Silicon nitride films and methods

a technology of silicon nitride and film, applied in the direction of coating, metallic material coating process, chemical vapor deposition coating, etc., can solve the problems of unwanted carbon content in the film, occurrence and/or buildup of amine salts in the reaction chamber, and aforementioned finer feature is jeopardized, so as to reduce the carbon content of the film and reduce the effect of carbon conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0117]Table 1 includes a number of reaction partners, and temperature and pressure parameters that may be used to make SiN films in accordance with the embodiments described herein.

TABLE 1Reactant AReactant BReactant CTemp(° C.)Press. (torr)Ref. indexBTBASNH3—50-5501-41.80-2.05BTBAS—N2 / H250-5501-41.80-2.05BTBASNH3N2 / H250-5501-41.80-2.05SiH3ClNH3Optionally50-5501-4N2 / H2SiH3ClTBAOptionallyN2 / H2SiH2Cl2NH3Optionally50-5501-41.80-2.05N2 / H2SiH2Cl2TBAOptionallyN2 / H2SiH(CH3)—(N(CH3)2)2NH3Optionally50-5501-41.80-2.05N2 / H2SiH(CH3)(Cl2)NH3Optionally50-5501-41.80-2.05N2 / H2SiHCl—(N(CH3)2)2NH3Optionally50-5501-41.80-2.05N2 / H2(Si(CH3)2NH)3NH3Optionally50-5501-41.80-2.05N2 / H2

example 2

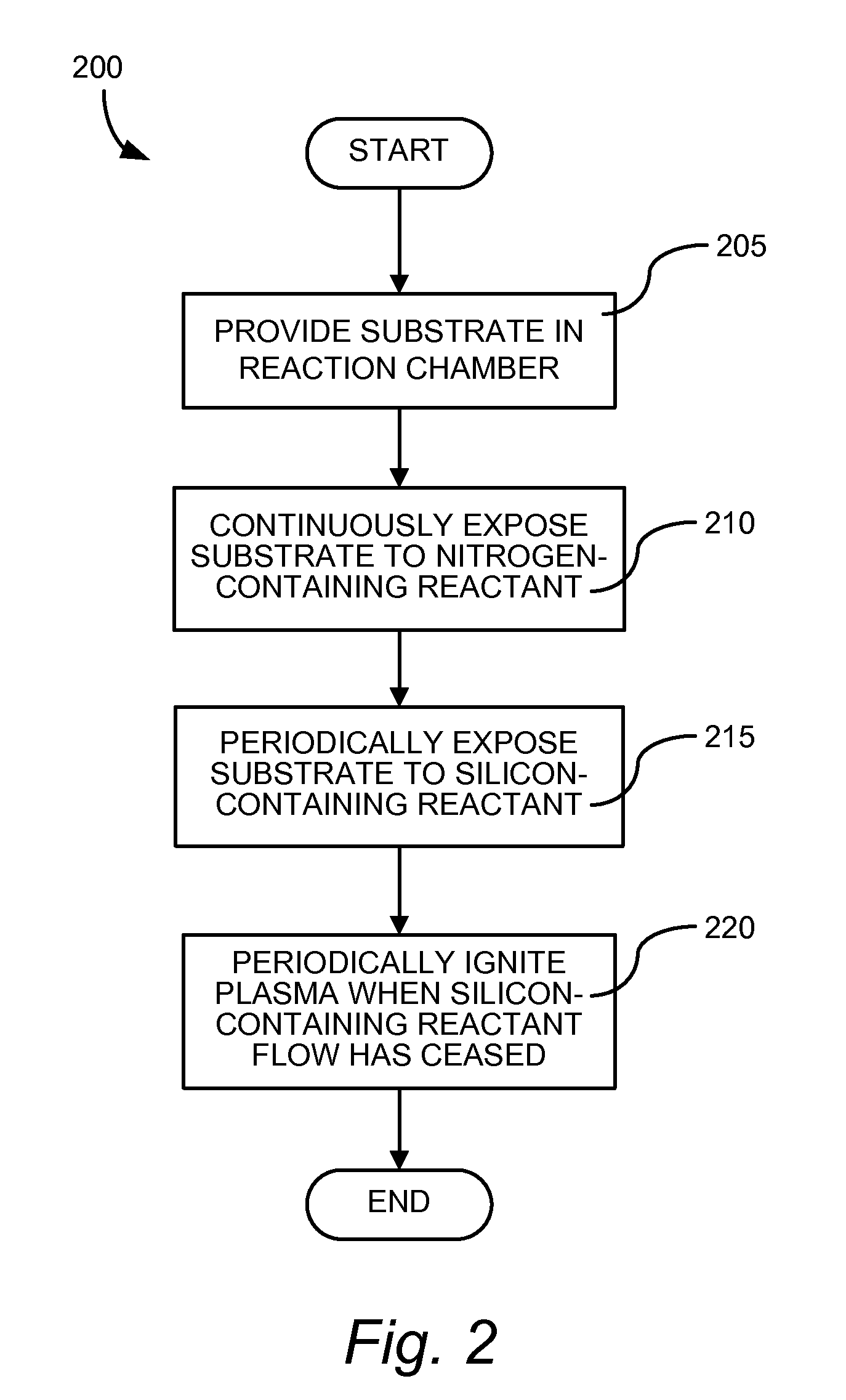

[0118]A 300 mm wafer is placed into vacuum chamber and the chamber evacuated to 0.5 torr. The wafer is supported within the chamber on an aluminum pedestal which is heated throughout the procedure. For example, the pedestal is heated at a constant temperature that is between about 50° C. and about 550° C. The pressure in the chamber is increased to 2 torr using an inert gas such as argon or nitrogen. Dichlorosilane (DCS) is introduced into the reactor as a vapor phase flow at between about 1 slm and about 5 slm (standard liters per minute) for between about 1 second and about 30 seconds in order to adsorb DCS onto the surface of the wafer. After the DCS flow is ceased, the inert gas flow in the reactor purges the remaining vapor phase DCS and any byproducts. Then, a t-butylamine (TBA) vapor phase flow is established in the reactor at between about 1 slm and about 5 slm for between about 1 second and about 30 seconds. A plasma, for example 13.56 MHz at 2.5 kW power, is ignited above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com