A CNC Rolling Machine Tool for Torsion Shaft Tooth Root Rolling

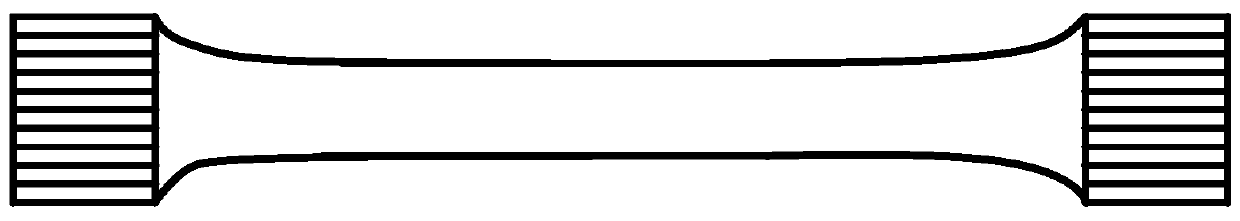

A torsion shaft and tooth root technology, applied in the field of CNC rolling machine tools, can solve the problems of inconvenient operation, large bending deformation, dangerous operation, etc., and achieve the effect of simple air flow adjustment, not easy to bend and deform, and strong safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

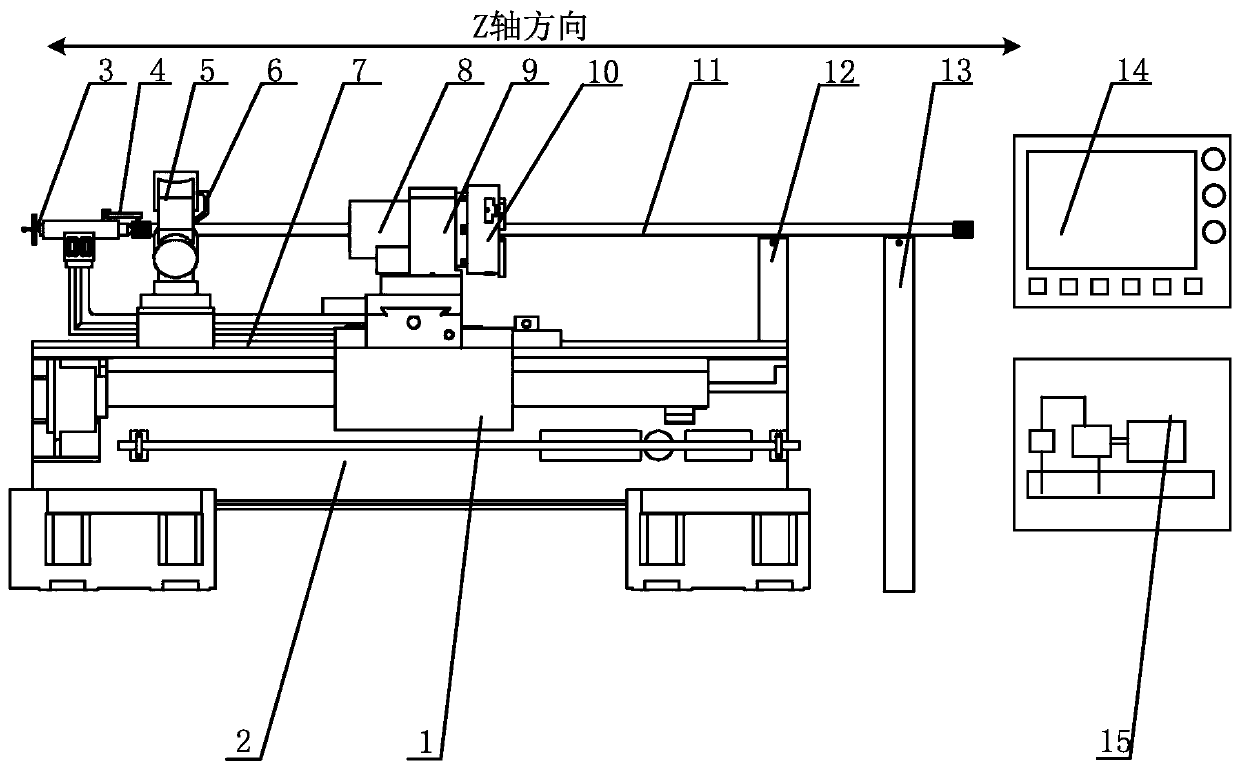

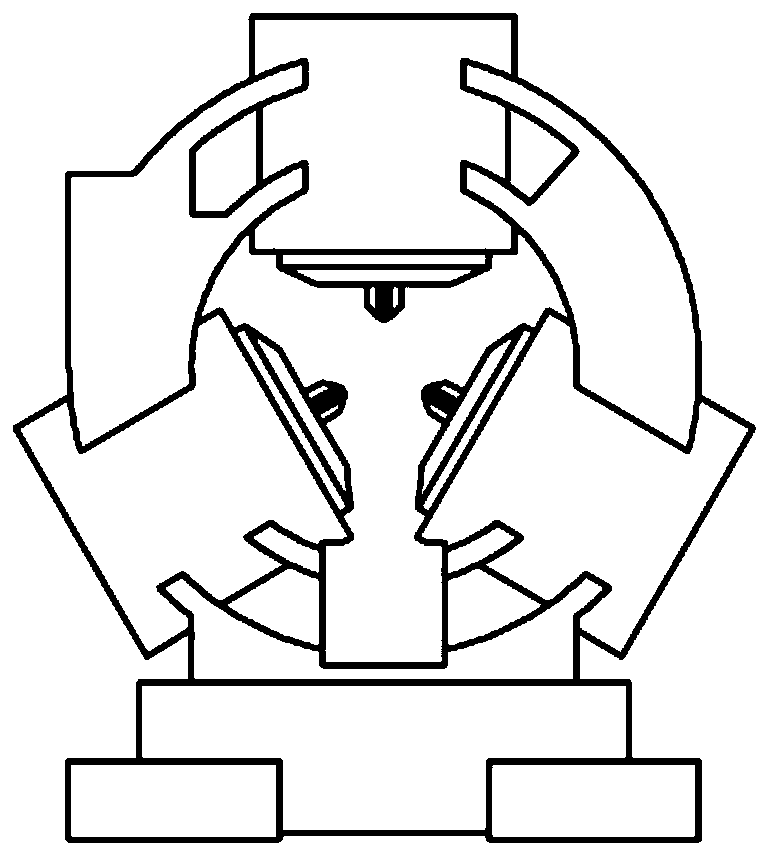

[0024] The torsion axis numerically controlled dedendum rolling machine tool of the present invention is based on the CK6150 horizontal numerically controlled lathe, which carries out numerical control transformation and mechanical structure optimization, removes the left spindle box, adds dedendum rolling heads, It is fixed at the original headstock position by bolt connection; the left top is added to realize the axial positioning of the torsion shaft; the synchronous movement structure of the torsion shaft and the feed mechanism is added to connect the left top with the middle supporting plate, thereby driving the torsion shaft to move axially ; Increase the proximity switch to realize the automatic tool setting of the tooth root of the torque shaft; increase the CNC indexing turntable, and drive the CNC indexing turntable through the numerical control system to realize the indexing rotation; increase the hydraulic chuck and rotary hydraulic cylinder, and control the rotary h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com