Patents

Literature

30results about How to "Easy flow adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

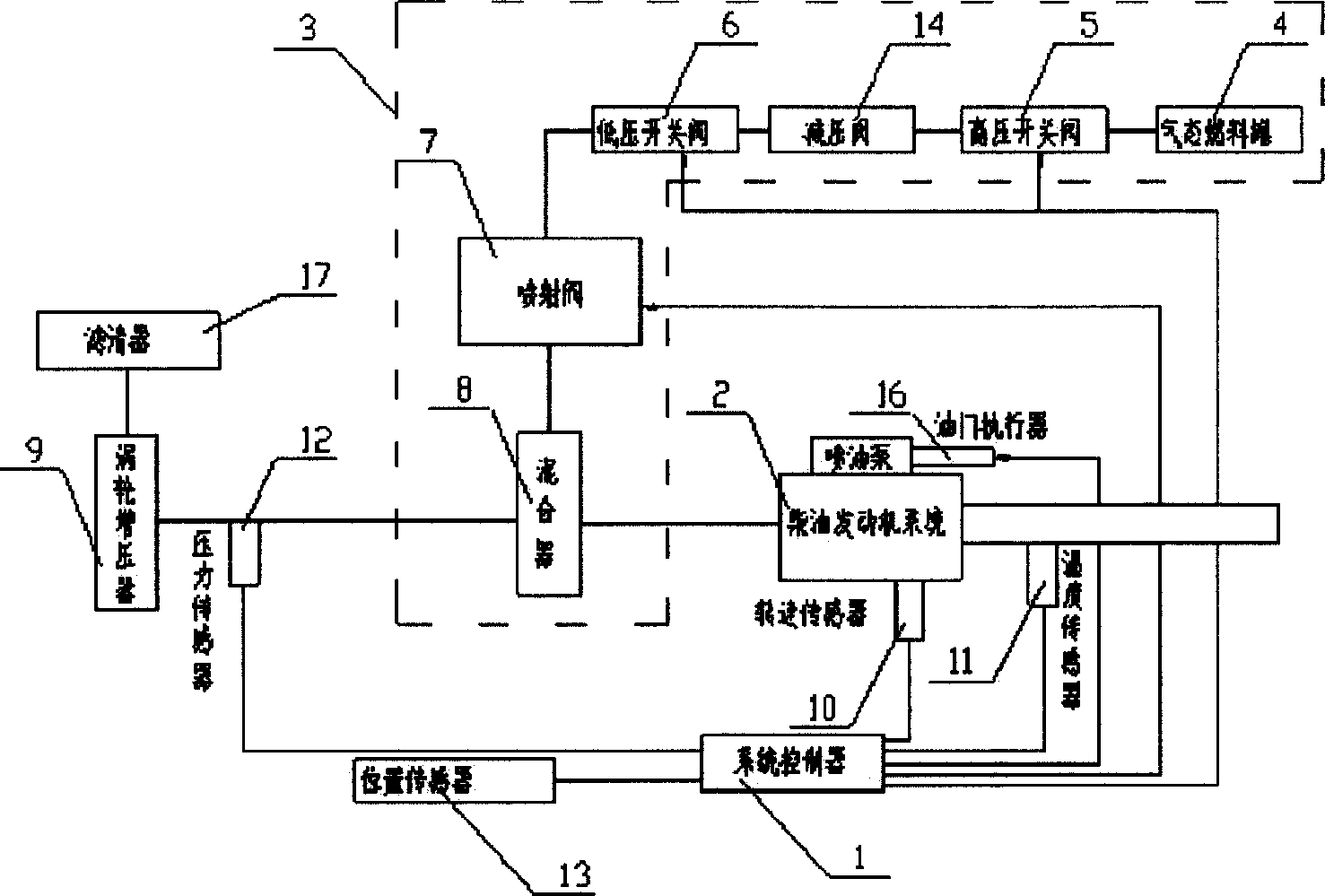

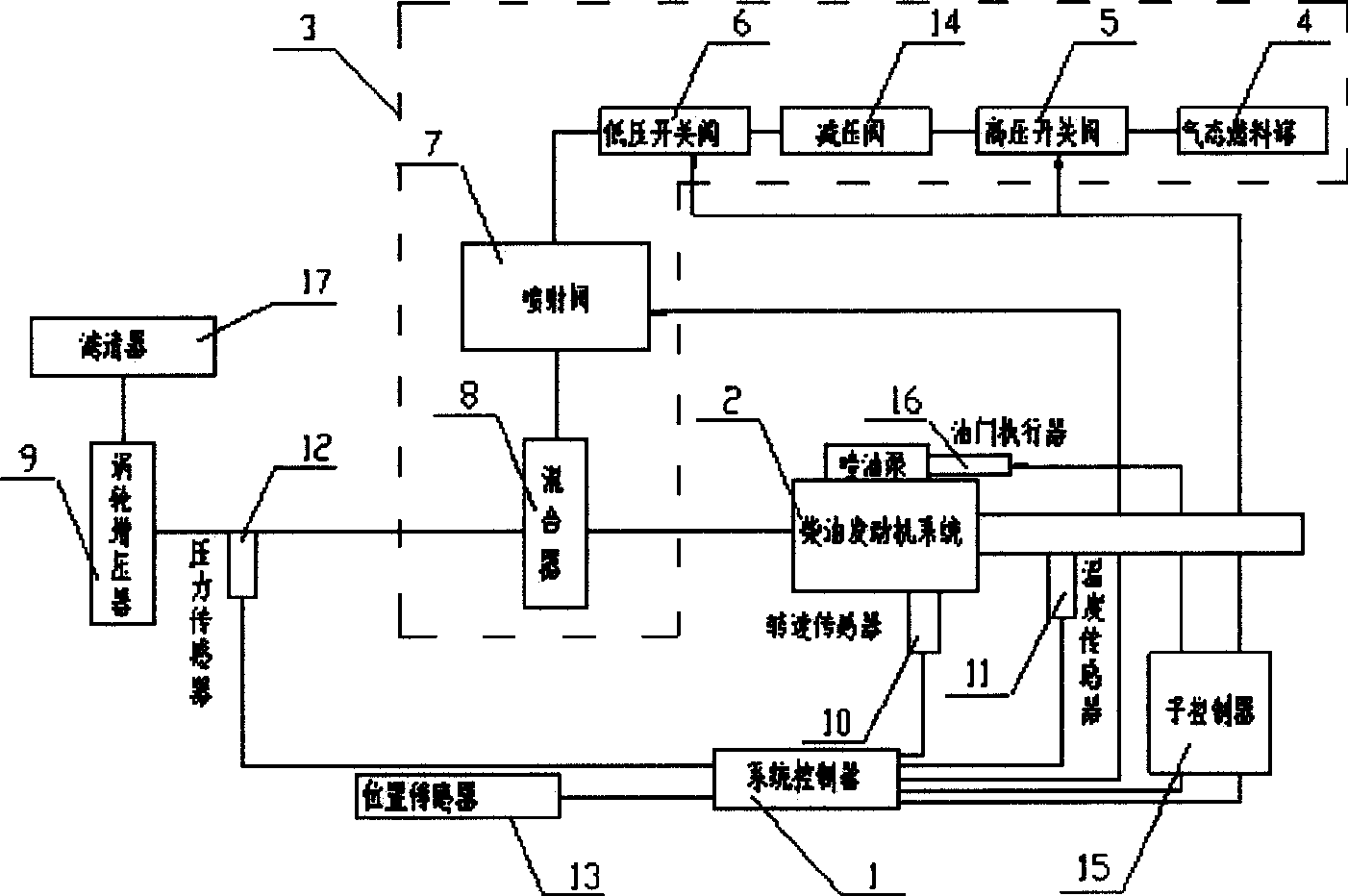

Electronic fuel oil jetting controller and controlling method for double fuel engine

InactiveCN1740542AFast flow adjustmentEasy flow adjustmentElectrical controlCombustion enginesFuel oilSystem controller

The present invention discloses one kind of electronic fuel oil jetting controller and controlling method for double fuel engine. The double fuel engine includes diesel engine system and gas fuel supply system, and system controller with engine throttle valve position signal as reference for determining the load of the engine. The present invention determines the gas fuel jetting amount and diesel oil inputting amount based on the parameters of engine rotation speed, admission pressure and exhaust temperature, and the gas fuel is fed to the mixer via the 1-12 jetting valves successively opened to mix with air before being jetted to the engine and ignited with the diesel oil the diesel oil engine inputs. The present invention has the advantages of high control precision, easy flow control, simple structure, low manufacture cost, etc.

