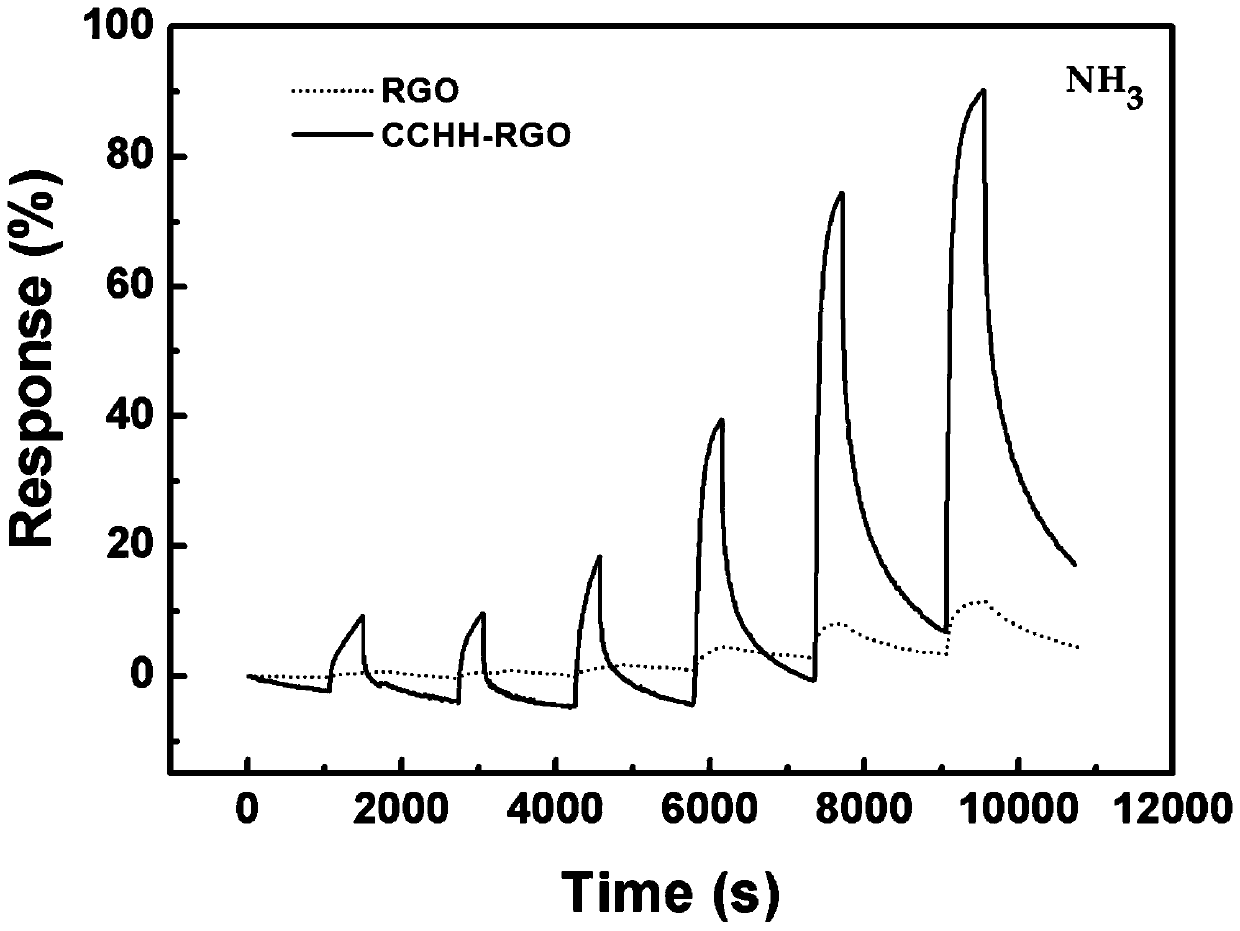

A kind of gas-sensitive film sensor of the compound structure of basic cobalt carbonate and rgo and preparation method thereof

A thin-film sensor and composite structure technology, applied in the field of sensing, can solve the problems of cumbersome preparation process, lack of adsorption sites of RGO, low conductivity of basic cobalt carbonate, etc., to shorten the process, reduce the interference of environmental noise, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the gas-sensitive film sensor of the composite structure of basic cobalt carbonate of the present invention and RGO comprises the steps:

[0030] 1) Preparation of mixed reaction solution

[0031] 1.1) Preparation of graphene oxide dispersion

[0032] Take 1-40 mg of graphene oxide, put it into 30 ml of deionized water and shake it for 10-60 minutes, and then sonicate for 4-24 hours to obtain a uniformly dispersed graphene oxide dispersion.

[0033] 1.2) Preparation of the mixed solution of cobalt chloride hexahydrate and urea

[0034] Weigh 0.5-2.5g of cobalt chloride hexahydrate and 0.5-2.5g of urea, then add them into 30ml of deionized water, ultrasonicate for 3 minutes, and stir continuously for 10 minutes with a magnetic stirrer to make cobalt chloride hexahydrate and urea completely Dissolve in deionized water and mix well.

[0035] 1.3) The mixing process of the graphene oxide dispersion and the mixed solution of cobalt chloride hexah...

Embodiment 1

[0045] The method for preparing the gas-sensitive film sensor of the composite structure of basic cobalt carbonate and RGO of the present embodiment comprises the following steps:

[0046] 1) Preparation of mixed reaction solution

[0047] 1.1) Preparation of graphene oxide dispersion

[0048] Take 20 mg of graphene oxide, put it into 30 ml of deionized water and shake it for 30 minutes, and then sonicate it for 8 hours to obtain a uniformly dispersed graphene oxide dispersion.

[0049] 1.2) Preparation of the mixed solution of cobalt chloride hexahydrate and urea

[0050] Weigh 1g of cobalt chloride hexahydrate and 1g of urea, then add them to 30ml of deionized water, ultrasonicate for 3 minutes, and stir continuously for 10 minutes with a magnetic stirrer, so that cobalt chloride hexahydrate and urea are completely dissolved in deionized water and mixed uniform.

[0051] 1.3) The mixing process of the graphene oxide dispersion and the mixed solution of cobalt chloride hex...

Embodiment 2

[0066] The method for preparing the gas-sensitive film sensor of the composite structure of basic cobalt carbonate and RGO of the present embodiment comprises the following steps:

[0067] 1) Preparation of mixed reaction solution

[0068] 1.1) Preparation of graphene oxide dispersion

[0069] Take 1 mg of graphene oxide, put it into 30 ml of deionized water and shake it for 10 minutes, and then sonicate it for 4 hours to obtain a uniformly dispersed graphene oxide dispersion.

[0070] 1.2) Preparation of the mixed solution of cobalt chloride hexahydrate and urea

[0071] Weigh 0.5g of cobalt chloride hexahydrate and 0.5g of urea, then add them into 30ml of deionized water, ultrasonicate for 3 minutes, and stir continuously for 10 minutes with a magnetic stirrer, so that cobalt chloride hexahydrate and urea are completely dissolved in deionized water and mix completely.

[0072] 1.3) The mixing process of the graphene oxide dispersion and the mixed solution of cobalt chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com