Coating material for ruminant feed additive and preparing method thereof

A feed additive and coating material technology, applied in animal feed, animal feed, application, etc., can solve the problems of genetic material damage such as gene mutation, high price, narrow pH sensitive range, etc., to improve biocompatibility, improve Effect of effective utilization rate and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

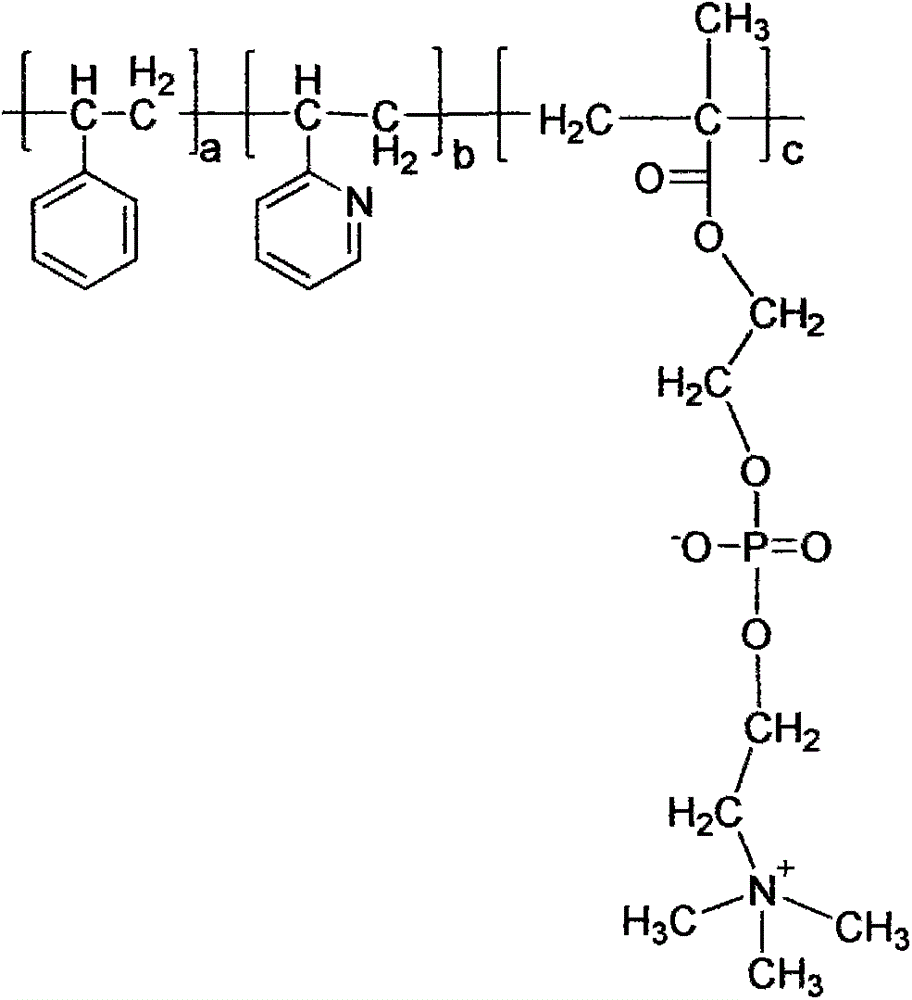

[0028] Styrene, 2-vinylpyridine and 2-methacryloyloxyethylphosphorylcholine (MPC) are fed in a molar ratio of 2:1:0.5, the solvent is water, AIBN triggers the reaction at 65°C for 5 hours, and the temperature rises Cured at 85°C for 1 hour. The molecular weight Mw of the obtained terpolymer was 180000, the viscosity was 1.2dl / g, and the conversion rate was 95%.

Embodiment 2

[0030] Styrene, 2-vinylpyridine and 2-methacryloyloxyethylphosphorylcholine (MPC) are fed in a molar ratio of 2.5:3:1, the solvent is water, ABVN is initiated, and the temperature is 55°C for 5 hours, and the temperature is raised Cured at 70°C for 1 hour. The molecular weight Mw of the obtained terpolymer was 260000, the viscosity was 2.3dl / g, and the conversion rate was 97%.

Embodiment 3

[0032] Styrene, 2-vinylpyridine and 2-methacryloyloxyethylphosphorylcholine (MPC) were fed in a molar ratio of 3:6:0.5, the solvent was water, BPO was initiated, and the reaction was carried out at a temperature of 90° C. for 6 hours. The molecular weight Mw of the obtained terpolymer was 210000, the viscosity was 0.8dl / g, and the conversion rate was 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com