Owner:广州多威服饰有限公司

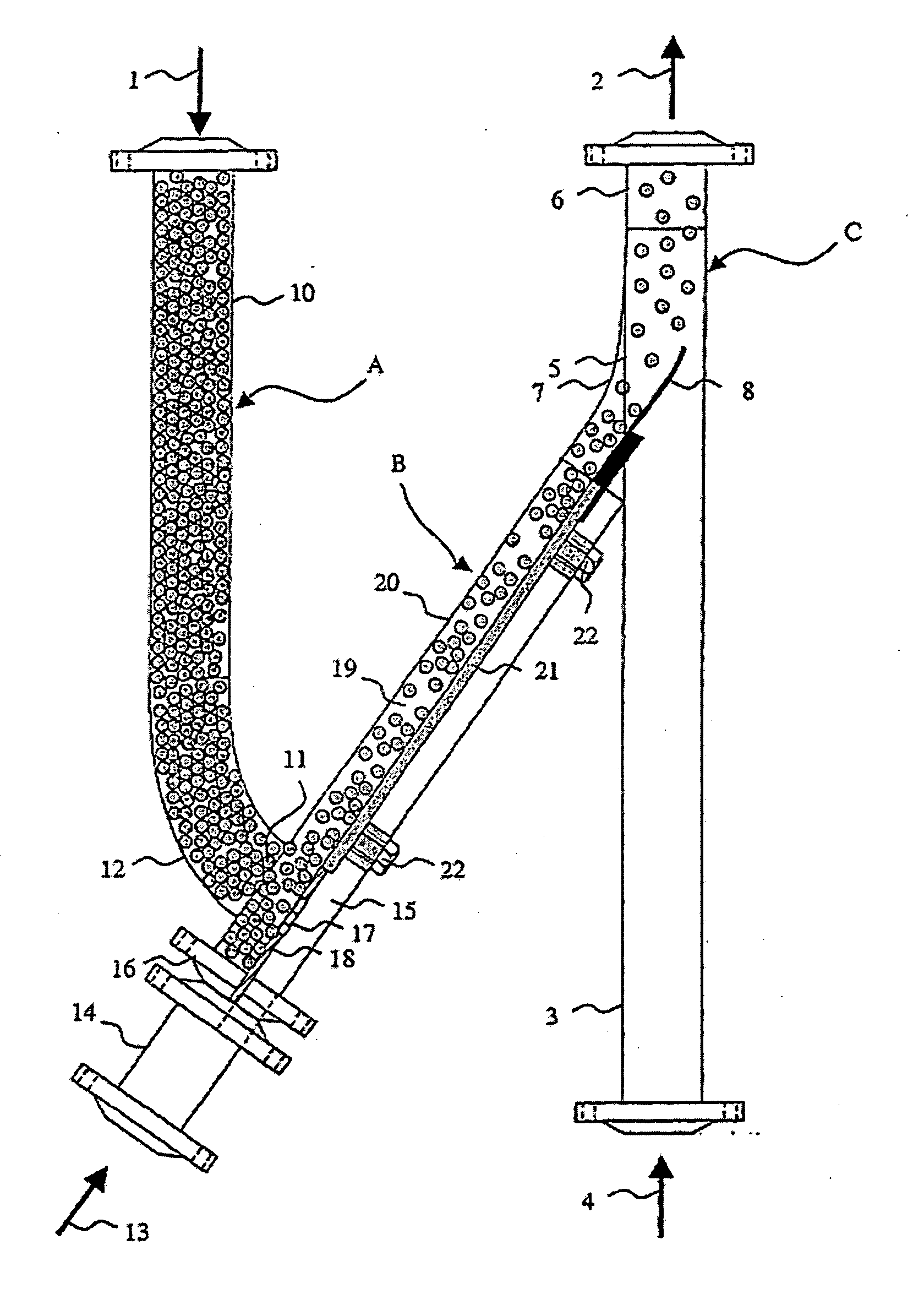

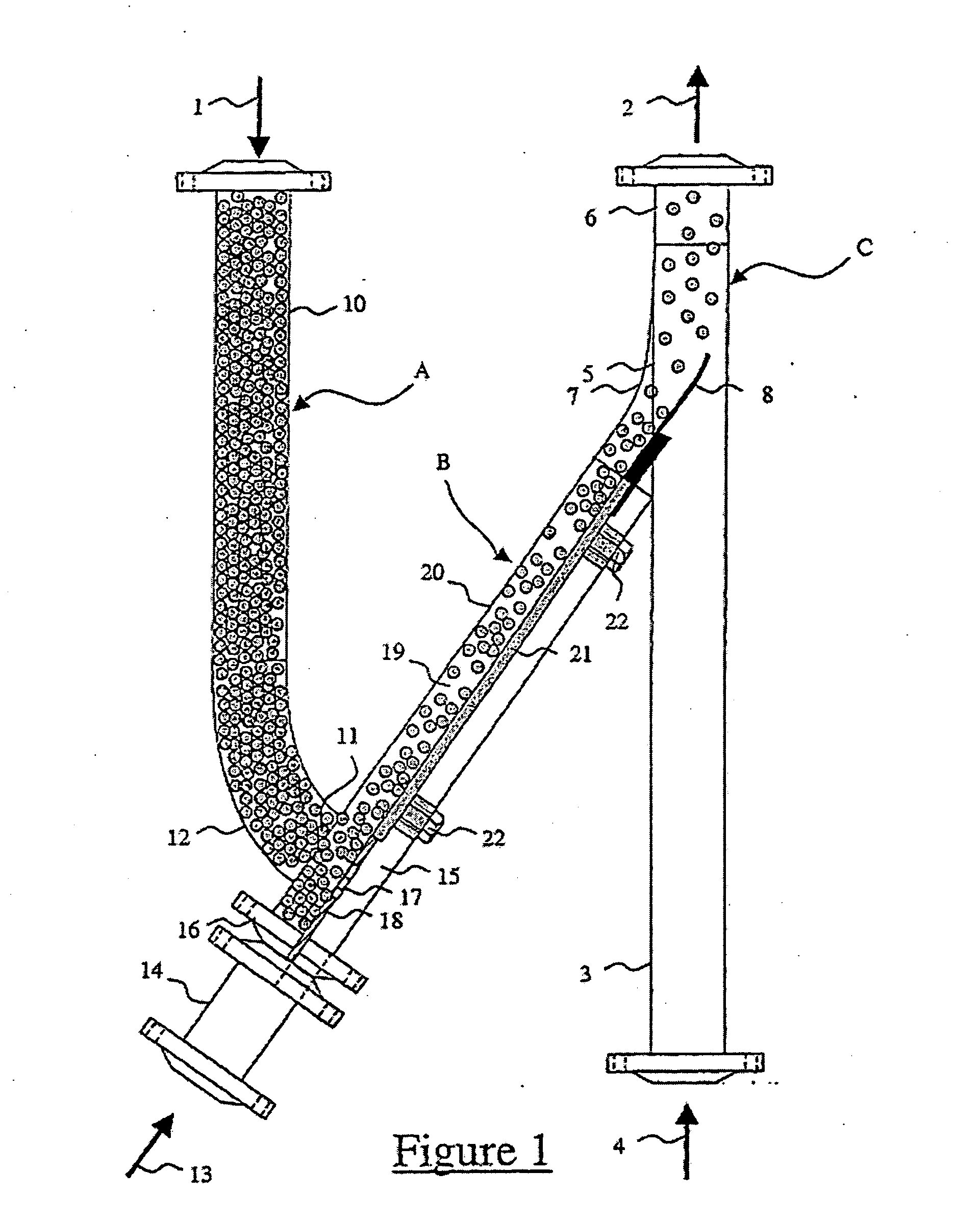

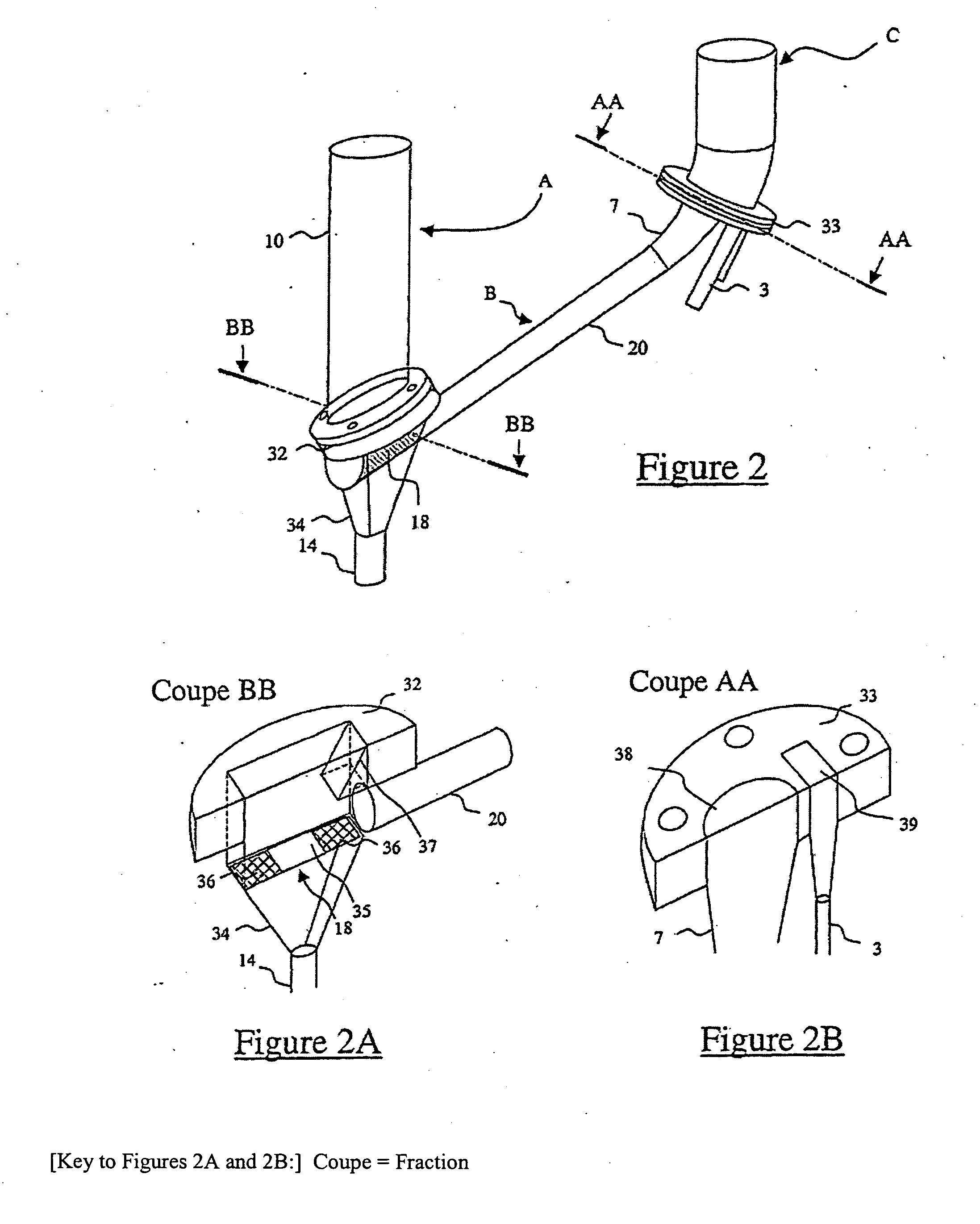

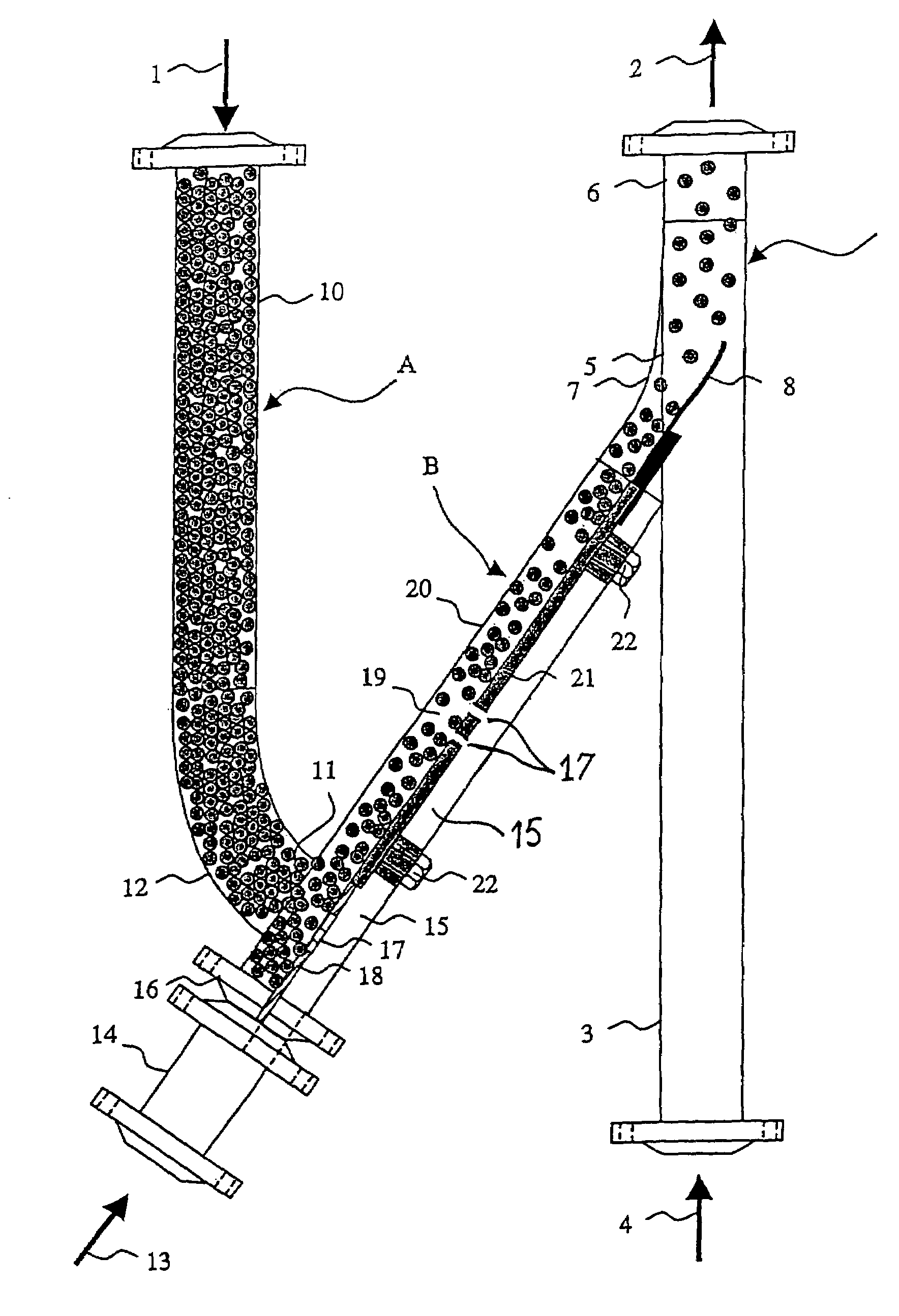

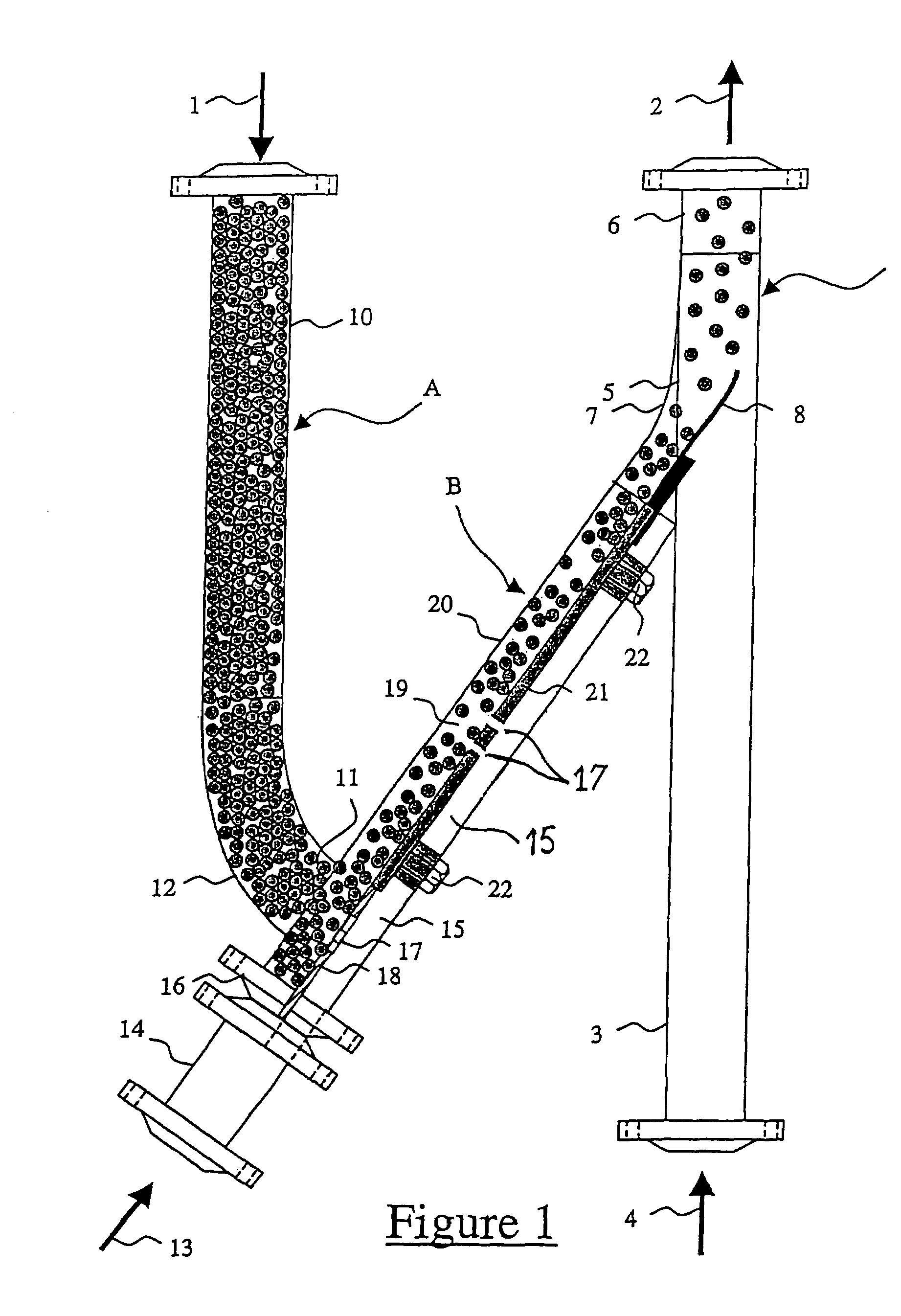

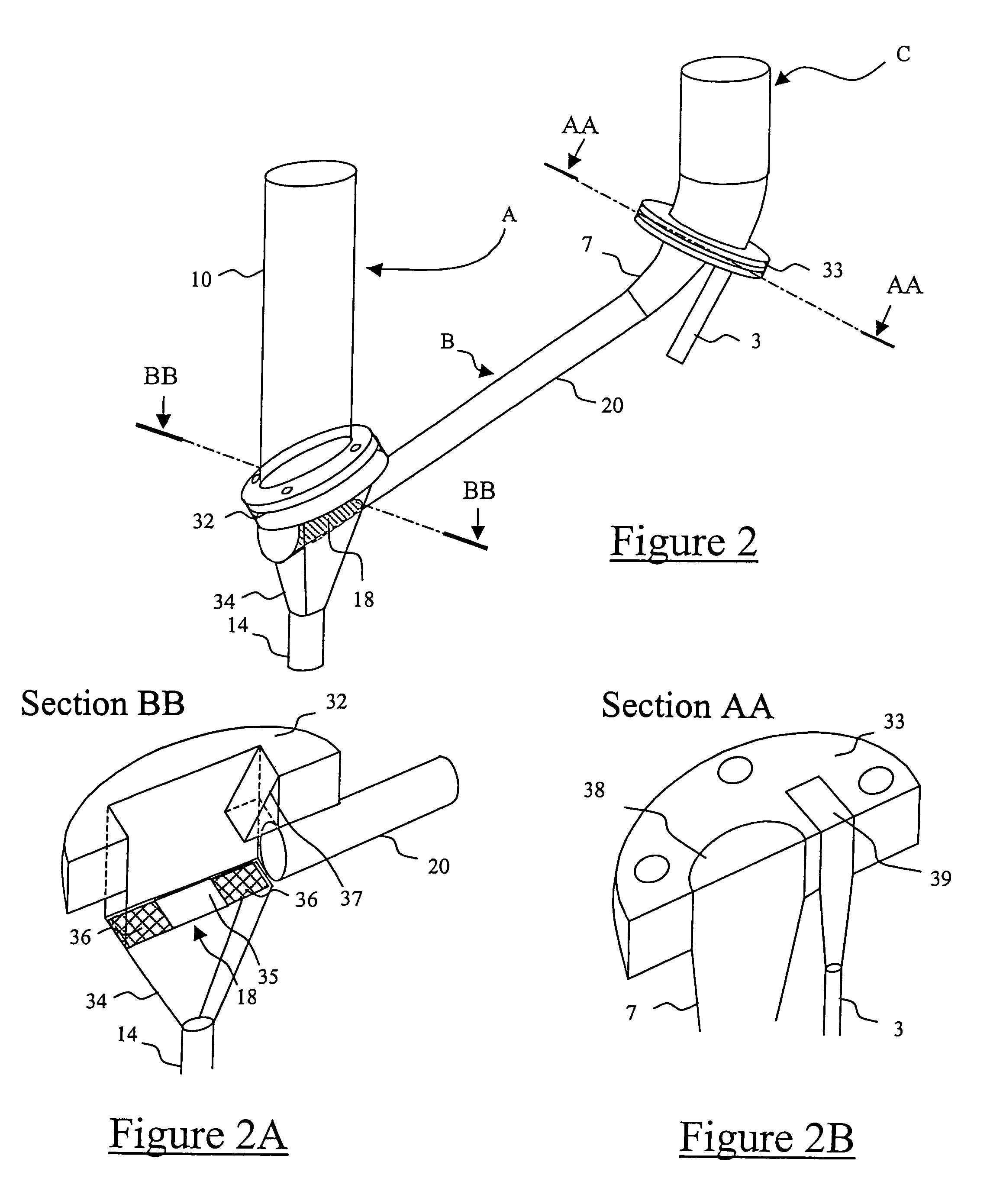

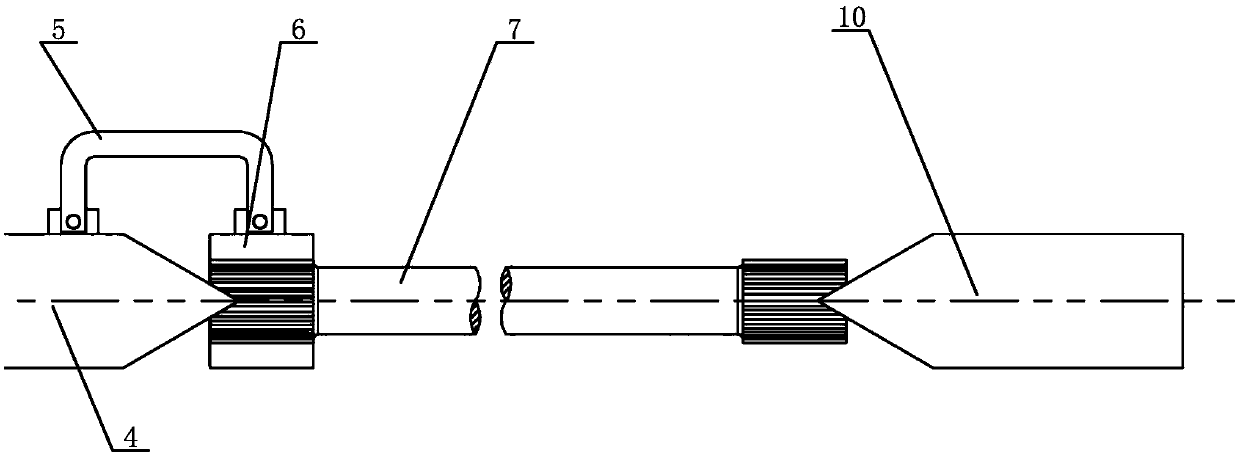

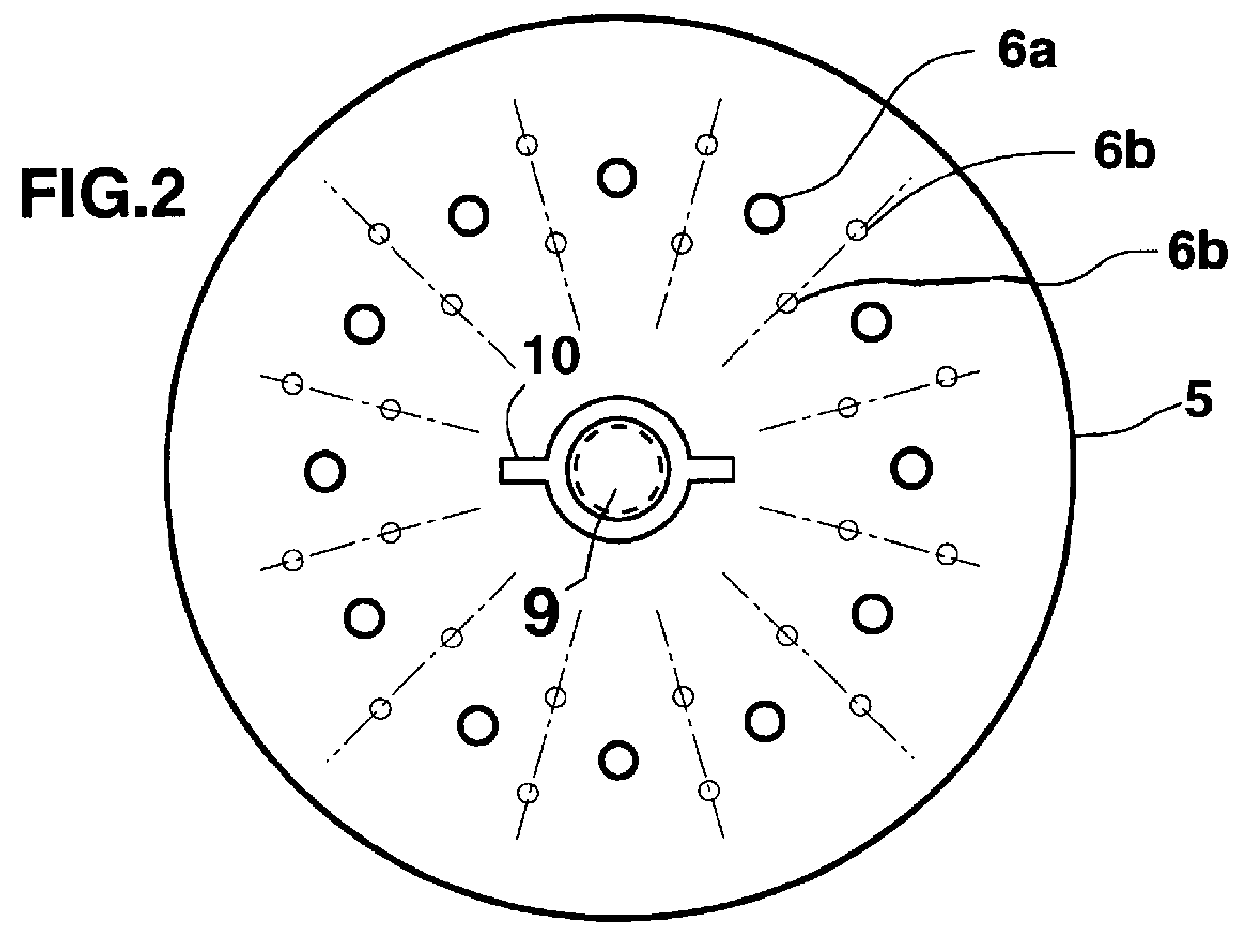

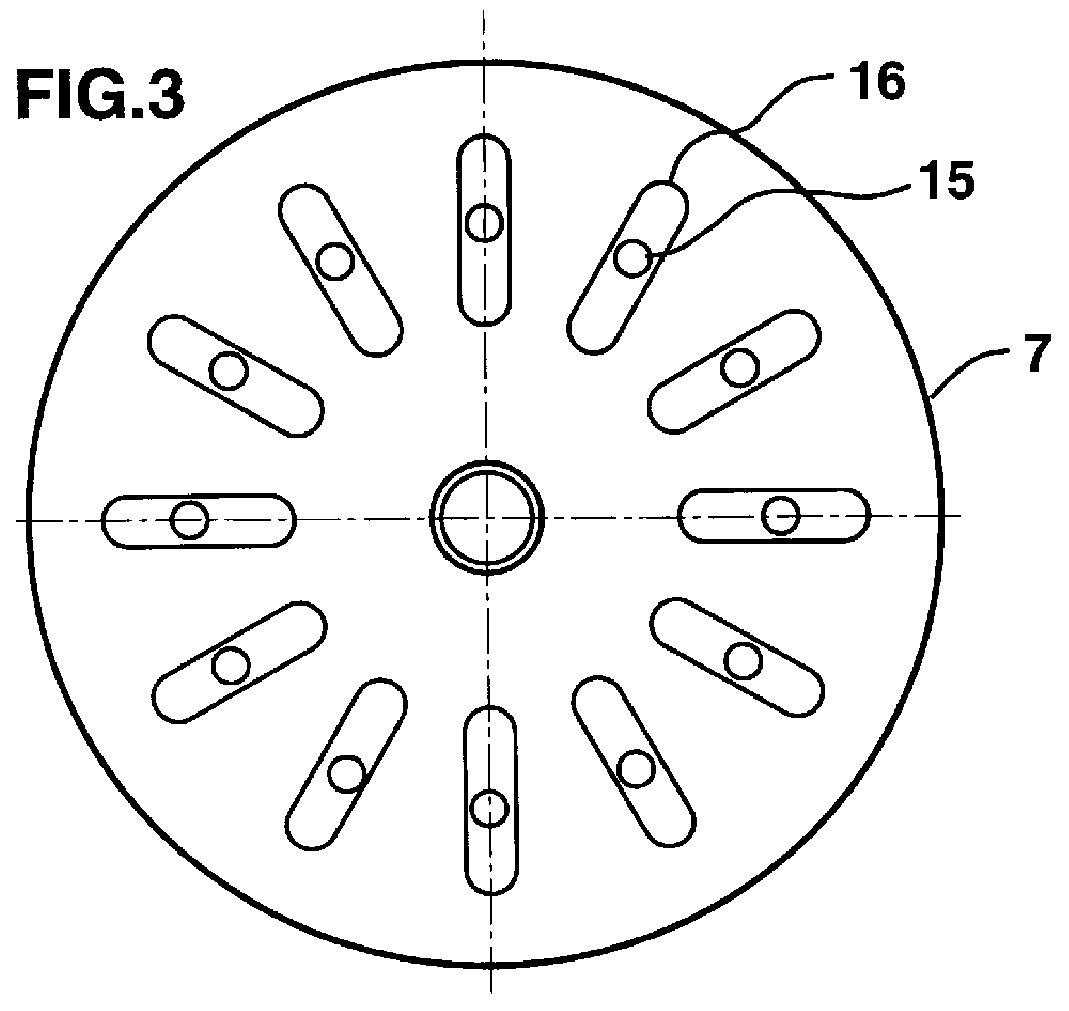

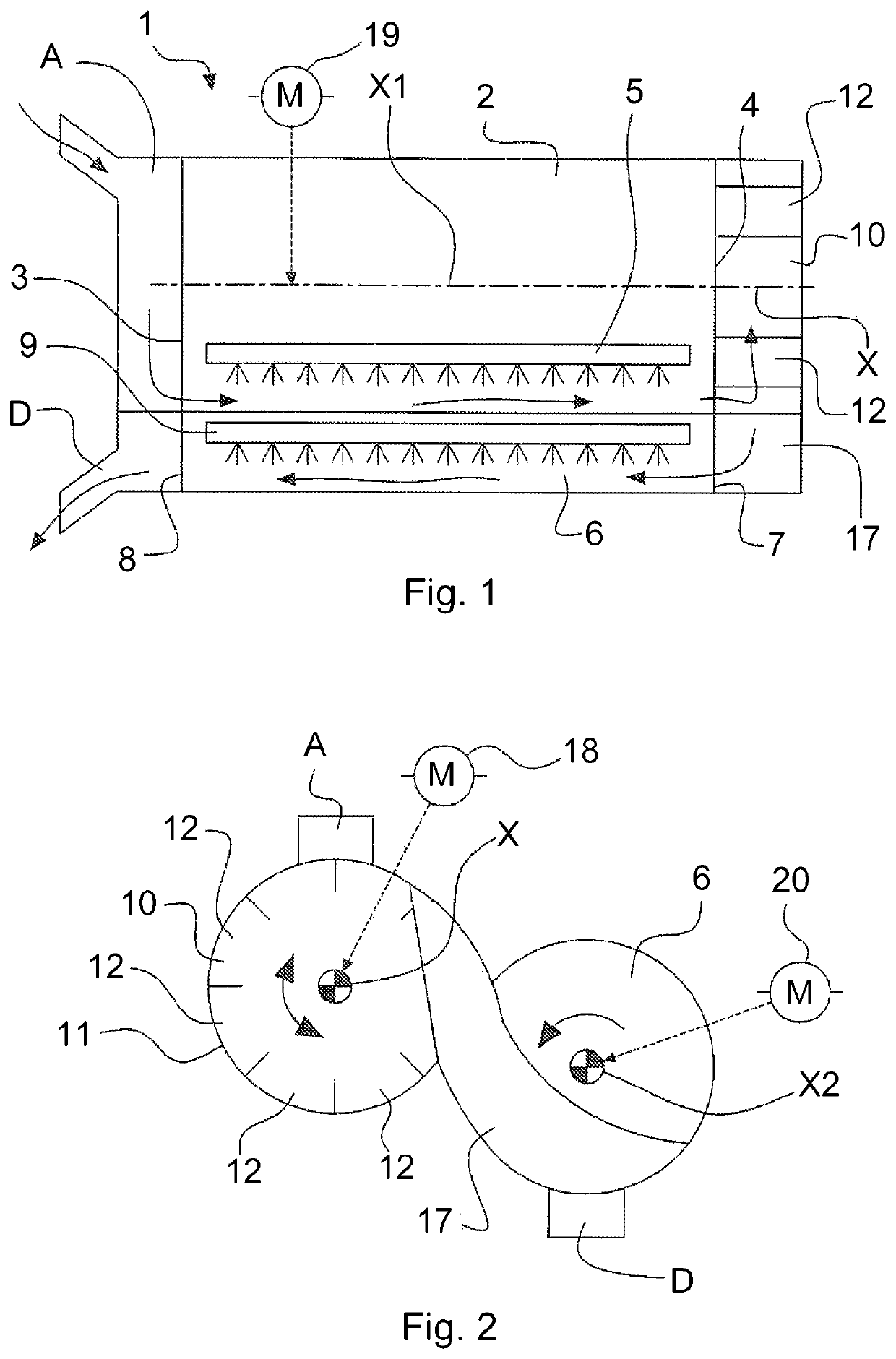

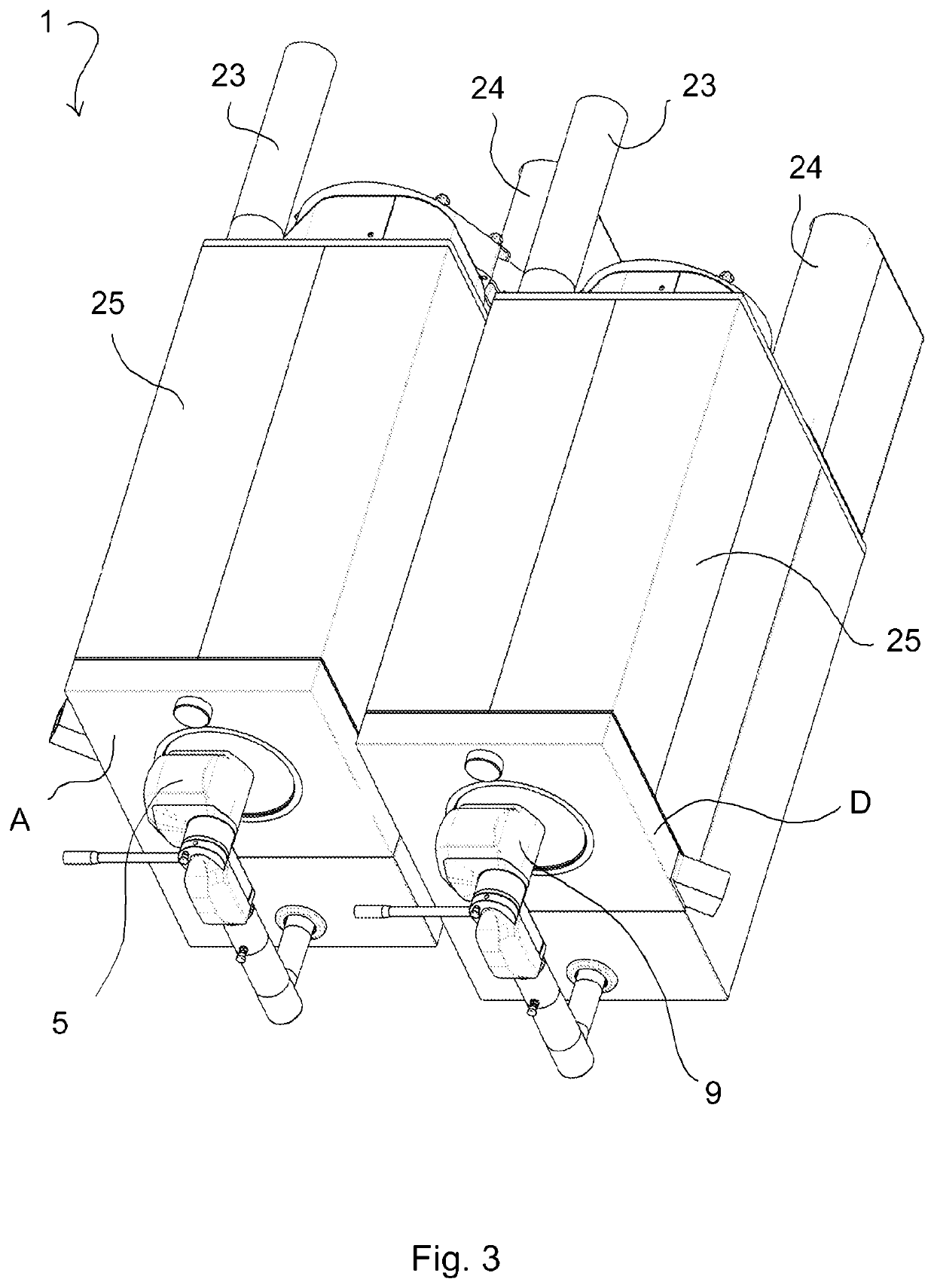

Device for the transport of granular solid particles with a controlled flow rate

ActiveUS20050058516A1Easy flow adjustmentReduce sensitivityVolume/mass flow measurementBulk conveyorsPtru catalystEngineering

Process and device for the transport of granular solids with a controlled flow rate, in particular for the transport of catalyst in a hydrocarbon reforming unit. The device comprises a gravity-feed pipe (A) for solid particles in the dense phase, a pneumatic transport pipe (C) in the dilute phase, and an inclined transfer pipe (B) that connects, without a buffer space, the base of the feed pipe to the pneumatic transport pipe, whereby this transfer pipe comprises means (17, 18, 35) for injection of a secondary gas located at the junction between the feed pipe and the transfer pipe.

