Lower cathode rare earth metal electrolytic tank and electrolysis technique adopting the same

A rare earth metal and electrolytic cell technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of affecting the electrolysis yield, slagging at the bottom of the furnace, and reducing the service life of the cathode, so as to avoid impurity pollution, reduce redissolution, The effect of high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

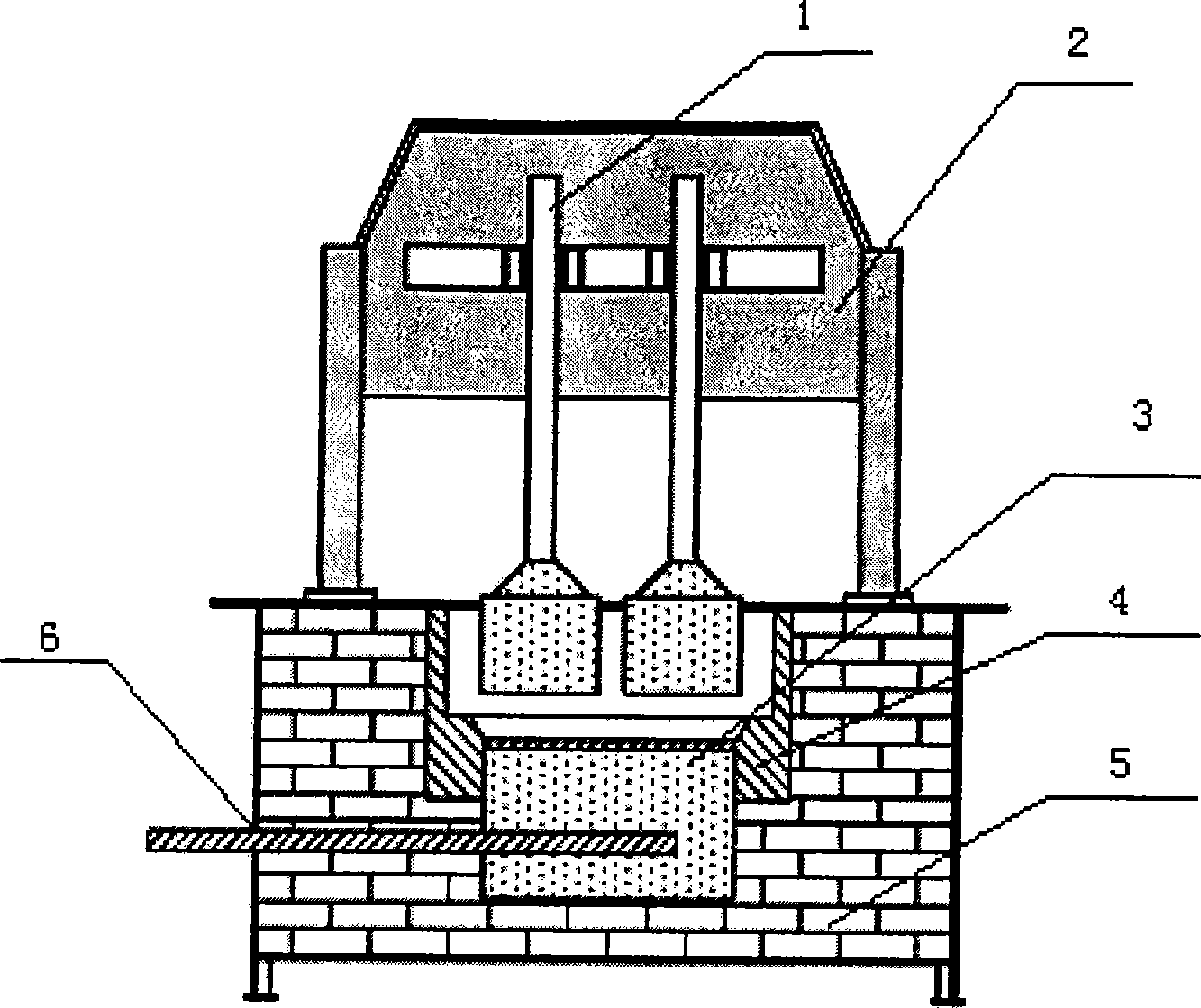

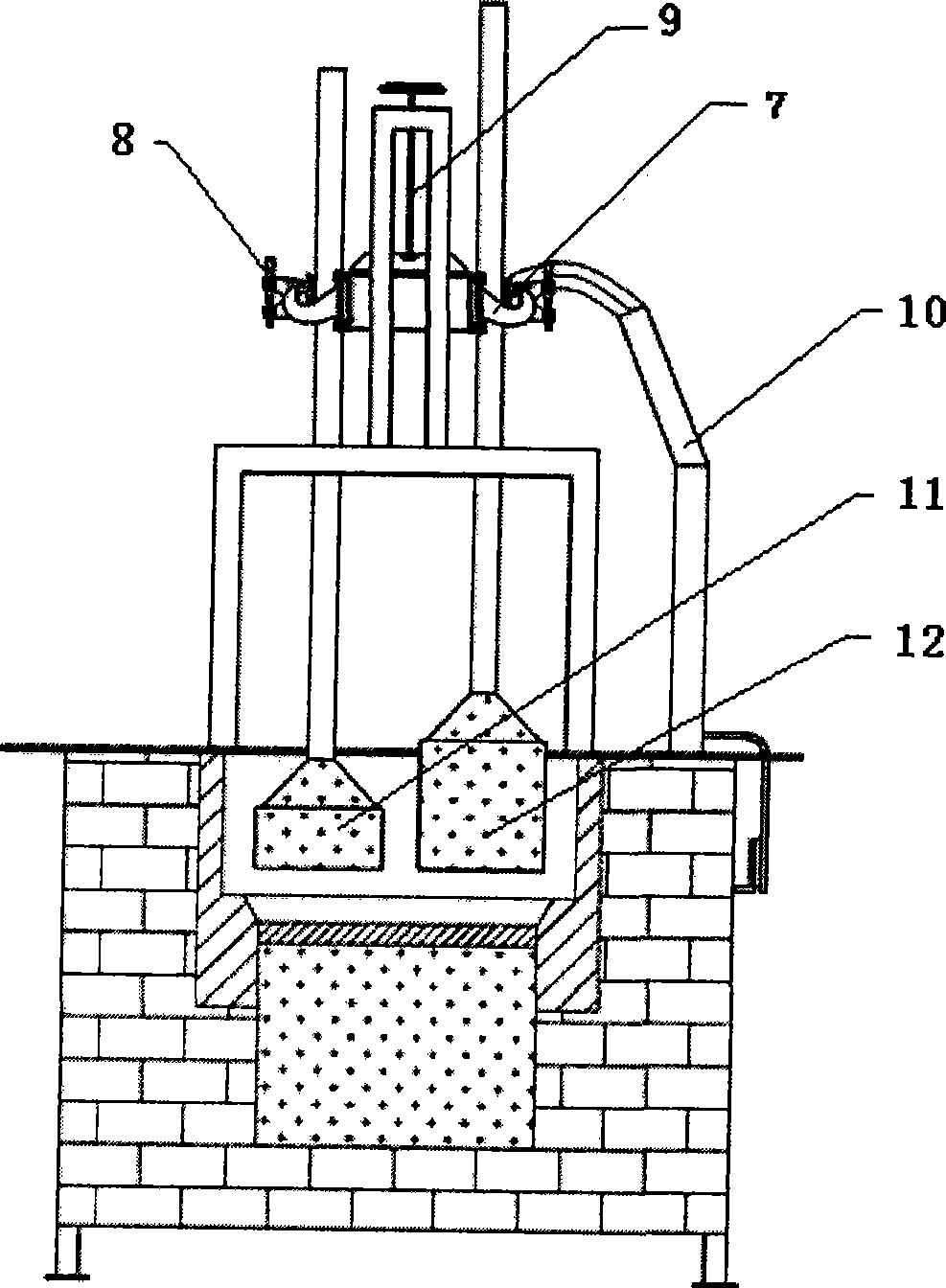

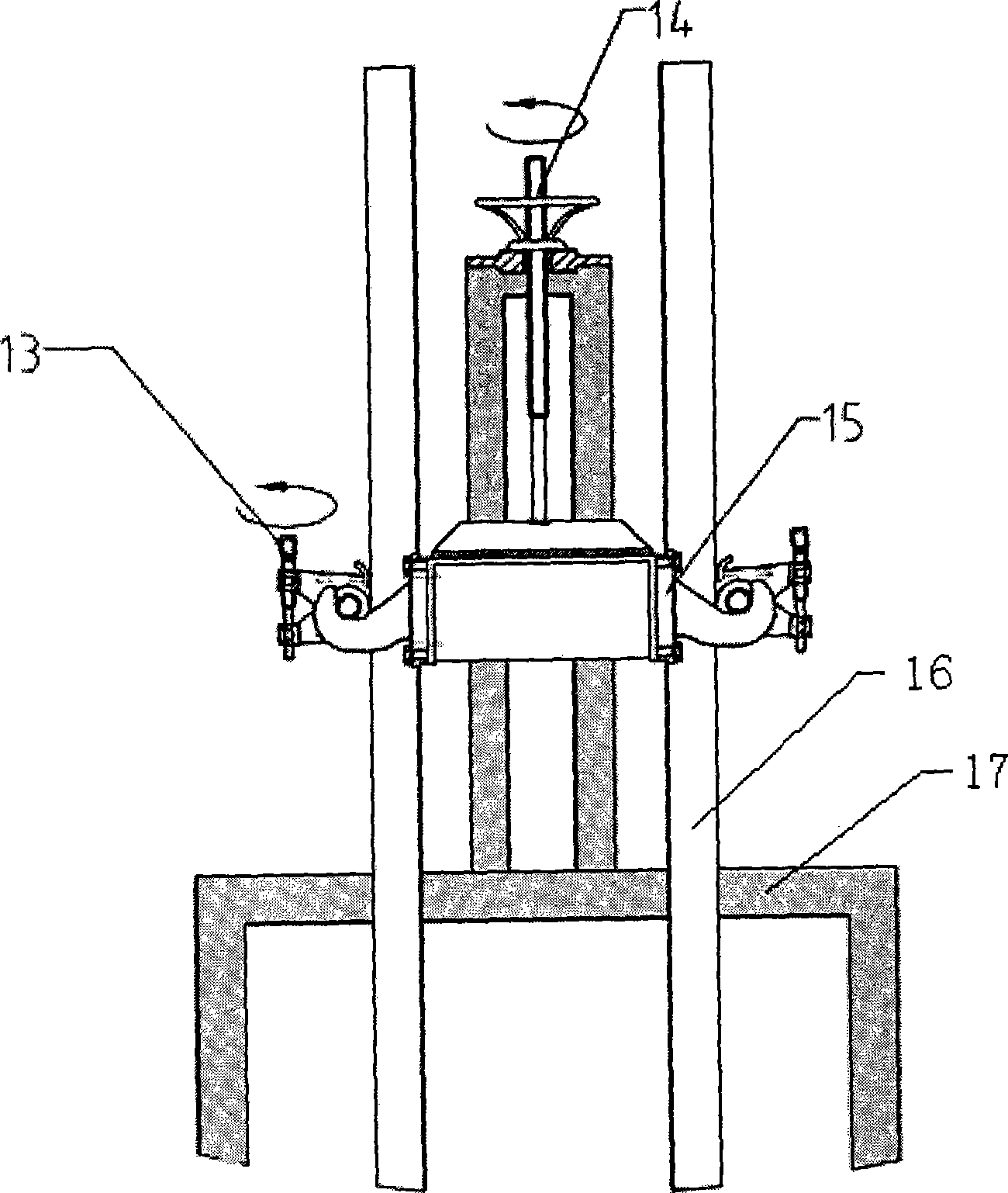

[0046] A high-power graphite block is used as a structural material for the cathode, and a tungsten plate fixed on the upper part of the graphite carbon block is used as the cathode. The cathode current density is 4.3A / cm 2 , The anode is a rectangular graphite block, a total of four anodes are used, and the anode current density is 1A / cm 2 , The rectangular furnace hearth is built with nitriding silicon carbide plates. The outside of the furnace hearth is insulated masonry. The upper bracket of the tank is welded by angle steel and square steel to support the horizontal conductive bus. The horizontal conductive bus is a bilateral parallel frame. The anode guide rod is clamped on the horizontal conductive bus, and the entire anode group is hung above the electrolytic cell.

