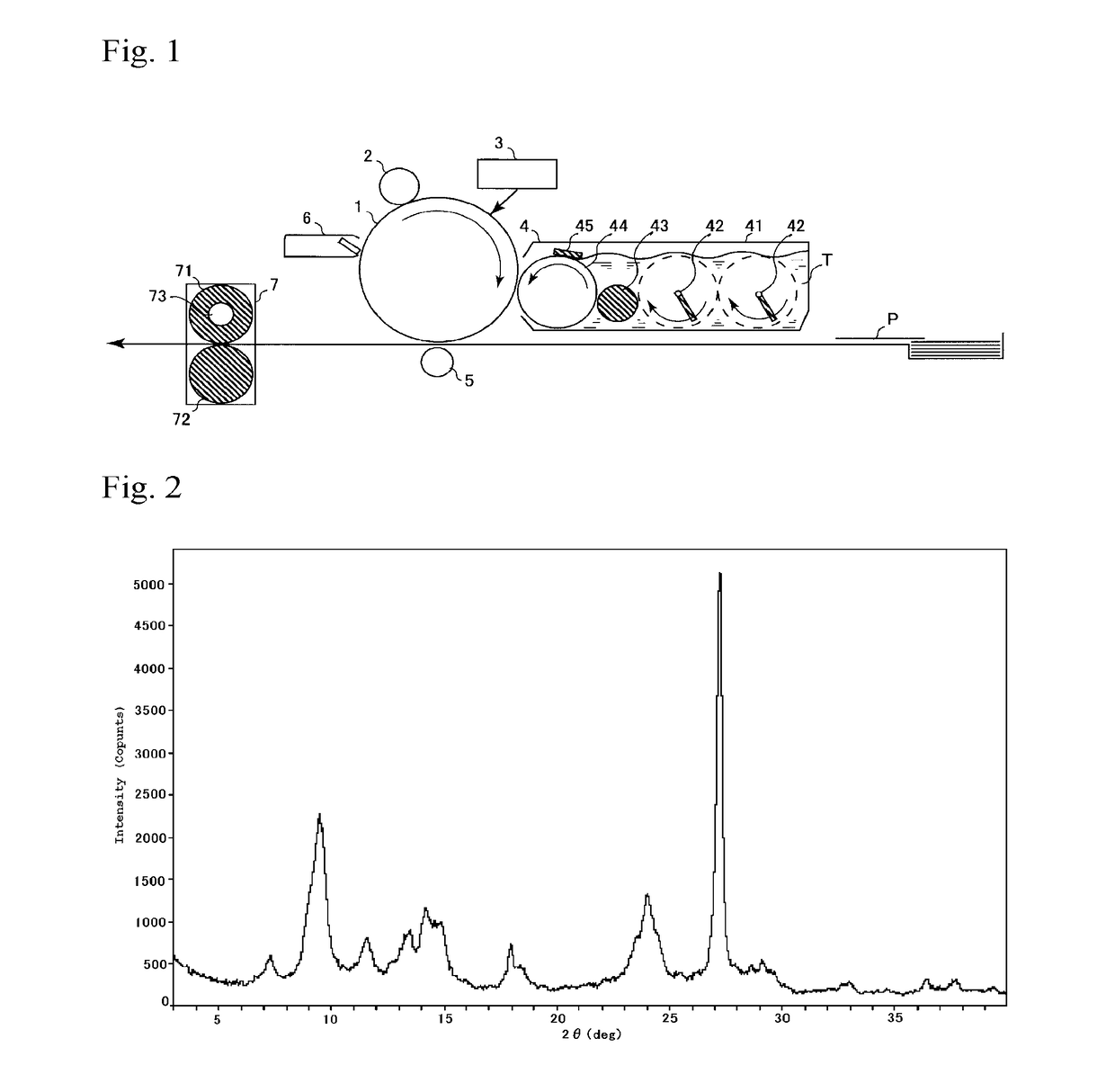

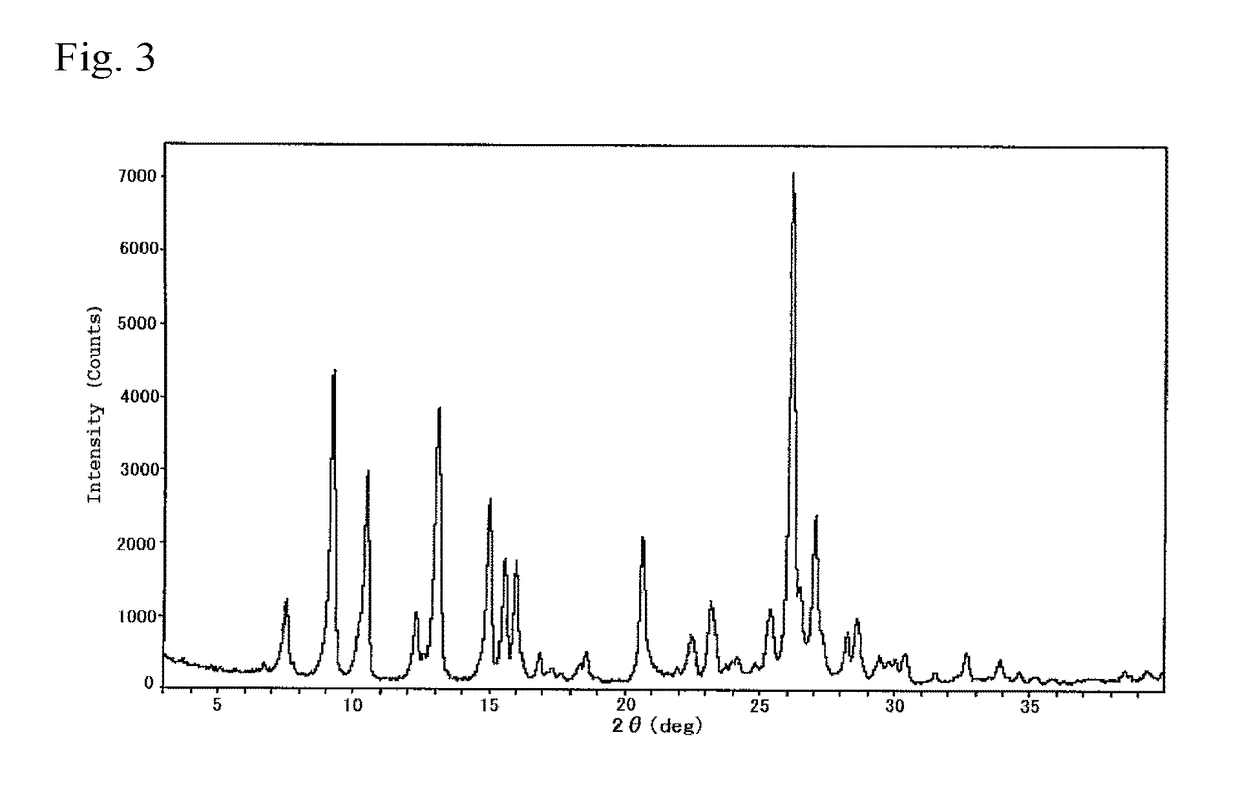

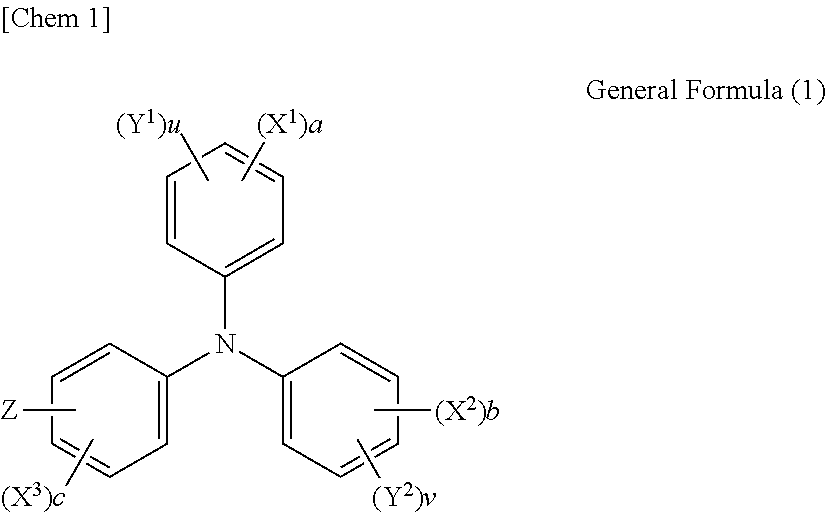

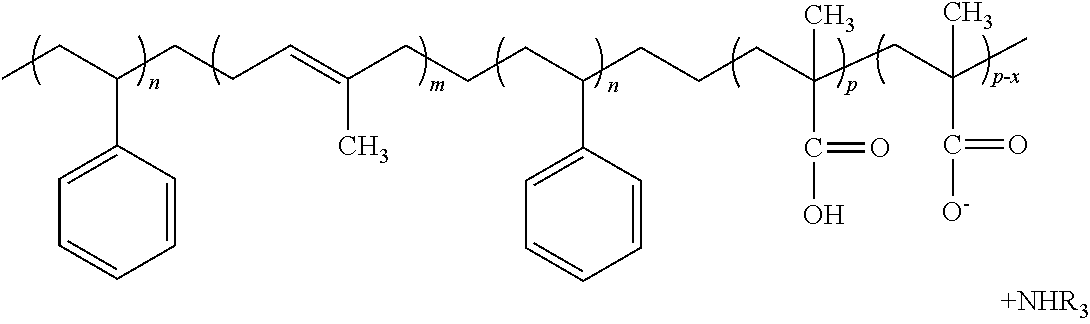

Coating liquid for electrophotographic photoreceptor production, electrophotographic photoreceptor, and image formation apparatus

ActiveUS20170090308A1Improve stabilityImprove electrical performanceElectrographic process apparatusImage formationCharge generation

Provided is a lamination-type electrophotographic photoreceptor comprising a conductive substrate, and a charge transport layer and a charge generation layer both on the conductive substrate, wherein the charge transport layer comprises a charge transport substance represented by the general formula (1), a binder resin, and a particulate silicon compound.

Owner:MITSUBISHI CHEM CORP

Substrate coated with a hydrophilic elastomer

ActiveUS8680362B2Improve hydrophilicityGood coating stabilitySynthetic resin layered productsBaby linensElastomerPolymer science

Substrates, coated with a block copolymer comprising at least four blocks being at least two hard blocks, one soft block and one hydrophilic block, wherein a the soft block is sandwiched between the hard blocks.

Owner:PROCTER & GAMBLE CO

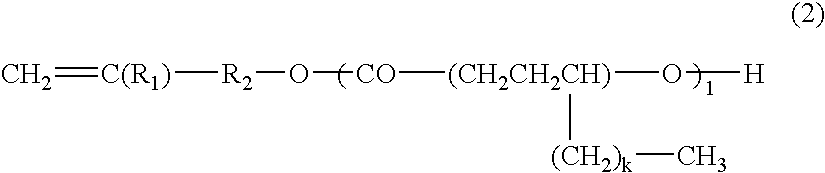

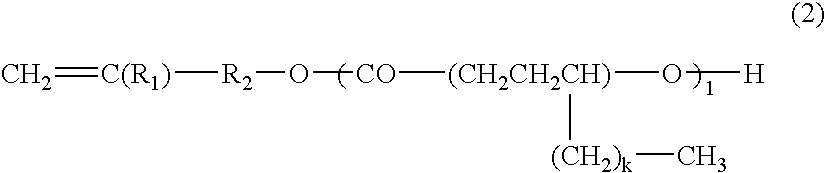

Cationic electro-deposition coating compositions

InactiveUS7045575B2Good weather resistance and corrosion resistanceImprove adhesionFibre treatmentPolyurea/polyurethane coatingsEpoxyMeth-

A cationic electro-deposition coating composition, comprises: Component (A): an amino-containing epoxy resin (A) obtained by adding an amino-containing compound (a-2) to an epoxy resin (a-1) having an epoxy equivalent of from 400 to 3000, Component (B): an amino-containing acrylic resin (B) obtained by adding an amino-containing compound (b-4) to a copolymer resin obtained by radical copolymerization of, as essential components, a polylactone-modified hydroxyl-containing radical copolymerizable monomer (b-1), which is obtained by adding a lactone to a hydroxyl-containing acrylic monomer (b), and glycidyl (meth)acrylate (b-2), and another radical copolymerizable monomer (b-3); and Component (C): a blocked polyisocyanate curing agent (C) as a curing component, the component (A), component (B) and component (C) being added in amounts of 5 to 80 wt %, 5 to 80 wt % and 10 to 40 wt %, respectively, based on the total solid content of the components (A), (B) and (C).

