Self-driven quasi-single-phase flow vacuum drainage system

A technology of vacuum drainage and single-phase flow, which is applied to waterway systems, sewage discharge, water supply devices, etc., can solve the problems of low practicability and low reliability, achieve simple construction, reduce energy consumption and later operation and maintenance costs, and improve The effect of the emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

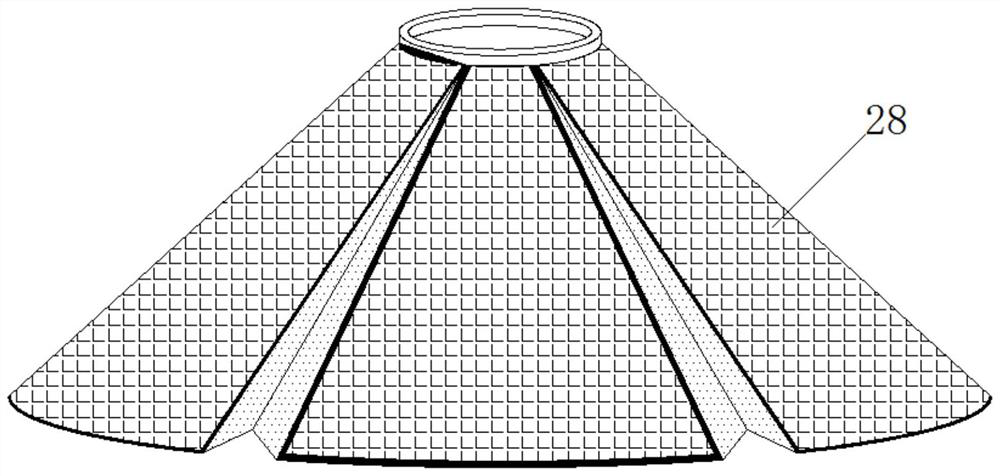

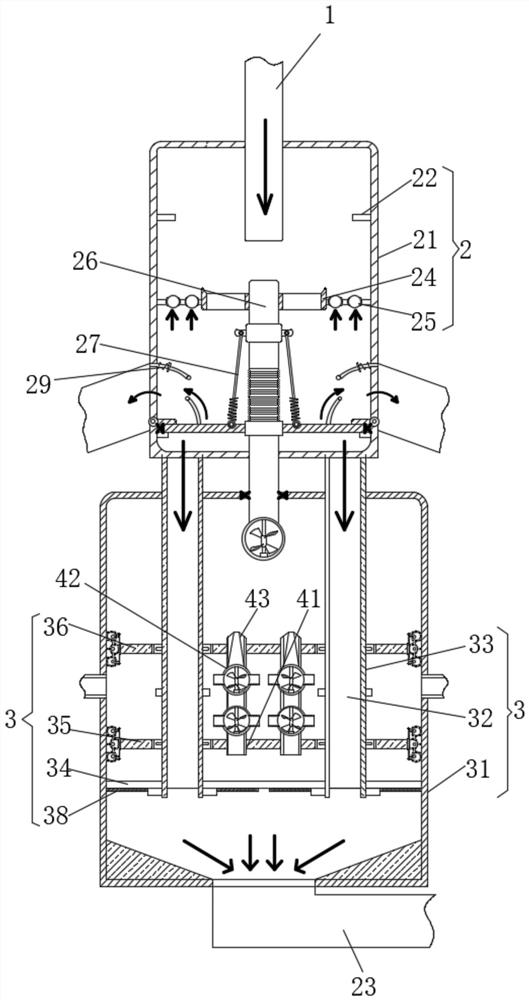

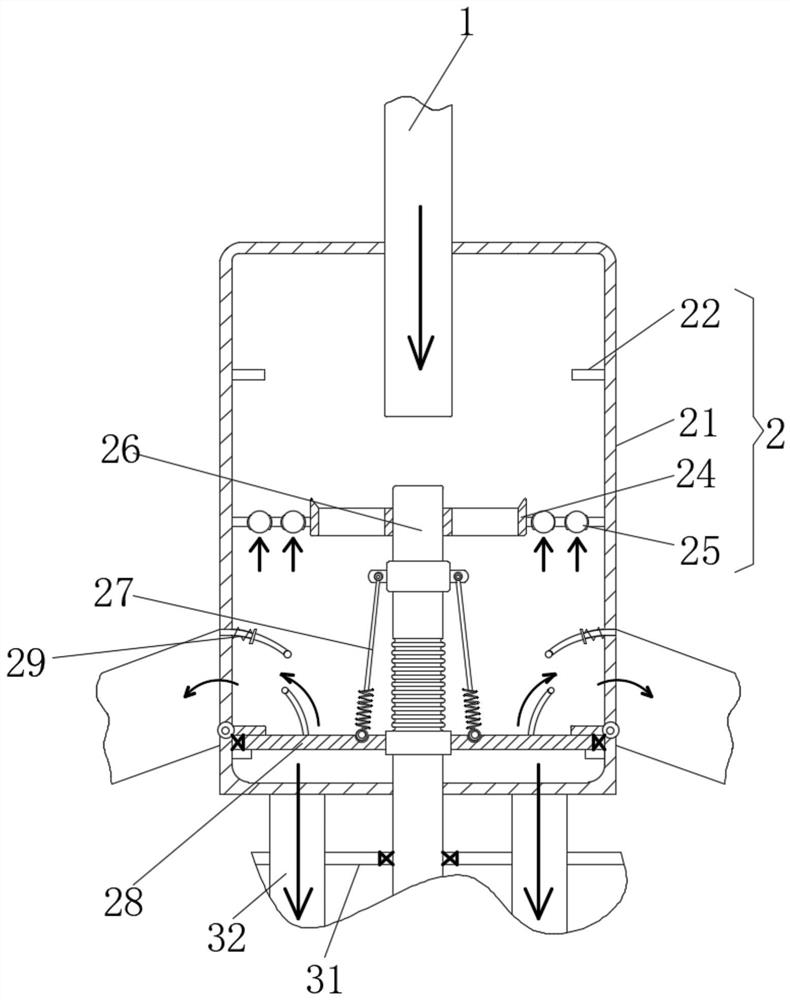

[0028] see Figure 1-5 , a self-driven quasi-single-phase flow vacuum drainage system, including a grading mechanism 3, the grading mechanism 3 includes a water storage tank 31, the inside of the water storage tank 31 is fixedly connected with a connecting pipe-32, and the outside of the connecting pipe-32 is sleeved with Threaded pipe 33, the bottom of threaded pipe 33 is rotatably connected with drive plate 34, the middle part of threaded pipe 33 is threaded with first threaded plate 35, the upper side of threaded pipe 33 is threaded with second threaded plate 36, the second thread Both sides of the plate 36 are connected with elastic blocks 37 in rotation, and the bottom surface of the drive plate 34 is slidingly connected with a cleaning hair roller 38. Therefore, by cleaning the hair roller 38, attachments are avoided, and the middle part of the threaded pipe 33 is fixedly connected with the flange. The threaded pipe 33 is provided with two sections of thread, and the pit...

Embodiment 2

