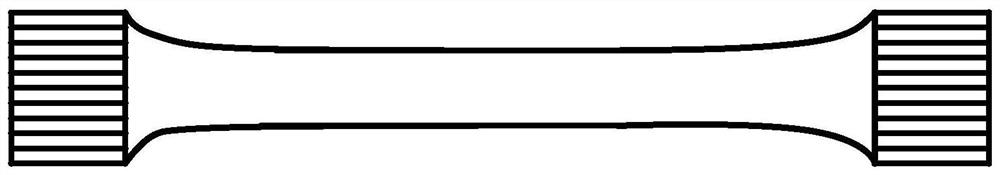

A CNC Rolling Machine Tool for Torsion Shaft Cylindrical Rolling

A torsion shaft and CNC lathe technology, which is applied to metal processing machinery parts, manufacturing tools, positioning devices, etc., can solve problems such as complex structure, large oil pollution, and reduced rolling processing efficiency, and achieve low oil cleanliness requirements , high rolling processing efficiency, and the effect of improving quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

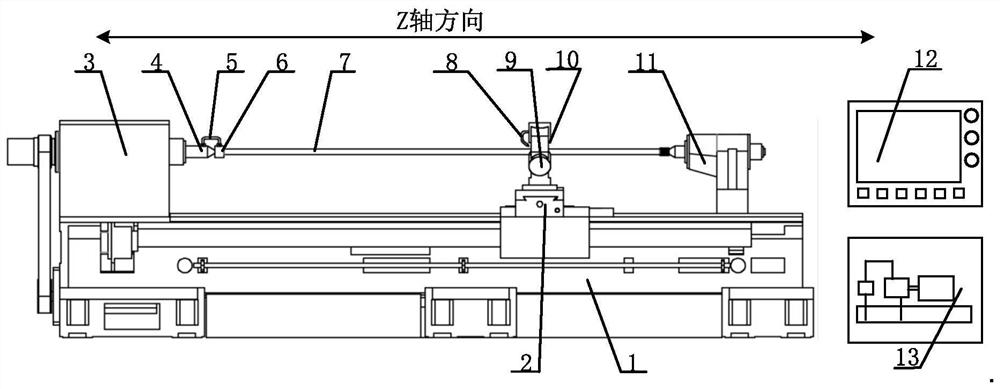

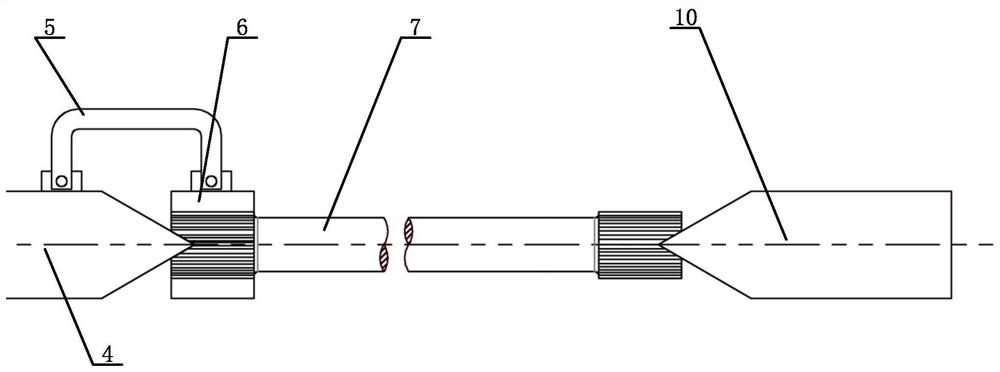

[0025] The torsion shaft numerical control cylindrical rolling machine tool of the present invention carries out numerical control transformation and mechanical structure optimization on the basis of the CK6163 horizontal numerical control lathe. Remove the tool changer on the middle pallet, add the cylindrical rolling head, and install the cylindrical rolling head on the middle pallet by bolting; The torsion shaft rotates synchronously with the main shaft; the displacement sensor is added to realize the intelligent judgment of the extreme positions of both ends of the cylindrical rolling; the hydraulic system is added to provide the rolling force for the cylindrical rolling head.

[0026] like figure 2 As shown in the figure, when the torsion shaft cylindrical rolling process is performed: the left inner center 4 is fixed on the machine tool spindle 3 on the machine tool main body 1 through the connecting mechanism, and rotates synchronously with the machine spindle; the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com