Owner:KANSAI PAINT CO LTD

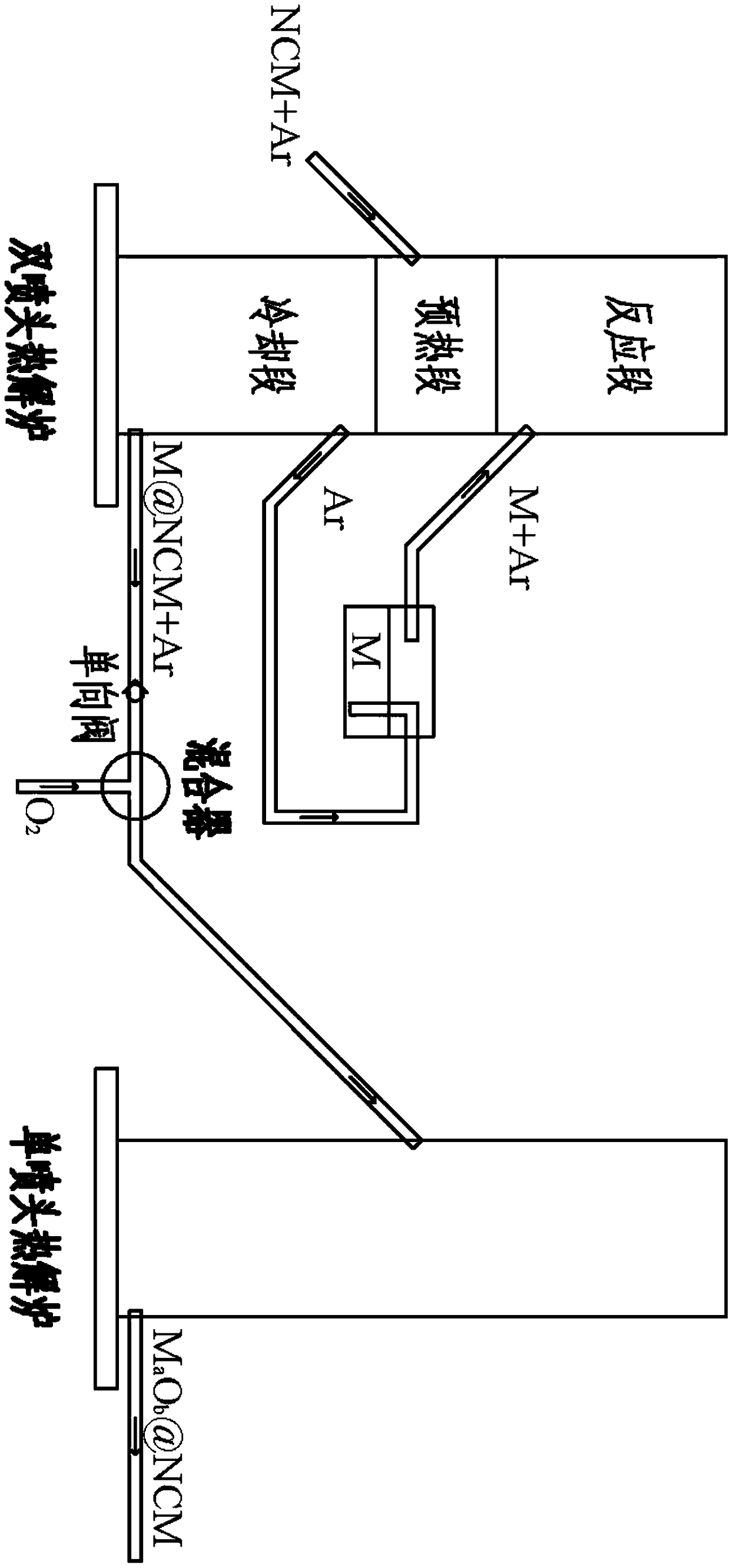

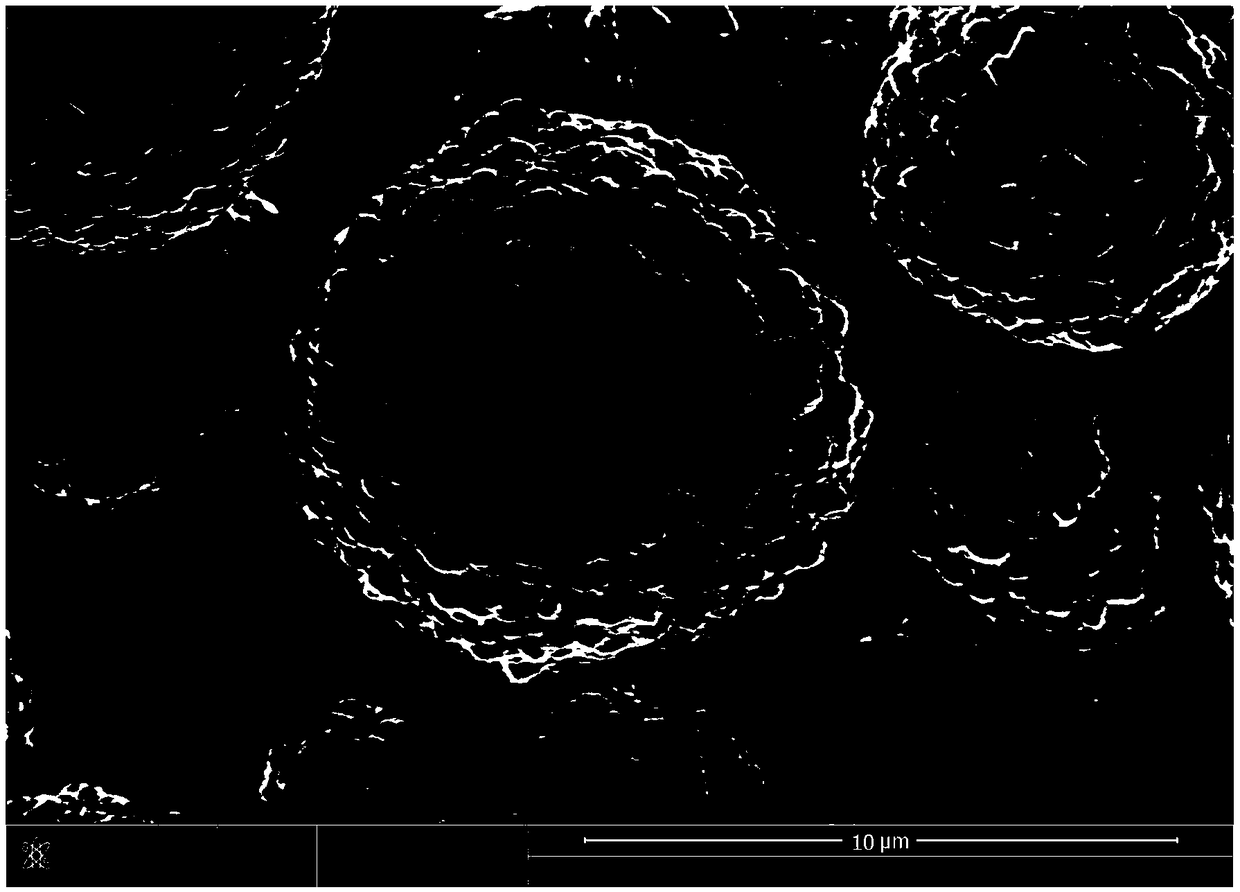

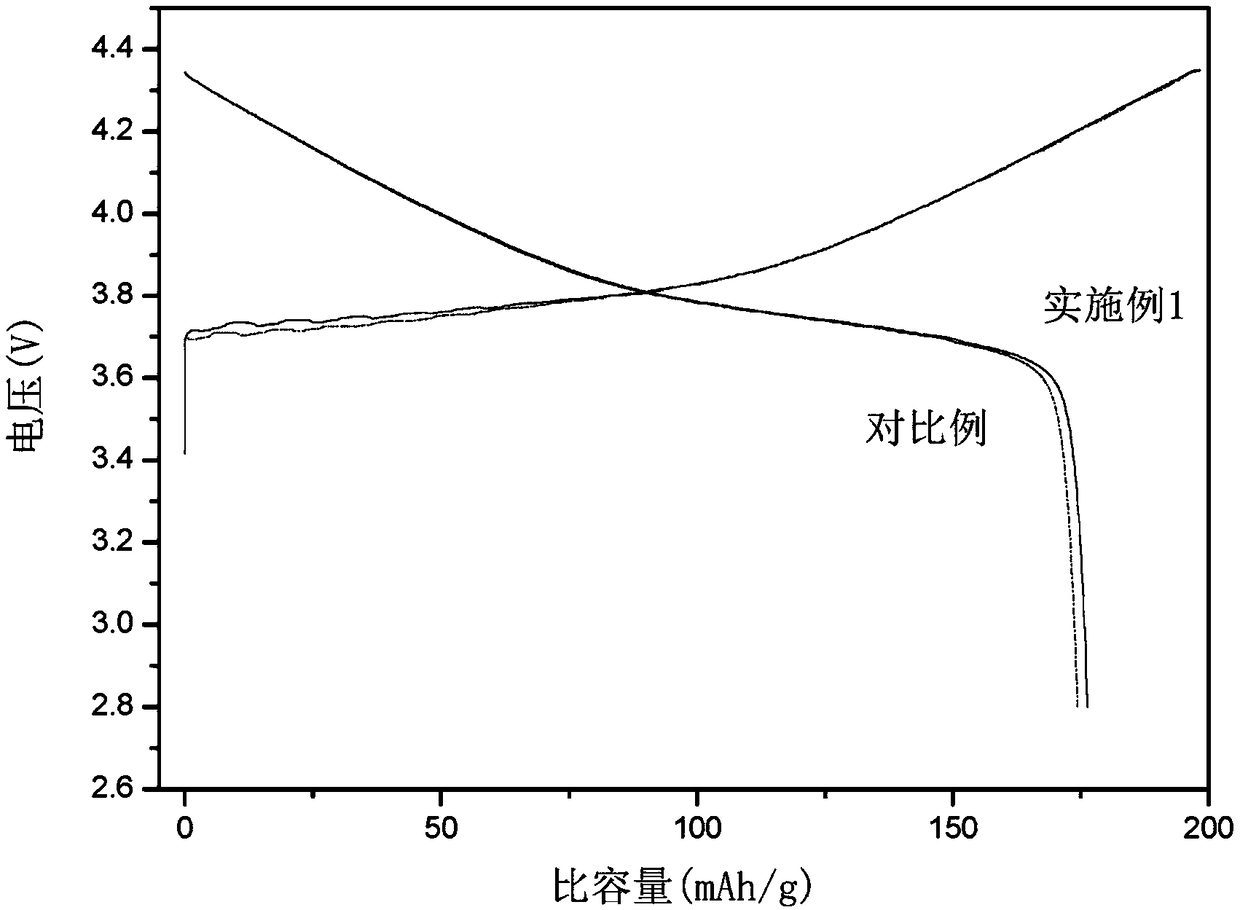

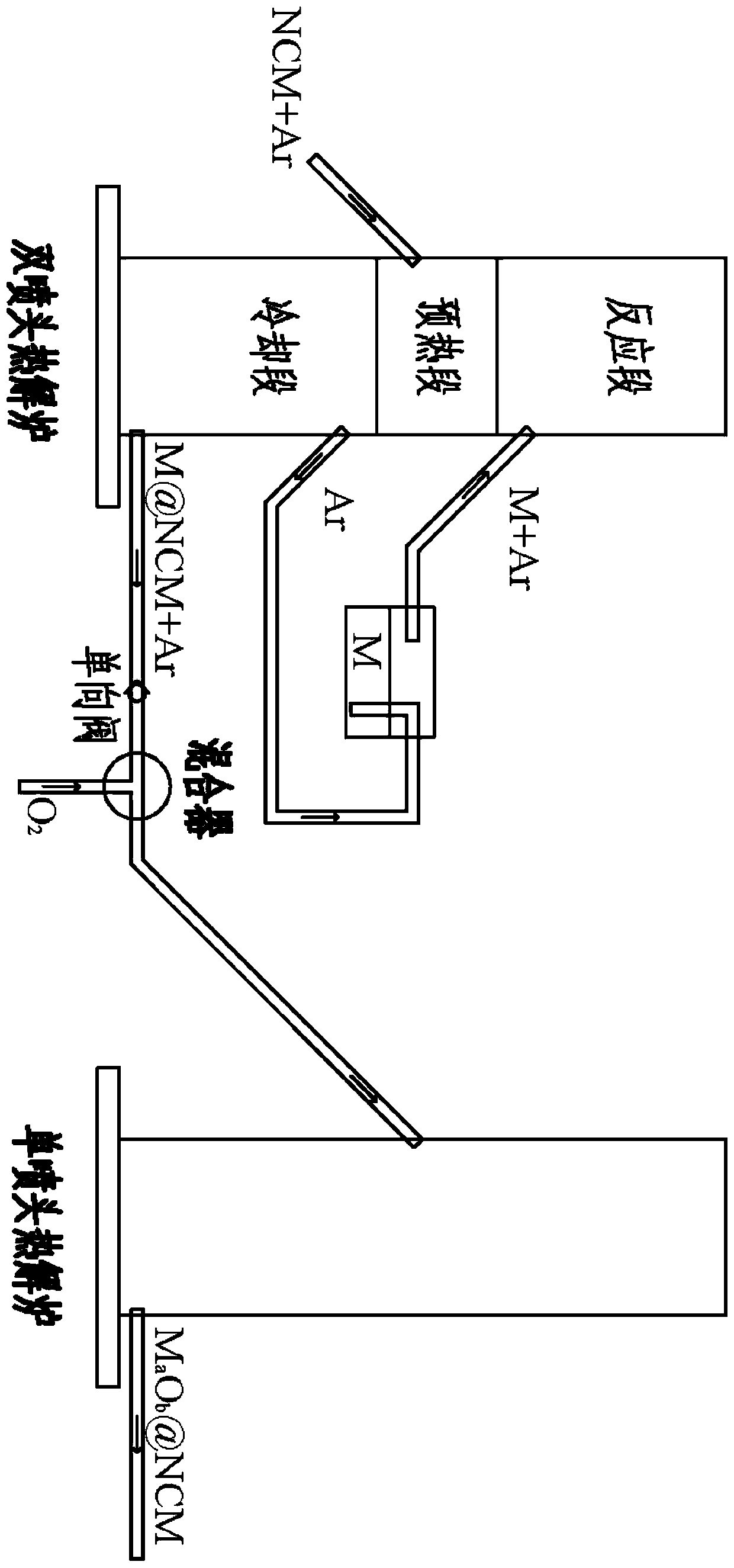

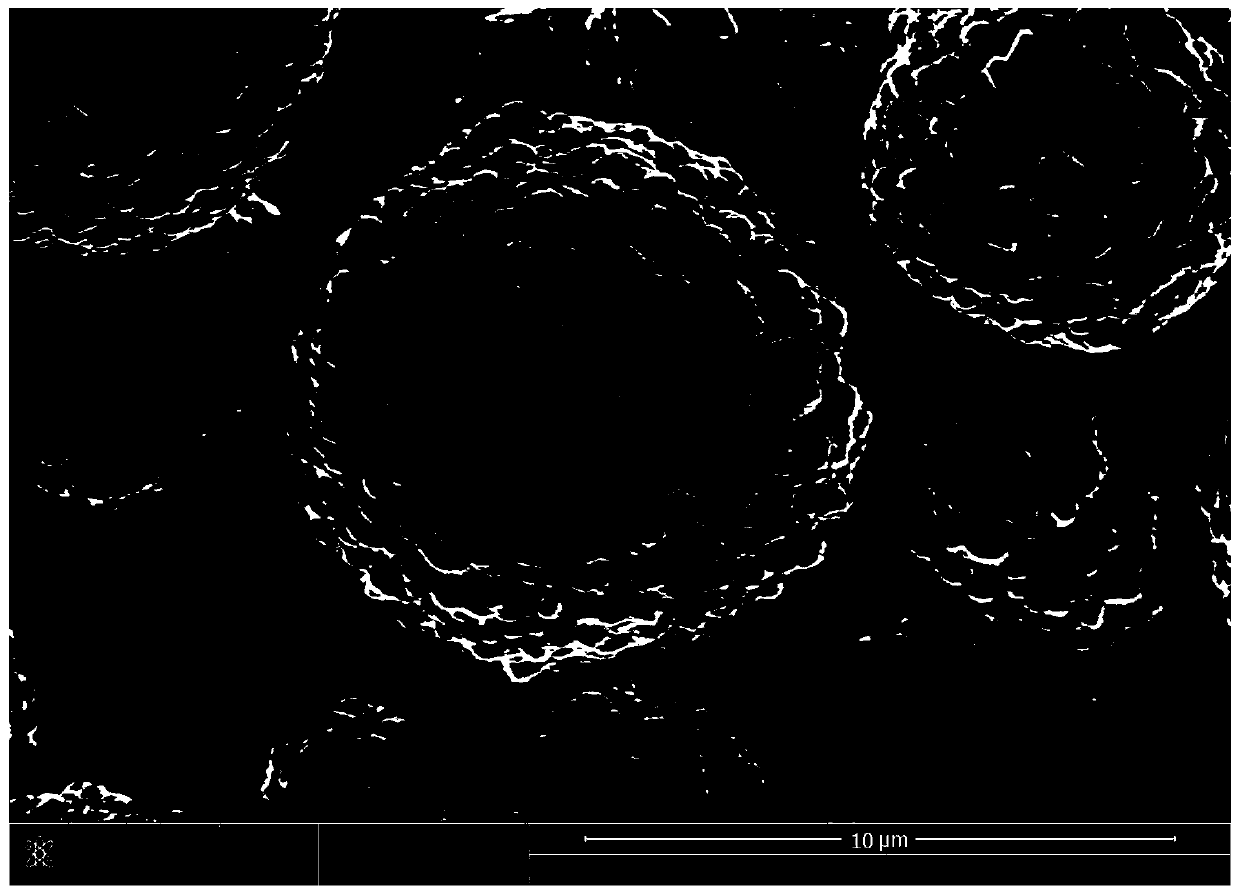

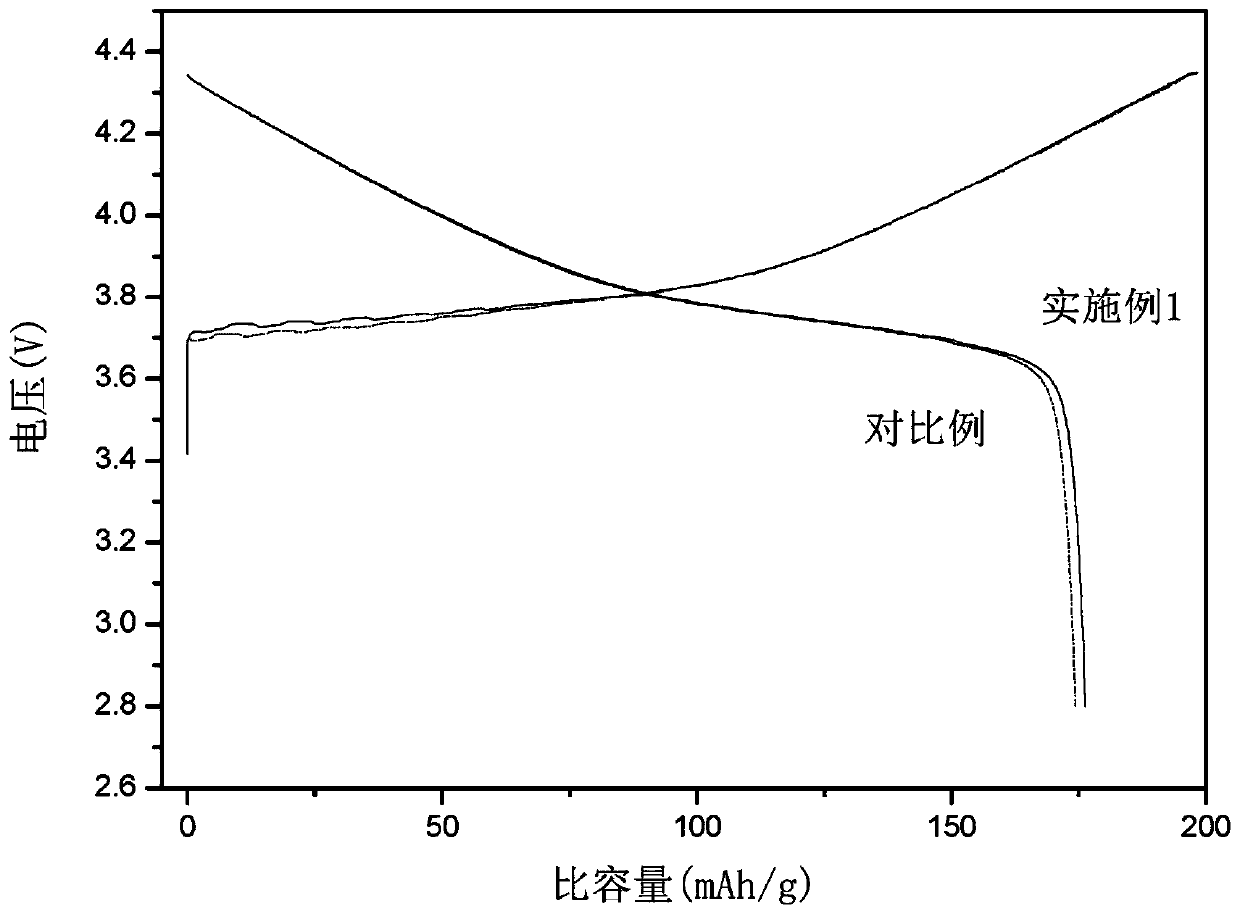

Preparation method of lithium nickel cobalt manganate for coated power battery.

ActiveCN108832083AWrap implementationImprove bindingCell electrodesSecondary cellsManganateMetal particle

The invention discloses a preparation method of lithium nickel cobalt manganate for coated power battery. The method comprises the following steps: 1) preheating the lithium nickel cobalt manganate particles; 2) heating the metal to be coated to boiling under an inert gas atmosphere to obtain metal vapor; 3) blowing the preheated lithium nickel cobalt manganate particles into a pyrolysis furnace with an inert gas, and simultaneously blowing metal vapor into the pyrolysis furnace for reaction with the inert gas; 4) the obtained particles are sent to a mixer through an inert gas, and mixed withan oxygen-containing mixed gas to form a solid-gas mixture; 5) the solid-gas mixture is sent to a pyrolysis furnace for reaction. The invention adopts the method of molten metal vapor to coat the lithium nickel cobalt manganate, the metal particles can be uniformly adhered on the surface of the lithium nickel cobalt manganate particles by the fine particles, the coating of the ultra-thin layer isrealized, the molten metal is firmly combined with the cathode material, is not easy to fall off, the coating stability is good, and the performance of the lithium nickel cobalt manganate cathode material can be remarkably improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

