Novel blast furnace stokehole molten iron silicon increasing device

A technology of molten iron and blast furnace, which is applied in the field of silicon-increasing devices for molten iron in front of a new type of blast furnace, which can solve the problems of scattered materials, inability to move, and cumbersome feeding operations in the feeding bin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

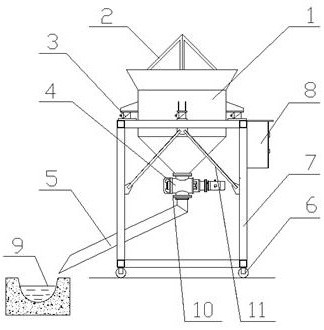

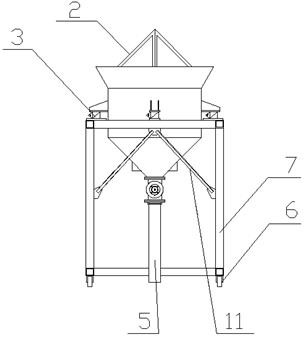

Embodiment 1

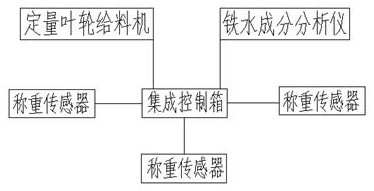

[0032] Using the present invention to increase the iron water in front of the blast furnace, the amount of iron water is 81.6T, and the iron water component analyzer is analyzed. The amount of silicon containing 1.02% in the iron water is 1.75% silicon, 75% silicon iron. The component is Si65.6%, density 3.98t / m 3 , Volume density is 2.5T / m 3 , Granularity <50mm, the target silicon is 1.57%, the target silicon iron is 1.0t, and the bag is used through the car through the triangular cutter 2 to open the bunker 1, ready for the raw material The position of the present invention is adjusted by the travel wheel 6, and the position adjustment is adjusted, the outlet position of the conductive slip 5 is manually adjusted, and the outlet position is positive to the target, that is, the front iron groove 9, the integrated control box 8 The controller is provided, the controller calculates the added silicon iron according to the data of the iron water component analyzer, and the set of...

Embodiment 2

[0034] Based on the above embodiment, the data foundation is changed, and the mounting of the triangulation cutter 2 is performed, and the test data retains two digits after the test data, the test data retains two digits after the test data. Conclusion data As shown in the following table:

[0035] Numbering Iron water Silicon target delivery Target Si content Real silicon Real Si content Total cost of charge after using a triangular cutter 2 Did not use a triangular cutter 2 1 86.00T 0.90T 1.31% 0.90T 1.31% 2.00min 8.00min 2 76.20T 0.90T 1.45% 0.90T 1.45% 2.00min 8.00min 3 82.10T 1.20T 1.45% 1.20T 1.45% 3.00min 10.00min

[0036] It can be seen that the three weighing sensor 3 employed by the present invention simultaneously, the monitoring weight is higher, the accuracy is higher, and the accuracy of the Si amount and the amount of silicon is maintained, so that it remains at very small. Inside the error.

[0037]At the same t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com