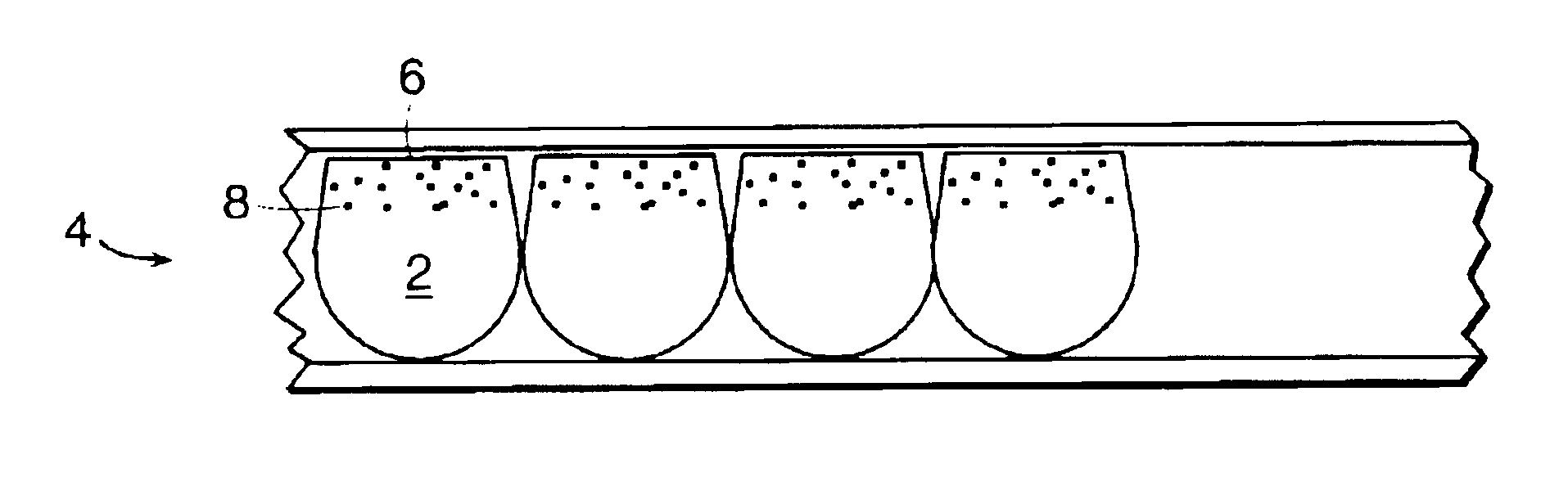

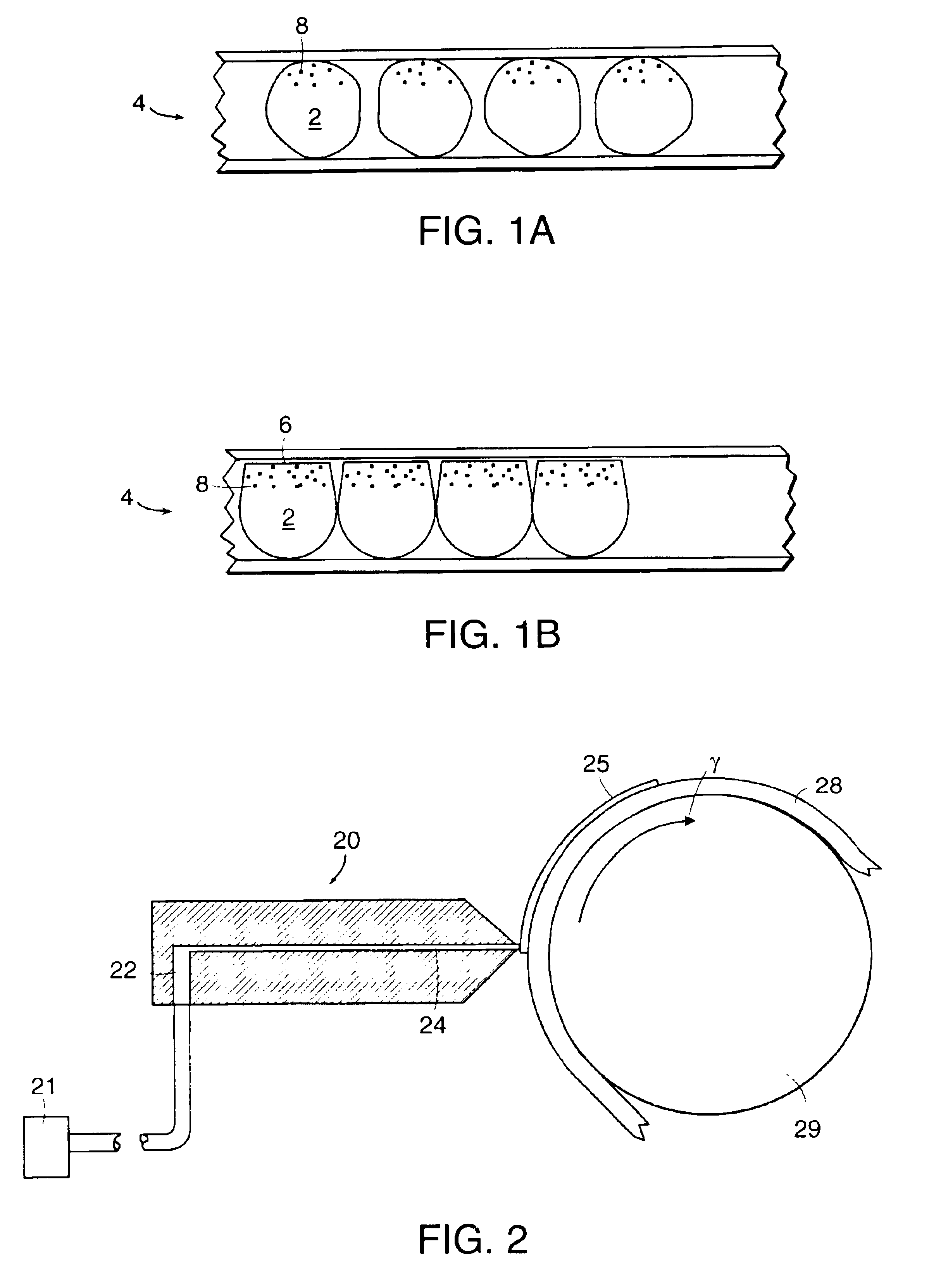

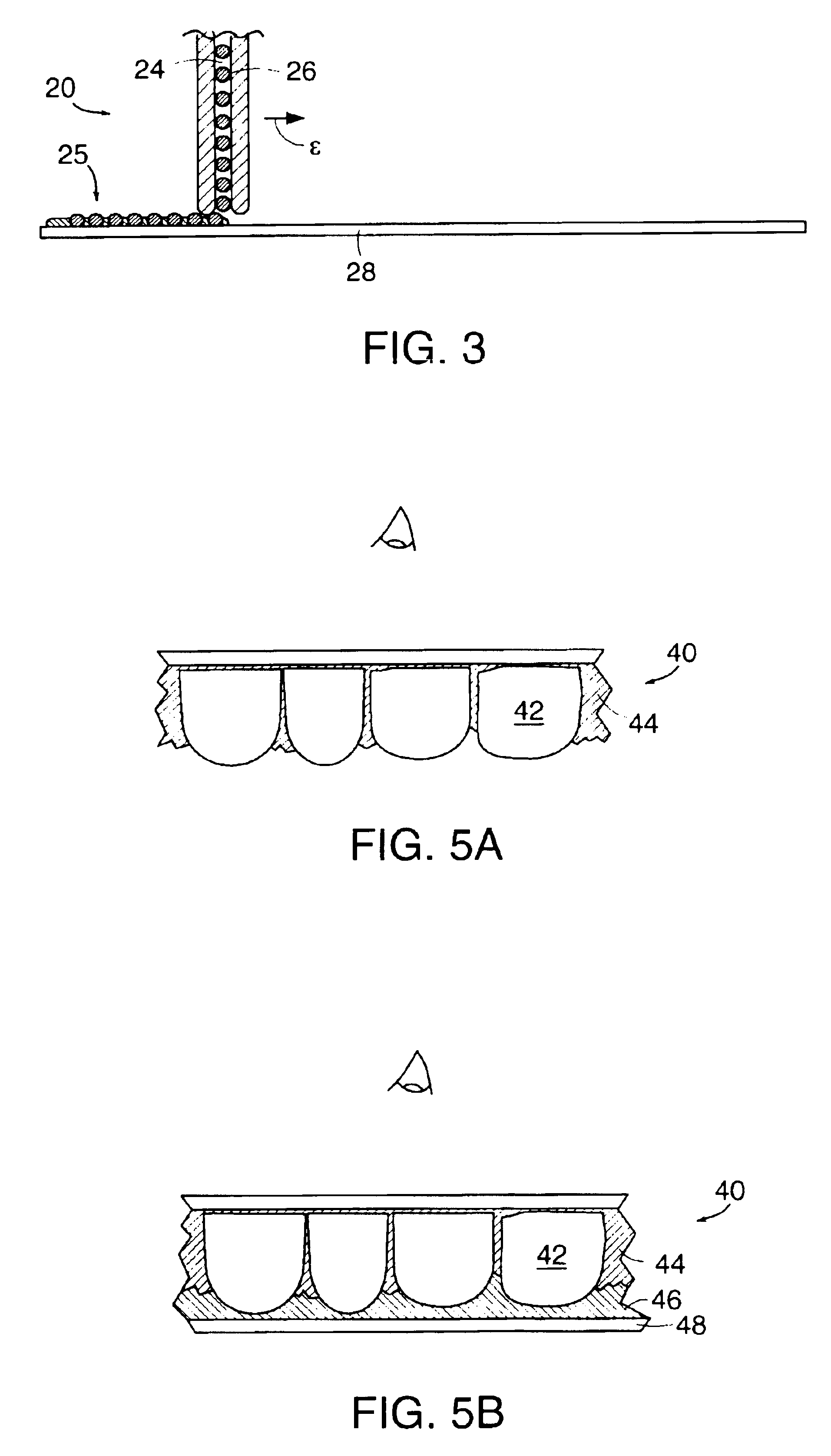

Encapsulated electrophoretic displays having a monolayer of capsules and materials and methods for making the same

a technology of electrophoretic display and capsule, which is applied in the field of materials and methods for forming a monolayer of capsules for an encapsulated electrophoretic display, can solve the problems that current displays are not capable of achieving uniform brightness or good contras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

2. EXAMPLE 2

The following is an example of the preparation of microcapsules by in situ polymerization.

In a 500 mL non-baffled jacketed reactor is mixed 50 mL of a 10 wt % aqueous solution of ethylene co-maleic anhydride (Aldrich), 100 mL water, 