A kind of preparation method of nitrogen-doped porous carbon material

A nitrogen-doped porous carbon and reaction technology, which is applied in the preparation/purification of carbon, etc., can solve the problems of high cost, the template method is not suitable for large-scale production, and the nitrogen atom doping process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh 0.8524g of copper chloride dihydrate, place it in a 50mL polytetrafluoroethylene-lined autoclave, add 25mL of ethanol, mix well, and cover the kettle tightly.

[0026] (2) Put the autoclave in a muffle furnace and react at 160°C for 24h. Cool to room temperature, filter under reduced pressure, and dry the product in vacuum at 50°C for 12 hours. Store in a dark place under a nitrogen protection atmosphere to obtain cuprous chloride nanocrystals with a diameter of 2-10 nm.

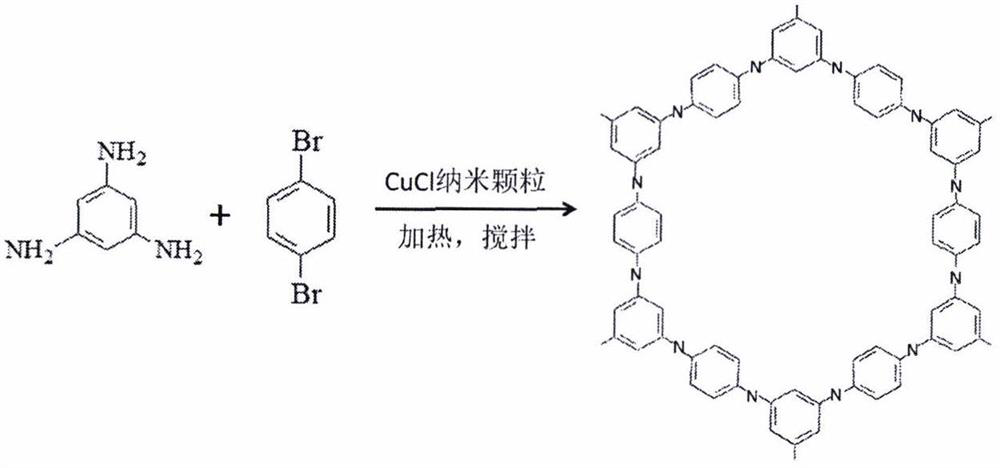

[0027] (3) 0.025g of cuprous chloride crystal powder, 0.246g of 1,4-dibromobenzene and 0.123g of 1,3,5-triaminobenzene were dissolved in 5.0mL of acetonitrile, nitrogen was added to form a protective atmosphere, and the temperature Maintained at 80°C, refluxed for 12h.

[0028] (4) The reaction mixture was taken out, washed with 25% ammonia water, water and acetone respectively, and dried and stored.

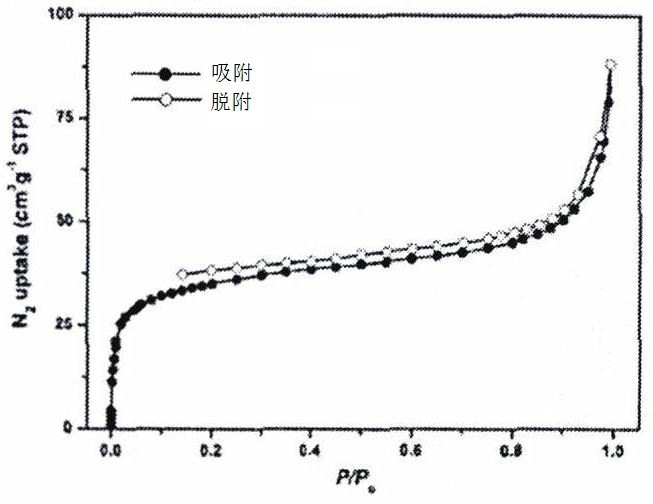

[0029] figure 1 A schematic diagram of the preparation of a covalent organic framework...

Embodiment 2

[0033] (1) Weigh 0.8524g of copper chloride dihydrate, place it in a 50mL polytetrafluoroethylene-lined autoclave, add 25mL of ethanol, mix well, and cover the kettle tightly.