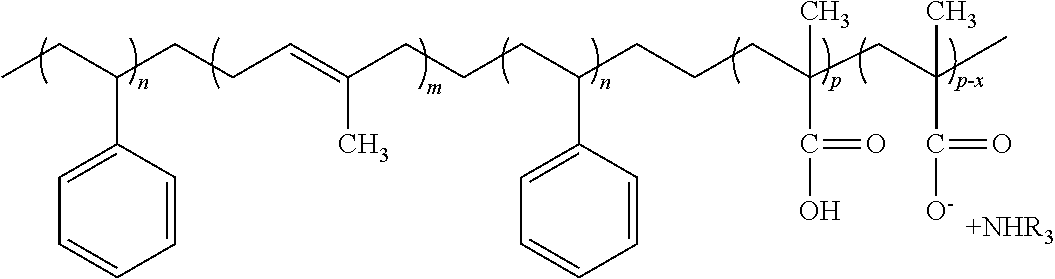

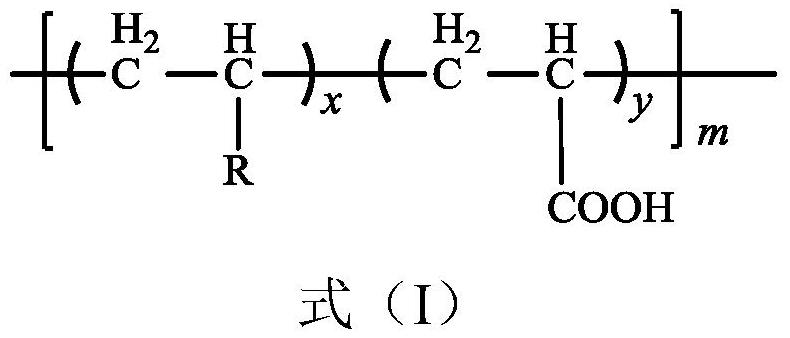

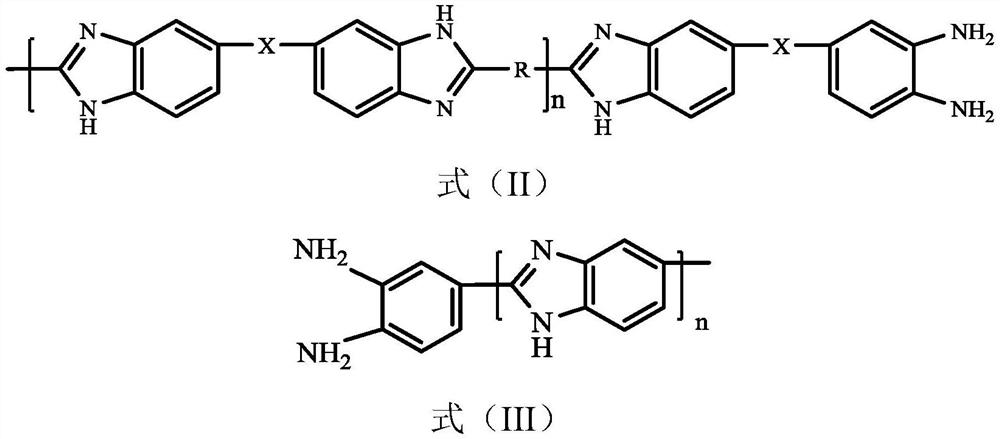

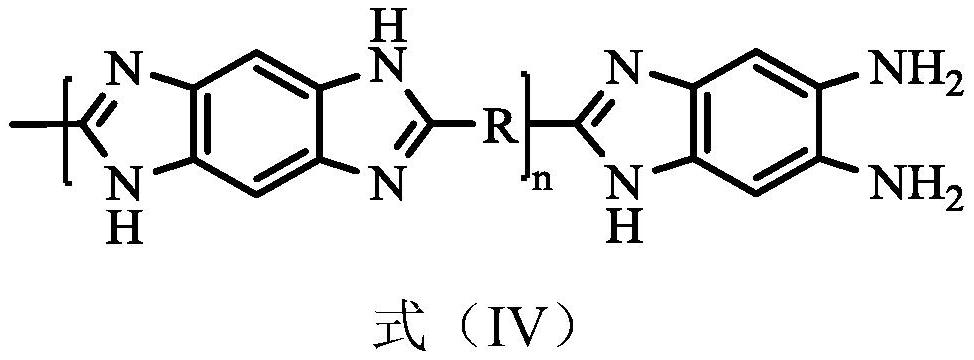

Graft copolymer coated silicon-based material and preparation method thereof

ActiveCN113054182AWith strengthInhibition of volume expansionCell electrodesSecondary cellsPolymer sciencePolymer chemistry

According to a graft copolymer coated silicon-based material and a preparation method thereof provided by the invention, a polyacrylic acid grafted benzimidazole copolymer coats the surface of the silicon-based material, and the polyacrylic acid and the benzimidazole copolymer have strong covalent bonds so as to ensure the compatibility of the two substances; the copolymer has certain strength so that the volume expansion of the silicon material can be effectively inhibited; a hydrogen bond formed by PAA in the copolymer and a silicon substrate, especially SiO, has good coating stability, and PAA-g-PBI has a three-dimensional network structure and an effect of reversible ionic bond reconstruction, and a specific structure can show a high adhesive force, high mechanical strength and self-healing characteristics to silicon, and can effectively adapt to volume expansion and shrinkage of a silicon-based material; and the structural stability can still be maintained after a huge volume change is generated so that the silicon-based material with high cycle stability is obtained.

Owner:ZHUHAI COSMX BATTERY CO LTD

Antibiofouling composition, antibiofouling membrane and method for forming the same

ActiveUS9346022B2Improve featuresSimple treatmentSemi-permeable membranesMembranesSolventPolymer chemistry

The present invention provides an antibiofouling composition, an antibiofouling membrane and a method for forming the same. The antibiofouling composition comprises a copolymer and at least one solvent. The copolymer comprises at least one hydrophobic segment and at least one antibiofouling segment where the hydrophobic segment comprises a plurality of hydrophobic moieties and the antibiofouling segment comprises a plurality of antibiofouling moieties. The molar ratio of the total of hydrophobic moieties to the total of the antibiofouling moieties is 0.5˜6.0.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

High humid and heat resistant anti-rust oil

InactiveCN104450030ASlow down the electrode reactionImprove liquidityLubricant compositionKetoneAcetylated Lanolin

The invention discloses high humid and heat resistant anti-rust oil. The high humid and heat resistant anti-rust oil consists of the following raw materials in parts by weight: 60-70 parts of No.0 light diesel oil, 20-30 parts of rare earth anti-rust hydraulic oil, 0.2-0.3 part of vegetable fat powder, 0.8-1 part of methyl perfluorobutyl ketone, 1-2 parts of sodium bisphosphate, 2-3 parts of urea, 1-2 parts of benzotriazole, 1-2 parts of zinc dialkyl dithiophosphate, 2-5 parts of hydrogenated castor oil, 2-3 parts of ethylene glycol, 3-4 parts of phthalic acid ester, 2-3 parts of 1,2-dially phthalate, 1-2 parts of hexamethylene tetramine and 4-10 parts of acetylated lanolin. According to the anti-rust oil disclosed by the invention, the rare earth anti-rust hydraulic oil is added; by virtue of an alkyl ketone dispersion liquid, the flowability can be improved, and the reaction activity can be increased; and added rare earth ions can react with OH<-> which is produced in a process of performing oxygen absorption corrosion on the surface of a metal base material to produce insoluble complexes, so that the corrosion electrode reaction can be slowed down, and a very good slow-release effect can be achieved.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

A kind of preparation method of nickel-cobalt lithium manganese oxide for coated power battery

ActiveCN108832083BWrap implementationImprove bindingCell electrodesSecondary cellsPower batteryManganate

The invention discloses a preparation method of lithium nickel cobalt manganate for coated power battery. The method comprises the following steps: 1) preheating the lithium nickel cobalt manganate particles; 2) heating the metal to be coated to boiling under an inert gas atmosphere to obtain metal vapor; 3) blowing the preheated lithium nickel cobalt manganate particles into a pyrolysis furnace with an inert gas, and simultaneously blowing metal vapor into the pyrolysis furnace for reaction with the inert gas; 4) the obtained particles are sent to a mixer through an inert gas, and mixed withan oxygen-containing mixed gas to form a solid-gas mixture; 5) the solid-gas mixture is sent to a pyrolysis furnace for reaction. The invention adopts the method of molten metal vapor to coat the lithium nickel cobalt manganate, the metal particles can be uniformly adhered on the surface of the lithium nickel cobalt manganate particles by the fine particles, the coating of the ultra-thin layer isrealized, the molten metal is firmly combined with the cathode material, is not easy to fall off, the coating stability is good, and the performance of the lithium nickel cobalt manganate cathode material can be remarkably improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