[0047] Install the anode in the electrolytic cell and load it with LaF in proportion 3: LiF=15:4 electrolyte molten salt, roasting to start the electrolysis cell; the electrolysis cell is operating normally, t...

Embodiment 2

[0051] A high-power graphite block is used as a structural material for the cathode, and a tungsten plate fixed on the upper part of the graphite carbon block is used as the cathode. The cathode current density is 3.6A / cm 2 , The anode is a rectangular graphite block, a total of four anodes are used, and the anode current density is 1.2A / cm 2 , The rectangular furnace hearth is built with nitriding silicon carbide plates. The outside of the furnace hearth is insulated masonry. The upper bracket of the tank is welded by angle steel and square steel to support the horizontal conductive bus. The horizontal conductive bus is a bilateral parallel frame. The anode guide rod is clamped on the horizontal conductive bus, and the entire anode group is hung above the electrolytic cell.

[0052] Install the anode in the electrolyzer, and put it in the proportion of CeF 3 : LiF=15:2 electrolyte molten salt, roasting to start the electrolysis cell; the electrolysis cell is operating normally, t...

Embodiment 3

[0056] A high-power graphite block is used as a structural material for the cathode, and a tungsten plate fixed on the upper part of the graphite carbon block is used as the cathode. The cathode current density is 3.8A / cm 2 , The anode is a rectangular graphite block, a total of four anodes are used, and the anode current density is 1.2A / cm 2 , The rectangular furnace hearth is built with nitriding silicon carbide plates. The outside of the furnace hearth is insulated masonry. The upper bracket of the groove is welded by angle steel and square steel. It is used to support the horizontal conductive bus. The horizontal conductive bus is a bilateral parallel frame. The anode guide rod is clamped on the horizontal conductive bus, and the entire anode group is hung above the electrolytic cell.

[0057] Install the anode in the electrolyzer and put it in the proportion of PrF 3 : LiF=10:1.2 electrolyte molten salt, roasting to start the electrolysis cell; the electrolysis cell is runnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com