Adjusting ball valve

A ball-regulating and flow-regulating technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as equipment failures, strong resonance of on-site pipelines and other equipment, and hazards to the living environment of surrounding residents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

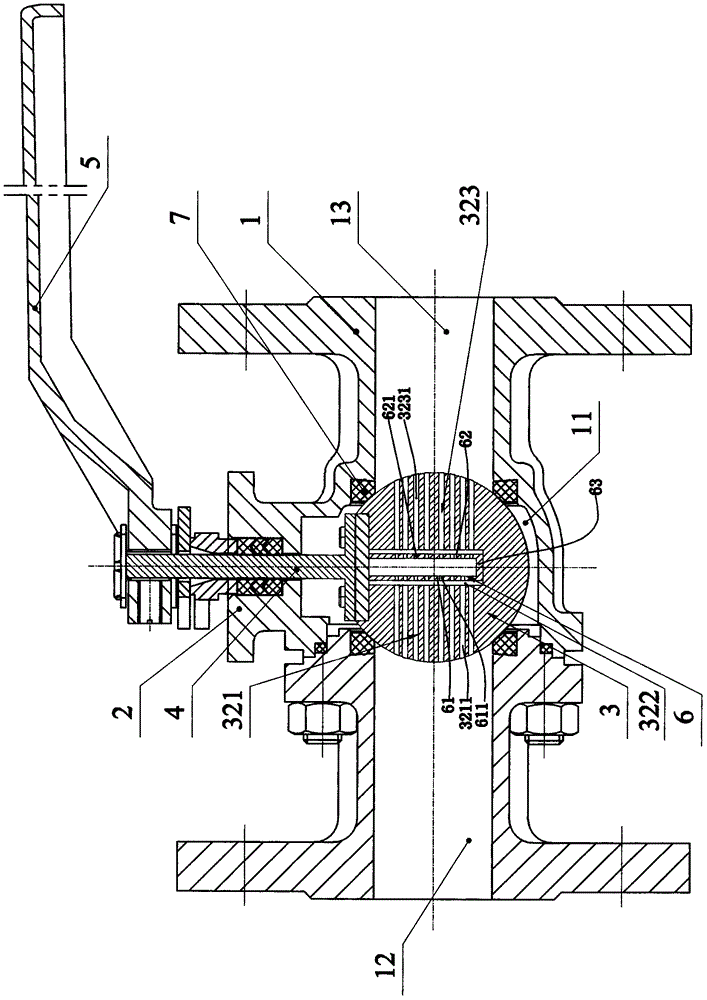

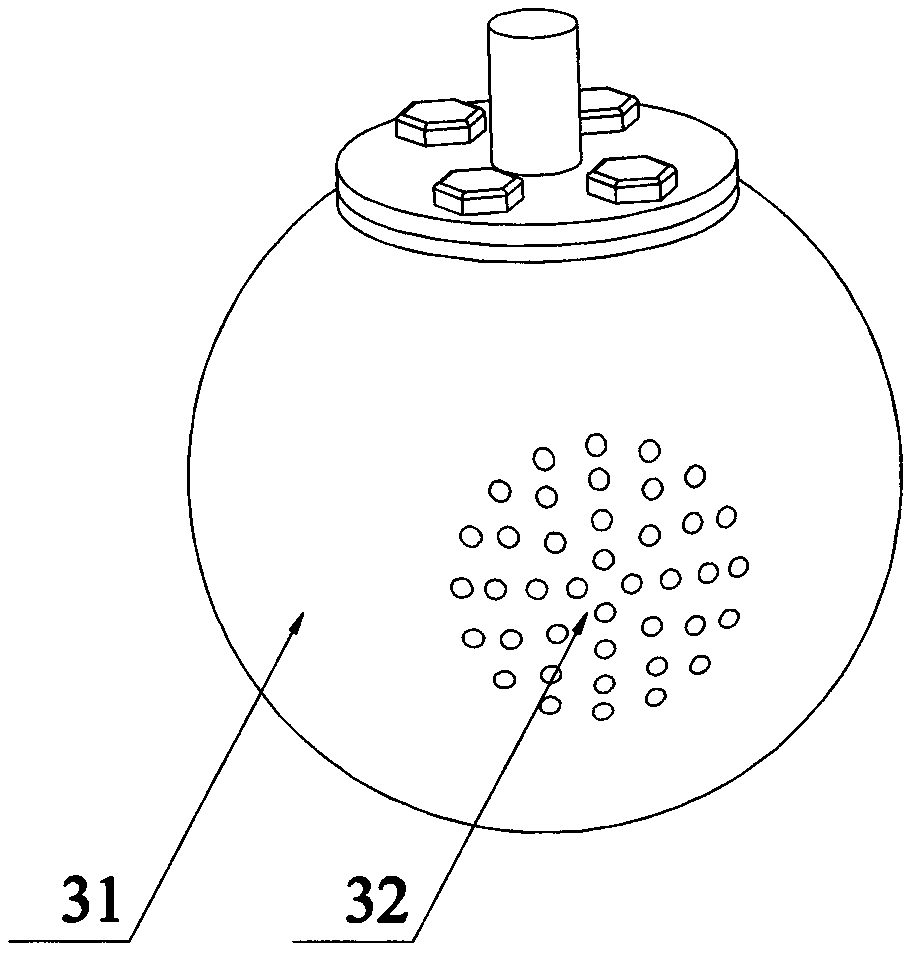

[0043] Such as Figure 1-5The specific embodiment of the present invention shown includes a valve body 1, a valve cover 2, a ball 3, a valve seat 7, a valve stem 4 and a driving mechanism 5 for driving the rotation of the valve stem. The driving mechanism described in this embodiment is a rotating handle .

[0044] The valve body 1 is provided with a valve cavity 11 and a medium inlet 12 and a medium outlet 13 which are connected to the valve cavity 11. The ball 3 is rotatably arranged in the valve cavity 11 and connected with the valve stem 4 in linkage. The sphere 3 described above includes a closing portion 31 capable of closing the medium inlet 12 and the medium outlet 13 and a conducting portion 32 capable of conducting the medium inlet 12 and the medium outlet 13, and the conducting portion 32 includes The inlet is sequentially connected to the conduction entry part 321, the middle through groove 322 and the conduction outflow part 323 in the direction of the medium out...

Embodiment 2

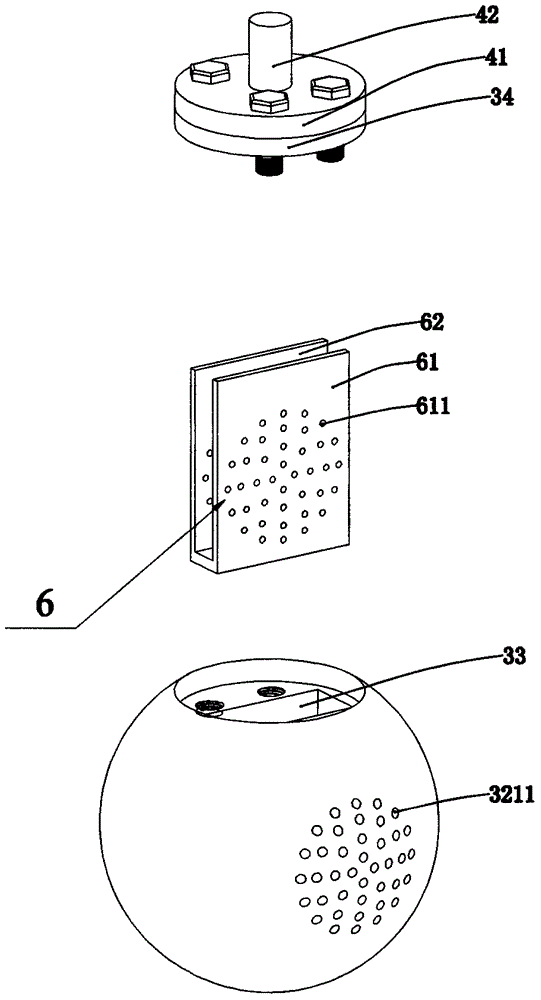

