High-quality insoluble sulfur and method for producing the same

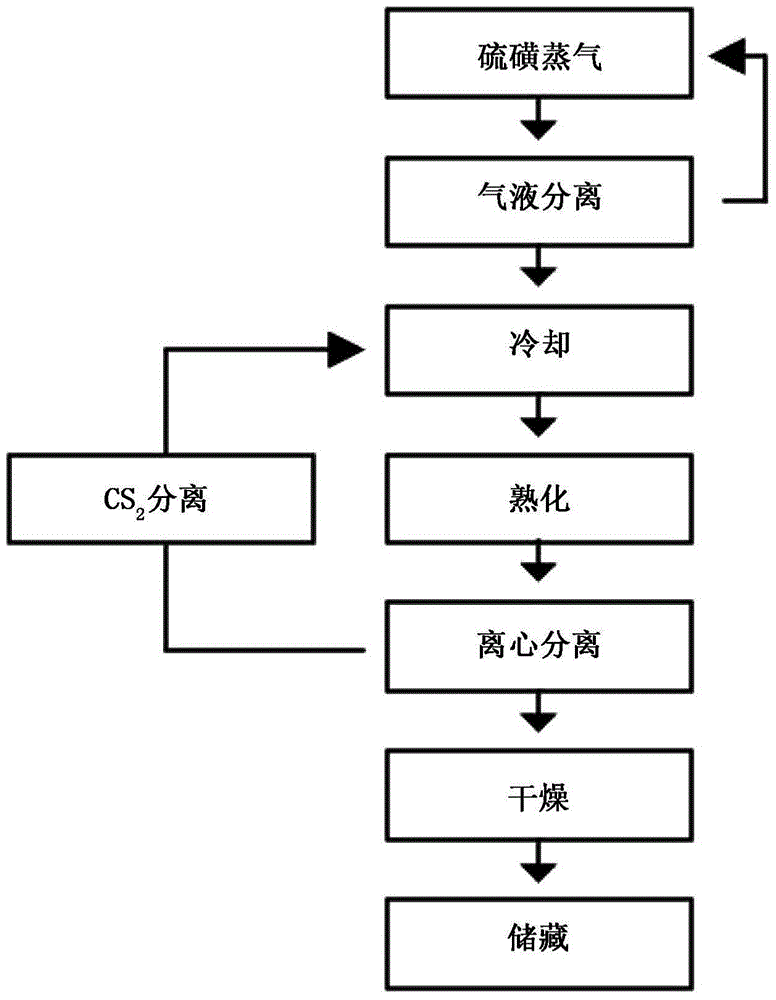

A manufacturing method and technology of sulfur, applied in the direction of sulfur preparation/purification, chemical/physical/physicochemical fixed reactors, etc., can solve problems such as pipeline blockage, difficulty in producing insoluble sulfur, and increased sieve residue content, etc. To achieve the effect of preventing pipe blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