[0034] (2) Put the autoclave in a muffle furnace and react at 160°C for 24h. Cool to room temperature, filter under reduced pressure, and dry the product in vacuum at 50°C for 12 hours. Store in a dark place under a nitrogen protection atmosphere to obtain cuprous chloride nanocrystals with a diameter of 2-10 nm.

[0035] (3) 0.025g of cuprous chloride crystal powder, 0.246g of 1,4-dibromobenzene and 0.123g of 1,3,5-triaminobenzene were dissolved in 5.0mL of acetonitrile, nitrogen was added to form a protective atmosphere, and the temperature Maintained at 120°C, refluxed for 10h.

[0036] (4) The reaction mixture was taken out, washed with 25% ammonia water, water and acetone respectively, and dried and stored.

Embodiment 3

[0038] (1) Weigh 0.8524g of copper chloride dihydrate, place it in a 50mL polytetrafluoroethylene-lined autoclave, add 25mL of ethanol, mix well, and cover the kettle tightly.

[0039] (2) Put the autoclave in a muffle furnace and react at 160°C for 24h. Cool to room temperature, filter under reduced pressure, and dry the product in vacuum at 50°C for 12 hours. Store in a dark place under a nitrogen protection atmosphere to obtain cuprous chloride nanocrystals with a diameter of 2-10 nm.

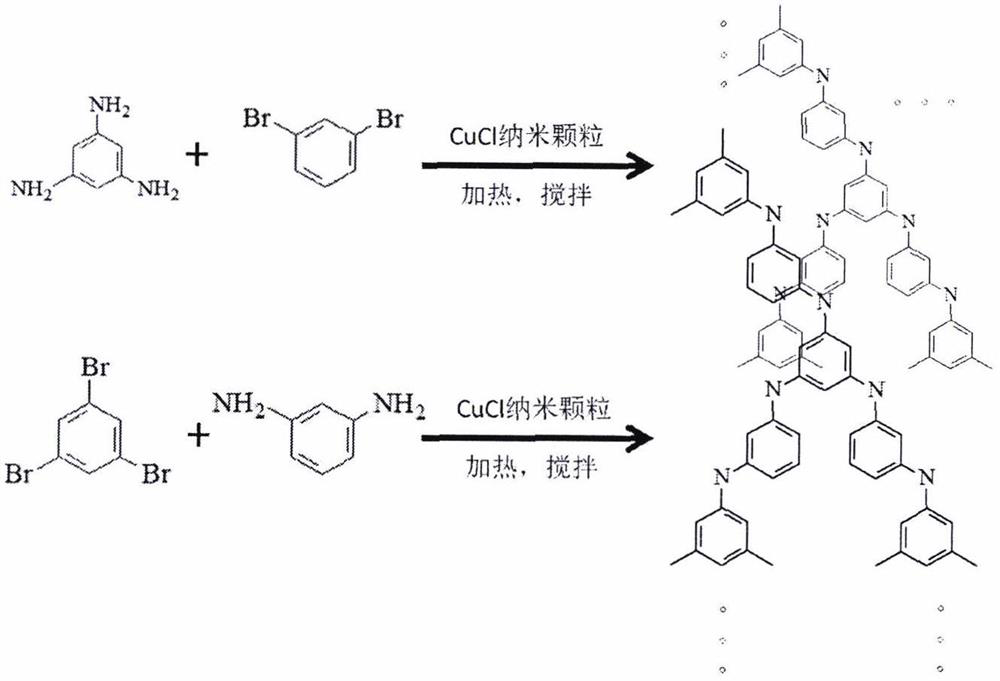

[0040] (3) 0.025g of cuprous chloride crystal powder, 0.236g of 1,4-dibromobenzene and 0.249g of 2,4,6-triethylbenzene-1,3,5-trimethylamine were dissolved in 5.0mL of acetonitrile , nitrogen was added to form a protective atmosphere, the temperature was maintained at 120 ° C, and reflux was performed for 10 h.

[0041] (4) The reaction mixture was taken out, washed with 25% ammonia water, water and acetone respectively, and dried and stored.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com