A single component for fuel cell and its preparation method

A technology of fuel cells and components, applied in the field of polymer electrolyte membrane fuel cells and its preparation, can solve the problems of protracted fuel cell manufacturing process and complex process, improve battery integration and overall efficiency, simplify water management system, The effect of avoiding the decline of ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

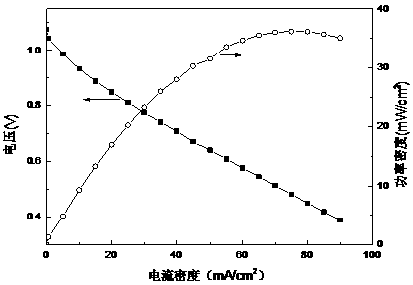

[0033] Example 1:

[0034] 1) Dissolve 1 g of PVA powder in 50 mL of deionized water, heat and stir at 80 degrees Celsius for 2 hours to obtain a PVA gel; add 5 mL of 4% Nafion solution to the PVA gel, heat and stir to obtain PVA-Nafion gel.

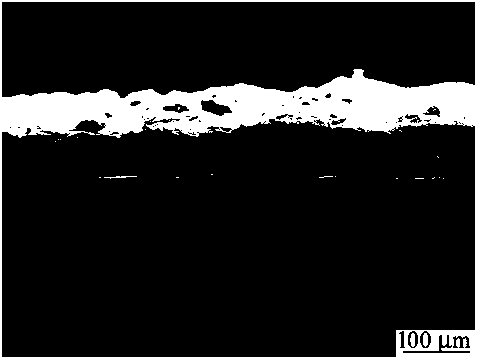

[0035] 2) Part of the PVA-Nafion gel is coated with a film with a thickness of 100 microns on the glass substrate by the film coating method, and dried naturally; the film thickness of the dried PVA-Nafion film is measured to be 80 microns, thereby obtaining PVA- The shrink ratio of Nafion film is 80%.

[0036] 3) The anion conductivity of the anion exchange resin was measured by AC impedance to be 20 mS / cm and the cation conductivity of the PVA-Nafion membrane obtained in step 2) was 30 mS / cm.

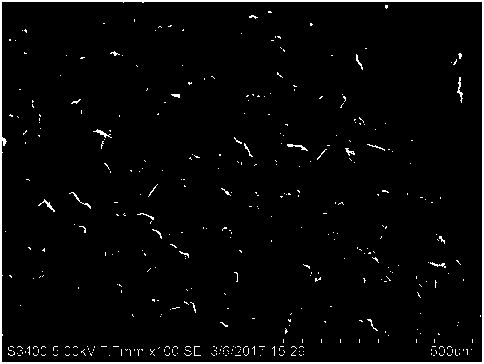

[0037] 4) According to the volume ratio of 30:20, anion exchange resin particles with a particle size of 50 microns were added to the PVA-Nafion gel obtained in step 1), heated and stirred for 1 hour to form a gel.

[0038] 5) Add 5 ml of nic...

Embodiment 2

[0043] The difference from Example 1 is that in step 5), cobalt chloride solution is used instead of nickel chloride solution, and other parameters are the same.

Embodiment 3

[0045] The difference from Example 1 is that ferric chloride solution is used in step 5) instead of nickel chloride solution, and other parameters are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com