Owner:INST FR DU PETROLE

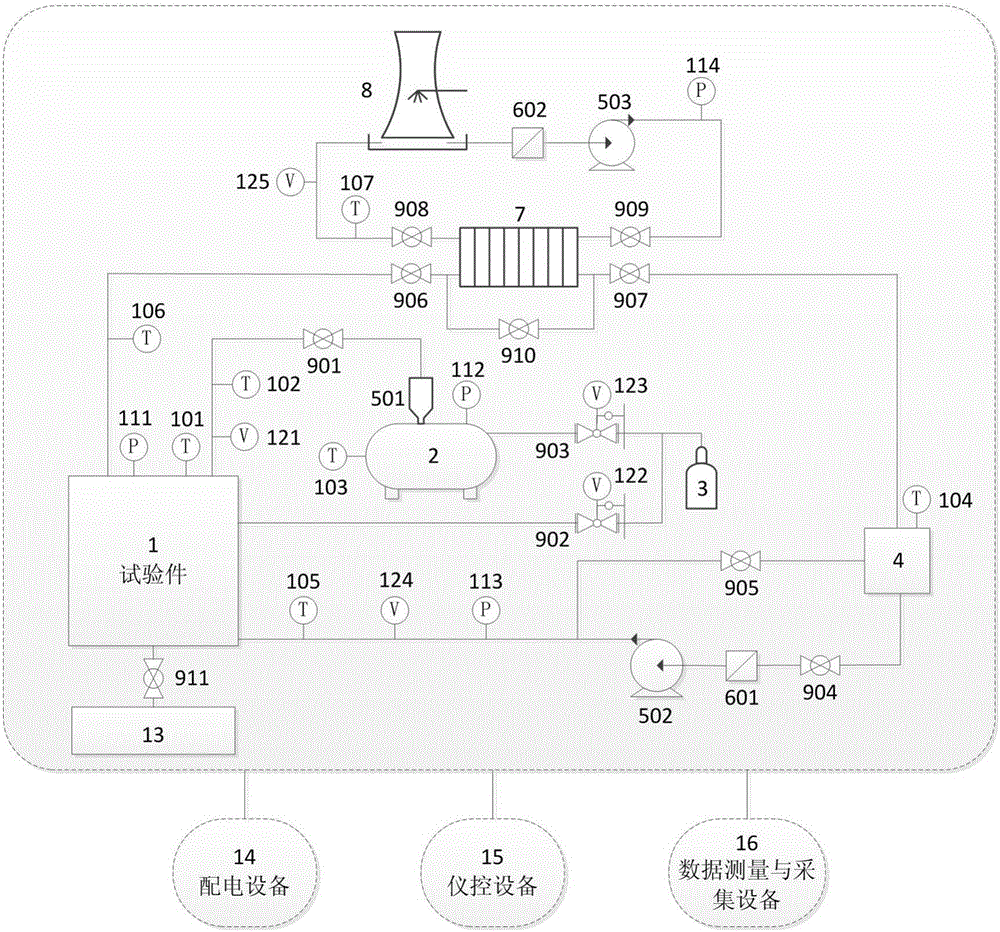

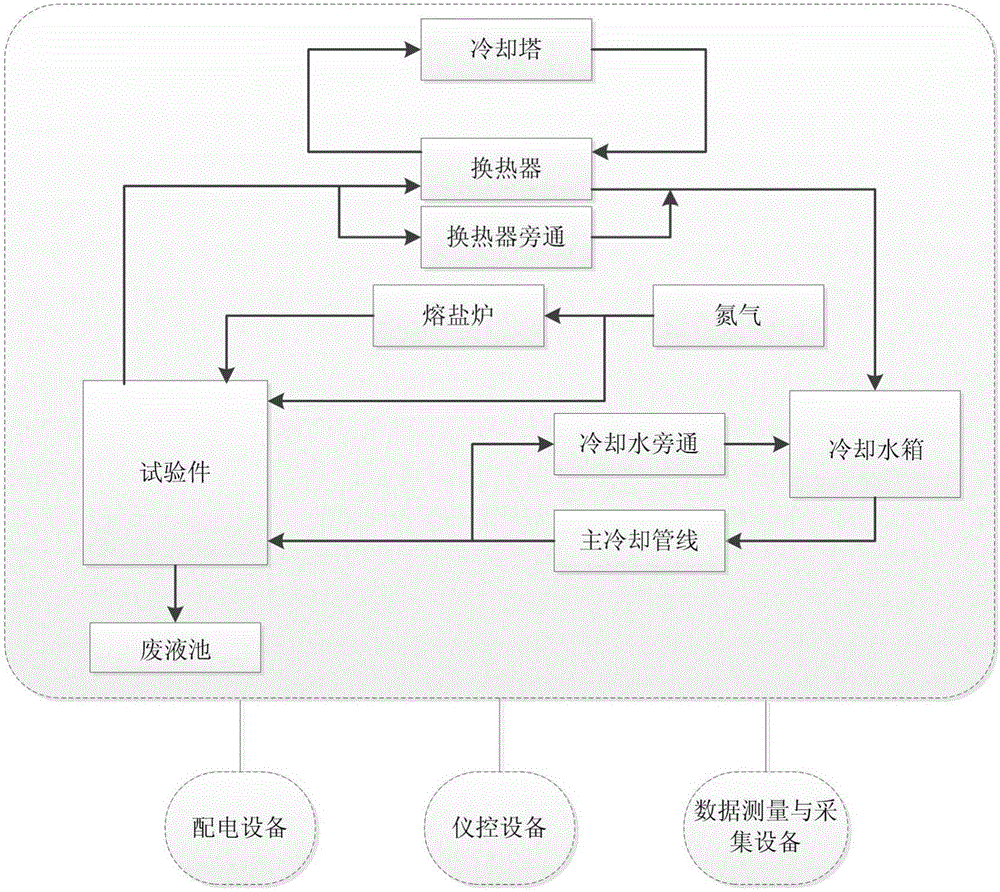

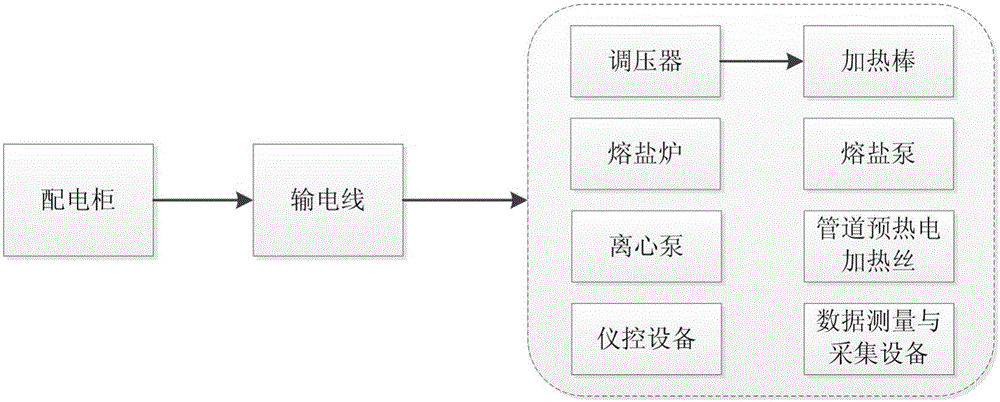

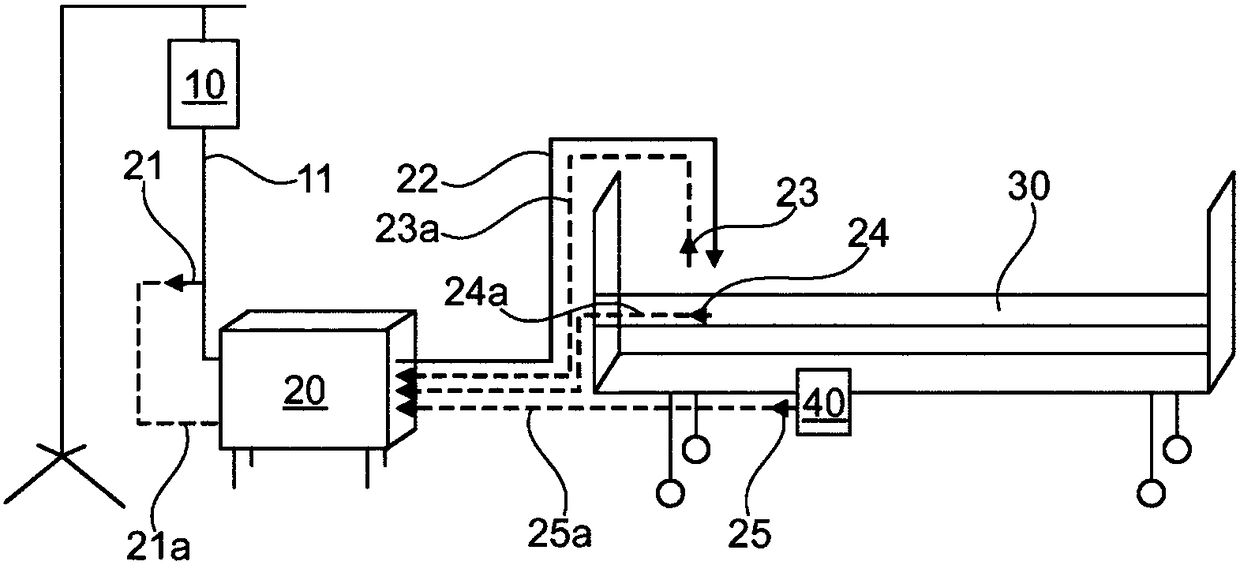

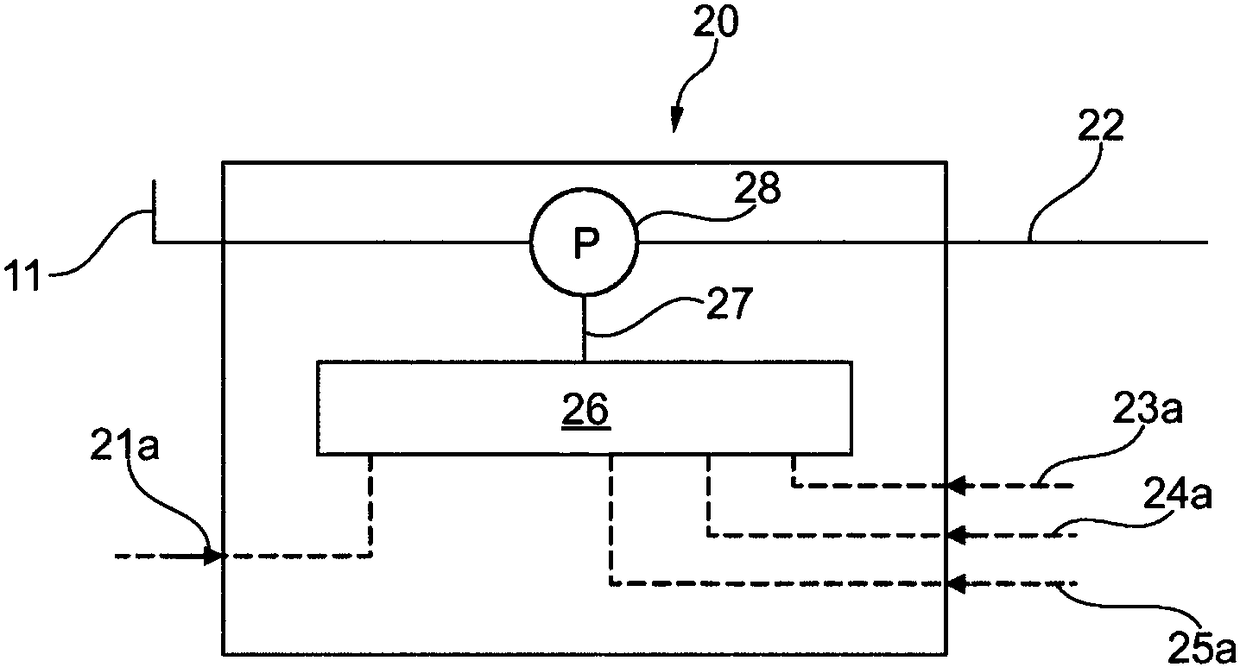

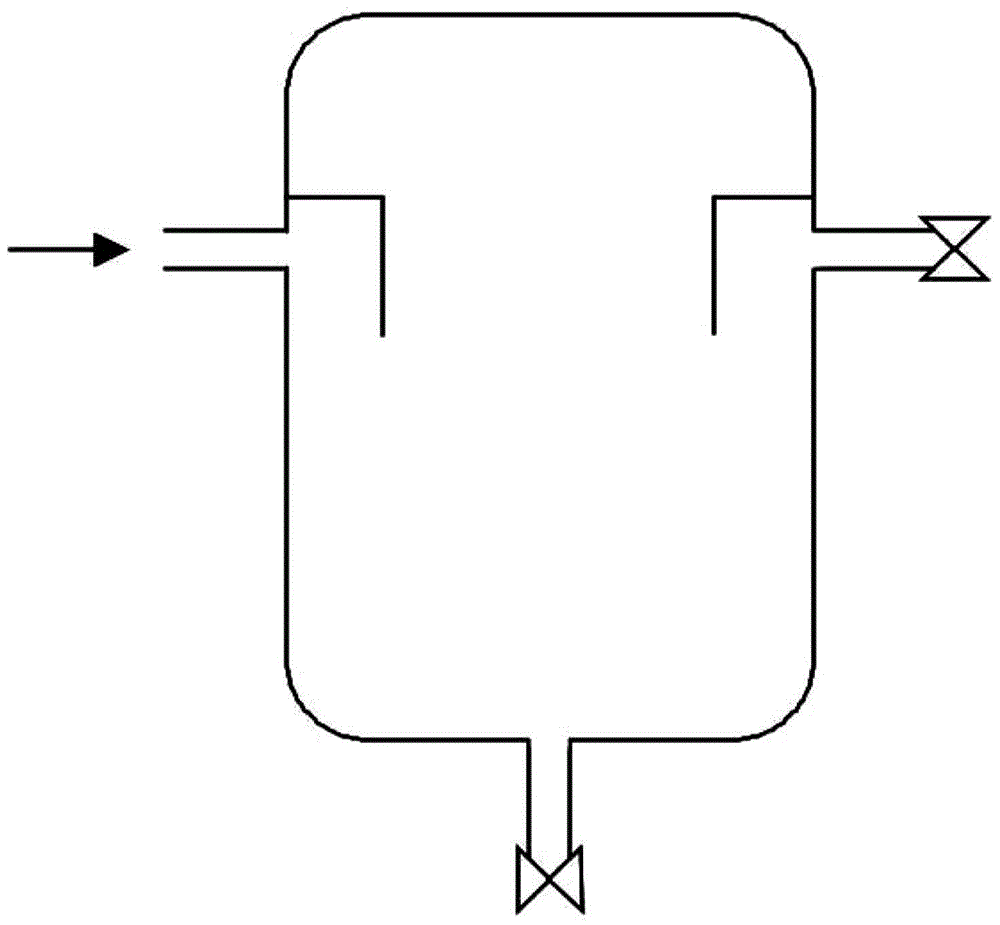

Large nuclear reactor molten pool natural-convection heat transfer test system and method

ActiveCN105911087AEnsure safetyEasy flow adjustmentMaterial thermal conductivityNuclear energy generationNuclear reactorSafety design

The invention relates to a large nuclear reactor molten pool natural-convection heat transfer test system and method. The system comprises a large molten pool natural-convection heat transfer test piece, a molten salt heating furnace supplying high temperature melt, a nitrogen source connected to the test piece and the molten salt furnace, and a cooling water loop. The test system also includes supporting power distribution equipment, instrument control equipment and data measurement and acquisition equipment. In the cooling water loop, a centrifugal water pump drives water in a cooling water tank to take away a decay heat source through a cooling channel of the test piece, heated cooling water restores to an initial water temperature through a plate heat exchanger and a cooling tower and then returns to the cooling water tank. When the molten pool temperature reaches a steady state, the test ends, and the waste liquid in the test piece is discharged into a waste liquid pool. The invention also provides a test method. By means of the large nuclear reactor molten pool natural-convection heat transfer test, molten pool heat transfer data under a reactor serious accident condition can be acquired for safety design.

Owner:XI AN JIAOTONG UNIV

Device for the transport of granular solid particles with a controlled flow rate

ActiveUS7021870B2Easy flow adjustmentReduce sensitivityVolume/mass flow measurementBulk conveyorsControl flowEngineering

Process and device for the transport of granular solids with a controlled flow rate, in particular for the transport of catalyst in a hydrocarbon reforming unit. The device comprises a gravity-feed pipe (A) for solid particles in the dense phase, a pneumatic transport pipe (C) in the dilute phase, and an inclined transfer pipe (B) that connects, without a buffer space, the base of the feed pipe to the pneumatic transport pipe, whereby this transfer pipe comprises means (17, 18, 35) for injection of a secondary gas located at the junction between the feed pipe and the transfer pipe.

Owner:INST FR DU PETROLE

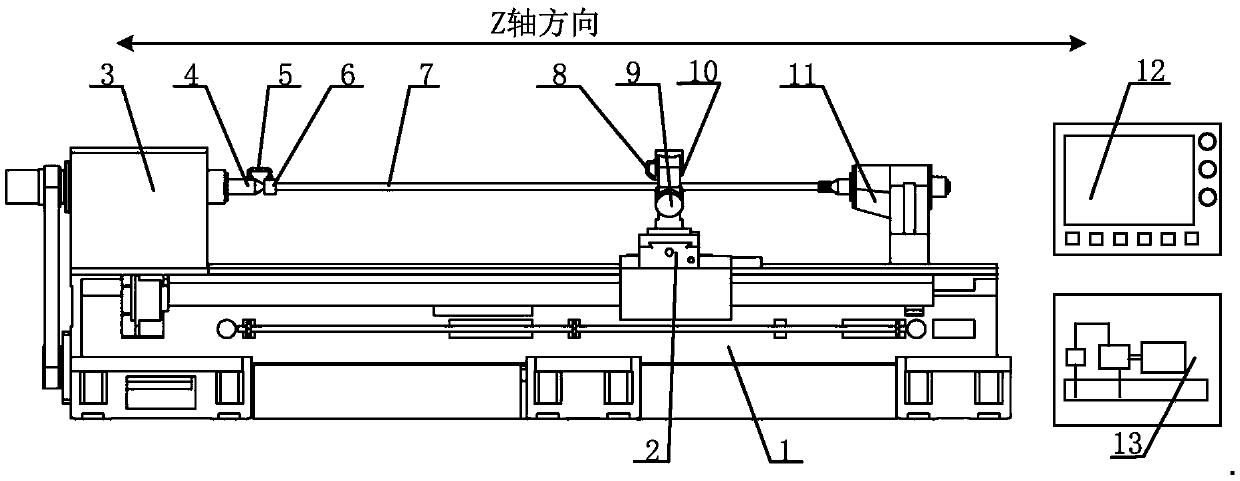

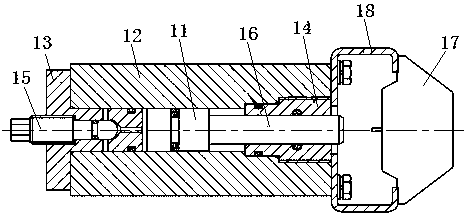

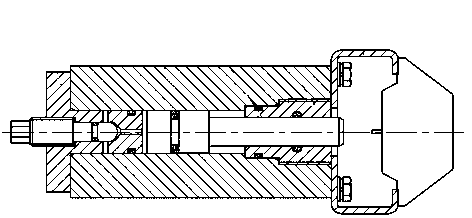

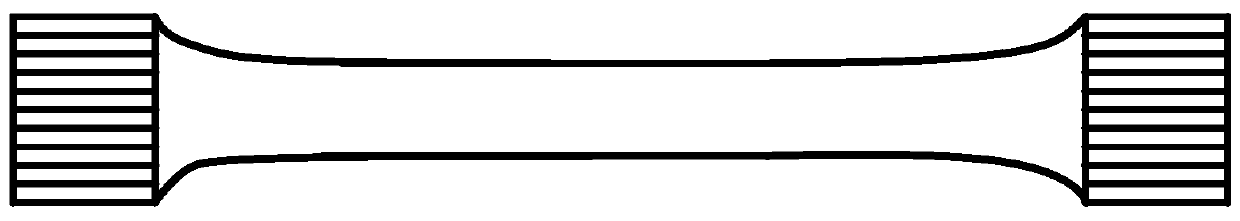

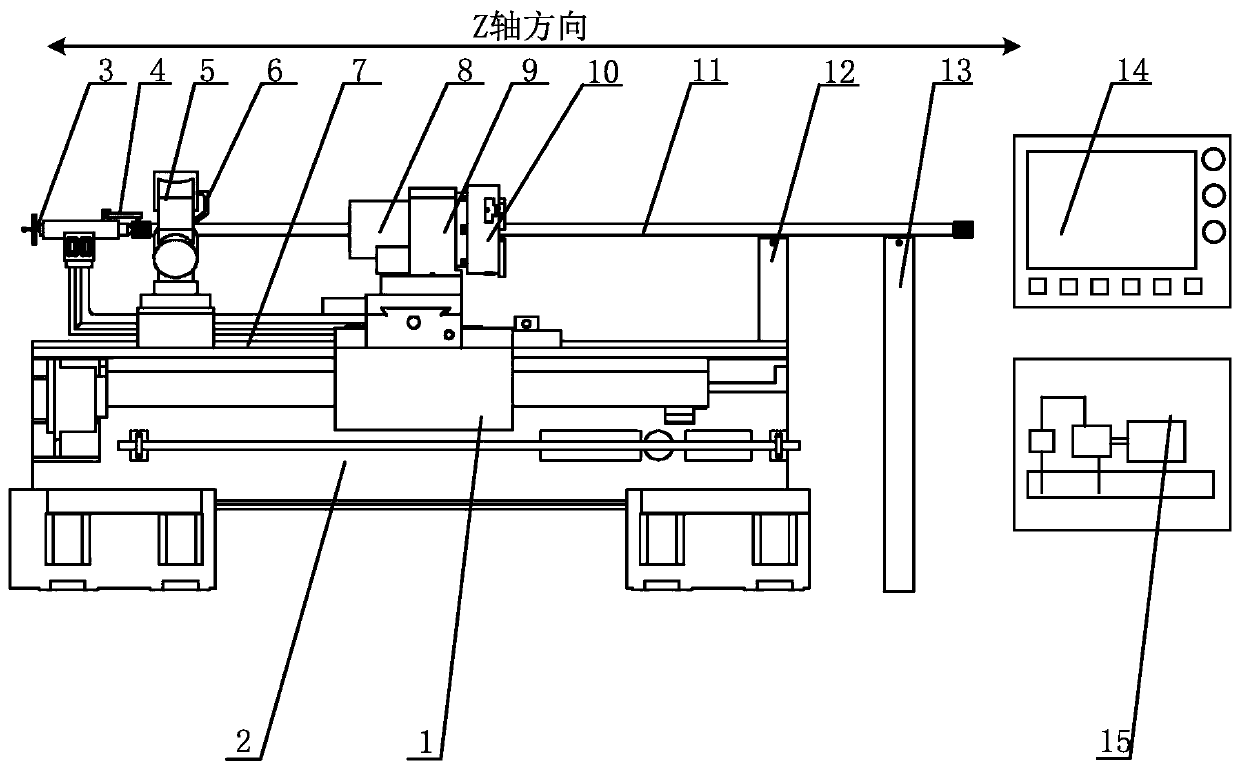

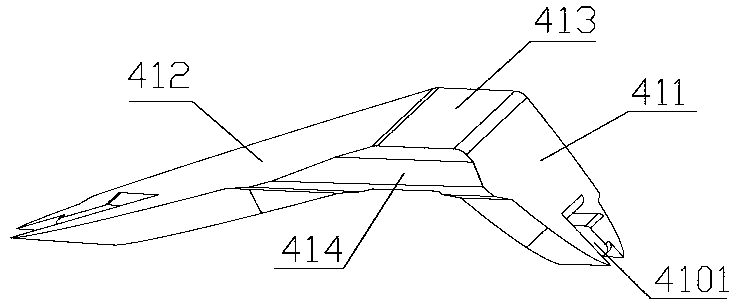

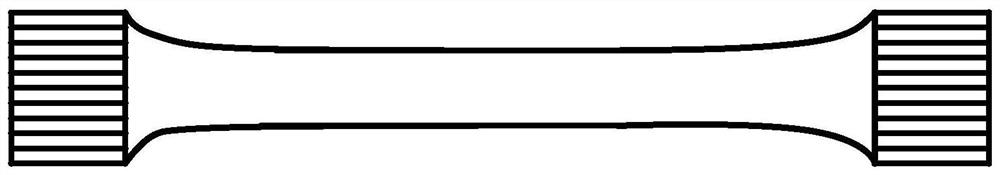

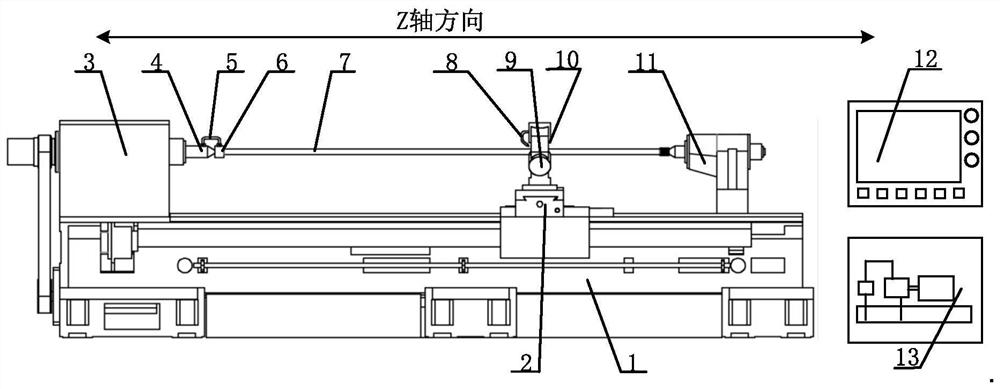

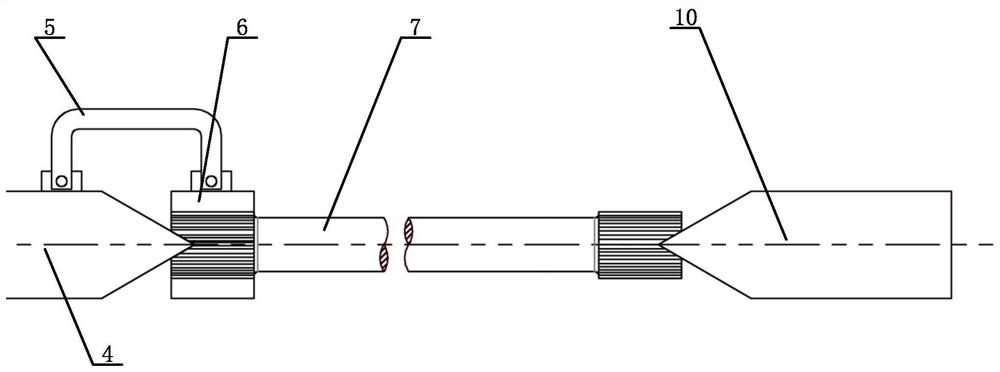

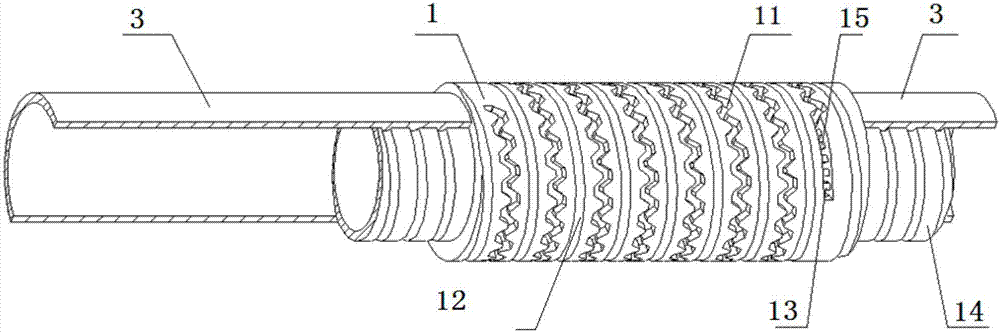

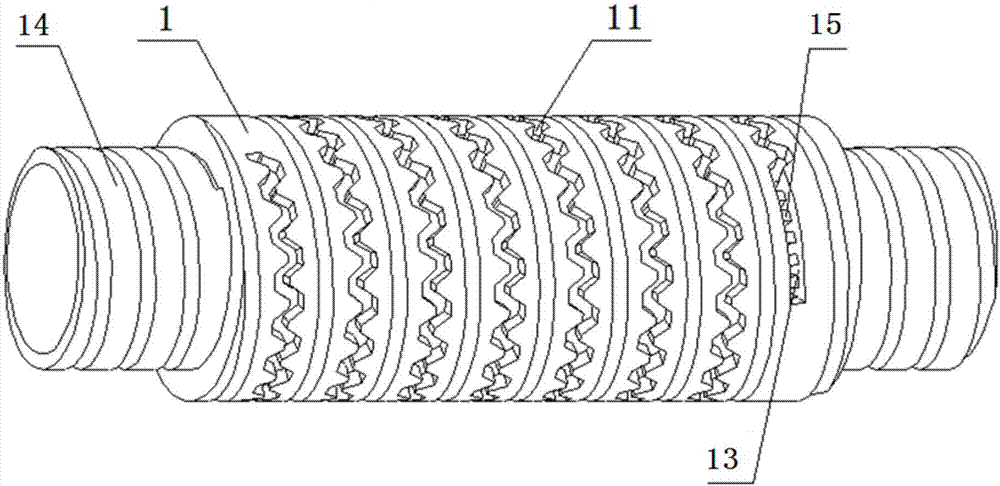

Numerical control rolling machine tool for outer circle rolling of torsion shaft

ActiveCN108673051AFastenedHigh speedWork clamping meansPositioning apparatusHydraulic cylinderEngineering

The invention provides a numerical control rolling machine tool for outer circle rolling machining of a torsion shaft. The numerical control rolling machine tool comprises a machine tool body, an outer circle rolling head, a dual centre locating device, a shifting fork connecting part, an internal spline clamp sleeve, a full closed protection cover, a displacement measurement system, a precise oilmist cooling system, a numerical control system and a hydraulic system. The outer circle rolling head of the machine tool adopts a multi-rolling-wheel symmetric rolling device structure, and when outer circle rolling machining of the torsion shaft is carried out, a workpiece bears multiple equal pressures in the radiation direction; a displacement sensor is mounted in a hydraulic cylinder of theouter circle rolling head, the change value of the rolling diameter in the outer circle rolling process is worked out through the rolling cylinder displacement value fed back by the displacement sensor, and intelligent judgment on the limiting position of the outer circle rolling arc end can be achieved; and the shifting fork connecting part replaces a traditional chuck, a transmission structure is optimized, meanwhile, worker operation is more convenient, the machine tool is more suitable for streamlined production operation, and the rolling machining efficiency is higher.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Pulsating spraying device

InactiveUS6098899AReduce sensitivityEasy flow adjustmentMovable spraying apparatusSpray nozzlesFluid controlControl room

A pulsating spraying device includes a housing having an inlet for a liquid under pressure, and a plurality of discharge openings for discharging the liquid; an inlet chamber communicating with the housing inlet; a plurality of pulsating control chambers each having an inlet passageway on one side communicating with the inlet chamber, and an outlet passageway on the opposite side communicating with at least one of the discharge openings; and a plurality of oscillating members, one located in each of the fluid control chambers, configured to be rapidly oscillated by the flow of liquid into the respective pulsating control chamber via its inlet passageway, and to drive the liquid via its outlet passageway out of the respective discharge opening in the form of pulses.