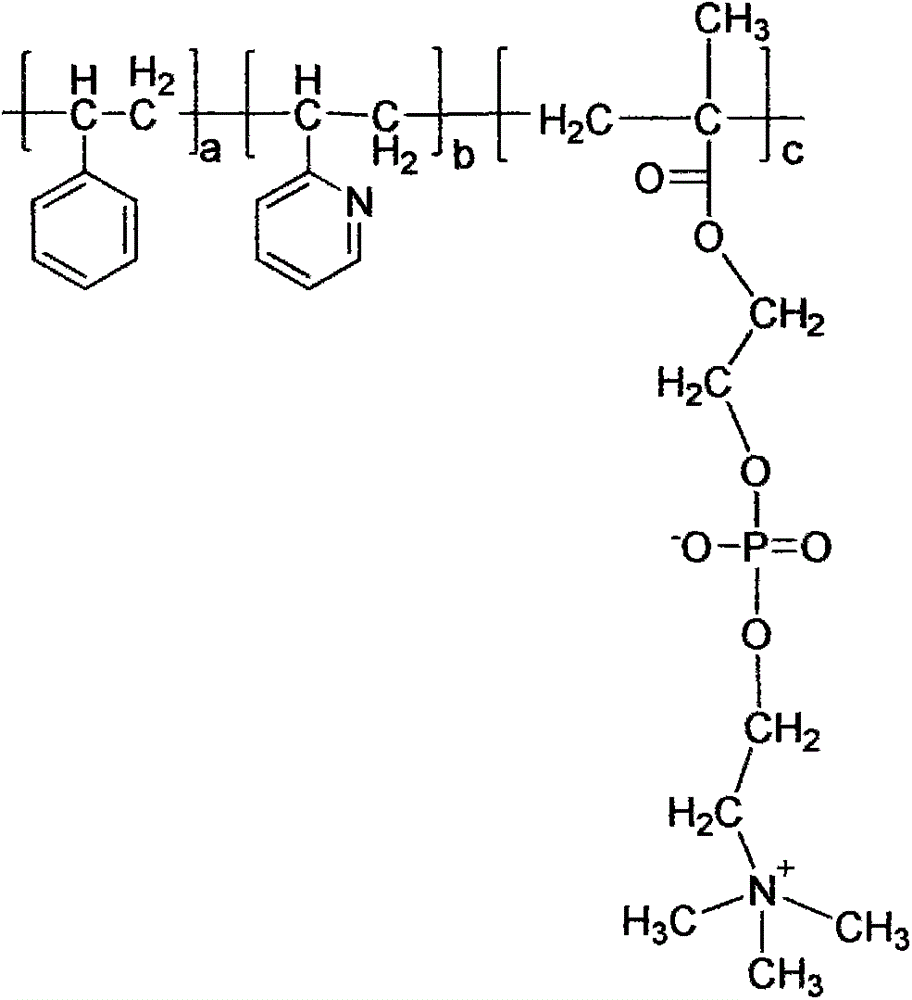

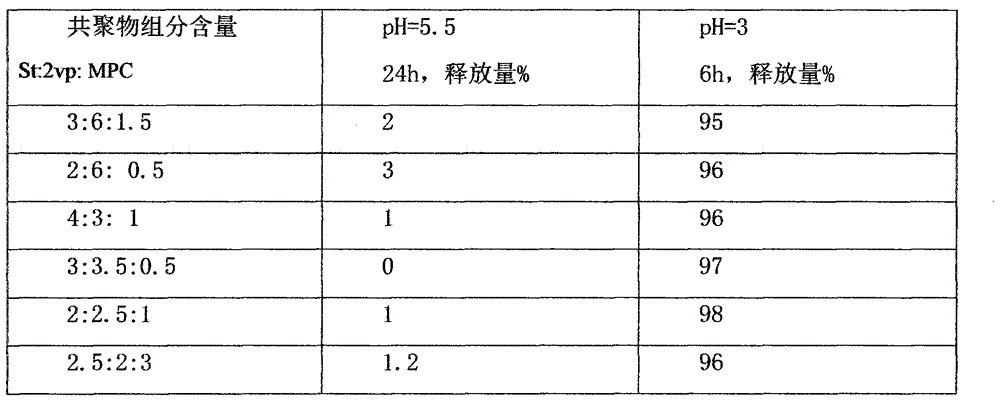

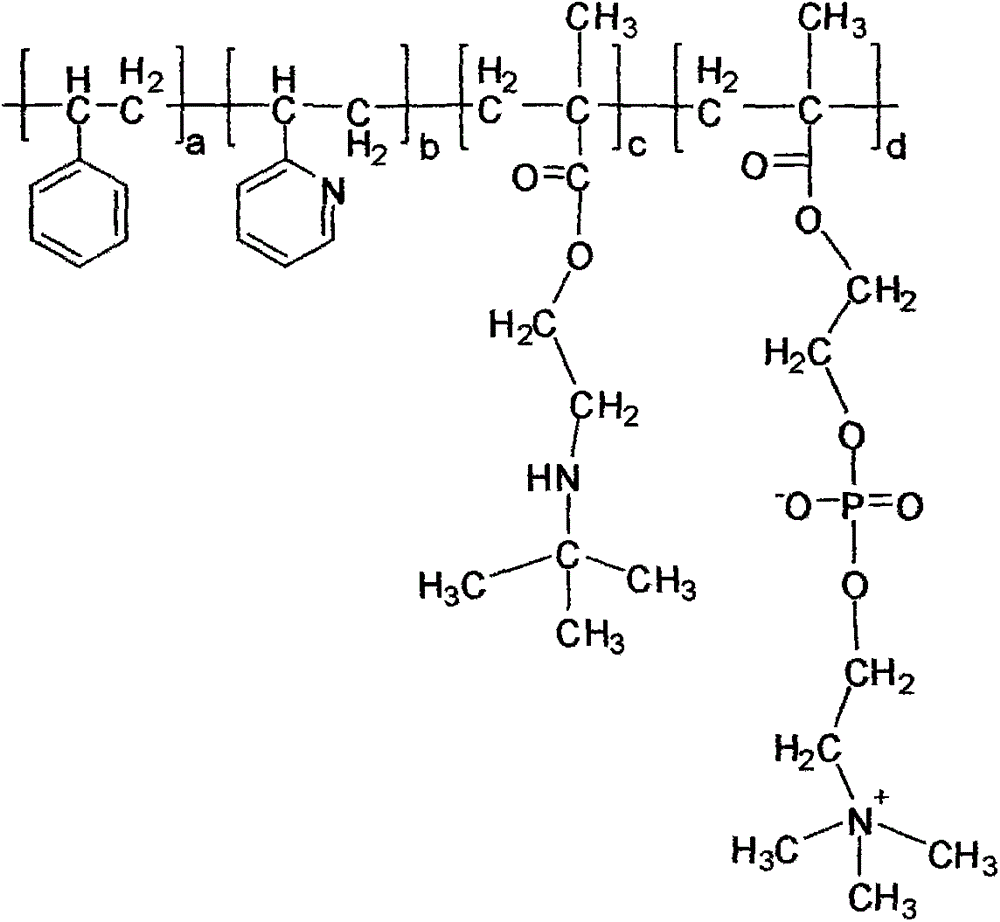

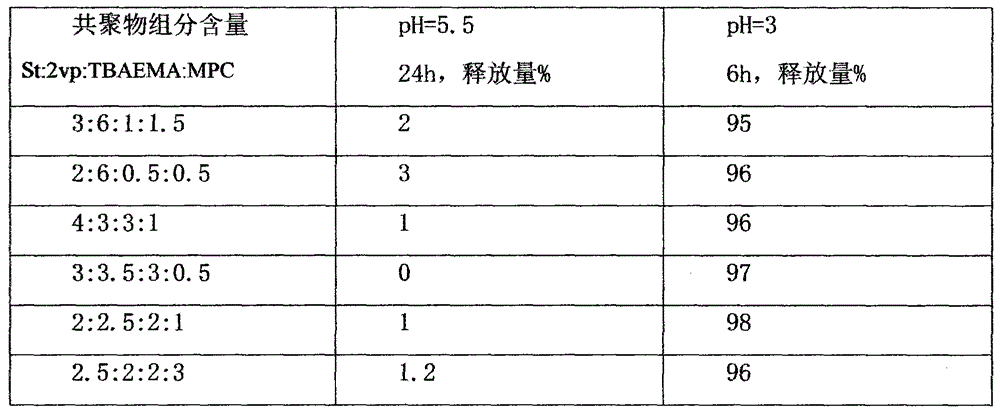

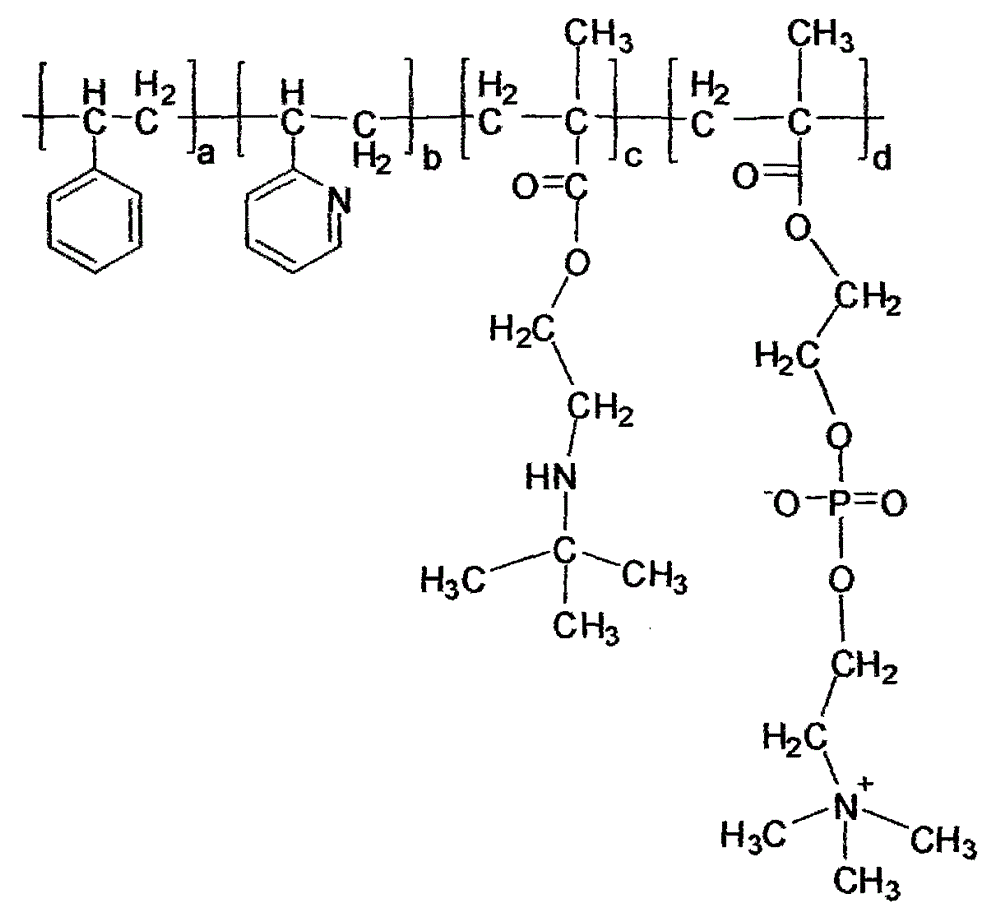

Coating material for ruminant feed additive and preparing method thereof

InactiveCN105884951AImprove effective useImprove biocompatibilityAnimal feeding stuffBiocompatibility TestingGenetic Materials

The invention discloses a coating material for a ruminant feed additive. The coating material is made from styrene, 2-vinylpyridine and 2-methacryloyloxyethyl phosphorycholine, and is a ternary random copolymer synthesized based on the monomer molar ratio of (2.5-4):(2.5-6):(0.5-3). The ternary copolymer is synthesized through molecular structure design. Through specific matching and synergistic effect of three monomers in the polymer, the coating material has the advantages of being sensitive to ph, high in coating stability, small in monomer residue number, capable of avoiding damage of genetic materials, high in biocompatibility and the like.