[0030] see Figure 1-5 , a self-driven quasi-single-phase flow vacuum drainage system, including a grading mechanism 3, the grading mechanism 3 includes a water storage tank 31, the inside of the water storage tank 31 is fixedly connected with a connecting pipe-32, and the outside of the connecting pipe-32 is sleeved with Threaded pipe 33, the bottom of threaded pipe 33 is rotatably connected with drive plate 34, the middle part of threaded pipe 33 is threaded with first threaded plate 35, the upper side of threaded pipe 33 is threaded with second threaded plate 36, the second thread Both sides of the plate 36 are connected with elastic blocks 37 in rotation, and the bottom surface of the flow-dispelling plate 34 is slidably connected with a cleaning hair roller 38. Therefore, by cleaning the hair roller 38, attachment of attachments is avoided, and a collection mechanism 2 is also included. The collection mechanism 2 includes There is a water collection box 21, the inner wall...

Embodiment 3

[0032] see Figure 1-5, a self-driven quasi-single-phase flow vacuum drainage system, including a grading mechanism 3, the grading mechanism 3 includes a water storage tank 31, the inside of the water storage tank 31 is fixedly connected with a connecting pipe-32, and the outside of the connecting pipe-32 is sleeved with Threaded pipe 33, the bottom of threaded pipe 33 is rotatably connected with drive plate 34, the middle part of threaded pipe 33 is threaded with first threaded plate 35, the upper side of threaded pipe 33 is threaded with second threaded plate 36, the second thread Both sides of the plate 36 are connected with elastic blocks 37 in rotation, and the bottom surface of the drive plate 34 is slidingly connected with a cleaning hair roller 38. Therefore, by cleaning the hair roller 38, attachments are avoided, and the middle part of the threaded pipe 33 is fixedly connected with the flange. The threaded pipe 33 is provided with two sections of thread, and the pitc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com