Owner:ROSENBERG PERETZ

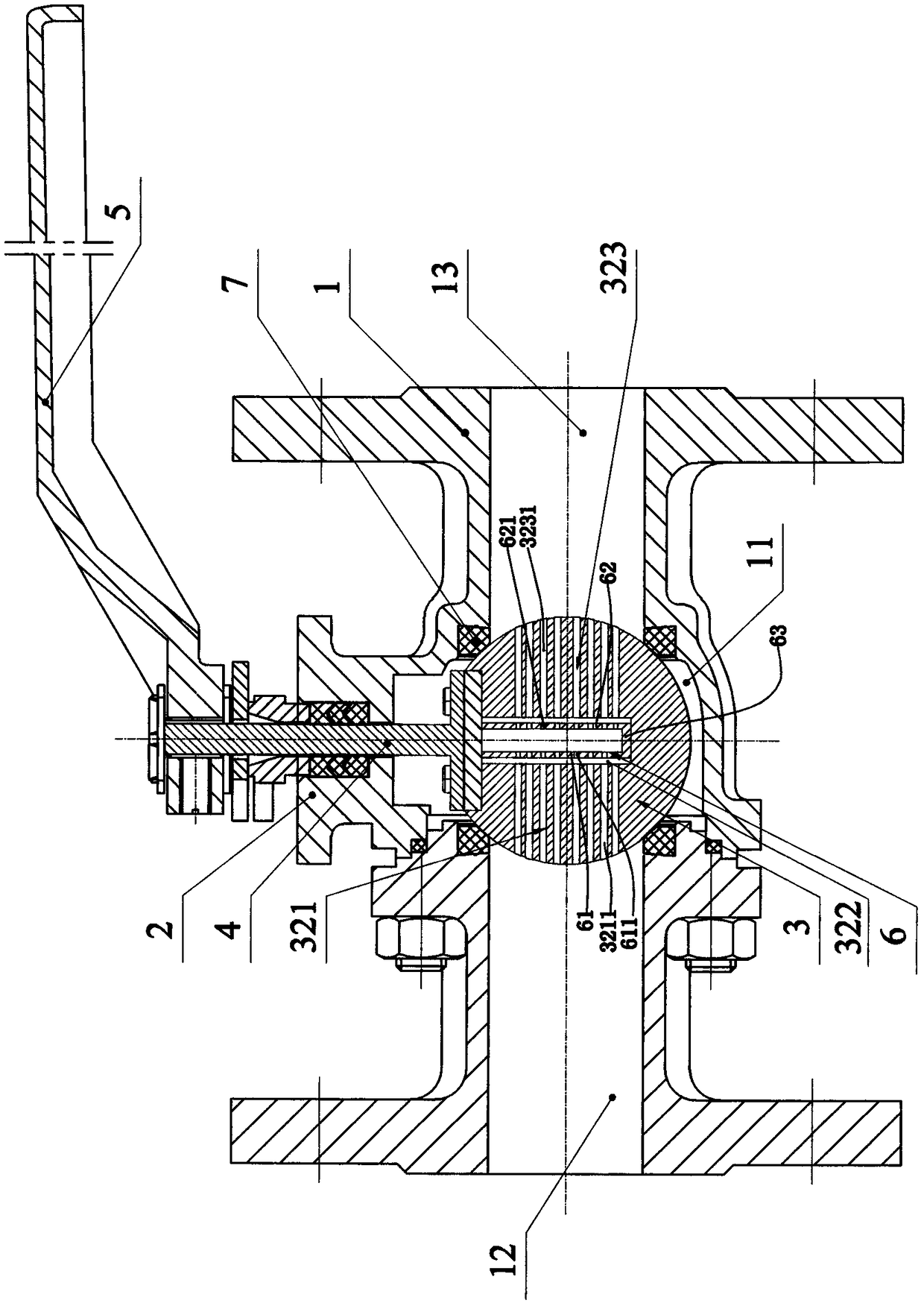

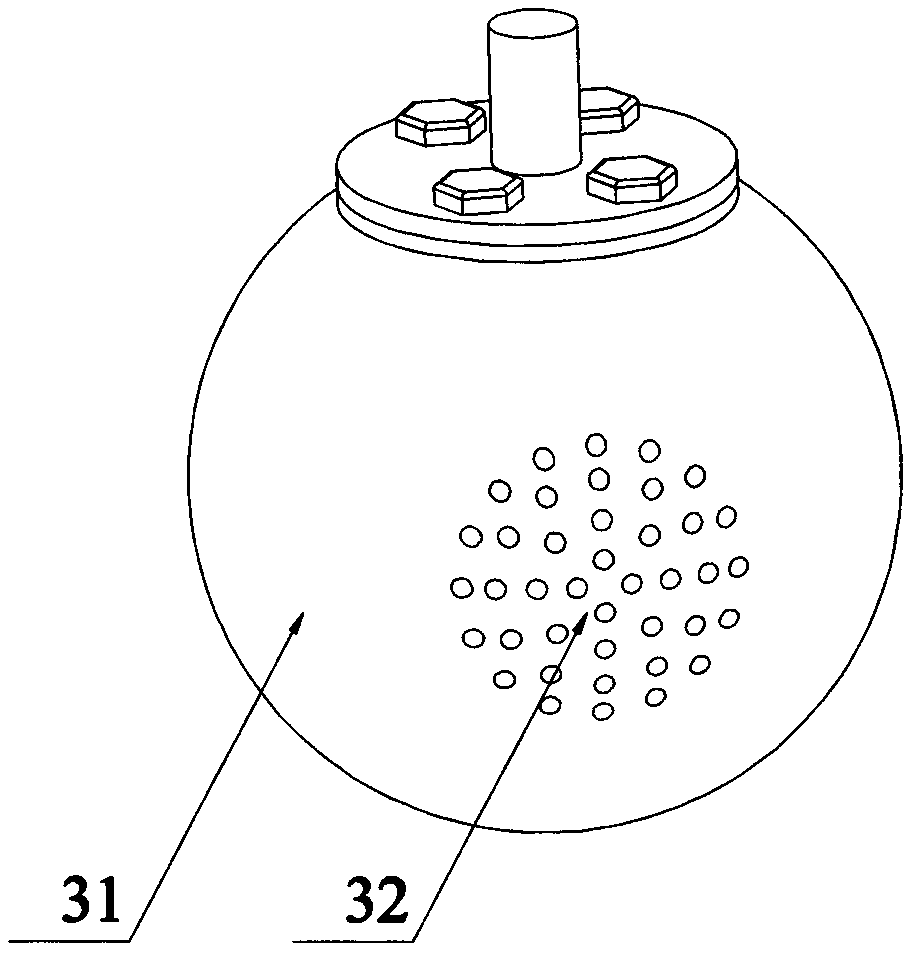

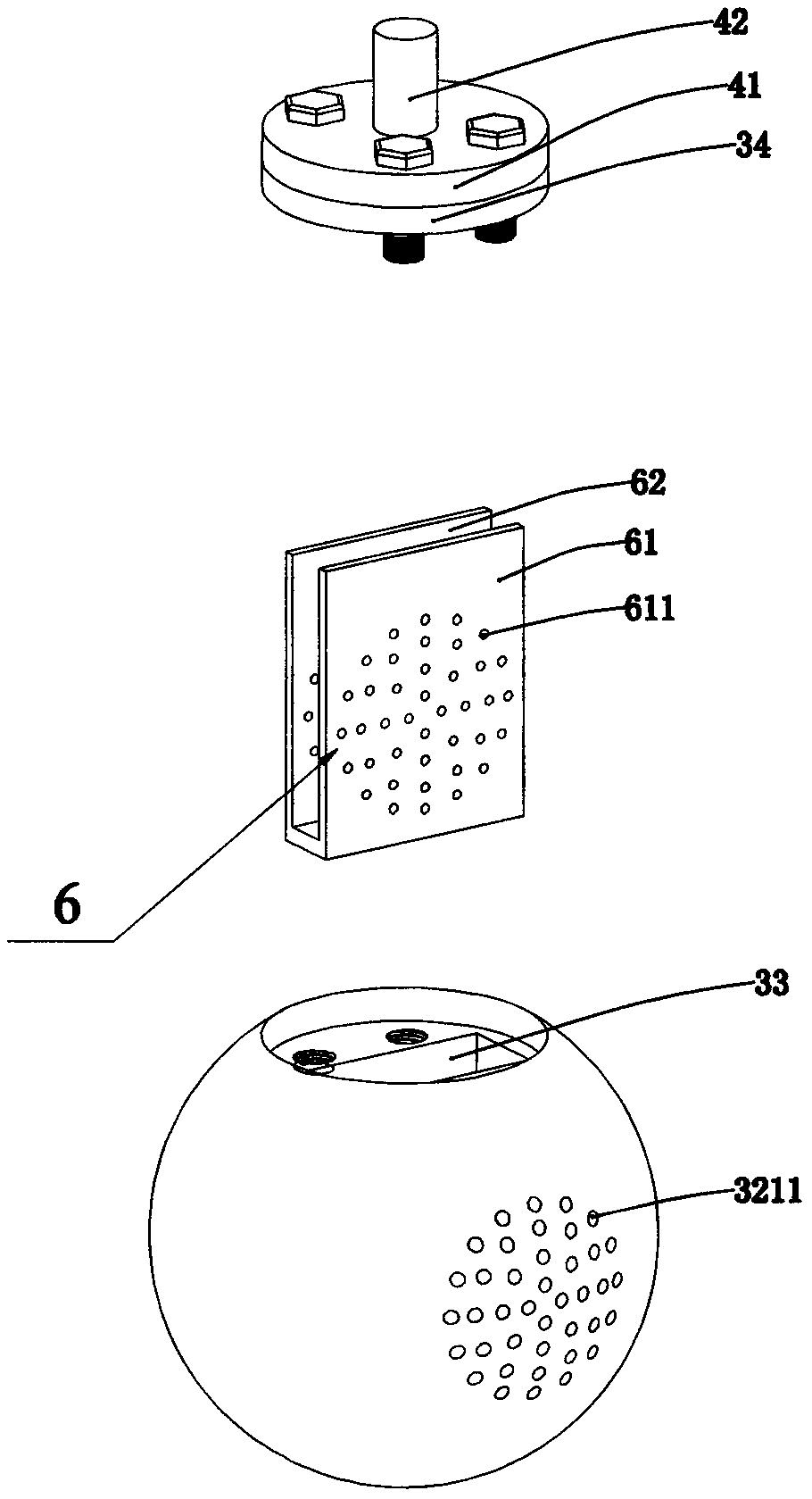

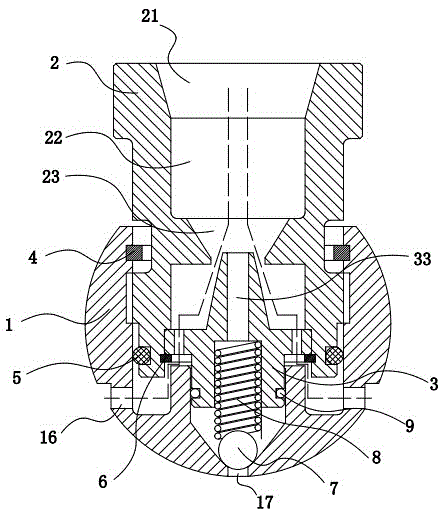

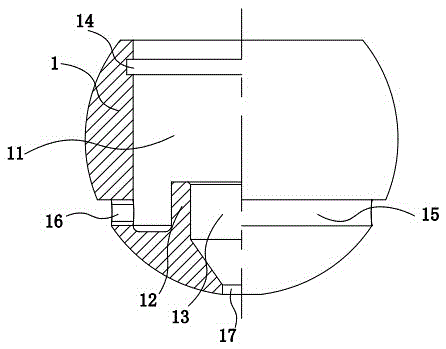

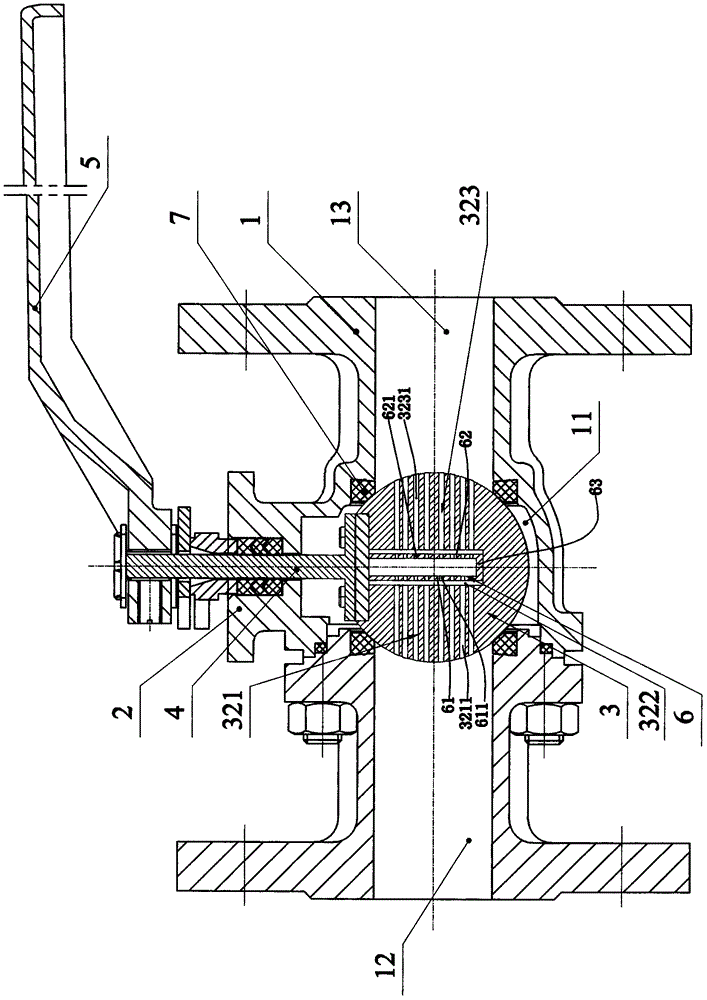

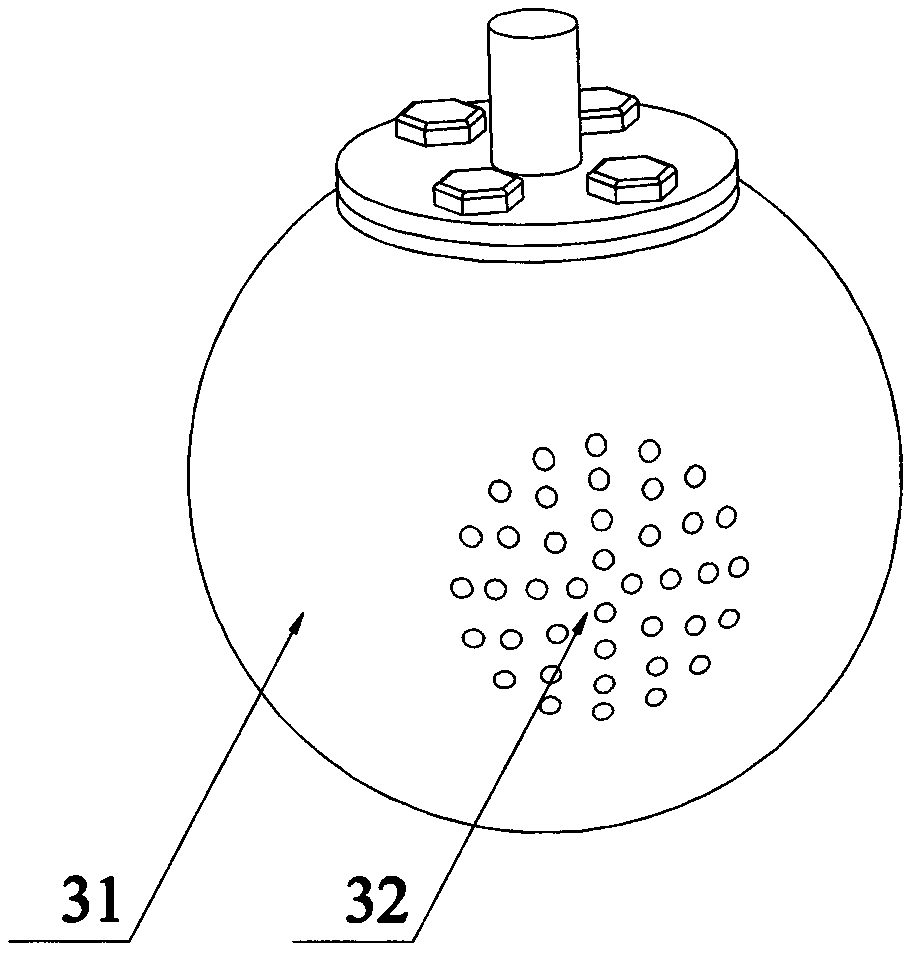

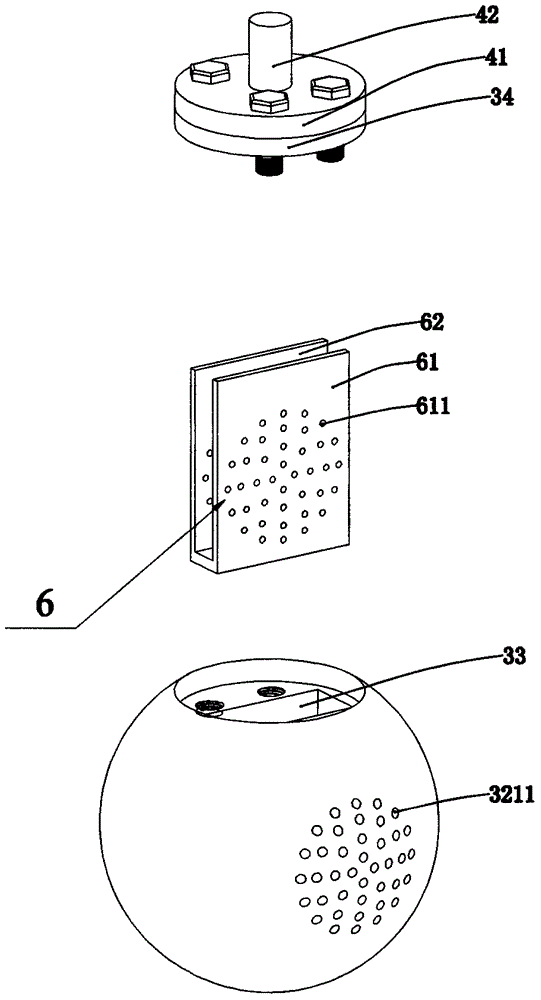

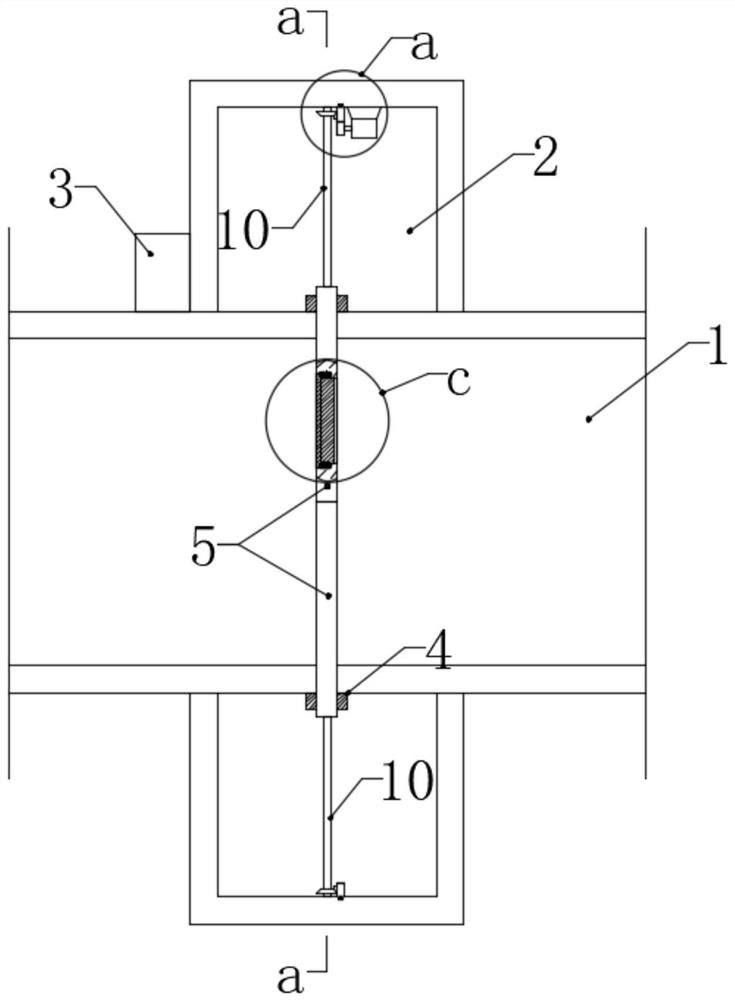

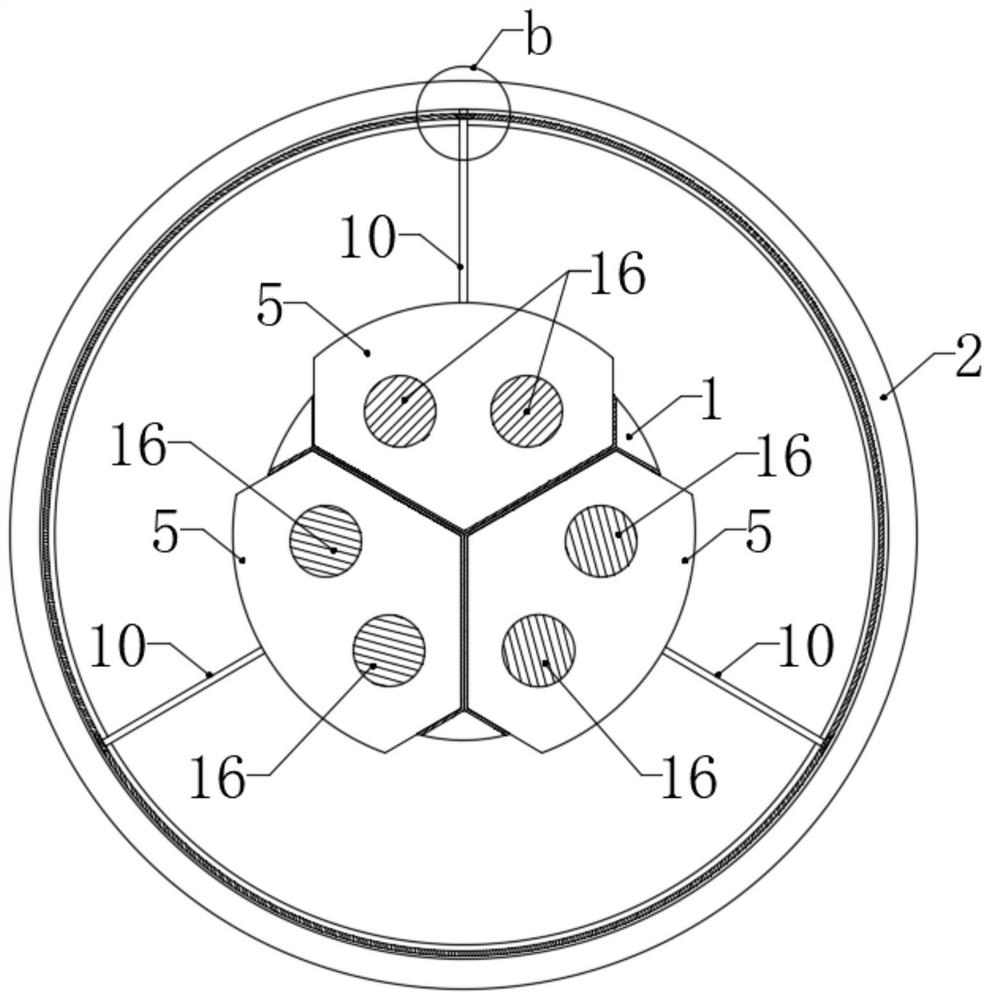

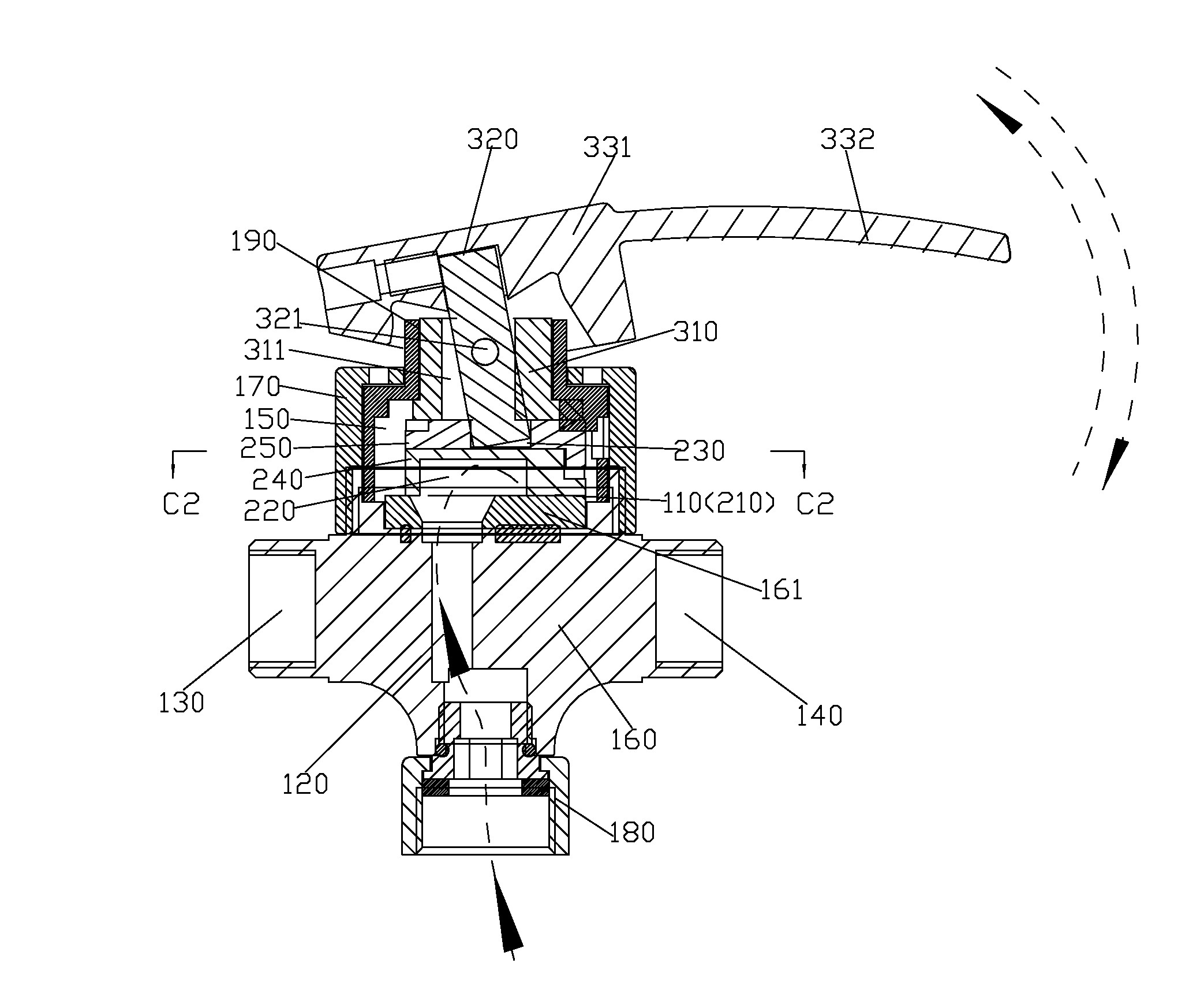

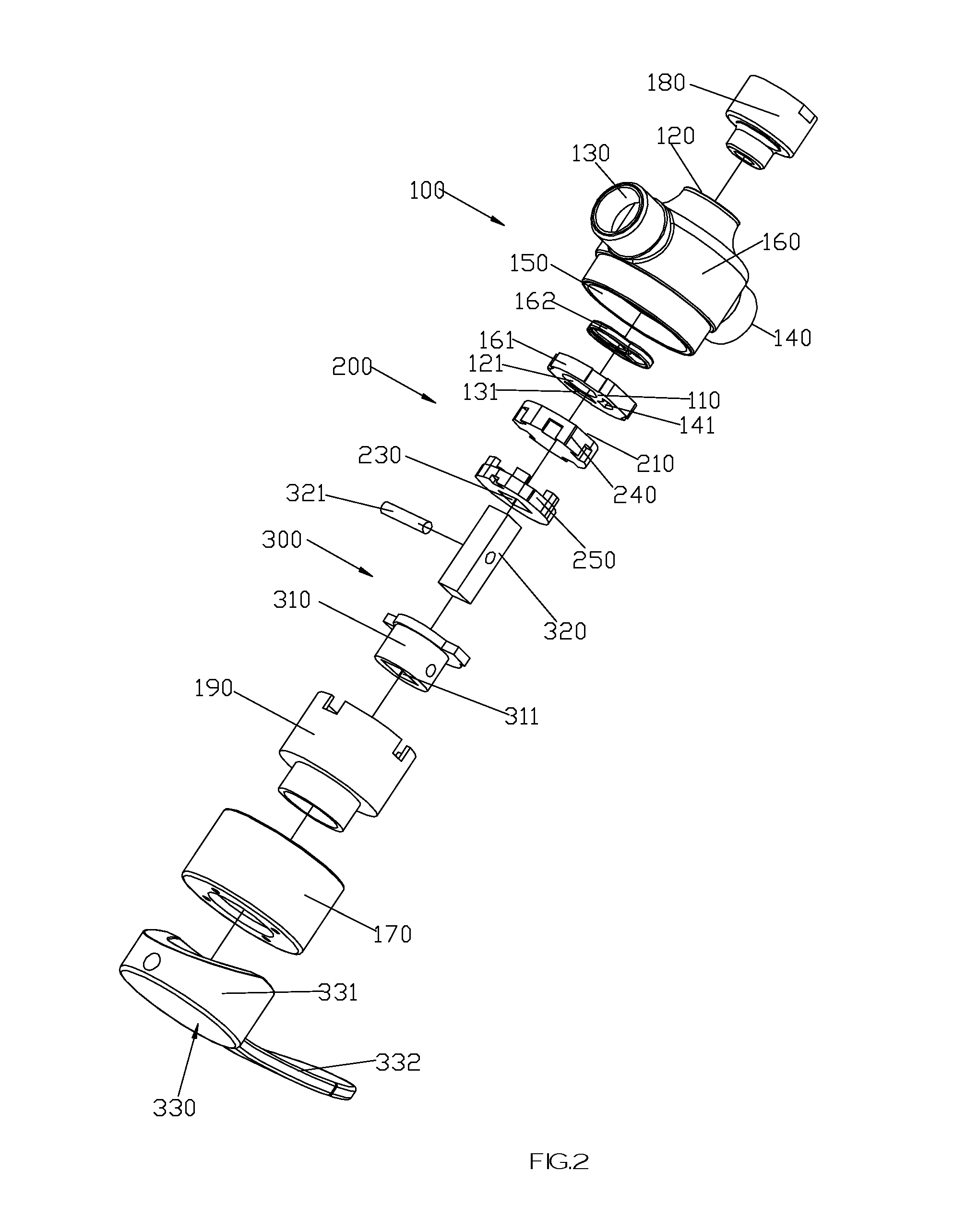

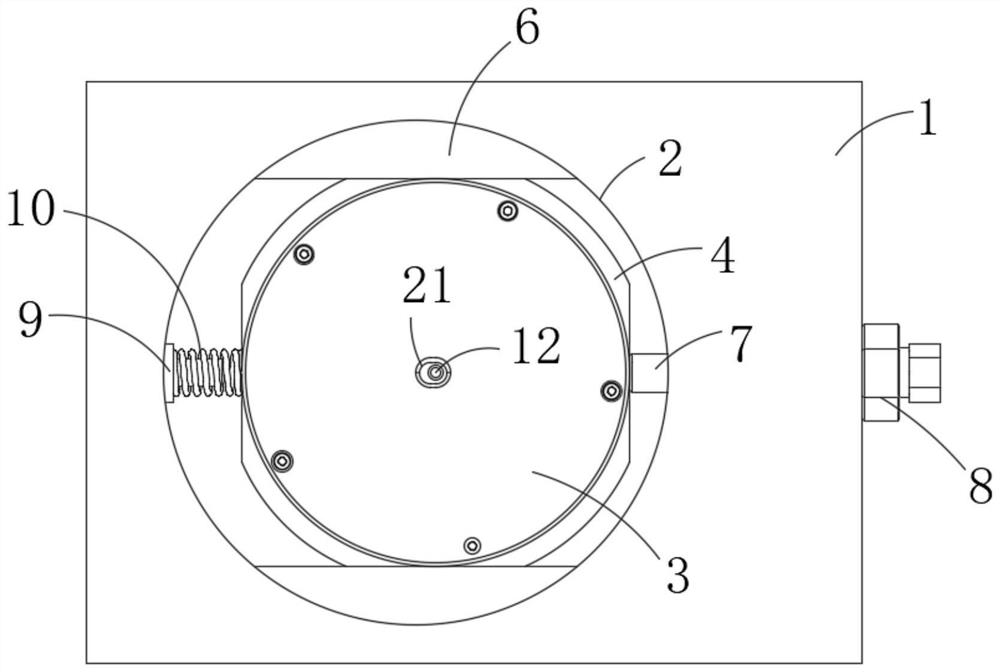

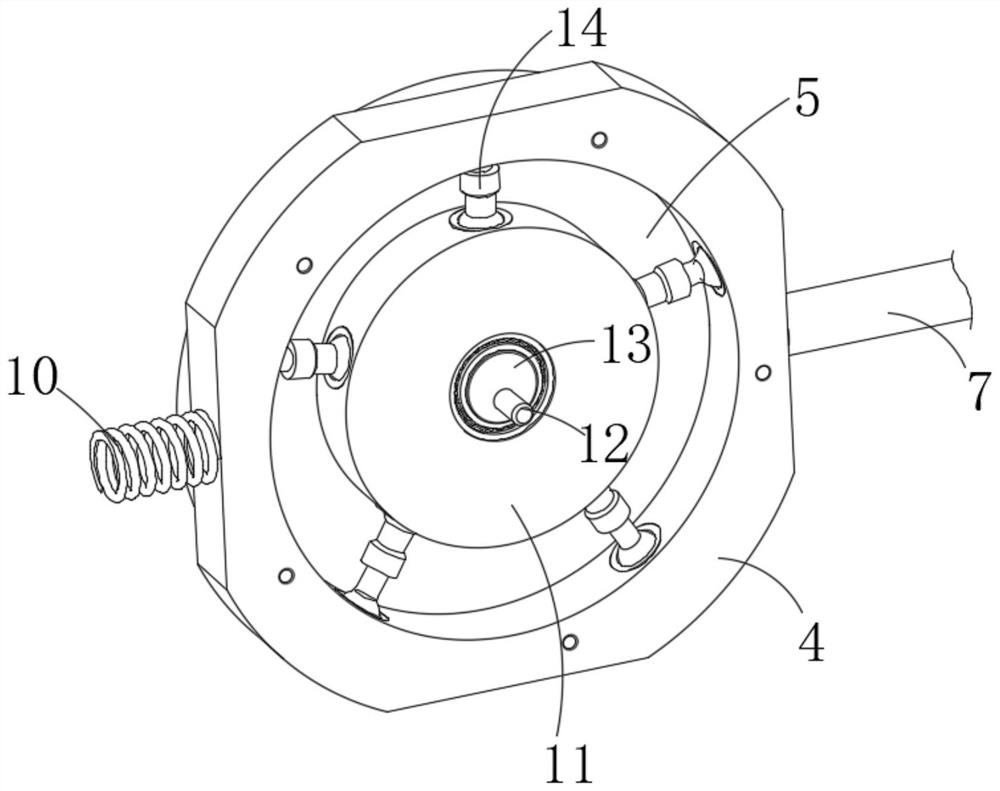

A regulating ball valve

The invention discloses an adjusting ball valve which comprises a valve, a bonnet, a ball, a valve stem and a driving mechanism. The valve stem can be driven by the driving mechanism to rotate, the valve is provided with a valve cavity, a medium inlet and a medium outlet, the medium inlet and the medium outlet are communicated with the valve cavity, the ball is arranged in the valve cavity, is connected with the valve stem in a linkage manner and comprises a closing portion and a communication portion, the medium inlet and the medium outlet can be closed by the closing portion and can be communicated with each other via the communication portion, the communication portion comprises a communication inlet portion, a middle straight slot and a communication outflow portion which are sequentially communicated and connected with one another in the direction from the medium inlet to the medium outlet, the communication inlet portion is provided with a plurality of inlet through holes which are parallelly formed at intervals, the communication outflow portion is provided with a plurality of outflow through holes which are parallelly formed at intervals, and the inner ends of the inlet through holes and the inner ends of the outflow through holes are communicated with the middle straight slot. The adjusting ball valve has the advantages of reasonable structural design and accuracy in flow adjustment.

Owner:HUANQIU VALVE GROUP

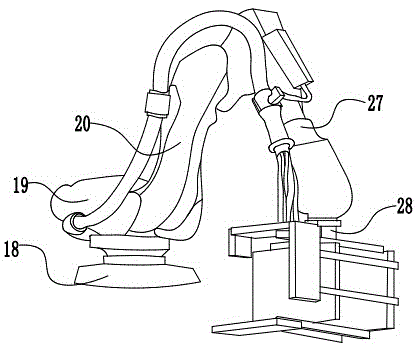

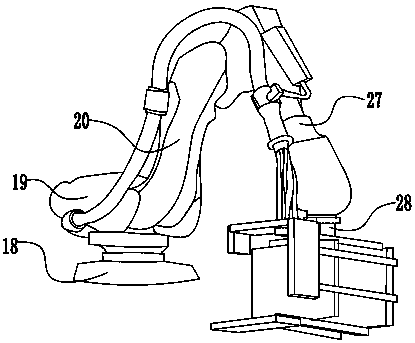

Control method of spray coating robot

InactiveCN105562266AEasy to controlEasy to adjustSpraying apparatusAgricultural engineeringSpray coating

The invention discloses a control method of a spray coating robot. According to the method, spray coating flow rate calculation is performed before fixed mold spray coating and movable mold spray coating, so that the spray coating flow rate can be regulated for meeting the mold temperature requirements. The method has the advantages that the automatic and manual switching operation can be performed, and the design is reasonable.

Owner:CHONGQING NEWSTAR TECH CO LTD

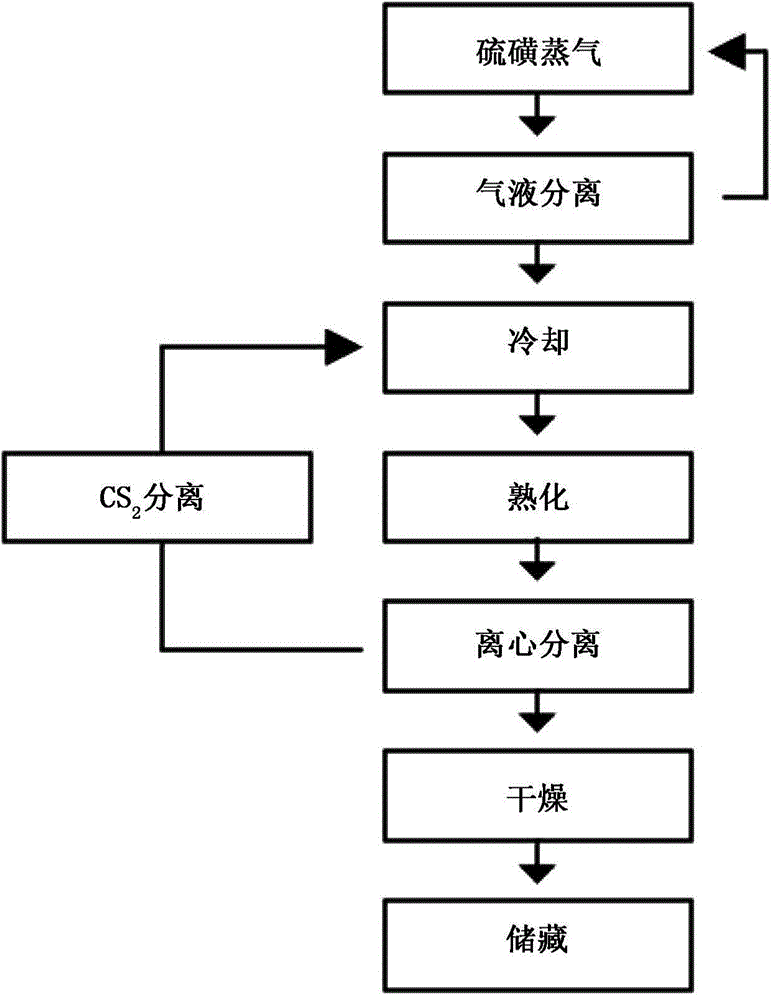