Owner:北京大乐成声科技有限公司

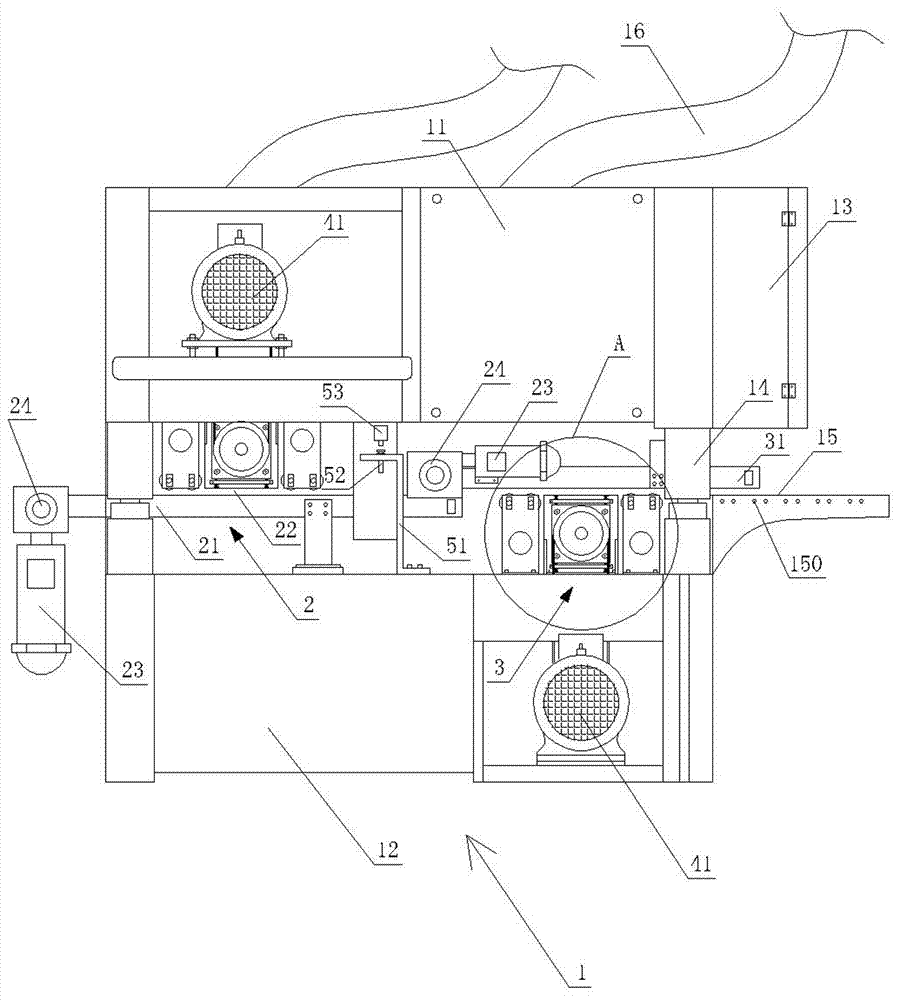

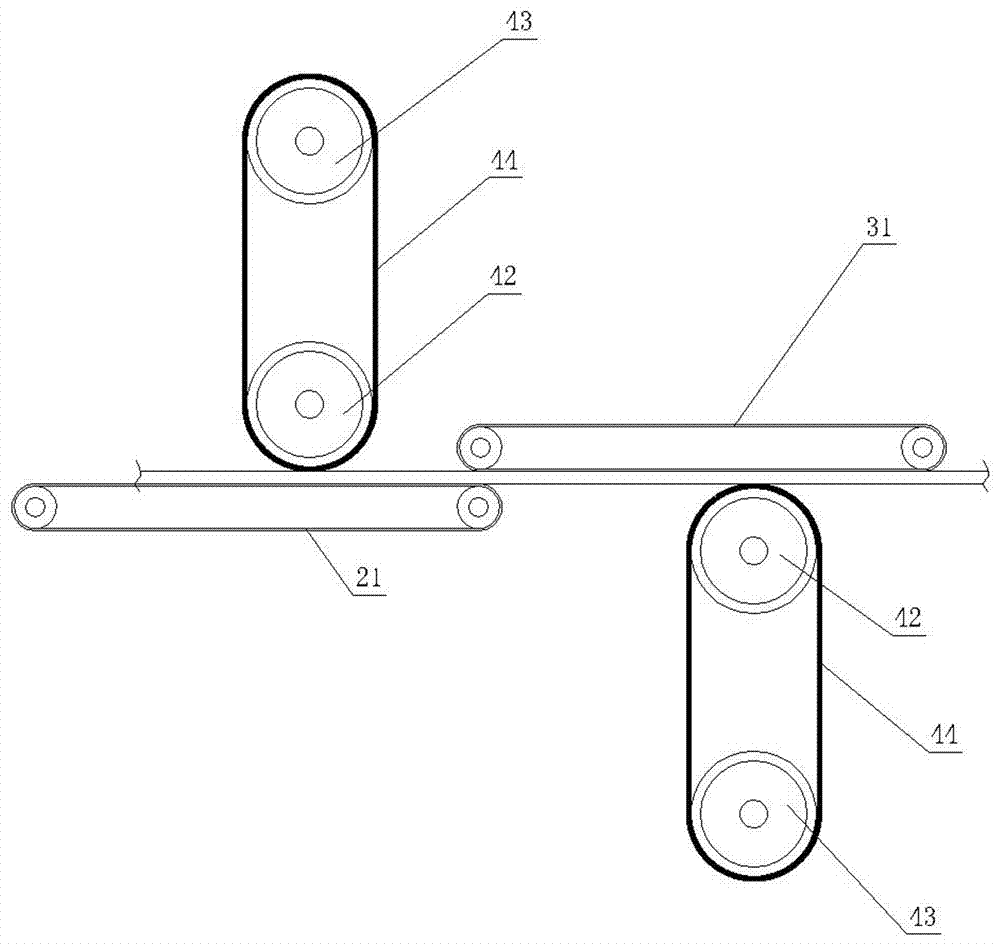

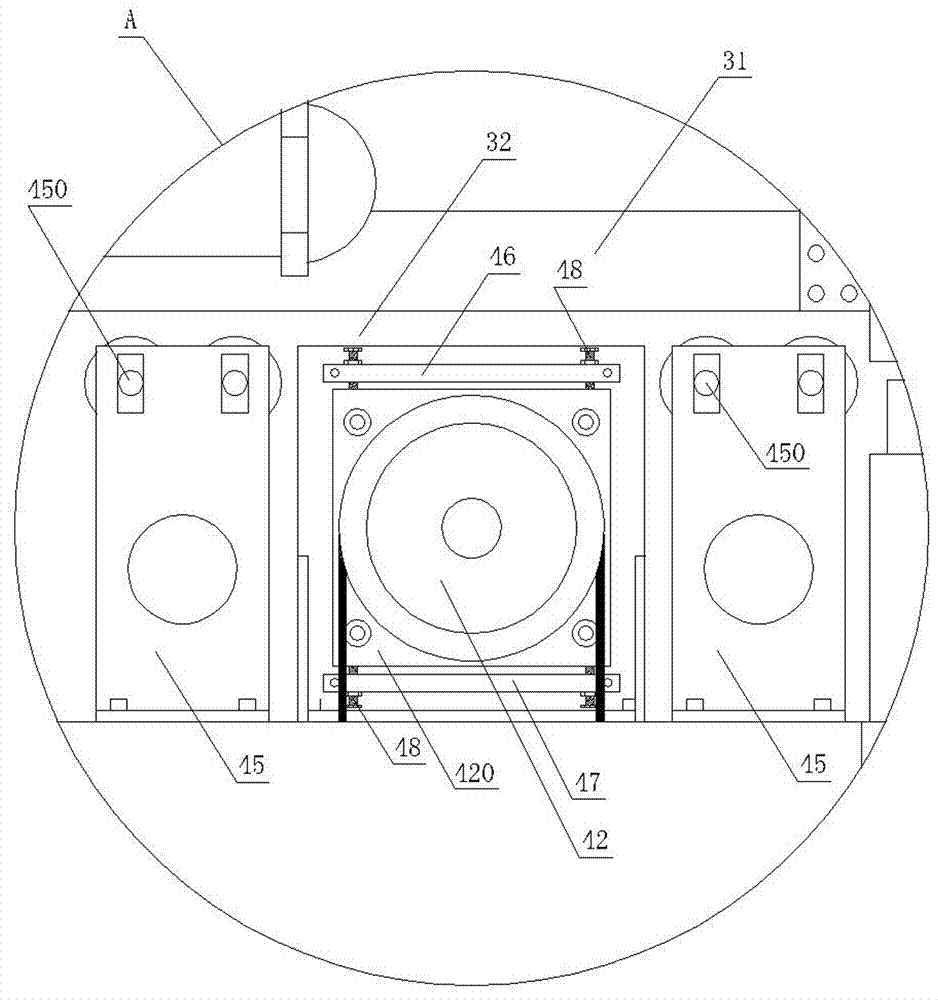

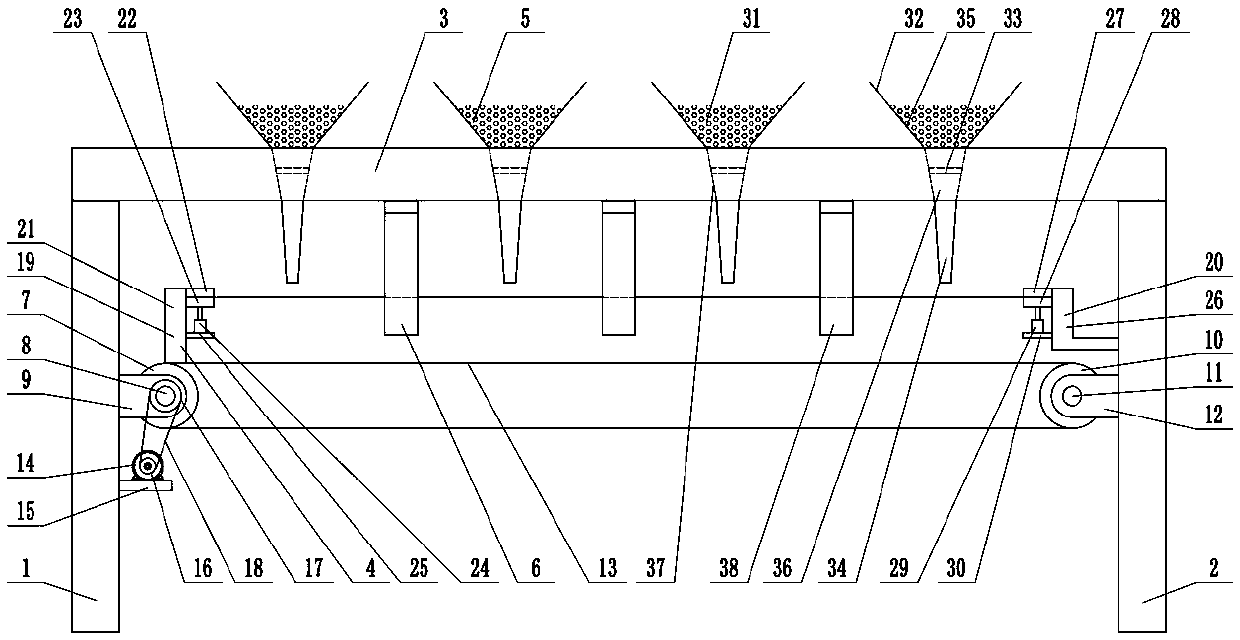

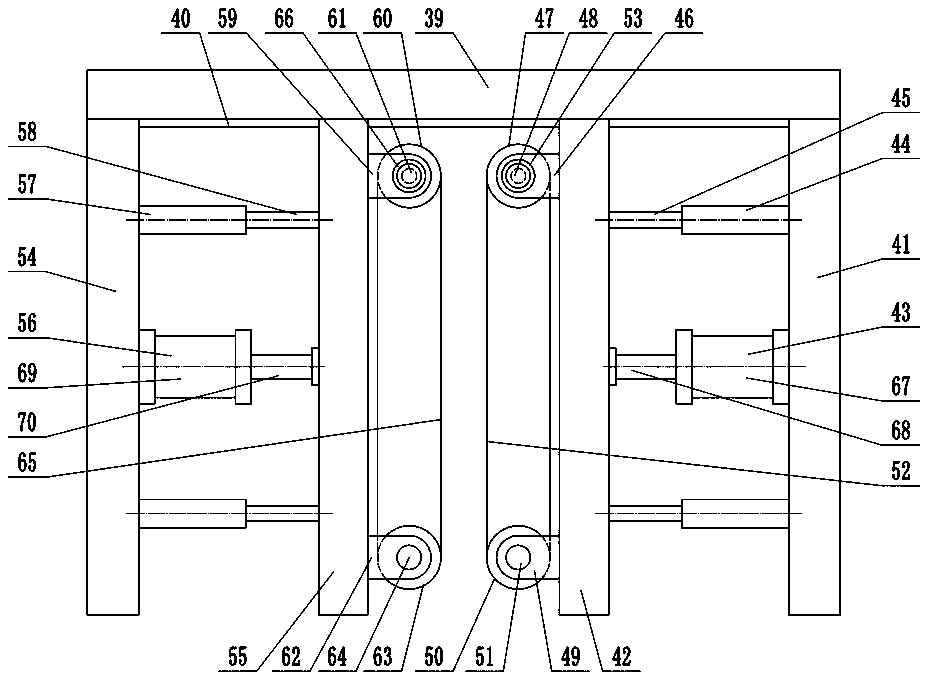

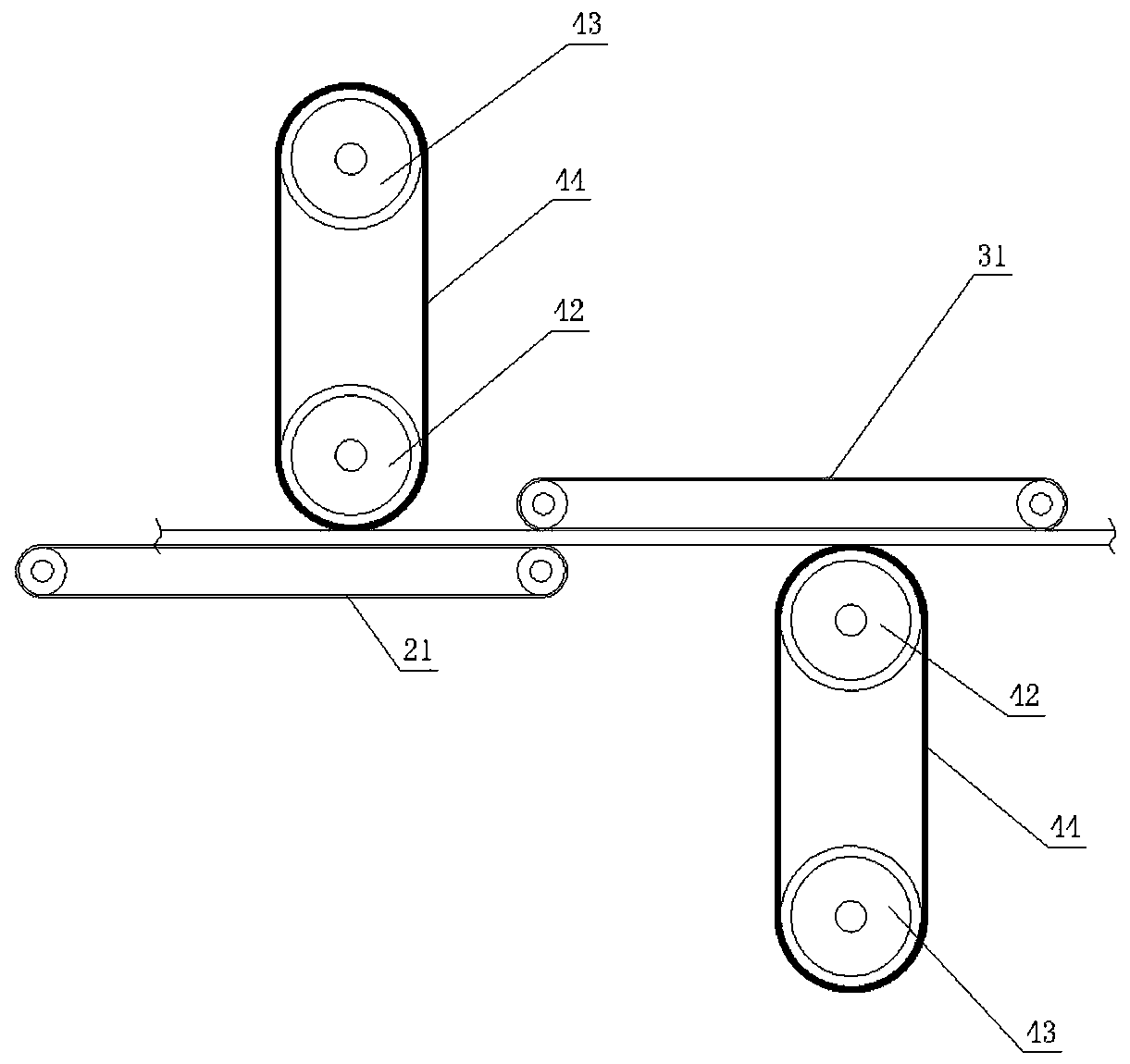

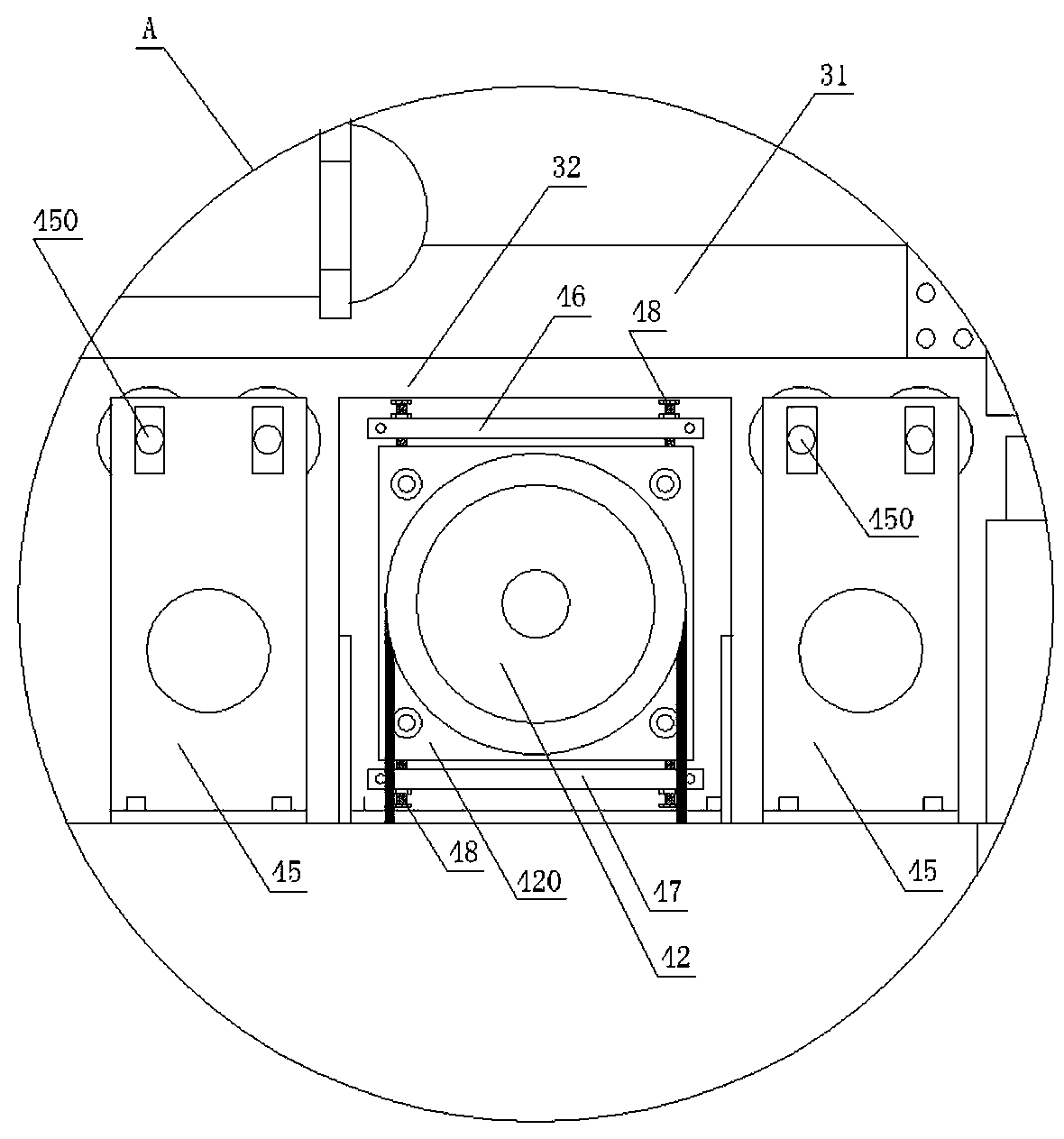

Coating device for seeds

The invention provides a coating device for seeds and belongs to the technical field of intelligent agriculture. The coating device comprises a seed coating strip clamping mechanism, seed dischargingmechanisms and seed coating strip winding mechanisms, wherein the seed coating strip clamping mechanism comprises a movable gripper and a fixed gripper; the movable gripper is arranged on a paving conveying belt; a fourth gripping plate of the fixed gripper is arranged on a fixed gripping support seat in a vertically slidable manner; one end of a second gripping relay is arranged on a second gripping relay support seat; the other end of a second gripping relay is connected with the fourth gripping plate; the seed discharging mechanism comprises two or more discharging components; the discharging components are equidistantly arranged on a coating platform; the seed coating strip winding mechanism comprises two or more winding components; the quantity of the winding components is smaller than one that of the discharging components; each winding component is arranged between every two adjacent discharging components. According to the coating device provided by the invention, spaced coating of the seeds is realized by using a seed coating strip and a rope-like seed coating strip is formed; the coating device is good in coating stability and reasonable in structure.

Owner:施正侃

Coating and sanding process of solid wood strips

ActiveCN107457656BEfficient designImprove sanding effectBelt grinding machinesAdhesive application devicesSolid woodMetallurgy

The invention discloses a solid wood batten coating and sanding process. The solid wood batten coating and sanding process comprises the following steps: 1) natural woods are pretreated as blanks; 2) first paint pulp is uniformly coated on the blanks to form first coating layers on the outer surfaces of the blanks; and the thicknesses of the first coating layers are controlled within 0.4-0.6 mm; 3) the primary asynchronous automatic sanding treatment is performed; 4) second paint pulp is uniformly coated on the first coating layers to form second coating layers on the outer surfaces of the blanks; and the thicknesses of the second coating layers are controlled within 0.1-0.3 mm; and 5) the secondary asynchronous automatic sanding treatment is performed. The coating and sanding process is more ideal in design; the quality of the coating layers on the surfaces of solid wood battens is high; and in the sanding operation process, the front surfaces and the back surfaces of the blanks are sanded in sequence, so that the quality of products is greatly improved.

