Solvent type wax release agent and preparation method thereof

A solvent-based, release agent technology, applied in the field of solvent-based wax release agent and its preparation, can solve the problems of poor thixotropy, poor stability, poor high temperature resistance, etc., achieve good coating thixotropy, improve high temperature resistance Performance, the effect of good coating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

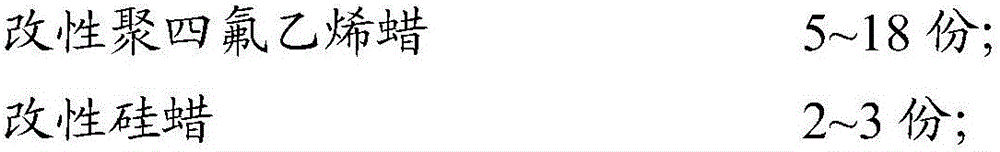

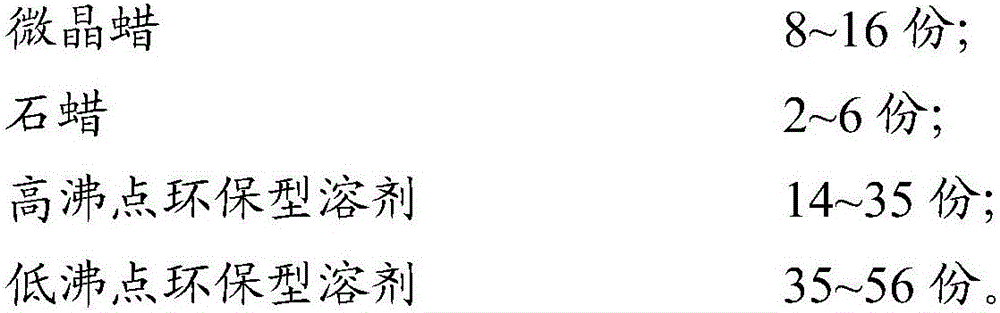

[0032] Embodiment 1 Preparation of solvent-based wax release agent

[0033] (1) Mix 5.0kg of modified polytetrafluoroethylene wax, 3.0kg of modified silicone wax, 16.0kg of microcrystalline wax and 6.0kg of paraffin wax, and heat to 125°C for melting;

[0034] (2) After the mixture in step (1) is completely melted, slowly add 35.0 kg of hydrodesulfurized and dearomatized gasoline at 110° C. and 60 rpm stirring condition, and lower the temperature to 80° C. at 60 rpm stirring condition. Slowly add 35.0 kg of hydrodesulfurization and dearomatization petroleum ether under stirring conditions of 80°C and 60 rpm;

[0035] (3) After the hydrodesulfurization and dearomatization of petroleum ether is completed, the temperature is slowly lowered to 55° C. under stirring at 60 rpm, and the product is packaged and cooled to room temperature to obtain a finished solvent-based wax release agent.

Embodiment 2

[0036] Example 2 Preparation of solvent-based wax release agent

[0037] (1) Mix 10.0kg of modified polytetrafluoroethylene wax, 3.0kg of modified silicone wax, 12.0kg of microcrystalline wax and 5.0kg of paraffin wax, and heat to 95°C for melting;

[0038] (2) After the mixture in step (1) is completely melted, slowly add 30.0 kg of hydrodesulfurized and dearomatized gasoline at 100° C. and stirring at 75 rpm, and lower the temperature to 75° C. while stirring at 75 rpm. Slowly add 45.0 kg of hydrodesulfurization and dearomatization petroleum ether under stirring conditions of 75°C and 75 rpm;

[0039] (3) After the hydrodesulfurization and dearomatization petroleum ether is added, the temperature is slowly lowered to 48° C. under stirring at 75 rpm, and the product is packaged and cooled to room temperature to obtain a finished solvent-based wax release agent.

Embodiment 3

[0040] Example 3 Preparation of solvent-based wax release agent

[0041] (1) Mix 18.0kg modified polytetrafluoroethylene wax, 2.0kg modified silicon wax, 8.0kg microcrystalline wax and 2.0kg paraffin wax, heat to 135°C for hot melting;

[0042] (2) After the mixture in step (1) is completely melted, slowly add 14.0 kg of hydrodesulfurized and dearomatized gasoline at 120° C. and 15 rpm stirring condition, and lower the temperature to 95° C. at 15 rpm stirring condition. Slowly add 56.0 kg of hydrodesulfurization and dearomatization petroleum ether under stirring conditions of 95°C and 15 rpm;

[0043] (3) After the hydrodesulfurization and dearomatization of petroleum ether is completed, the temperature is slowly lowered to 75° C. under stirring at 15 rpm, and the product is packaged and cooled to room temperature to obtain a finished solvent-based wax release agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com