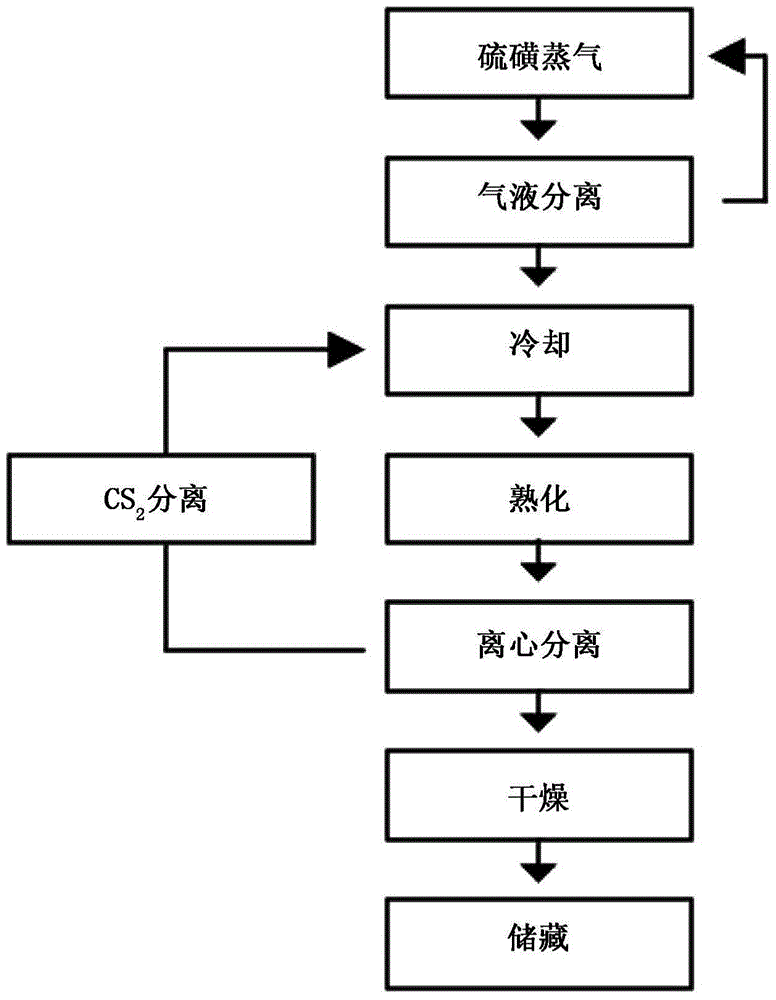

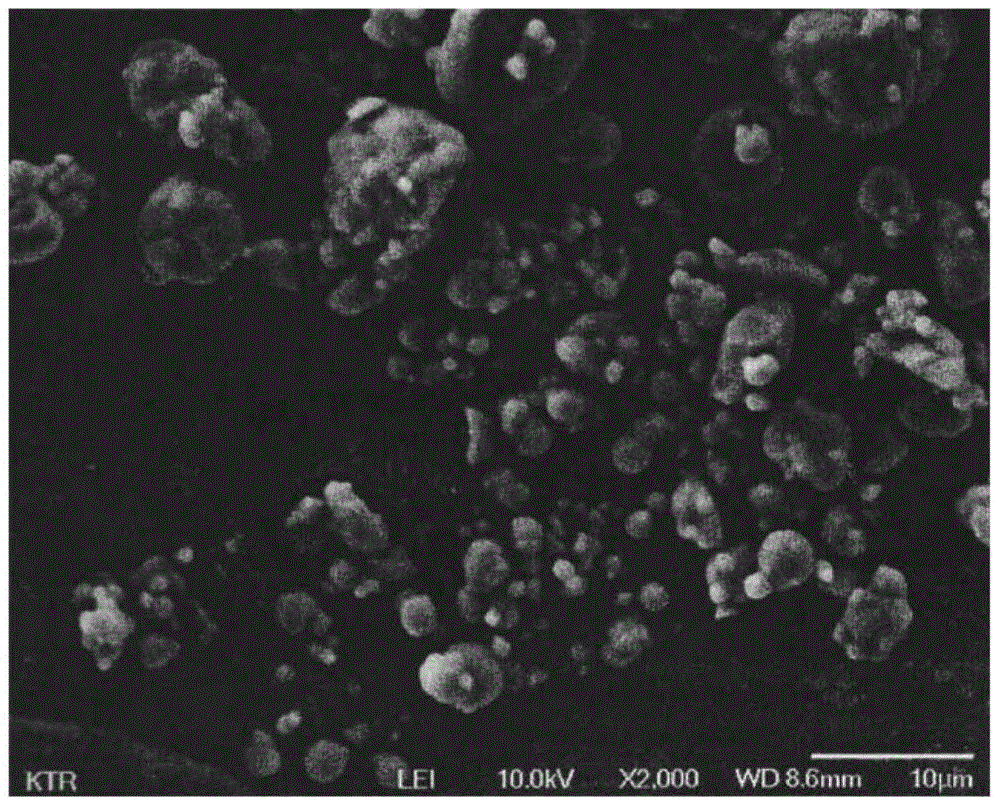

High quality insoluble sulfur and method for production the same

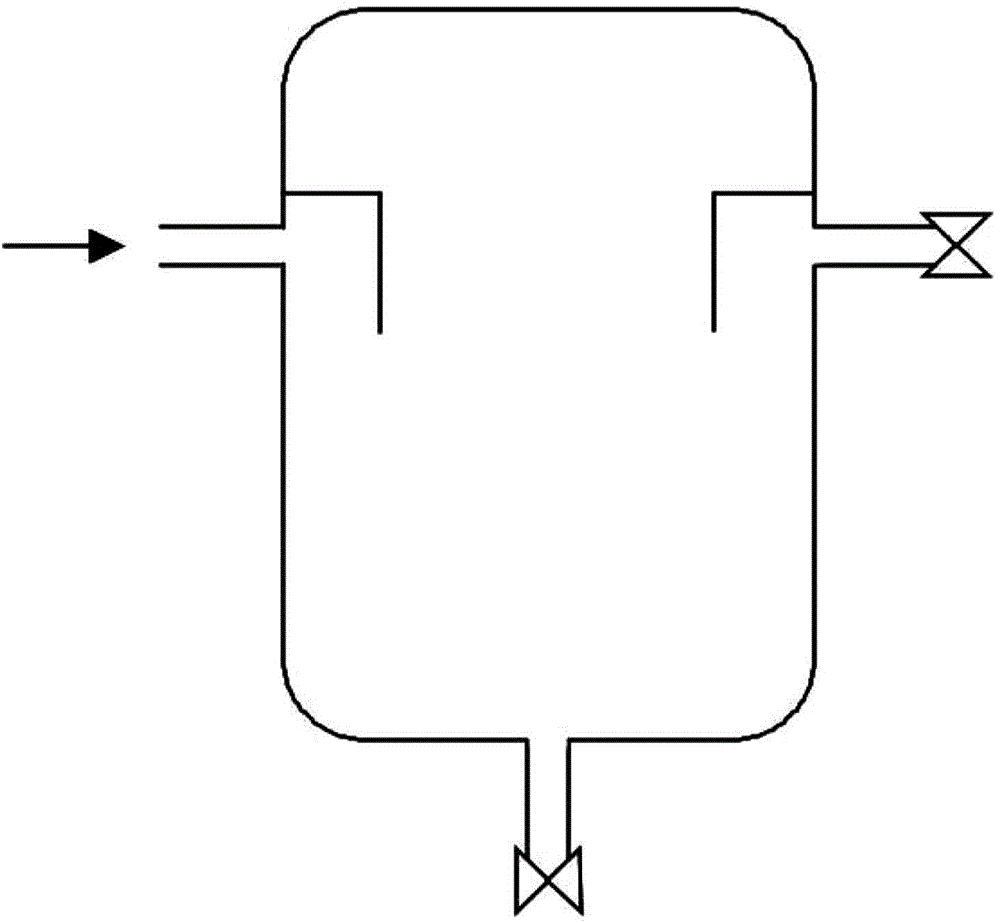

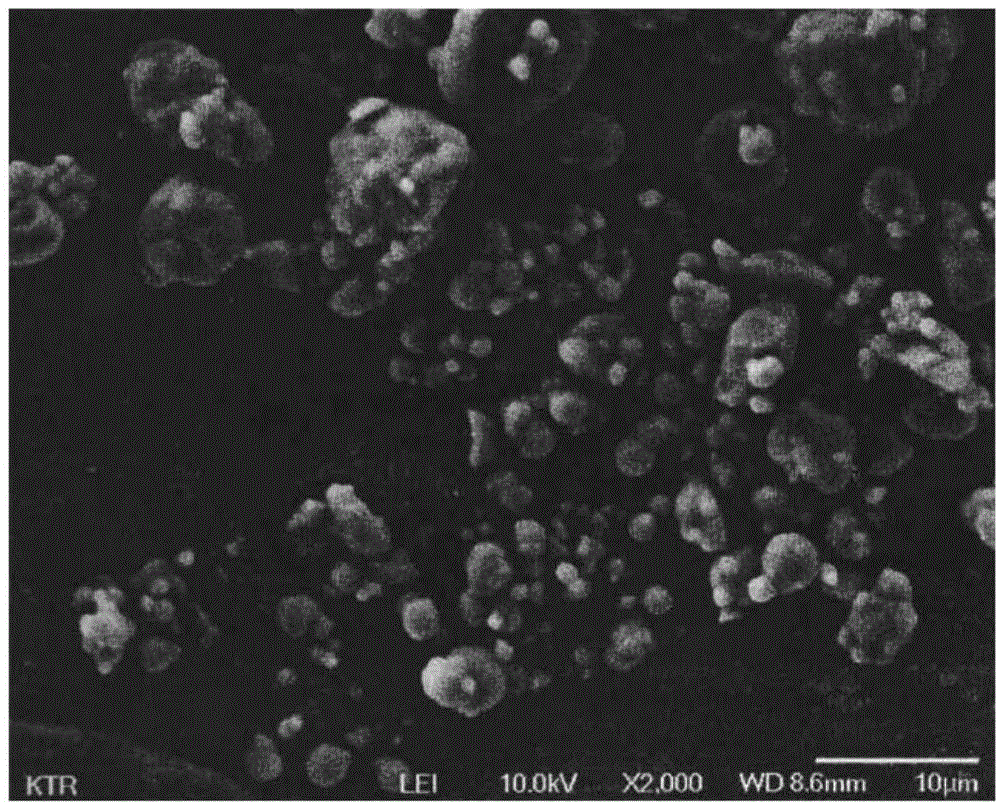

ActiveCN104445087AImprove qualityAvoid cloggingSulfur preparation/purificationChemical/physical/physico-chemical stationary reactorsVapor–liquid separatorSulfur

The present invention provides a high quality insoluble sulfur and a method for production the same. The method comprises molten sulfur is removed from sulfur steam by a gas-liquid separator before the sulfur steam is supplied to a cooler, so as to manufacture the high quality insoluble sulfur. According to the method for production the high quality insoluble sulfur, problems such as pipeline blockage in the manufacturing process are prevented, and the high quality insoluble sulfur whose residue on sieve(over 1.5% for 100 meshes) is low in content can be manufactured. The insoluble sulfur manufactured according to the method is over 90% in content of insoluble sulfur in relative to the total sulfur, lower than 1.5% in residue on sieve, lower than 71% in high throughput screening (HTS), and 5-30 [mu]m in particle size, has a high quality, and thus can serve as a vulcanizing agent in the rubber industry, especially for producing tires.

Owner:H SULFUR

Adjusting ball valve

The invention discloses an adjusting ball valve which comprises a valve, a bonnet, a ball, a valve stem and a driving mechanism. The valve stem can be driven by the driving mechanism to rotate, the valve is provided with a valve cavity, a medium inlet and a medium outlet, the medium inlet and the medium outlet are communicated with the valve cavity, the ball is arranged in the valve cavity, is connected with the valve stem in a linkage manner and comprises a closing portion and a communication portion, the medium inlet and the medium outlet can be closed by the closing portion and can be communicated with each other via the communication portion, the communication portion comprises a communication inlet portion, a middle straight slot and a communication outflow portion which are sequentially communicated and connected with one another in the direction from the medium inlet to the medium outlet, the communication inlet portion is provided with a plurality of inlet through holes which are parallelly formed at intervals, the communication outflow portion is provided with a plurality of outflow through holes which are parallelly formed at intervals, and the inner ends of the inlet through holes and the inner ends of the outflow through holes are communicated with the middle straight slot. The adjusting ball valve has the advantages of reasonable structural design and accuracy in flow adjustment.