Owner:福建省尤溪县红树林木业有限公司

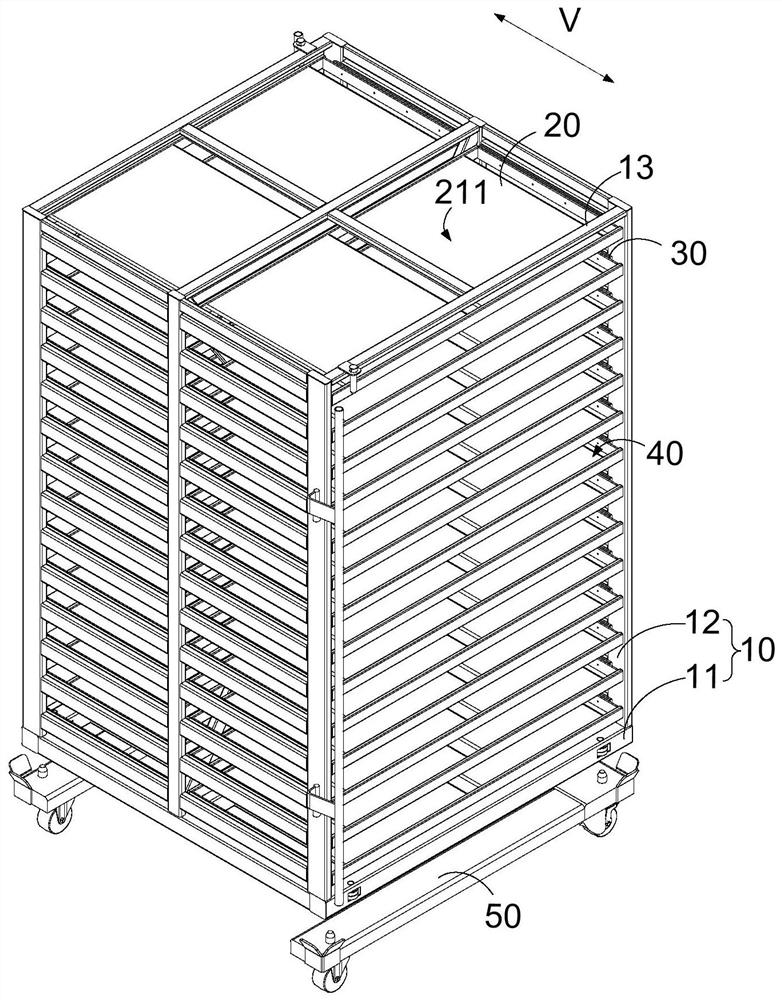

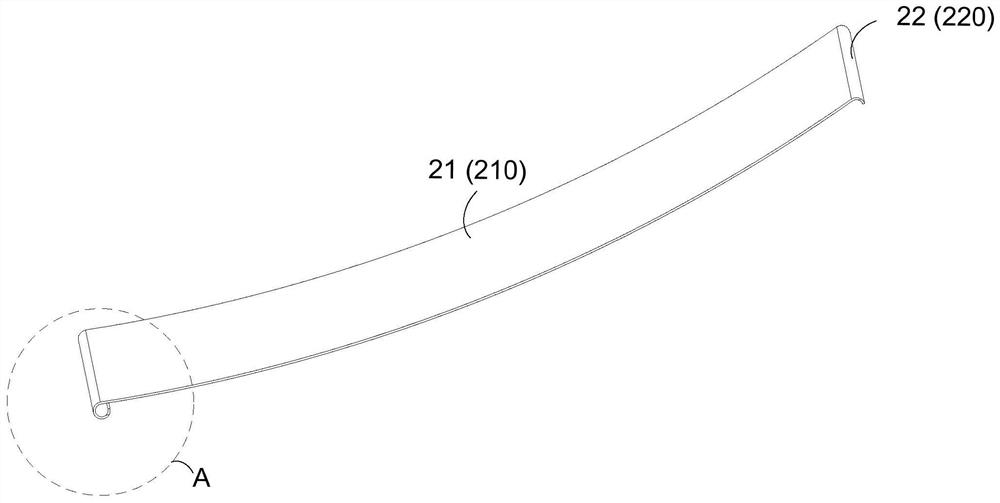

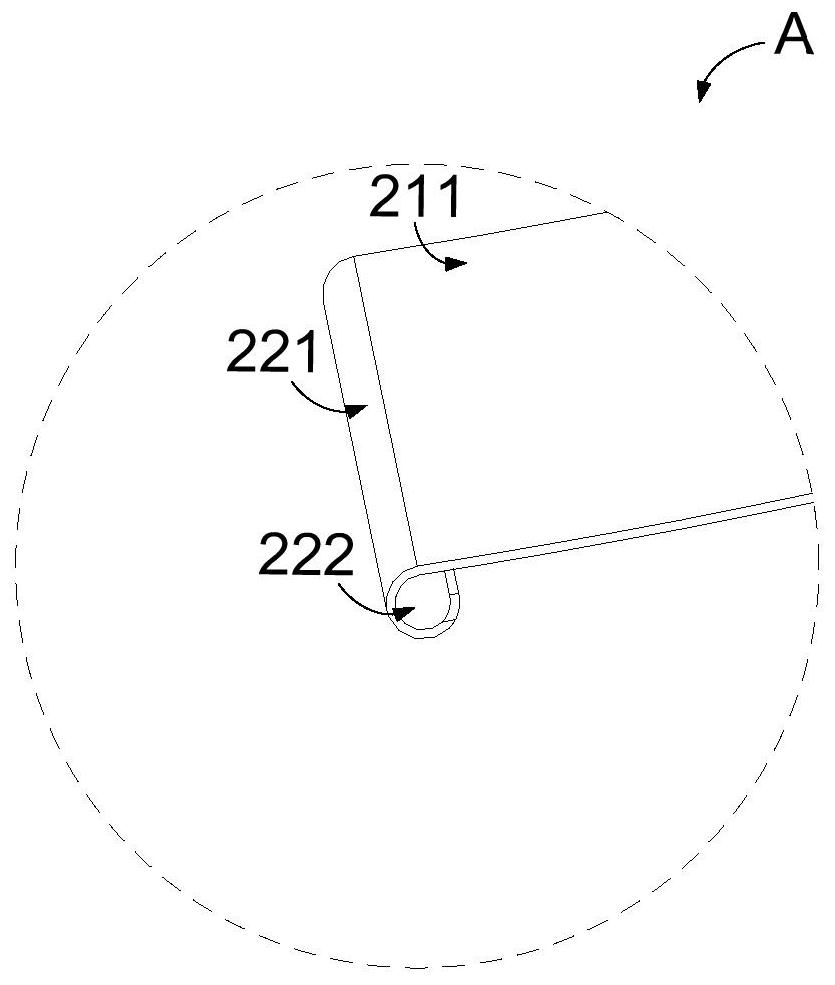

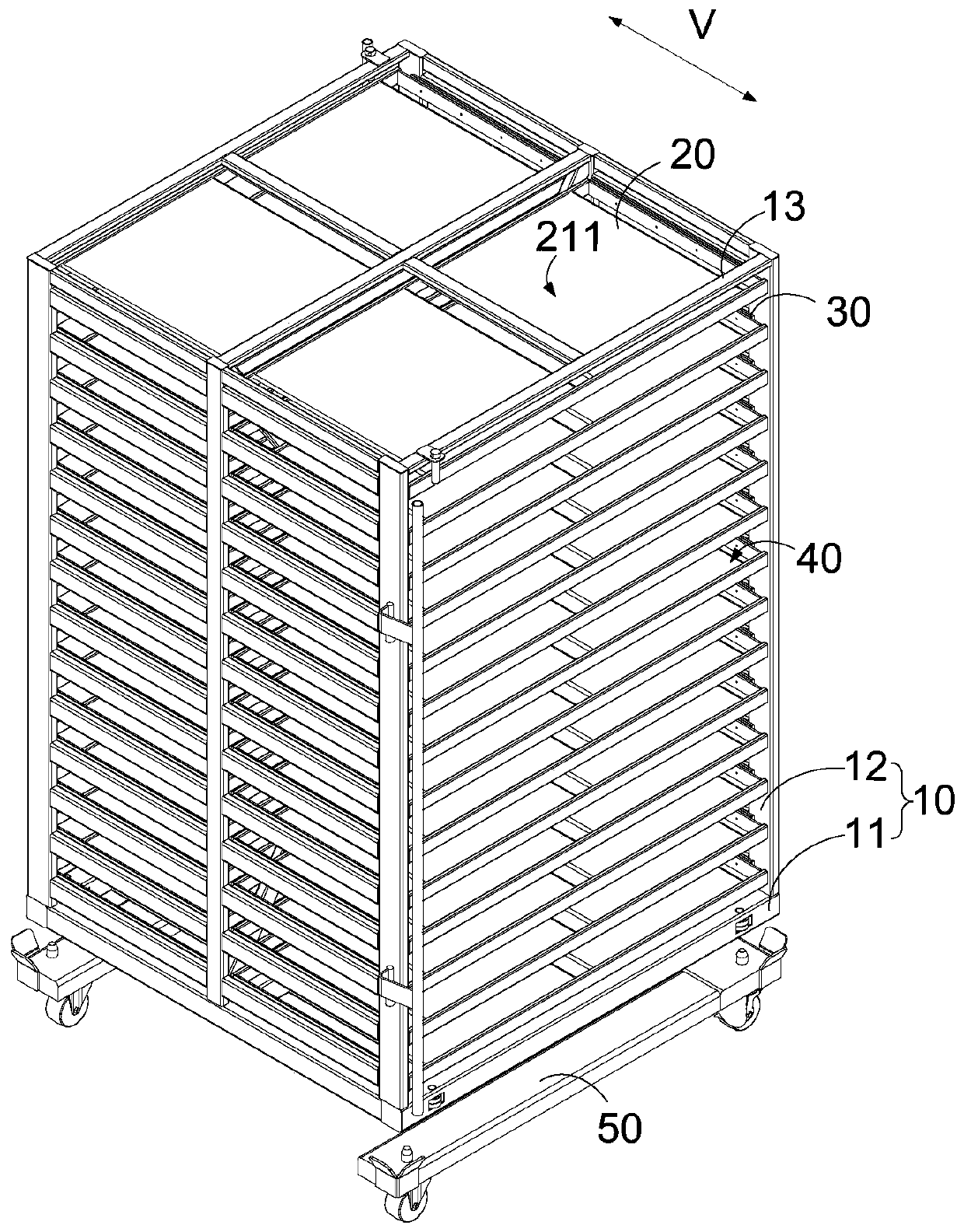

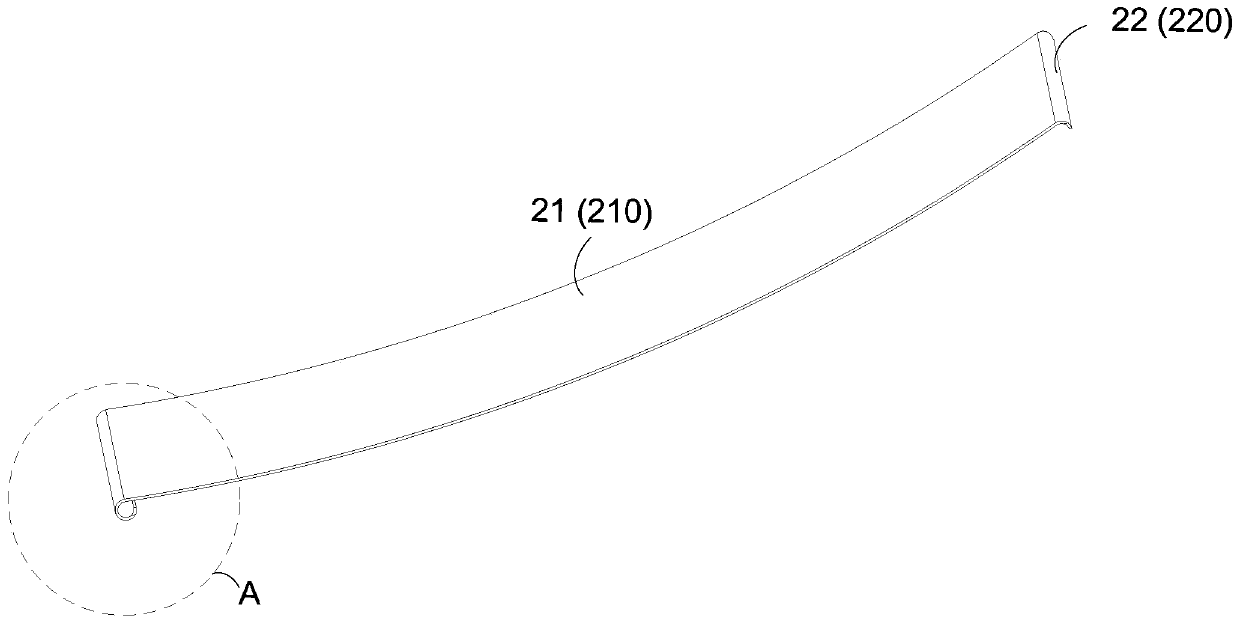

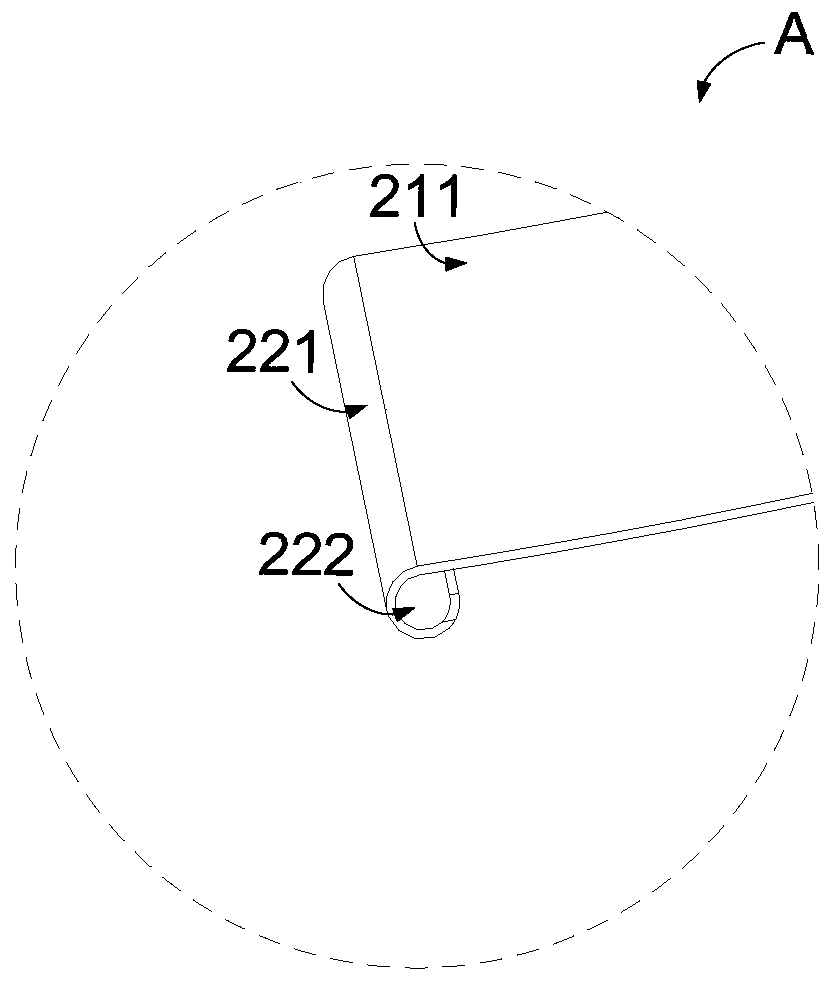

Aging frame and thermal film aging method

The invention discloses an aging rack and a thermal film aging method. The aging rack includes a main body, a tray, and a mounting part arranged on the main body. The aging rack is movably arranged on an aging production line through the main body, and a ventilation channel is formed in the main body. The ventilation channel is used to circulate the temperature and humidity gas in the aging production line. The tray is installed in the installation part so that the tray is located in the ventilation channel. The tray includes an arc surface, and the arc surface is used for stacking multiple thermal films. The technical scheme of the invention can improve the aging consistency of the thermal film.

Owner:南阳柯丽尔科技有限公司

Ageing rack and ageing method of thermosensitive film

The invention discloses an ageing rack and an ageing method of a thermosensitive film. The ageing rack comprises a main body, trays and installing parts arranged on the main body; and the ageing rackis movably arranged on an ageing production line through the main body, ventilating flowing channels are formed inside the main body and used for circulation of warm and humid gas in the ageing production line, the trays are installed on the installing parts so that the trays can be located in the ventilating flowing passages, and the trays comprise arc-shaped surfaces which are used for placing aplurality of thermosensitive films in a stacked mode. According to the technical scheme of the ageing rack and the ageing method of the thermosensitive film, the ageing conformity of the thermosensitive films can be improved.

Owner:南阳柯丽尔科技有限公司

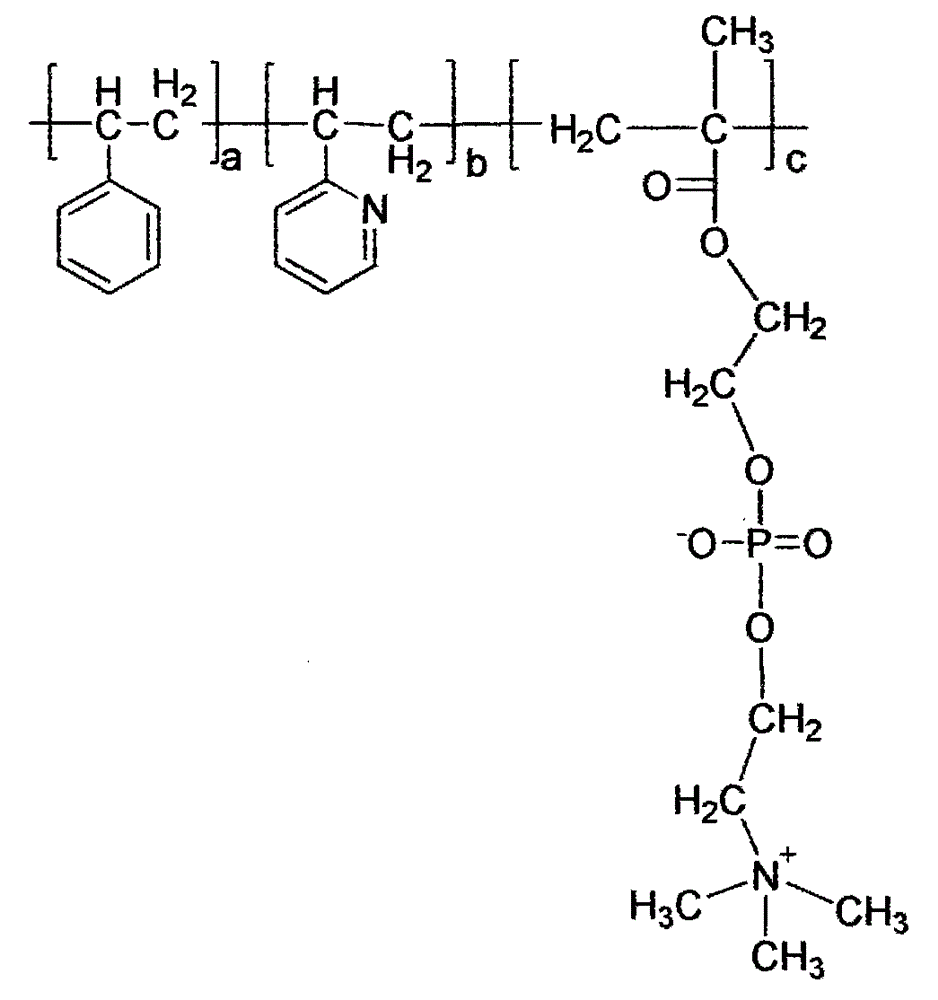

Feed additive coating material and preparation method thereof

InactiveCN105884950AEfficient use ofGood biocompatibilityAnimal feeding stuffMethacrylate2-Vinylpyridine

The invention discloses a coating material for coating a feed additive. The coating material is a random quadripolymer which is synthesized by taking styrene, 2-vinplpyridine, 2-tert-butylaminoethyl methacrylate and 2-methacryloyloxyethyl phosphorycholine as raw materials according to the monomer mole feed ratio of (2.5-4):(2.5-6):(0.5-3):(0.5-3). The quadripolymer is synthesized by designing a molecular structure. Through the specific proportion and synergistic effect among the four monomers in the polymer, the coating material has the advantages of being sensitive to pH, good in coating stability, few in monomer residue, capable of not damaging genetic materials, good in biocompatibility and the like.

Owner:BEIJING NOVTECT SCI & TECH CO LTD

A kind of solvent type wax release agent and preparation method thereof

ActiveCN106346653BImprove high temperature resistanceSmooth disengagementMicrocrystalline waxBoiling point

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com