Electronic fuel oil jetting controller and controlling method for double fuel engine

A dual-fuel engine and control method technology, applied in engine control, fuel injection control, combustion engine and other directions, can solve the problems of many moving parts, difficult manufacturing, and high requirements on manufacturing accuracy, and achieve improved control accuracy, good mixing effect, flow rate Adjust for quick effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

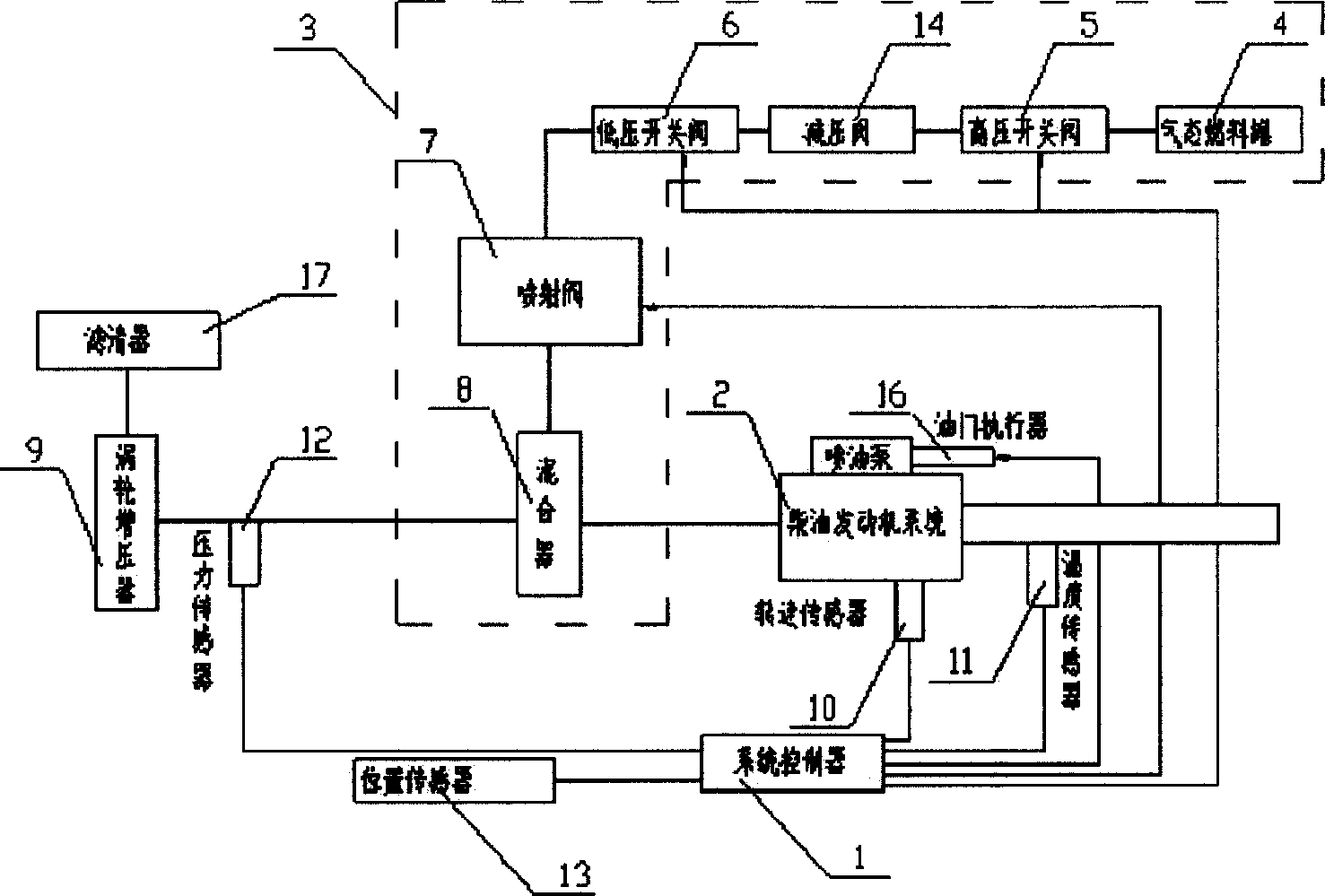

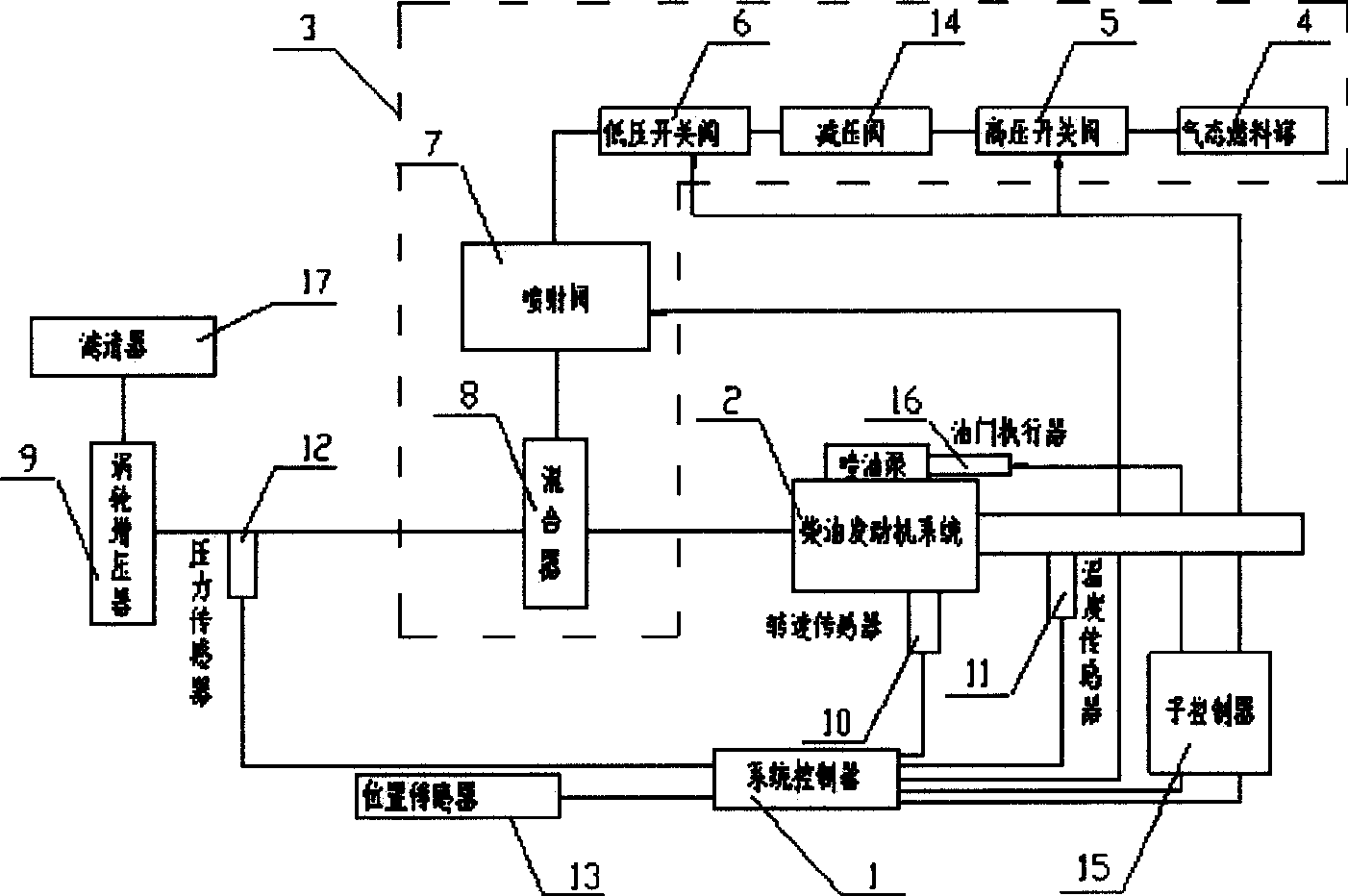

[0014] Embodiments of the present invention: install a set of gaseous fuel supply system (3) and a system controller (1) sold in the existing market on the existing diesel engine system (2), and in the existing gaseous fuel supply system ( 3) A pressure relief valve (14), a low pressure on-off valve (6) and an injection valve (7) are connected in series between the high-pressure on-off valve (5) and the mixer (8), and the system controller (1) preferably adopts The 80196 microprocessor in the prior art is used as the system controller, and the gaseous fuel tank (4) of the gaseous fuel supply system (3) is passed through the high pressure switch valve (5), the pressure reducing valve (14), the low pressure switch valve (6) and the injection valve (7) are connected to the mixer (8), and since a pressure reducing valve (14) is installed in the gaseous fuel supply system (3), the injection pressure of the gaseous fuel can be limited so as to ensure that the gaseous fuel supply syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com