Owner:HUANQIU VALVE GROUP

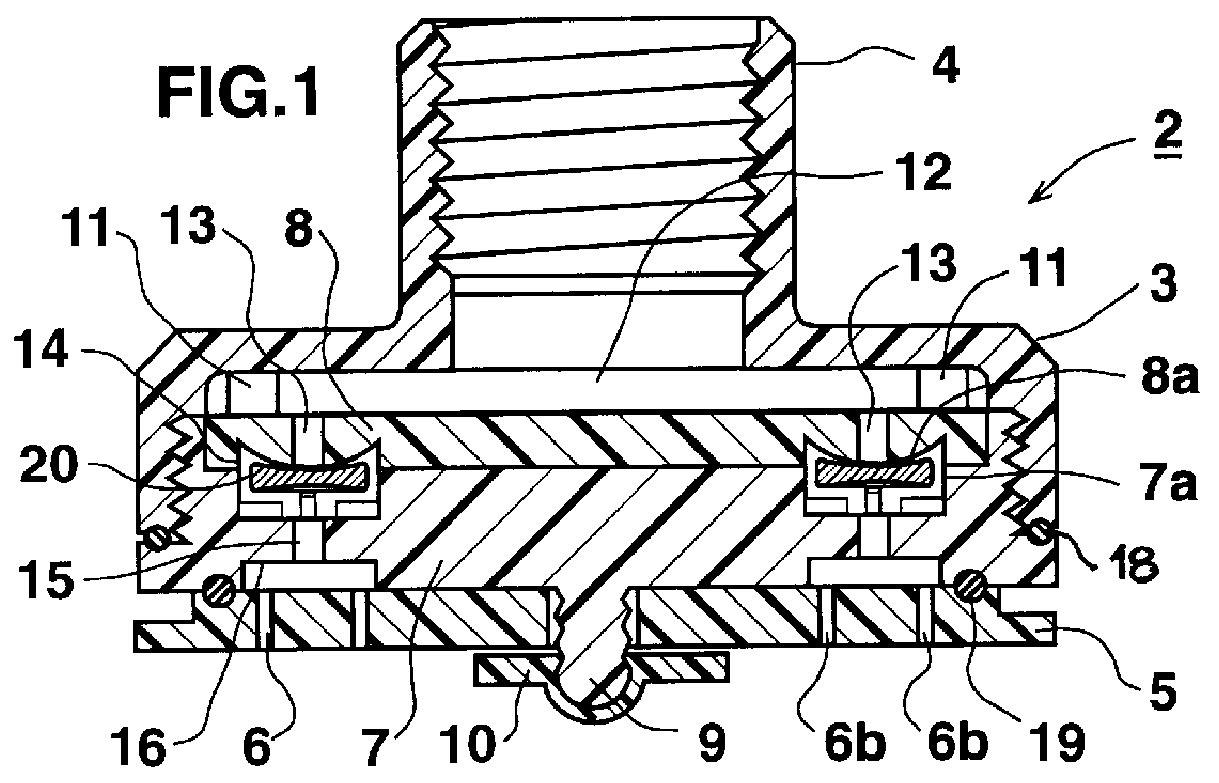

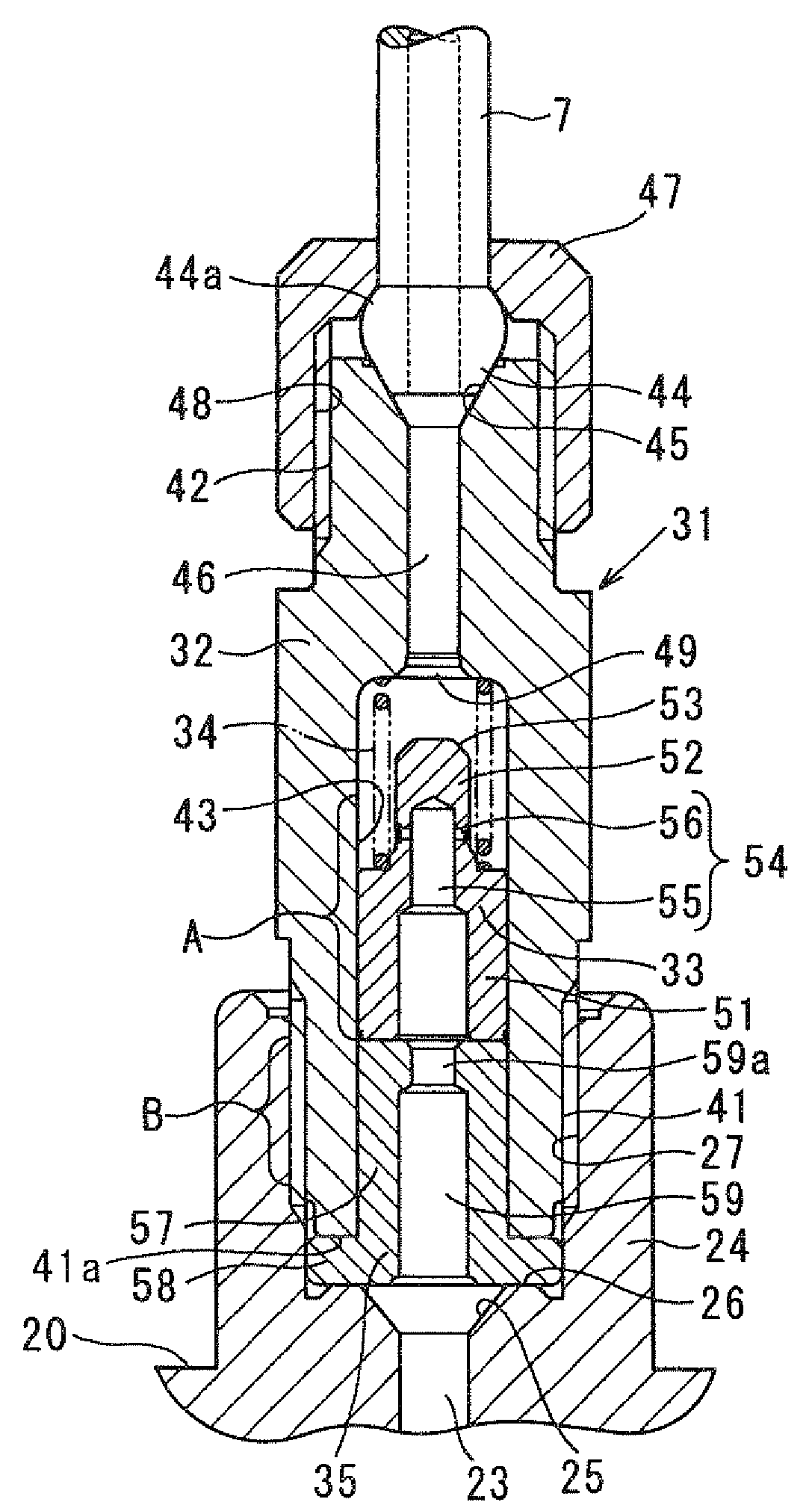

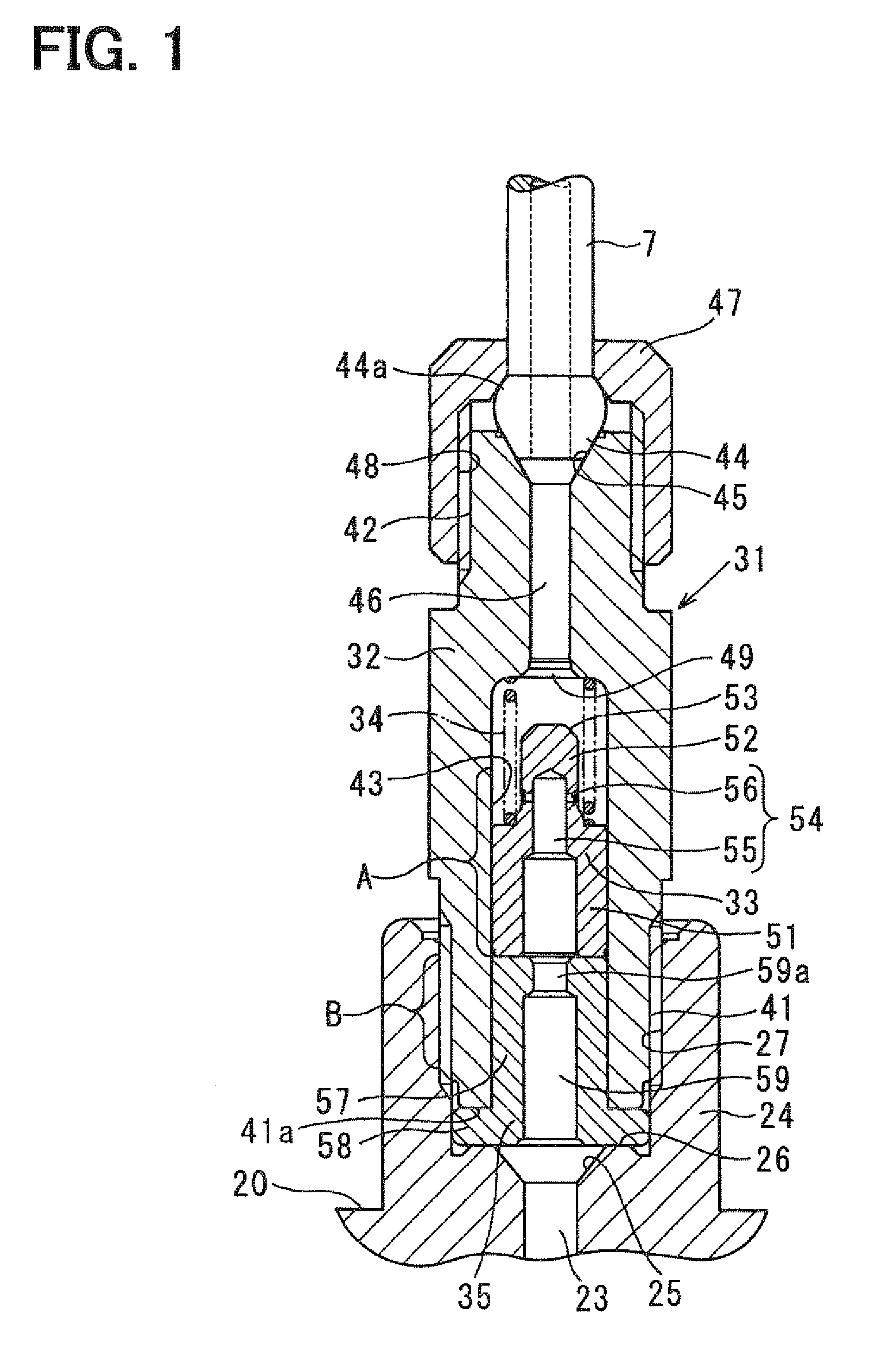

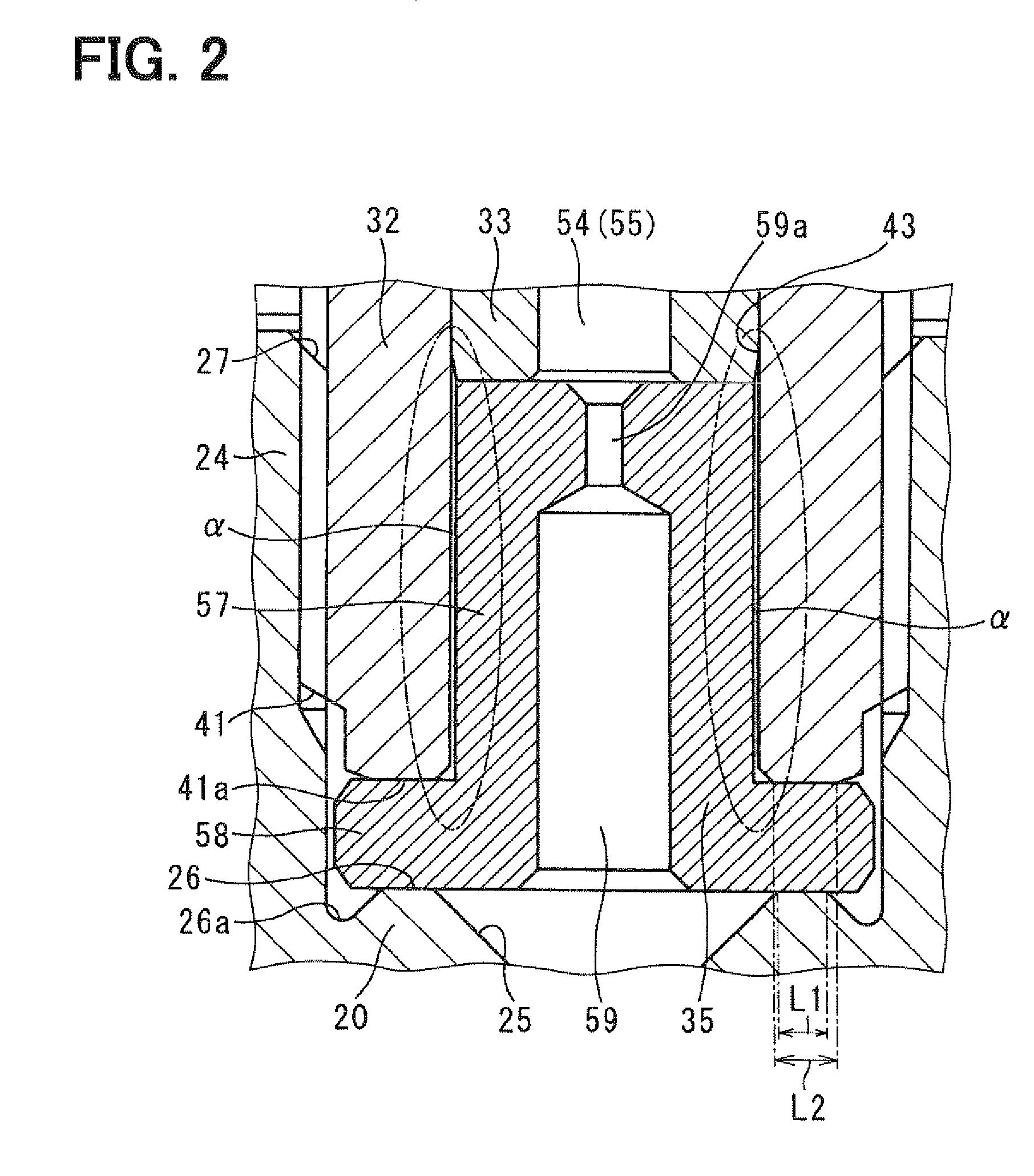

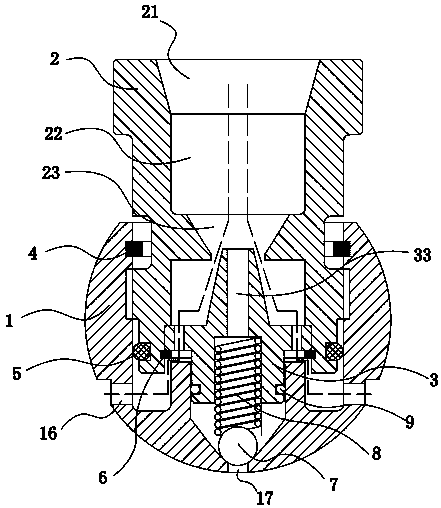

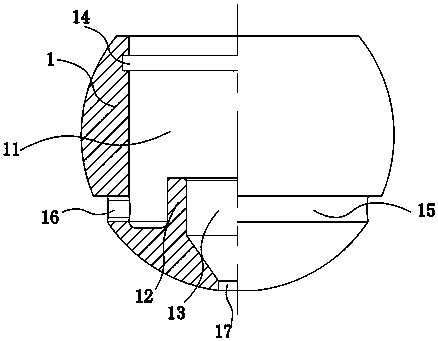

Flow damper

ActiveUS7487759B2Inhibit deteriorationEasy flow adjustmentMachines/enginesSpecial fuel injection apparatusEngineeringStreamflow

A flow damper includes a valve body, a piston, a spring, and a cap. The valve body is fastened to the rail main body and has a fuel passage therein. The fuel passage communicates between a fuel hole of the rail main body and the injector. The fuel passage includes a piston sliding hole on its rail main body-side. The piston is slidably held on an inner circumferential surface of the piston sliding hole. The spring urges the piston in an opposite direction from a direction of fuel flowing through the fuel passage. The cap includes a small diameter portion and a large diameter portion. The small diameter portion is fitted into the inner circumferential surface of the piston sliding hole with a gap between the small diameter portion and the piston sliding hole. The large diameter portion is located between the valve body and the rail main body.

Owner:DENSO CORP

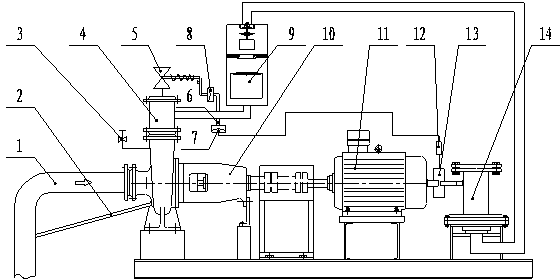

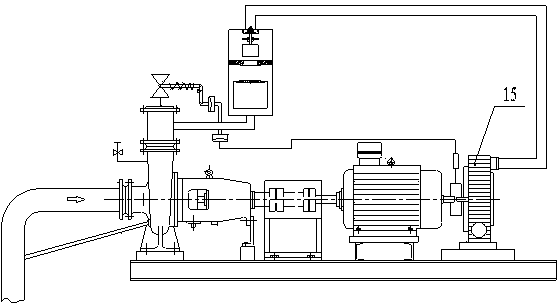

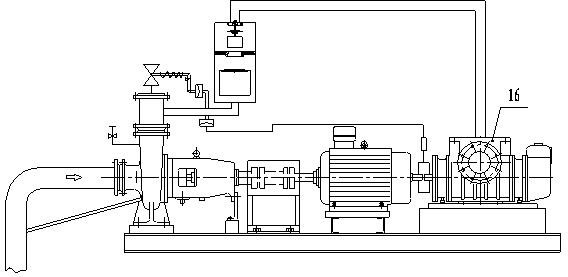

Drive clutch self-priming device

InactiveCN104279164ASimple structureCompact structurePriming pumpPump installationsControl systemControl engineering

The invention provides a novel drive clutch self-priming device mainly applied to lifting of medium liquid. The drive clutch self-priming device is technically characterized in that a double-shaft motor is adopted, each of the front and rear ends of the motor is provided with one shaft, the front shaft is connected with a centrifugal pump, a rear shaft is connected with a vacuumizing device through a clutch, an outlet of the centrifugal pump is provided with an outlet connection pipe fitting which is connected with an outlet self-priming valve and a clutch separation pipeline, and the clutch separation pipeline is connected with a clutch separation device which is connected with the clutch. The drive clutch self-priming device has the advantages that the self-priming device and the centrifugal pump are driven by one motor or diesel engine, no electric control system is needed, and accordingly the device is simpler and more compact in integral structure, lower in manufacturing cost, stable in performance and low in failure rate; a diaphragm type vacuumizing device, a gas ring vacuum pump, a roots pump and the like can serve as the vacuumizing device, and the drive clutch self-priming device is suitable for different working conditions of high flow, toxicity, harmfulness and the like.

Owner:辽宁格瑞特泵业有限公司

Novel flow control valve

PendingCN112049952ARegulate continuous stabilityEasy flow adjustmentSpindle sealingsOperating means/releasing devices for valvesGear wheelControl valves

The invention discloses a novel flow control valve, and relates to the field of flow control over pipelines. The novel flow control valve comprises a pipeline, a sealing pipe is installed on the outerside of the pipeline, a plurality of flow adjusting plates inserted into the pipeline are arranged in the sealing pipe, and a servo motor and a gear ring are arranged on the inner wall of the sealingpipe; and a gear is fixed to the driving end of the servo motor and engaged with the gear ring, the gear ring is connected with the inner wall of the sealing pipe in a sliding mode through a sealinggasket, an oblique gear ring is fixed to the side, away from the servo motor, of the gear ring, and a plurality of threaded rods are rotatably mounted on the side, close to the oblique gear ring, of the inner wall of the sealing pipe. Bevel gears are installed at the top ends of the threaded rods and engaged with the bevel gear ring, and the bottom ends of the threaded rods and the flow adjustingplates are installed in a threaded mode. According to the flow control valve, the flow of fluid in the pipeline can be rapidly, conveniently and stably adjusted through the arrangement of all the structures, the adjusting range of the flow control valve is 0-100%, and influences on the original flow of the pipeline can be avoided.

Owner:ZHEJIANG INST OF COMM

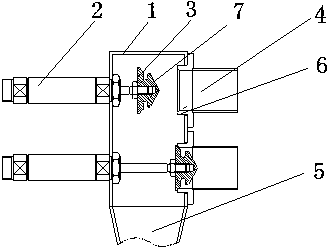

Signal cylinder and hydraulic operating mechanism with signal cylinder

InactiveCN104143489AEasy to processSimple structureSwitch power arrangementsProtective switch operating/release mechanismsInlet channelHigh pressure

The invention relates to a high-voltage switch operating mechanism, in particular to a signal cylinder and a hydraulic operating mechanism with the signal cylinder. The signal cylinder is adopted in the hydraulic operating mechanism and comprises a cylinder body component and a piston arranged in the cylinder body component. An oil inlet channel is arranged at one end of the cylinder body component. A flow adjusting component is arranged on the oil inlet channel. The side, opposite to a plug, of the piston is provided with a piston rod. The outer circumferential face of the end, away from the piston, of the piston rod and the cylinder body component are in seal fit. A constant high-pressure oil cavity is formed in the side, close to the piston rod, of the piston in the cylinder body component and a work oil cavity is formed in the other side of the piston. In the process of use, moving time of the piston can be adjusted simply by adjusting the flow of the oil inlet channel through the flow adjusting component, stepless accurate adjustment can be conducted on closing and opening time of a circuit breaker, and the problem that an existing signal cylinder is poor in closing and opening time adjusting accuracy of the circuit breaker is solved.

Owner:STATE GRID CORP OF CHINA +2

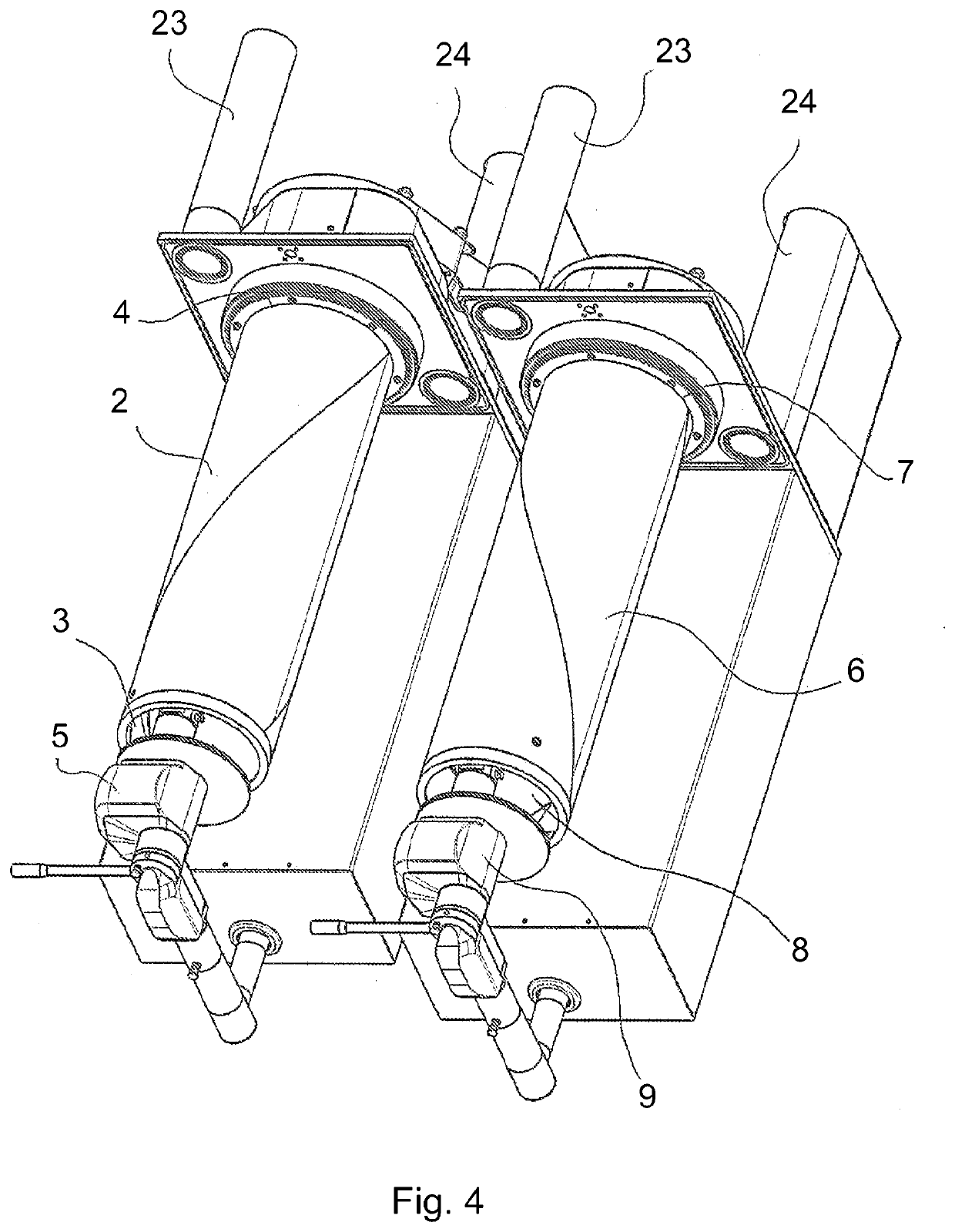

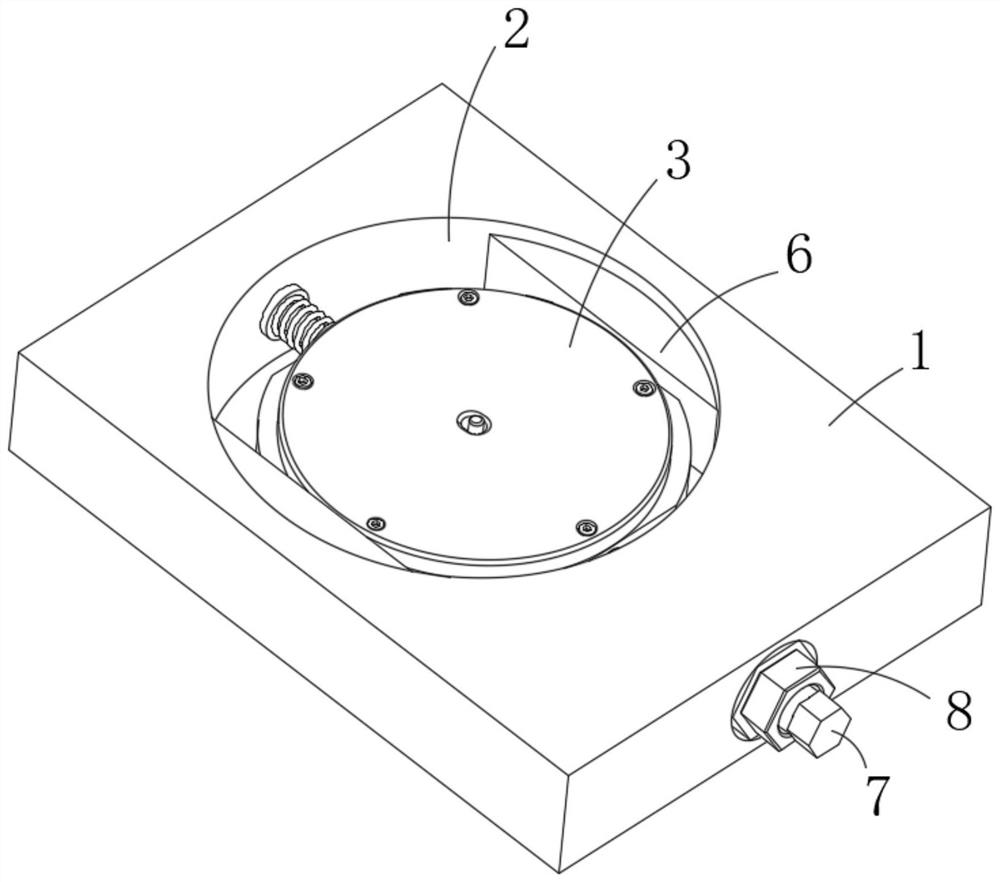

Apparatus and method for coating bulk material

ActiveUS20200070193A1Simple and effective regulationGentle handlingLiquid surface applicatorsGranule coatingCoated tabletsStationary phase

A coating apparatus (1) and method are disclosed for coating tablets in a rotating drilled container (2) at the outlet of which a rotating annular element (11) operates that is coaxial with the container, in which in an initial transition phase the annular element rotates in a direction that is opposite the rotation direction of the container to retain the tablets inside the container, forming a bed of tablets until a desired level is reached, and in a stationary phase the annular element rotates in a direction that is the same as the rotation of the container to permit the exit of the tablets, until the quantity of tablets entering the container is the same that the quantity exiting.