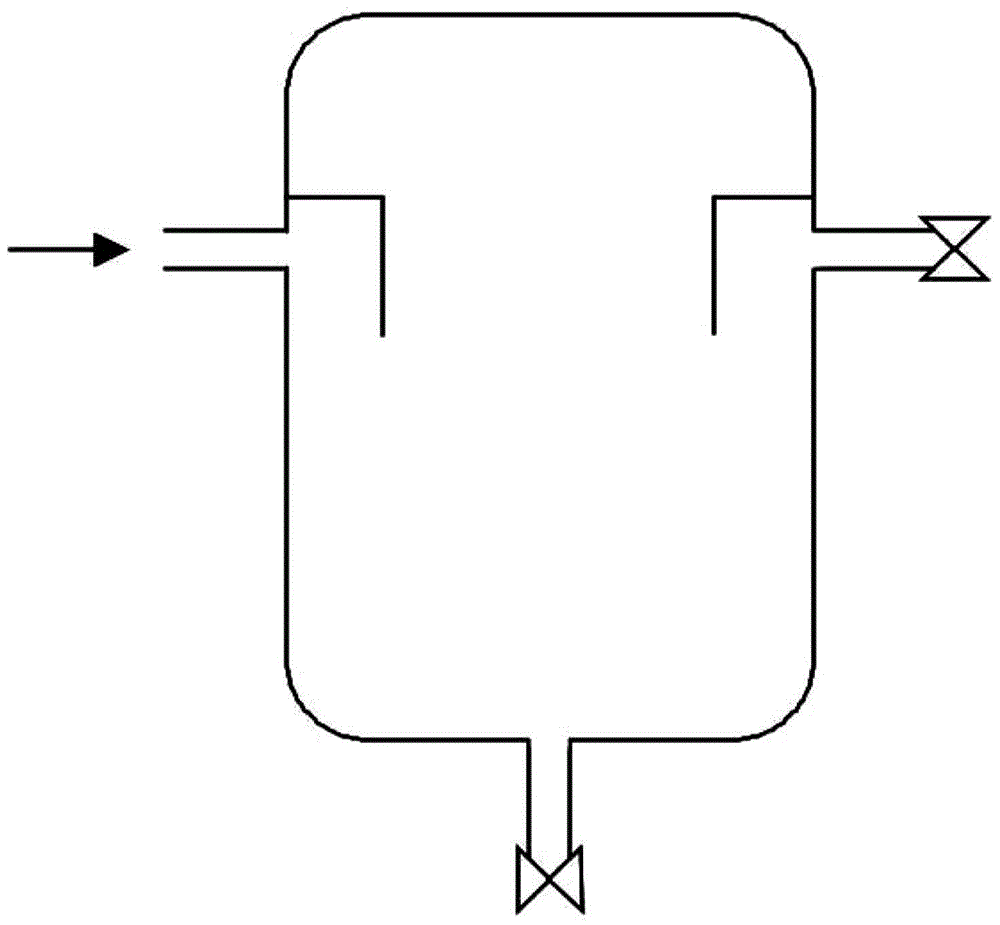

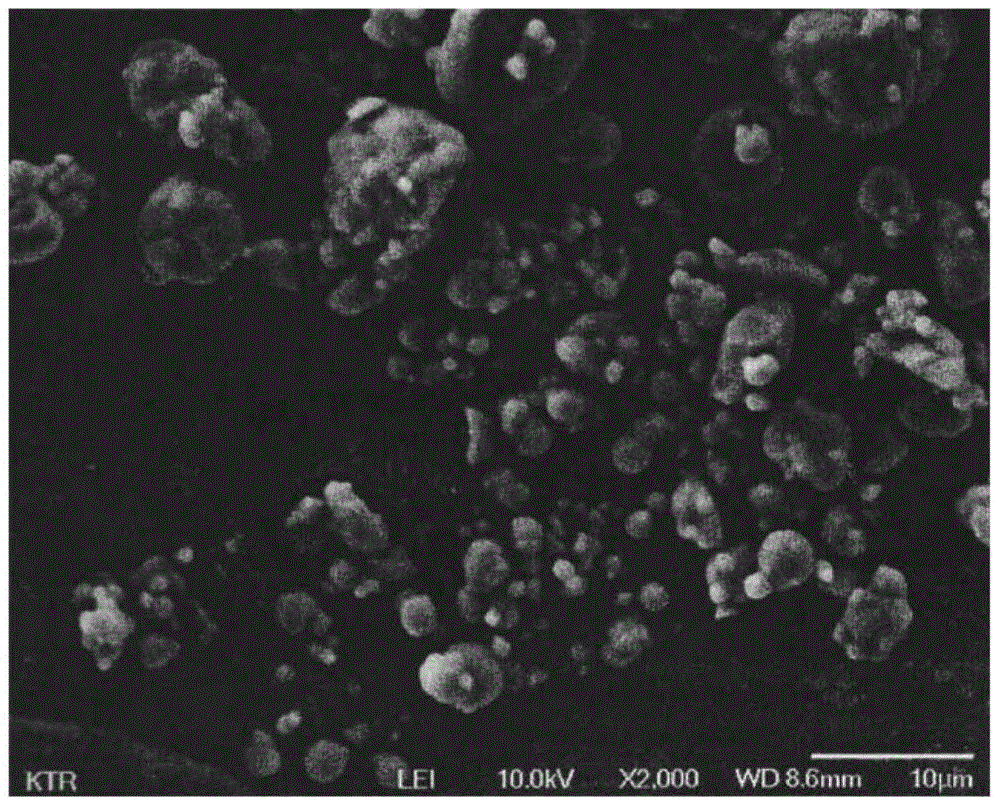

[0075] Sulfur vapor is produced by vaporizing liquid sulfur at about 130°C at about 635°C and supplied to the gas-liquid separator at 9kg / cm 2 maintain until the sulfur vapor is bright yellow (confirmed through the vent) and the liquid collected in the lower part of the gas-liquid separator is a red wine color without impurities, thereby removing sulfur droplets (liquid sulfur) from the sulfur vapor, after which Sulfur vapor was supplied at a flow rate of 500 kg / hr to a cooler filled with about 40% of carbon disulfide at 30° C. to 60° C. for cooling. At this time, the solution was continuously recirculated from the lower part of the cooler to the upper part at 120 tons / hr. The temperature inside the cooler is maintained at 30°C to 60°C and the pressure at 1.0kg / cm by the heat exchanger installed in the recirculation pipe of the cooler 2 ~1.2kg / cm 2 , and the carbon disulfide suspension containing the generated insoluble sulfur was stirred by a stirrer arranged at the lower p...

Embodiment 2

[0087] Sulfur vapor is produced by vaporizing liquid sulfur at about 130°C at about 635°C and supplied to the gas-liquid separator at 9kg / cm 2 Keep it down until the sulfur vapor is bright yellow (confirmed through the vent) and the liquid collected in the lower part of the gas-liquid separator is a red wine color without impurities, so that the sulfur droplets (liquid sulfur) are removed from the sulfur vapor, and then the sulfur vapor is separated into A flow rate of 600 kg / hr was supplied to a cooler filled with about 30% of carbon disulfide at 30° C. to 60° C. for cooling. At this time, the solution was continuously recirculated from the lower part of the cooler to the upper part at 120 tons / hr. The temperature inside the cooler is maintained at 30°C to 50°C and the pressure at 1.0kg / cm by the heat exchanger installed in the recirculation pipe of the cooler 2 ~1.2kg / cm 2 , and the carbon disulfide suspension containing the formed insoluble sulfur was stirred by a stirrer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com