0.5 g resorcinol (Aldrich), and 5.0 g urea (Aldrich). The mixture is stirred at 200 rpm and the pH adjusted to 3.5 with a 25 wt % NaOH solution over a period of 1 minute. The pH is monitored using a pH meter that was previously calibrated with pH 7.0 and pH 4.0 buffer solutions. To this is slowly added the oil phase, prepared as described above in Ex. 1, and agitation is increased to 450 rpm to reduce the average particle size to less than 200 μm. 12.5 g of a 37 wt % aqueous formaldehyde solution is then added and the temperature raised to 55° C. The solution is heated at 55° C. for two hours.

example 3

3. EXAMPLE 3

The following is an example of the preparation of microcapsules by interfacial polymerization.

To 44 g of the oil phase, prepared as described above in Ex. 1, is added 1.0 g of sebacoyl chloride (Aldrich). Three milliliters of the mixture is then dispersed in 200 mL of water with stirring at 300 rpm at room temperature. To this dispersion is then added 2.5 mL of a 10 wt. % aqueous solution of 1,6-diaminohexane. Capsules form after about one hour.

E. Binder Material

The binder typically is used as an adhesive medium that supports and protects the capsules, as well as binds the electrode materials to the capsule dispersion. A binder can be non-conducting, semiconductive, or conductive. Binders are available in many forms and chemical types. Among these are water-soluble polymers, water-borne polymers, oil-soluble polymers, thermoset and thermoplastic polymers, and radiation-cured polymers.

Among the water-soluble polymers are the various polysaccharides, the polyvinyl alcohols...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com