Owner:IMA IND MASCH AUTOMATICHE SPA

Packless sealing proportional valve

InactiveCN103759046AEasy flow adjustmentClose tightlyMultiple way valvesValve housingsEngineeringProportional valve

The invention relates to a valve for a pipeline, and in particular to a packless sealing proportional valve. The packless sealing proportional valve is composed of a valve body, a valve rod and a valve core, wherein a charge port and a discharge port are formed in the valve body. The packless sealing proportional valve is characterized in that the valve core is matched with the charge port and the discharge port by conical surfaces, the charge port and the discharge port are provided with sealing bosses, and conical sealing annular surfaces are arranged in the inner holes of the bosses. During the use of the packless sealing proportional valve disclosed by the invention, the charge port and the discharge port are connected with a charge tube and a discharge tube by pipeline joint parts respectively, the flow, opening and closing of the charge port and the discharge port are controlled by a valve rod regulator flow valve core and the valve core, the valve core is matched with the charge port and the discharge port by means of conical surfaces, and the application of a pressure is not required during closing. The packless sealing proportional valve has the advantages of being convenient to regulate flow, tight in closing, long in service life, and the like.

Owner:威海柳道机械有限公司

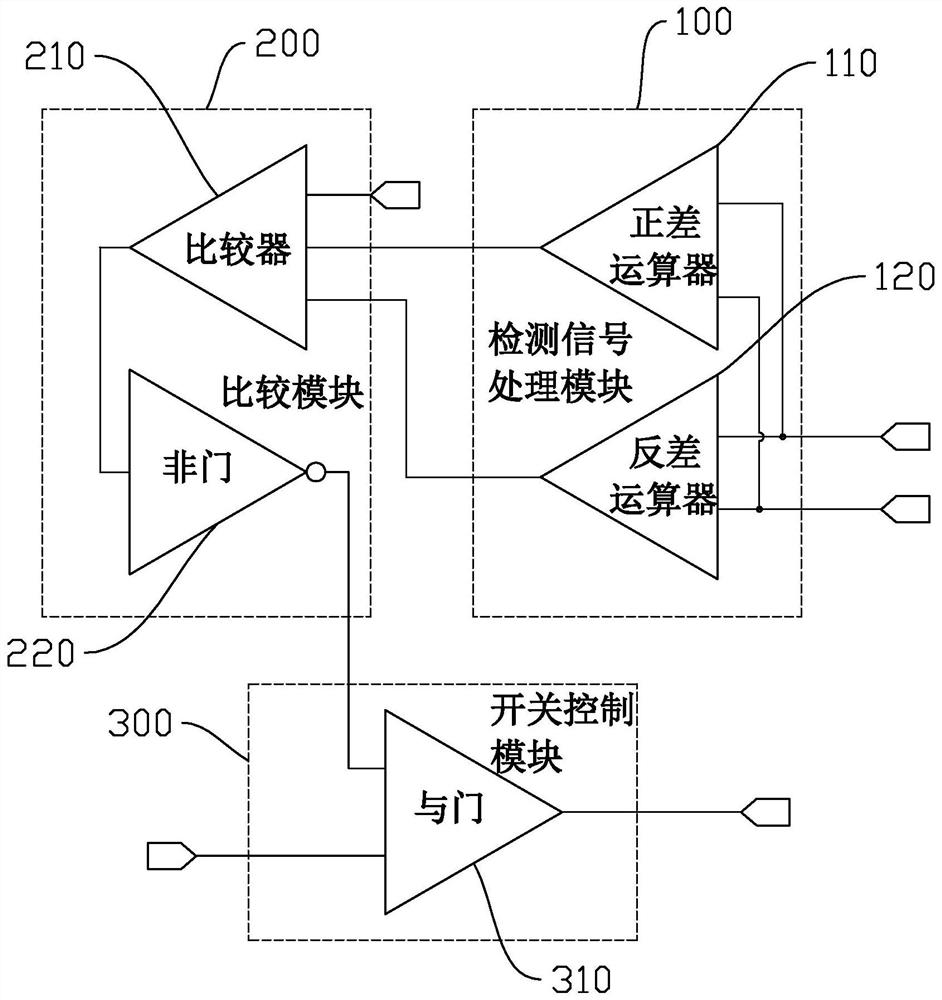

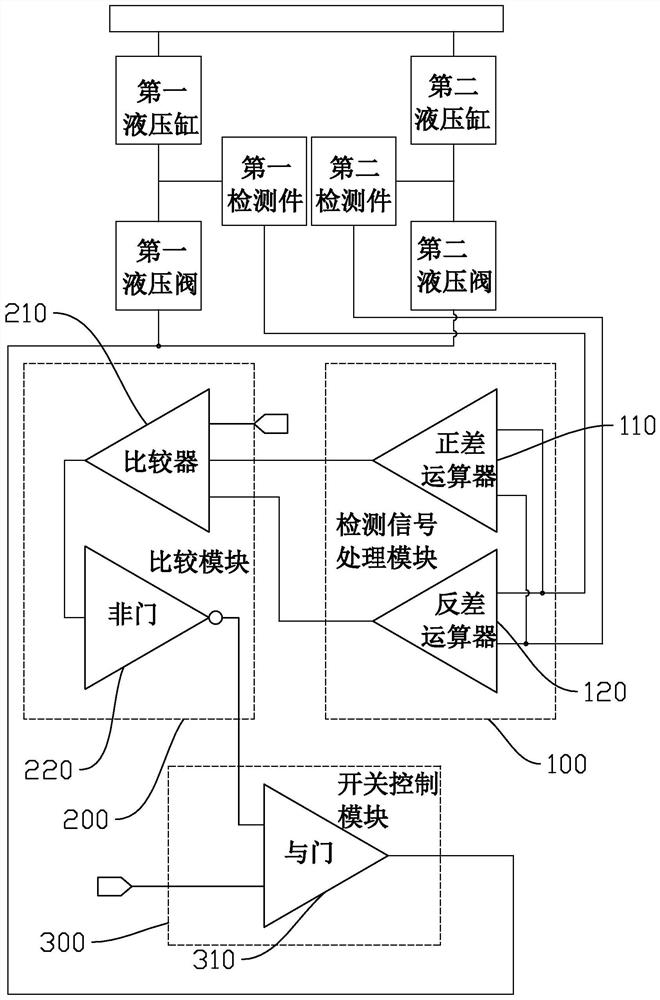

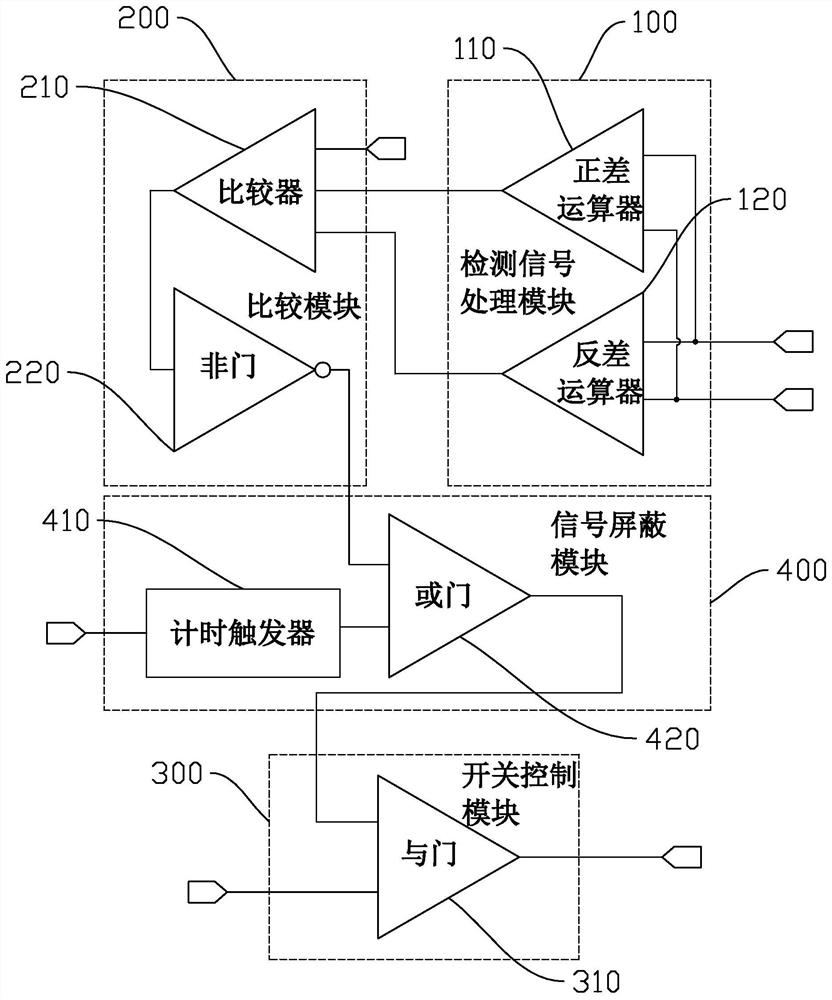

Hydraulic synchronizer protection circuit and hydraulic synchronizer

PendingCN112412905AAvoid load damageAvoid damageFluid-pressure actuator testingServomotor componentsHydraulic cylinderControl signal

The invention discloses a hydraulic synchronizer protection circuit and a hydraulic synchronizer with the hydraulic synchronizer protection circuit. The hydraulic synchronizer protection circuit comprises a detection signal processing module, a comparison module and a switch control module. The detection signal processing module is provided with a first detection signal input end and a second detection signal input end, the comparison module is provided with a calibration value signal input end, the comparison module is electrically connected with the output end of the detection signal processing module, the switch control module is provided with an external control signal input end, the switch control module is electrically connected with the output end of the comparison module, and the switch control module outputs a switch signal of a hydraulic valve. According to the hydraulic synchronizer protection circuit, the state information of hydraulic cylinders of different paths of the hydraulic synchronizer is collected, processed and compared, when the synchronization of the hydraulic cylinders of the different paths exceeds the limit, the work of the hydraulic valve is stopped, andthe hydraulic valve is prevented from being damaged due the load driven by the hydraulic synchronizer.

Owner:XTR SOLUTIONS

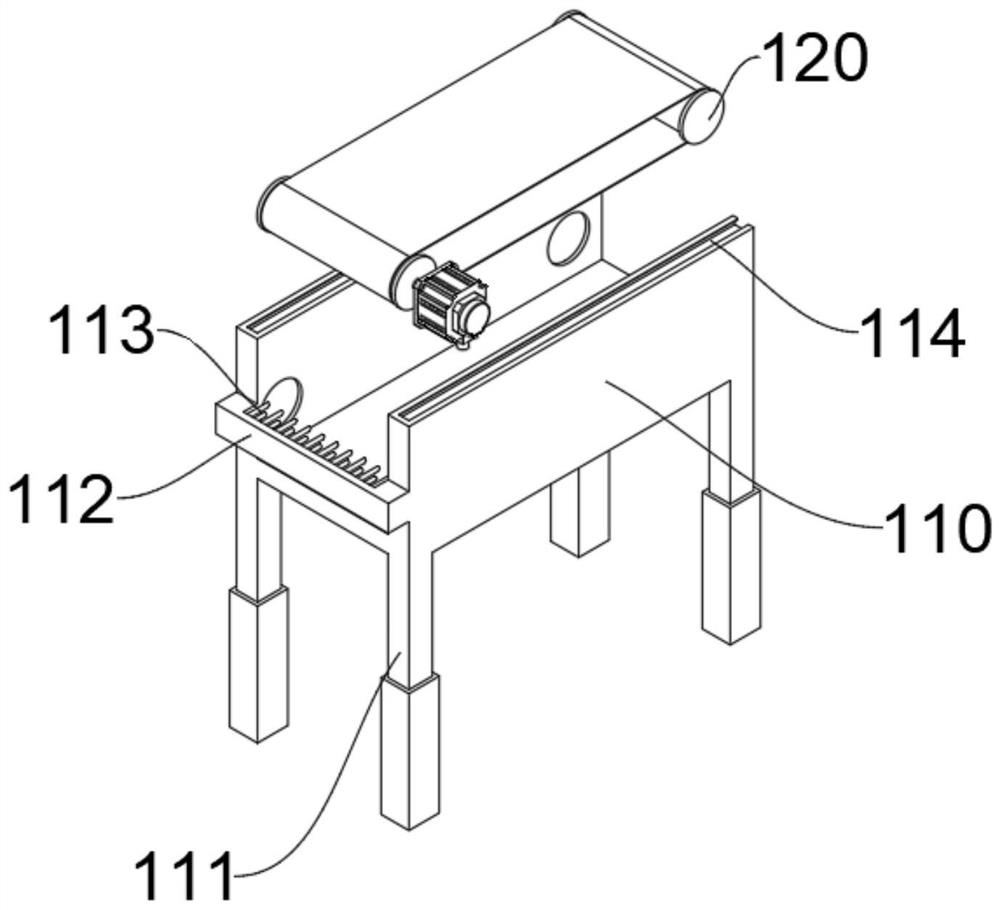

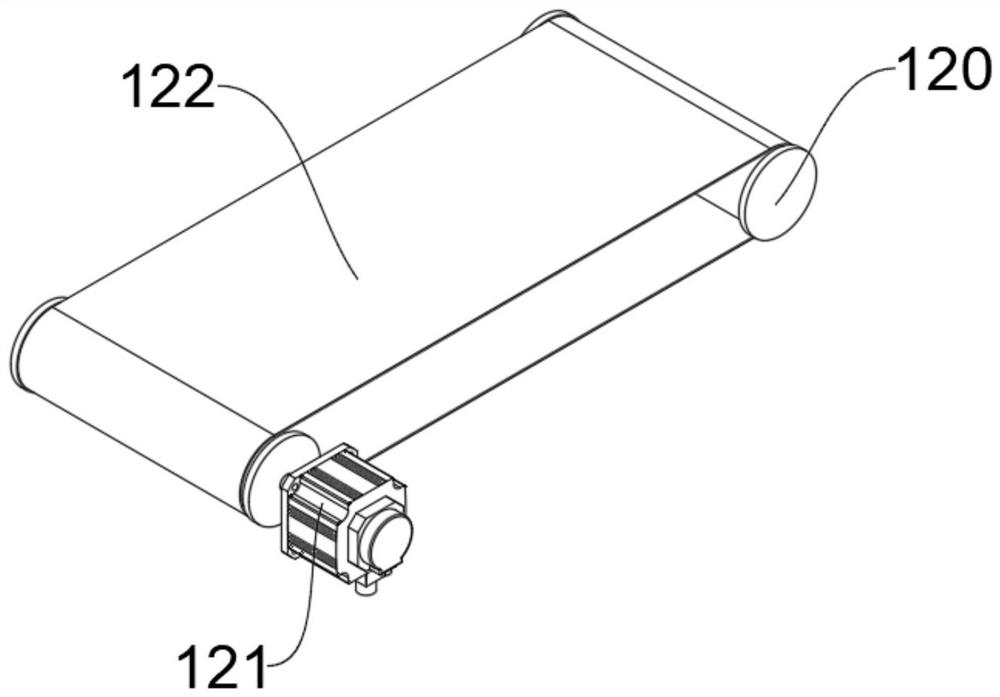

Cement conveying equipment based on quantitative conveying and capable of preventing cement ash from raising dust

InactiveCN112811111AEasy to transportPracticalCleaningLoading/unloadingDust controlElectric machinery

The invention relates to the technical field of cement conveying, and specifically relates to cement conveying equipment based on quantitative conveying and capable of preventing cement ash from raising dust. The cement conveying equipment based on quantitative conveying and capable of preventing cement ash from raising dust comprises a conveyor and a cement conveying mechanism communicating with the end part of the conveyor, wherein the cement conveying mechanism at least comprises a quantitative conveying device and a dust removal device, the quantitative conveying device comprises a conveying box, a discharging port is formed in the outer wall, away from the conveyor, of the conveying box, the end part of the conveying box communicates with the end part of the conveyor, and a spiral conveying rod is rotationally arranged in the conveying box, and the end part of the spiral conveying rod rotationally stretches out of the interior of the conveying box and is connected with a rotating motor; and the dust removal device comprises a collecting box, the collecting box is fixedly arranged at the top of the conveying box, the outer wall of the collecting box communicates with an induced draft fan, the air inlet end of the induced draft fan communicates with a dust suction pipe, the dust suction pipe is in a spiral shape, the end part of the dust suction pipe communicates with a dust suction cover, and the dust suction cover is slidably arranged at the top of the conveyor. According to the invention, cement can be conveyed conveniently, dust can be removed, and the situation that cement dust drifts away and harms health is avoided.

Owner:候若培

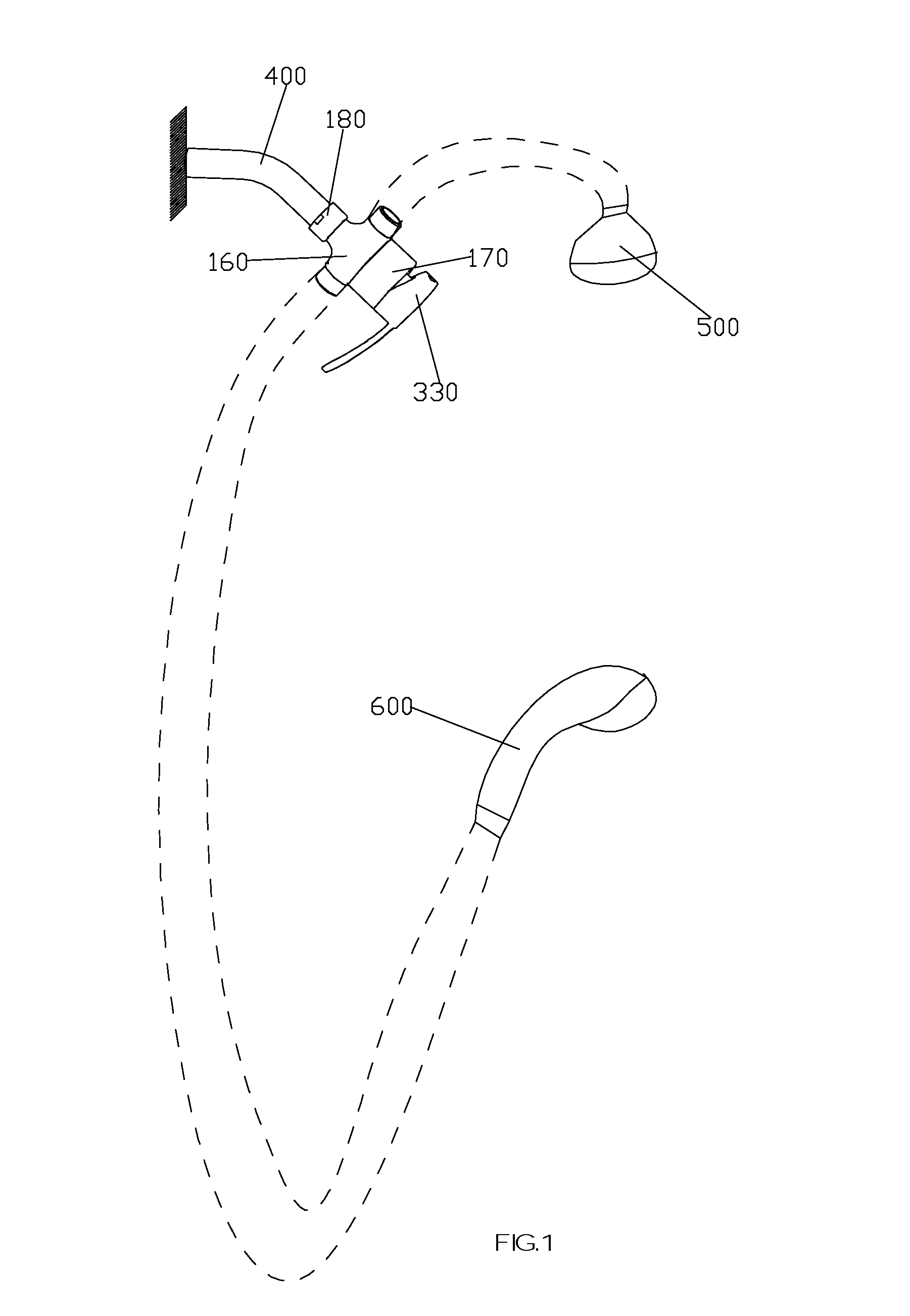

Valve for switching waterways and adjusting flow

ActiveUS20130276927A1Easy flow adjustmentOperation be convenient and fastOperating means/releasing devices for valvesMultiple way valvesEngineeringStreamflow

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

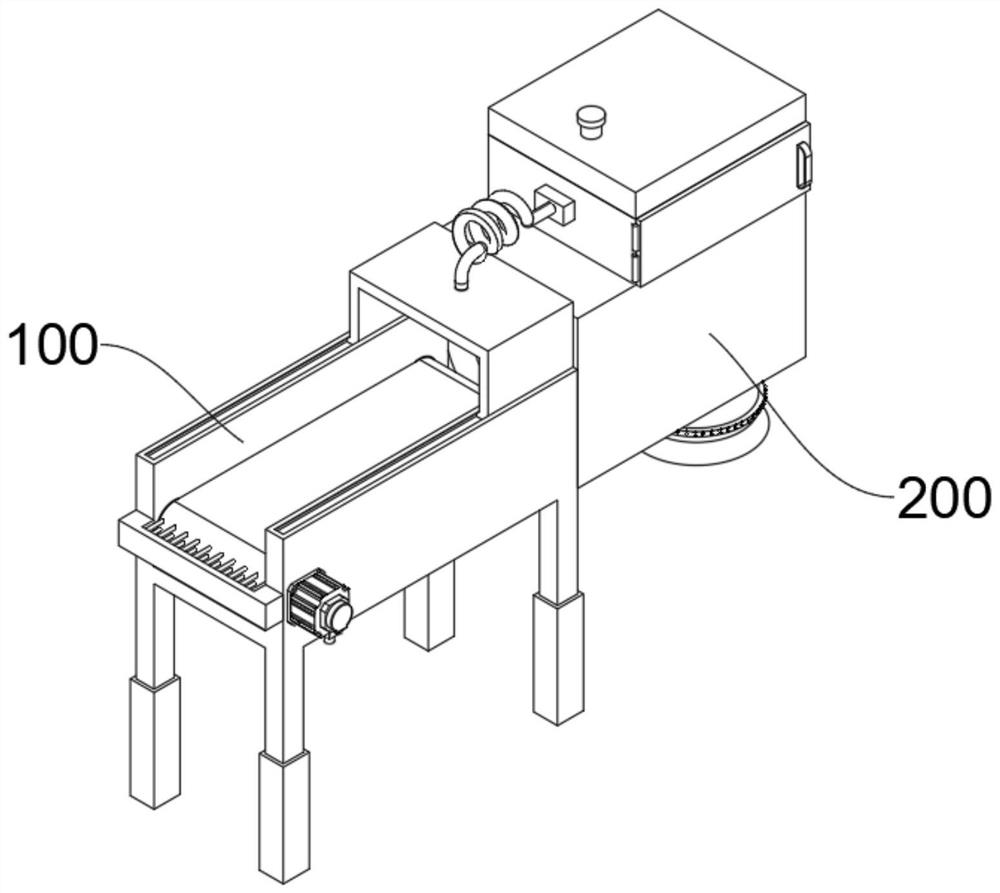

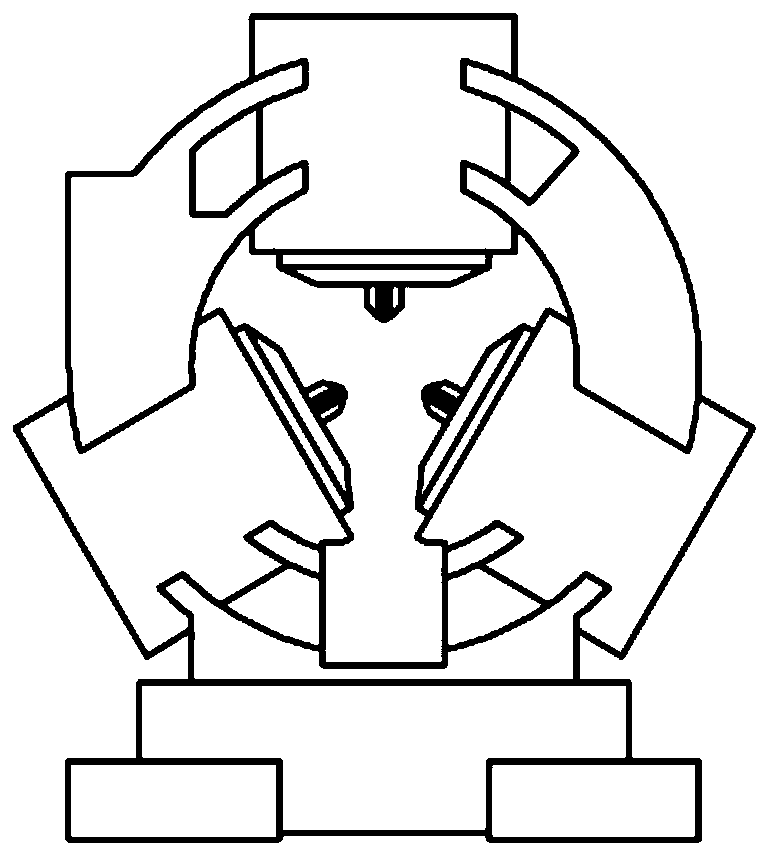

A CNC Rolling Machine Tool for Torsion Shaft Tooth Root Rolling

The invention provides a numerical control tooth root rolling machine tool for rolling machining of the tooth root of a torsion shaft. Rolling machining can be conducted on the tooth root of the torsion shaft by the numerical control tooth root rolling machine tool, and tooth root rolling machining efficiency is improved. The numerical control tooth root rolling machine tool comprises a machine tool main body, a left tip, a tooth root rolling head, a proximity switch, a torsion shaft and feeding mechanism synchronous movement structure, a numerical control indexing rotary table, a hydraulic chuck, a rotary hydraulic cylinder, an auxiliary support, a numerical control system and a hydraulic system. When the tooth root is rolled, the torsion shaft needs to be located and clamped, thereby being clamped tightly by the hydraulic chuck, and meanwhile the torsion shaft is axially located by the left tip. When the tooth root is rolled, indexing of the torsion shaft is needed, and the numericalcontrol indexing rotary table drives the torsion shaft to achieve indexing rotation. Therefore, through the numerical control rolling machine tool, numerical control rolling machining of torsion shaft splines of various models can be achieved, rolling efficiency is improved, and cost is lowered.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

