Preparation method of non-stick pan coating layer for cookware

A non-stick pan and coating layer technology, which is applied in the direction of household utensils, kitchen utensils, special materials for cooking utensils, etc., can solve the problem of unsatisfactory bonding and adhesion of molten TiC, TiCN or TiN and cracked coatings, and pores in the coating structure , easy to wear and other problems, to achieve the effect of ensuring environmental protection, non-toxicity, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

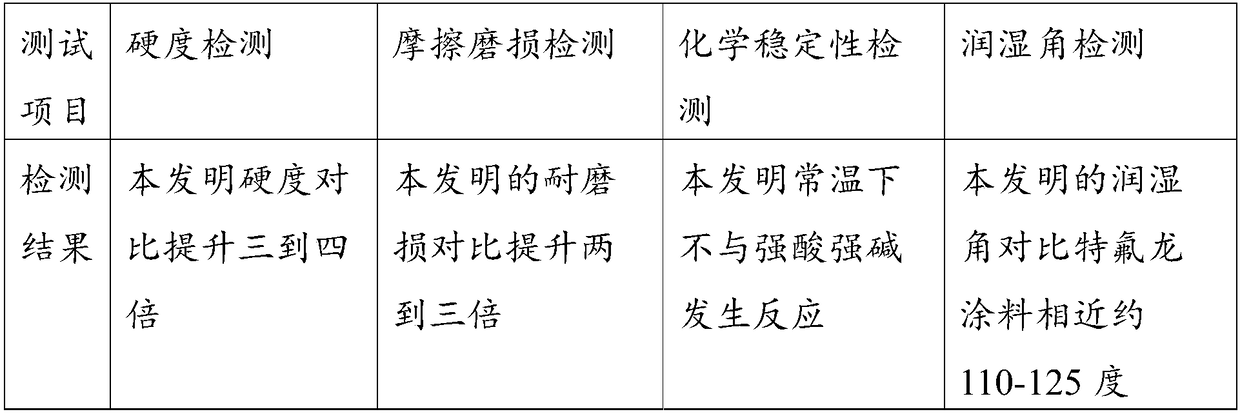

Examples

preparation example Construction

[0014] A kind of preparation method of the non-stick coating layer of cookware of the present invention, this preparation method comprises following specific operation steps:

[0015] (1), the boron nitride material that preparation purity is 99.5% is coating, stand-by; And the component of this boron nitride material is as follows: boron 43wt%, diboron trioxide 0.1wt%, carbon 0.03wt%, balance for water;

[0016] (2) Using the laser cladding process, the coating prepared above is clad on the substrate, that is, the inner surface of the pot to form a non-stick coating layer; wherein, the laser cladding process parameters are: laser power 1500 ~ 3500W, scanning The speed is 3-12mm / S, and the powder feeding volume is 6-20g / min.

[0017] Among them, the substrate is a metal pot or a ceramic pot; the average size of the powder particles of the boron nitride material is 60-160m, which makes the final non-stick pan coating more uniform; and through the boron nitride material in the ...

Embodiment 1

[0021] Prepare a boron nitride material with a purity of 99.5%, that is, a paint, for use; and the components of the boron nitride material are as follows: boron 43wt%, diboron trioxide 0.1wt%, carbon 0.03wt%, and the balance is water;

[0022] Using the preset laser cladding process, the coating obtained above is clad on the inner surface of the aluminum alloy pan to form a non-stick pan coating layer; wherein, the laser cladding process parameters are: laser power 2000W, scanning speed 10mm / S , The amount of powder feeding is 7.5g / min.

Embodiment 2

[0024] Prepare a boron nitride material with a purity of 99.5%, that is, a paint, for use; and the components of the boron nitride material are as follows: boron 43wt%, diboron trioxide 0.1wt%, carbon 0.03wt%, and the balance is water;

[0025] Using a synchronous laser cladding process, the coating obtained above is clad on the inner surface of the aluminum alloy pan to form a non-stick pan coating layer; wherein, the laser cladding process parameters are: laser power 1500W, scanning speed 12mm / S, The powder delivery rate is 6g / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com