[0050] Such as Figure 6-8 As shown in the specific implementation of the present invention, the difference between this embodiment 2 and embodiment 1 is that: the middle channel 322 is a cylindrical hole, and the flow regulating inner part 6 is fixedly arranged in the cylindrical hole The cylindrical member, the flow regulating inlet hole 611 is horizontally penetratingly arranged on the side wall of the cylindrical member corresponding to the side entering the through hole 3211, and the flow regulating outlet hole 621 is horizontally penetratingly arranged on the cylindrical member corresponding to the On the side wall of the outflow through hole, the inner end of the flow adjustment inlet hole 611 and the inner end of the flow adjustment outlet hole 621 communicate with each other in the inner cavity of the cylindrical member.

Embodiment 3

[0052] Such as Figure 9-10 As shown in the specific implementation of the present invention, the difference between this embodiment and Embodiment 1 is that there is one conduction entry part 321 described in this embodiment, and two conduction outflow parts 323 are provided; the one The conduction inlet portion 321 and the two conduction outflow portions 323 are evenly distributed at 120 degrees on the circumferential surface of the sphere. In addition, the shape of the intermediate channel 322 in this embodiment is a triangular column. Correspondingly, the shape of the flow regulating inner part 6 in the middle channel 322 of this embodiment may preferably be a cylindrical structure with a triangular cross section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com