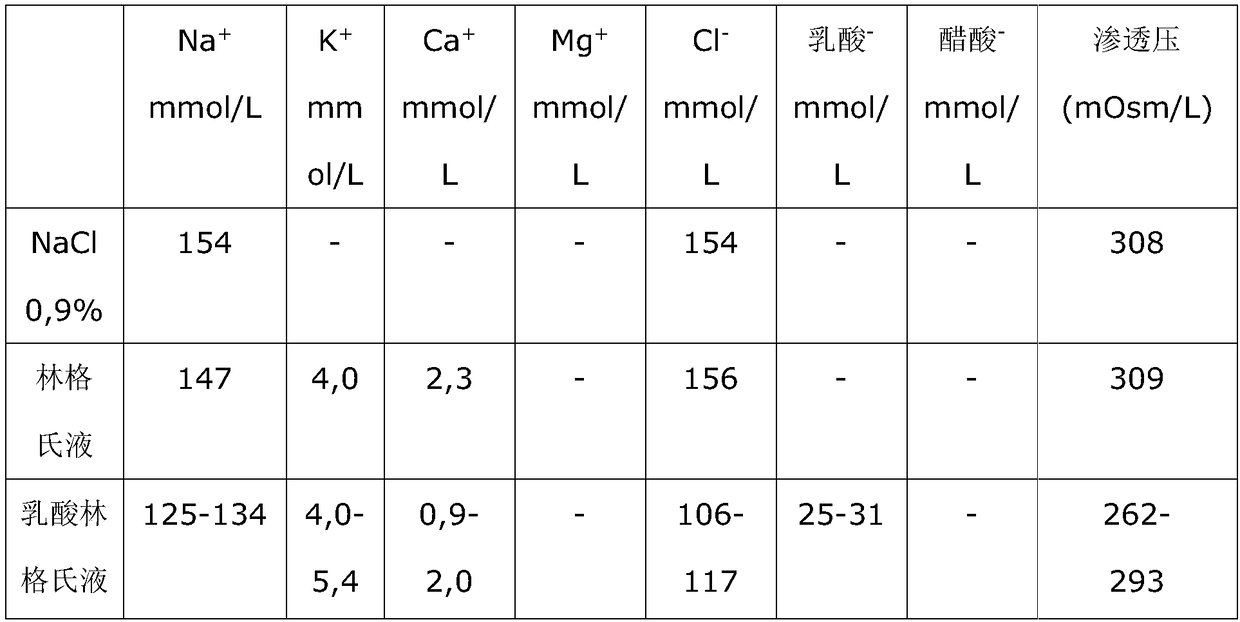

Volume adjustment infusion system and method

InactiveCN108136108APersonalizeConvenient treatmentElectrocardiographyMedical devicesControl cellCatheter

Owner:塞拉瑟姆有限责任公司

Radial variable plunger pump

InactiveCN113266545AEasy flow adjustmentSolve the defect problem of large lateral forcePositive-displacement liquid enginesMulti-cylinder pumpsPhysicsPlunger pump

The invention relates to the field of plunger pumps, in particular to a radial variable plunger pump, which comprises a shell seat, a putting-in opening arranged on the upper end face of the shell seat in a penetrating mode and a pump mechanism arranged on the inner side of the putting-in opening in a sliding mode in the linear direction, wherein the pump mechanism comprises a pump stator, a rotor which is arranged on the inner side of the pump stator and moves along a circular track, and a plunger part which is movably connected between the edge of the rotor and the inner wall of the pump stator, and a transmission shaft part for driving the rotor penetrates through the upper end face of the pump stator and then is connected with external power equipment; and the pump mechanism slides on the inner side of the putting-in opening in the linear direction, so that the eccentric distance between the inner wall of the stator and the rotor is changed, the pulling or pushing distance of the plunger part is changed at the same time, the service life of the plunger pump is prolonged, and flow adjustment is more convenient.

Owner:深圳市科斯腾液压设备有限公司

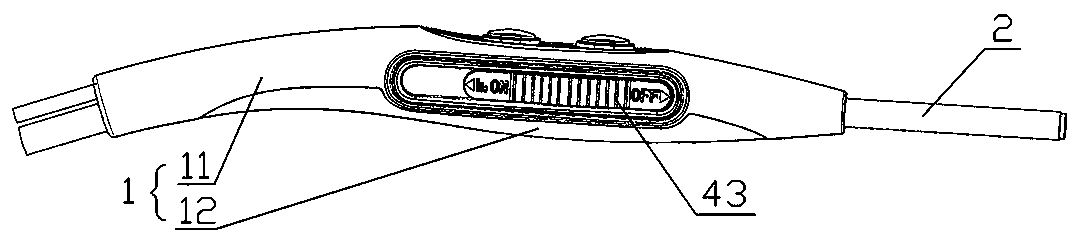

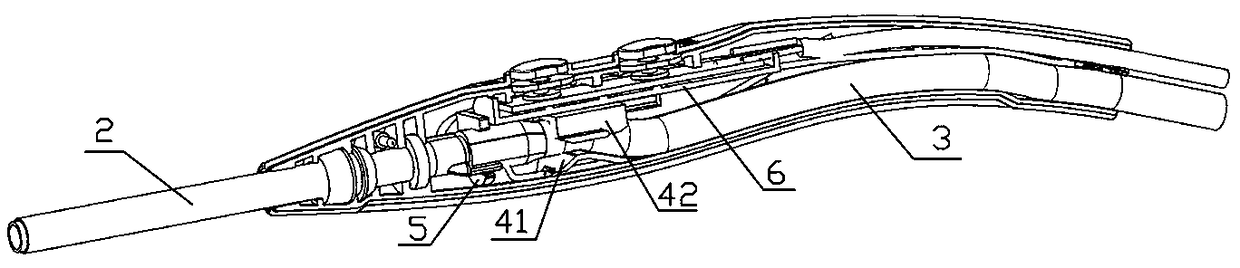

A built-in adjustable flow electrosurgical pencil

ActiveCN106109008BEasy flow adjustmentIncrease in sizeMedical devicesIntravenous devicesElectricityEngineering

The utility model relates to a built-in adjustable flow electrosurgical pen, which belongs to the technical field of medical equipment. The invention comprises a handle and a cutter head. A suction tube is arranged inside the handle. The cutter head part extends into the handle and is connected to the suction tube. There is a flow regulating mechanism to control the flow of the suction tube. The invention has a reasonable structure and is convenient for the rapid adjustment of the smoking flow rate of the electric knife pen, so as to improve the operation efficiency and reduce medical accidents.

Owner:ZHEJIANG SHUYOU SURGICAL INSTR

A CNC Rolling Machine Tool for Torsion Shaft Cylindrical Rolling

ActiveCN108673051BImprove processing efficiencyEasy to operateWork clamping meansPositioning apparatusHydraulic cylinderEngineering

The invention provides a numerically controlled cylindrical rolling machine tool for external rolling processing of a torsion shaft, which comprises a machine tool body, a cylindrical rolling head, a double-center positioning device, a fork connecting piece, an internal spline ferrule, a full A closed protective cover, a displacement measurement system, a precision oil mist cooling system, a numerical control system and a hydraulic system; the cylindrical rolling head of the present invention adopts the structure of a multi-roller symmetrical rolling device. The radial direction is subjected to multiple equal pressures; a displacement sensor is installed in the hydraulic cylinder of the cylindrical rolling head, and the displacement value of the rolling cylinder fed back by the displacement sensor is used to calculate the change value of the rolling diameter during the cylindrical rolling process, which can be Realize the intelligent judgment of the limit position of the outer circle rolling arc end; replace the traditional chuck with the shifting fork connector, optimize the transmission structure, and at the same time make the operation more convenient for workers, more suitable for streamlined production operations, and higher rolling processing efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

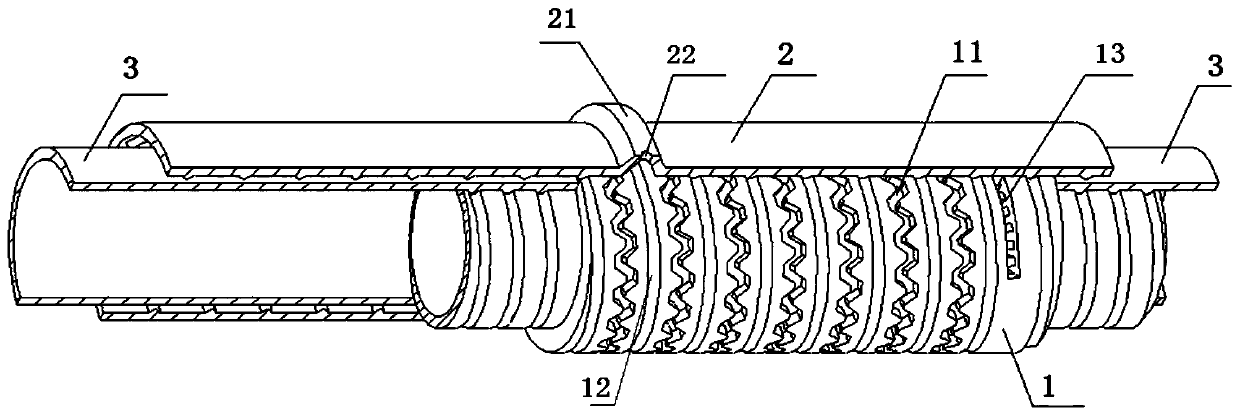

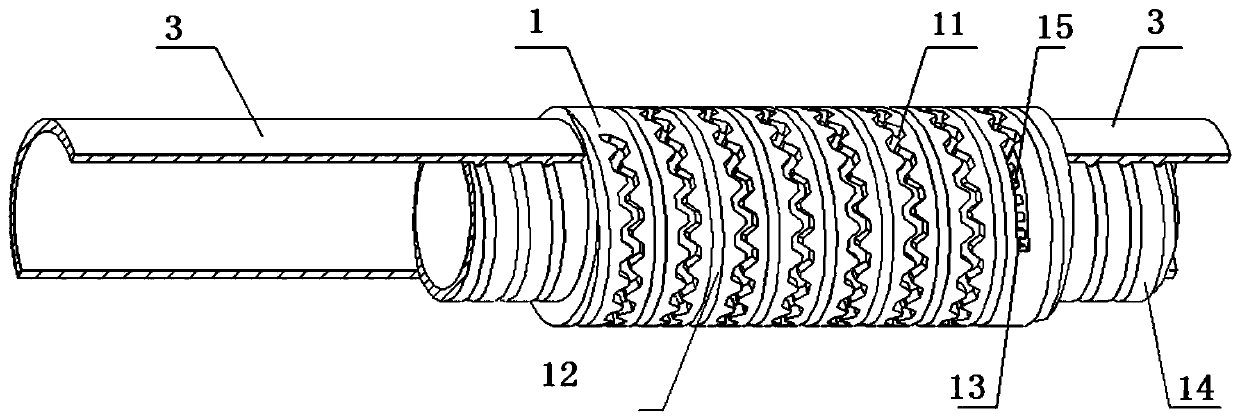

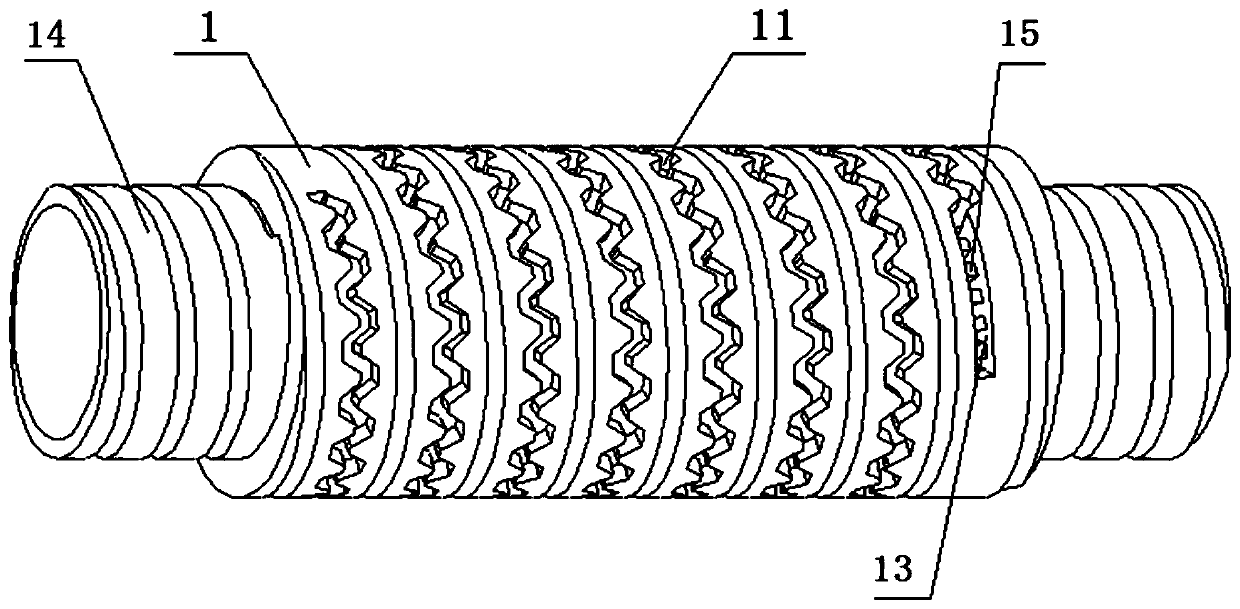

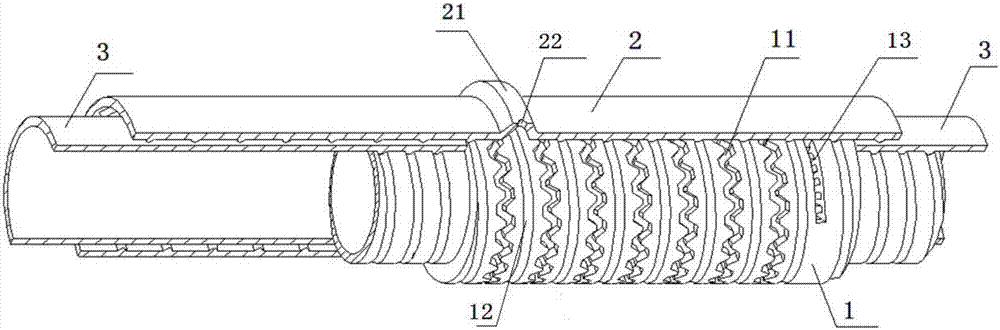

A detachable spiral labyrinth emitter with adjustable flow rate

ActiveCN107347584BEasy to cleanEasy maintenanceWatering devicesCultivating equipmentsEngineeringIrrigation

Owner:CHINA AGRI UNIV

Flow-adjustable detachable spiral type labyrinth emitter

ActiveCN107347584AEasy to cleanEasy maintenanceWatering devicesCultivating equipmentsEngineeringInternal cavity

Owner:CHINA AGRI UNIV

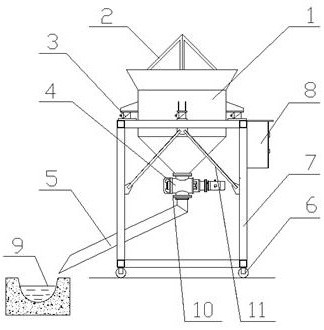

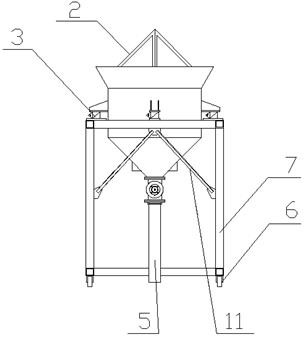

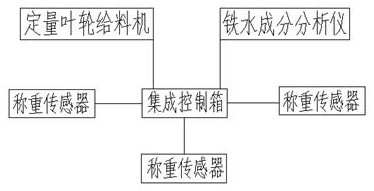

Novel blast furnace stokehole molten iron silicon increasing device

PendingCN112919153ADedicated to precisionAccelerate the efficiency of silicon increaseBags openingLoading/unloadingManufacturing engineeringMechanical engineering

The invention discloses an novel blast furnace stokehole molten iron silicon increasing device which comprises a rack, walking wheels are connected to bottom feet of the rack, the upper end of the rack is connected with a weighing sensor, the weighing sensor is connected with a stock bin, the upper end of the stock bin is open and connected with a triangular frame type cutting knife, and the bottom of the stock bin is connected with a quantitative impeller feeding machine. The quantitative impeller feeding machine is connected with a rotary connecting piece, the rotary connecting piece is connected with a material guiding articulated chute, a cross beam on the upper portion of the rack and a stand column are connected and fixed through a cable-stayed supporting arm, and the side face of the rack is connected with an integrated control box. The novel blast furnace stokehole molten iron silicon increasing device can be moved at will, precisely increase silicon at a fixed point, precisely calculate the silicon increasing amount, reduce the error, and facilitates feeding, the material flow is adjustable, and the labor consumption is reduced.

Owner:临沂玫德庚辰金属材料有限公司

Control method of spraying robot

InactiveCN105562266BEasy to controlEasy to adjustSpraying apparatusSpray coatingAgricultural engineering

The invention discloses a control method of a spray coating robot. According to the method, spray coating flow rate calculation is performed before fixed mold spray coating and movable mold spray coating, so that the spray coating flow rate can be regulated for meeting the mold temperature requirements. The method has the advantages that the automatic and manual switching operation can be performed, and the design is reasonable.

Owner:CHONGQING NEWSTAR TECH CO LTD

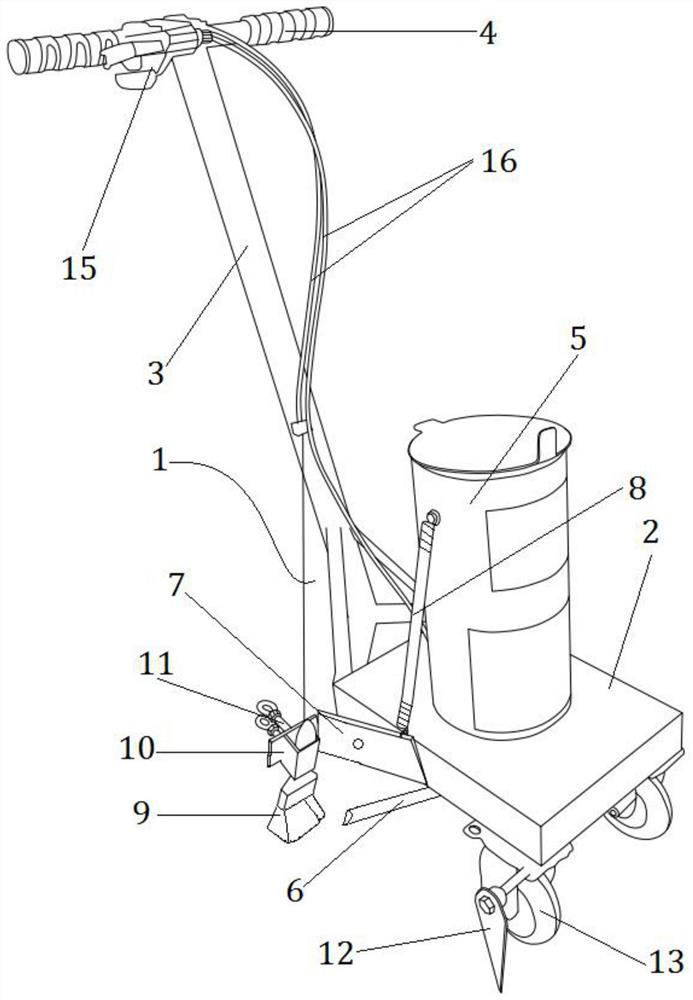

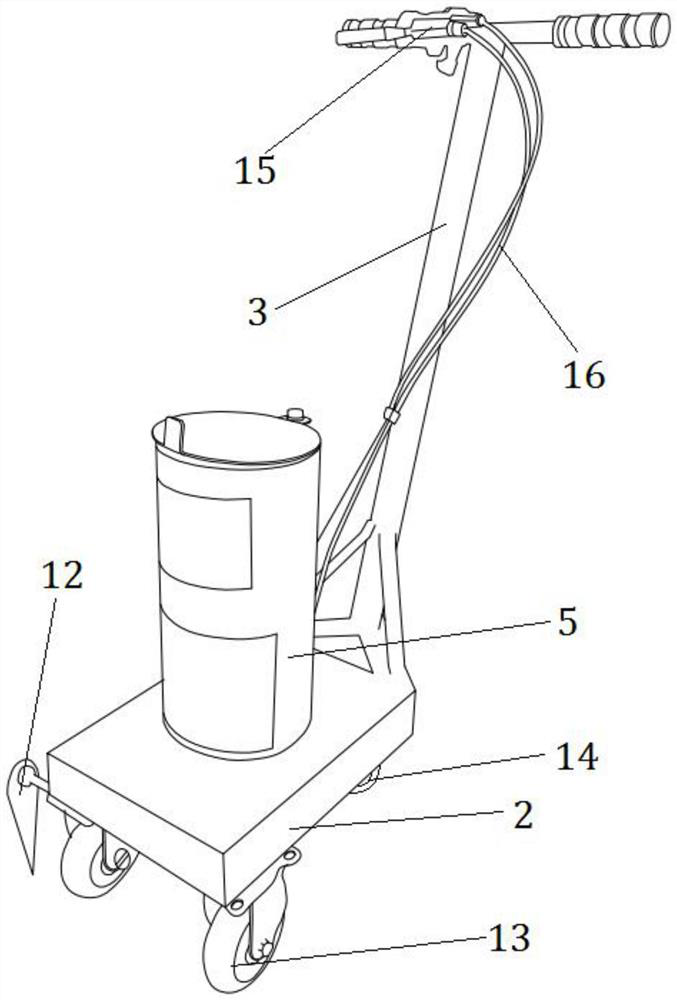

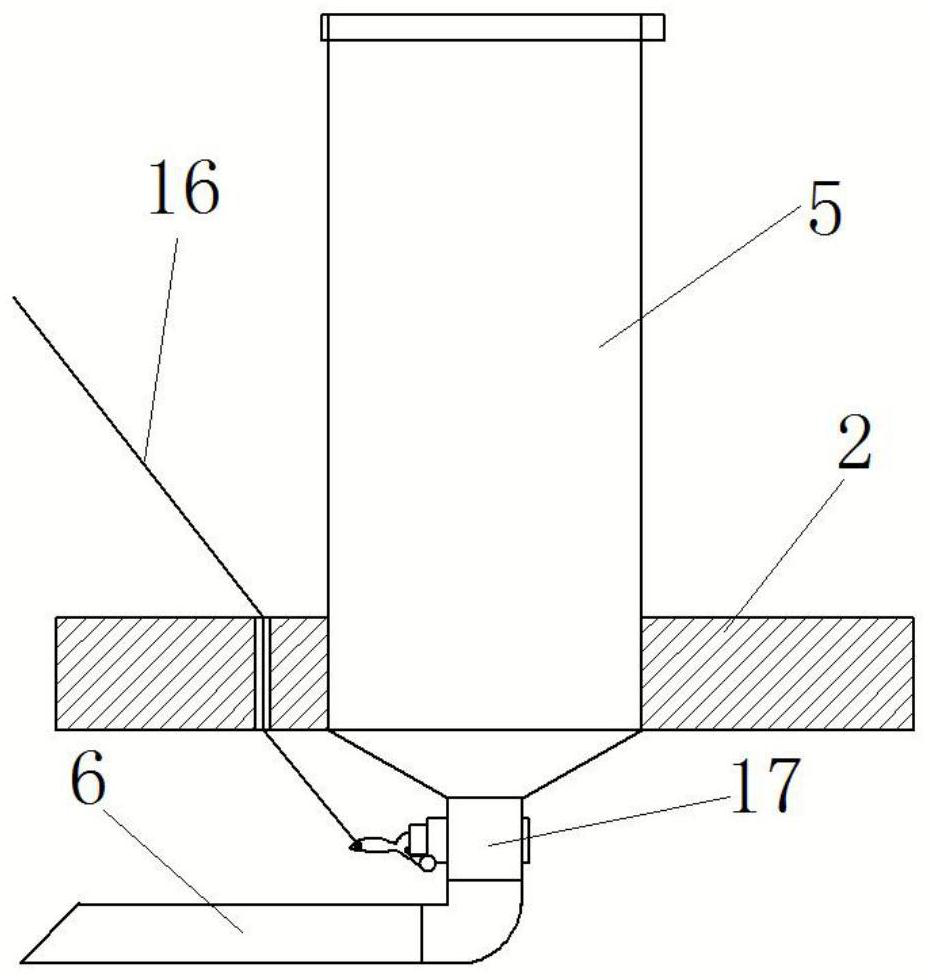

Efficient road surface edge sealing device

PendingCN112832106AEasy flow adjustmentExquisite structureRoads maintainenceEngineeringStructural engineering

The invention discloses an efficient road surface edge sealing device which comprises a vehicle body, a material storage barrel and a coating mechanism, the material storage barrel is arranged on the vehicle body, the bottom of the material storage barrel penetrates through a bottom plate of the vehicle body and communicates with a material scattering pipe through a flow adjusting mechanism, the coating mechanism is arranged on one side of the bottom plate, and the material scattering pipe and the coating mechanism are located on the same side of the bottom plate. The efficient road surface edge sealing device is attractive, straight and smooth in edge sealing construction of joint seams of a road surface, easy to operate, convenient to adjust flow of materials, capable of coating while filling, capable of reducing manual labor, high in practicability, capable of improving working efficiency, simple in structure, convenient to operate, small in investment, attractive in construction effect and capable of meeting construction requirements.

Owner:北京公联洁达公路养护工程有限公司

High-quality insoluble sulfur and method for producing the same

ActiveCN104445087BImprove qualityAvoid cloggingSulfur preparation/purificationChemical/physical/physico-chemical stationary reactorsVapor–liquid separatorSulfur

The present invention provides high-quality insoluble sulfur and a method for producing the high-quality insoluble sulfur by passing sulfur vapor through a gas-liquid separator to remove liquid sulfur before supplying sulfur vapor to a cooler. In the method for producing insoluble sulfur according to the present invention, problems in the production process such as pipeline clogging can be prevented, and high-quality insoluble sulfur with a low sieve residue content (100 mesh 1.5% or less) can be produced. The insoluble sulfur produced by the production method of the present invention is of high quality with an IS (insoluble sulfur to total sulfur) content of 90% or more, a sieve residue of 1.5% or less, an HTS of 71% or more, and a particle size of 5 μm to 30 μm. Insoluble sulfur can therefore be used as a vulcanizing agent in the rubber industry, especially in the manufacture of tires.

Owner:H SULFUR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com