Large nuclear reactor molten pool natural-convection heat transfer test system and method

A technology of natural convection and nuclear reactor, applied in the field of natural convection heat transfer test system of large nuclear reactor melting pool, it can solve the problem of small Rayleigh number of melting pool and achieve the effect of ensuring water temperature, reducing impact and facilitating flow adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

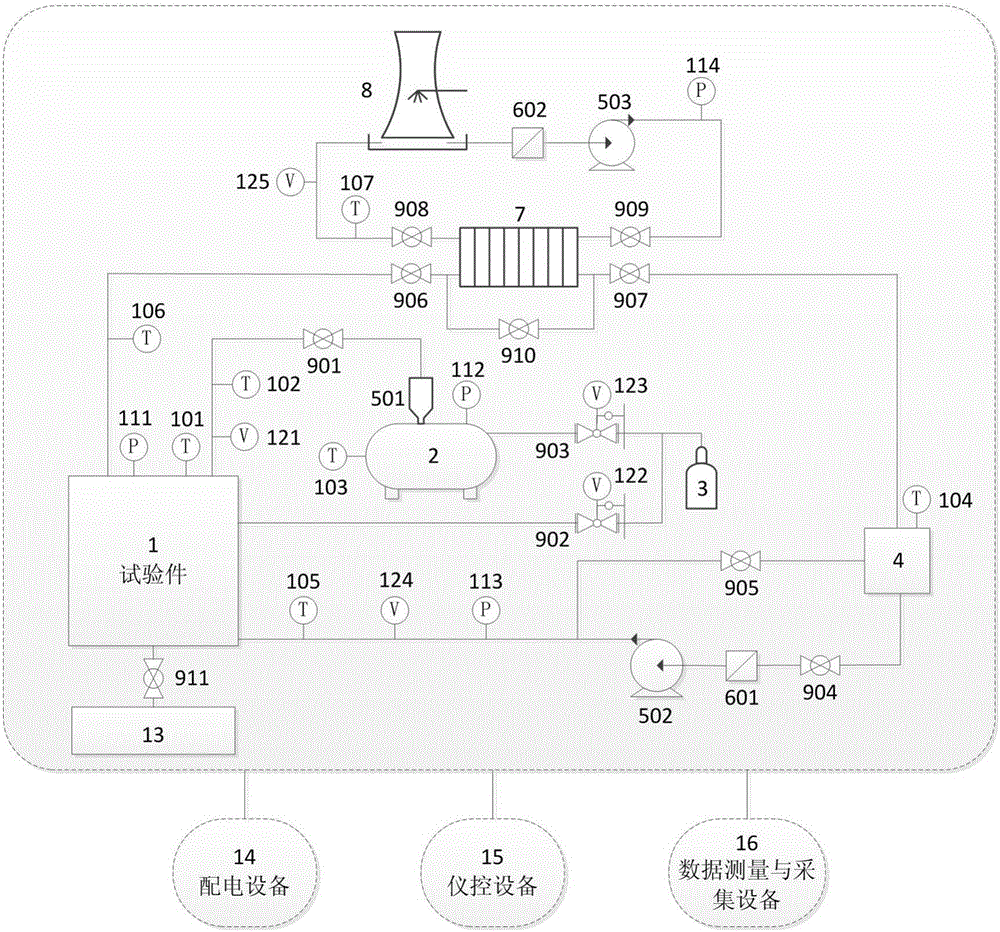

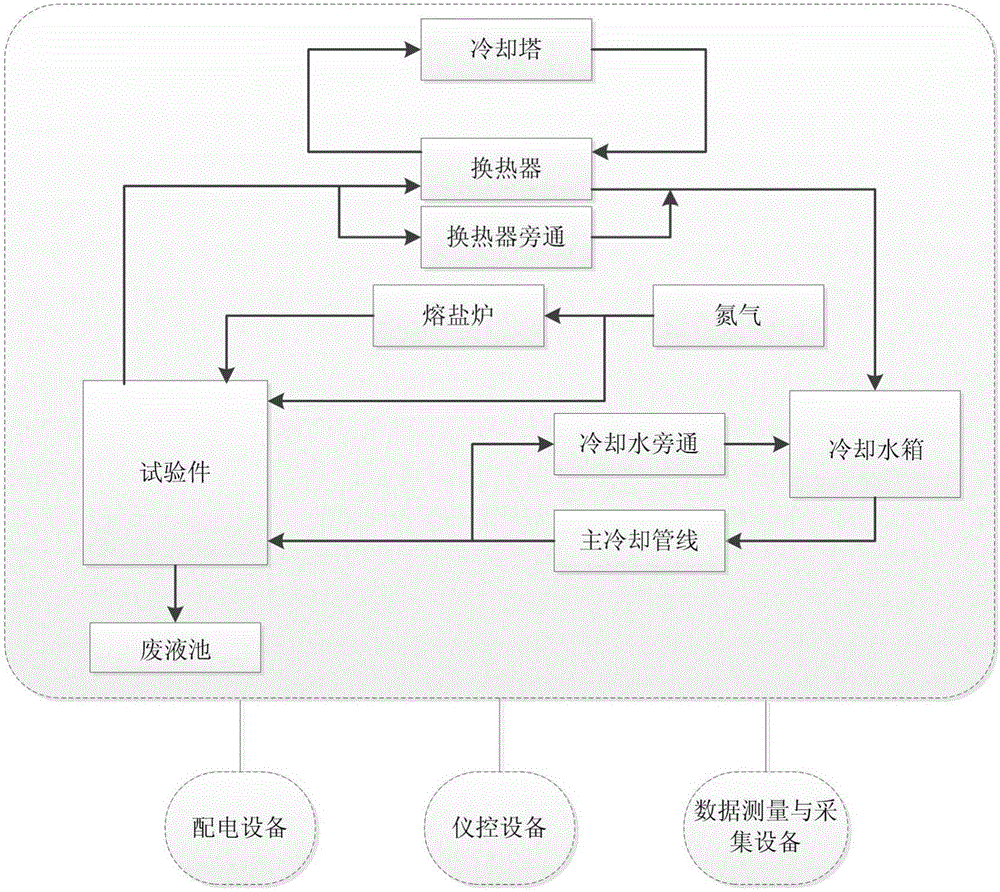

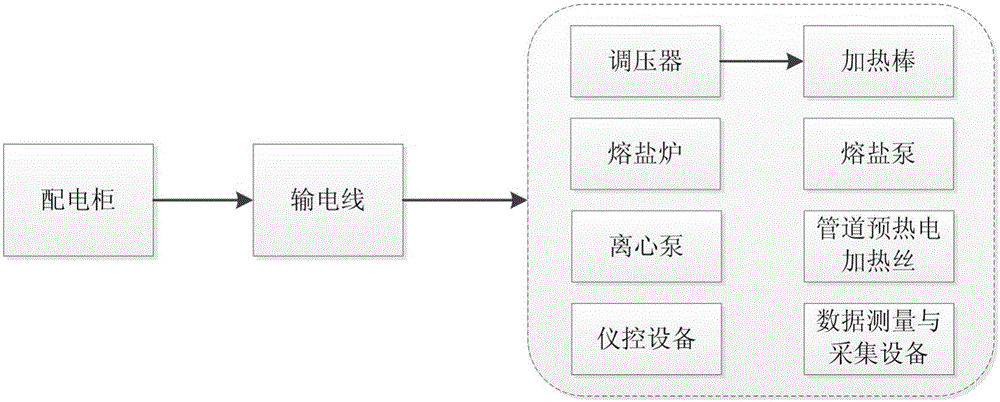

[0028] Such as figure 1 and figure 2 As shown, the present invention is a large-scale nuclear reactor fusion pool natural convection heat transfer test system and method. The test system includes a large-scale nuclear reactor fusion pool natural convection heat transfer test piece 1, a molten salt heating furnace 2 that provides high-temperature molten matter, and The nitrogen source 3 connected to the test piece and the molten salt furnace, and the cooling water system; the first centrifugal pump 502 drives the water in the cooling water tank 4 to take away the decay heat source through the cooling channel of the test piece 1, and the heated cooling water passes through the plate heat exchange Return to the cooling water tank 4 after the cooling of the device 7 and the cooling tower 8 returns to the initial water temperature; the test ends when the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com