Process for formed hydraulic tappet guide cylinder

A hydraulic tappet and process technology, which is applied to metal extrusion dies, engine components, machines/engines, etc., can solve the problems of uneven grain size, segregation and porosity, and poor fatigue resistance of materials. The effect of refining, improving mechanical properties, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

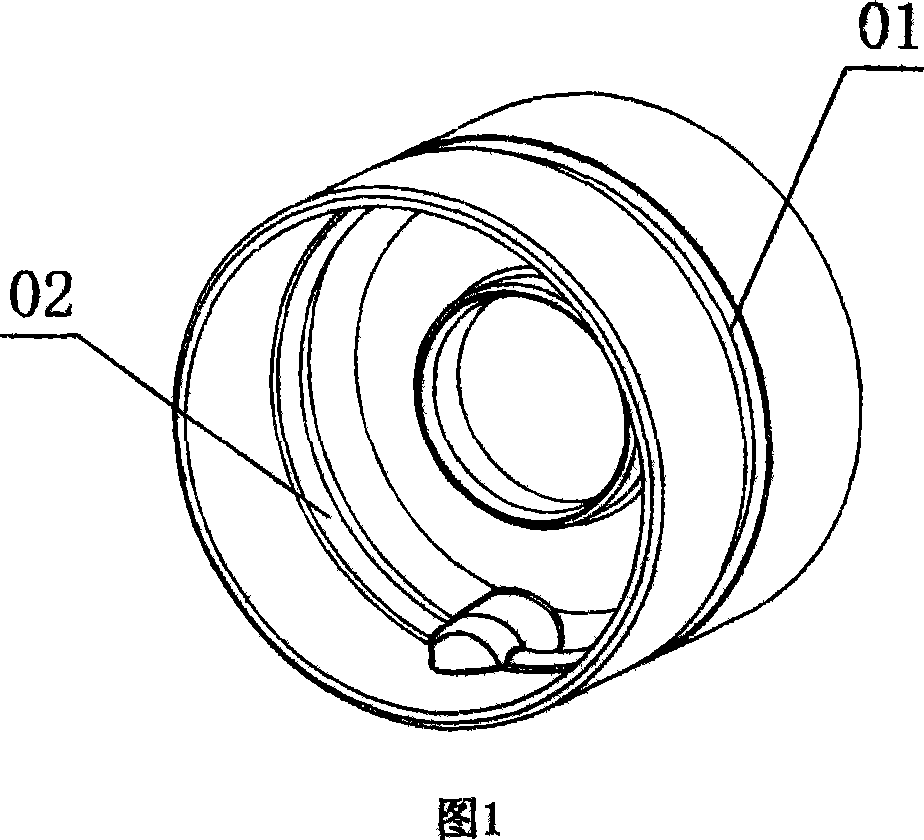

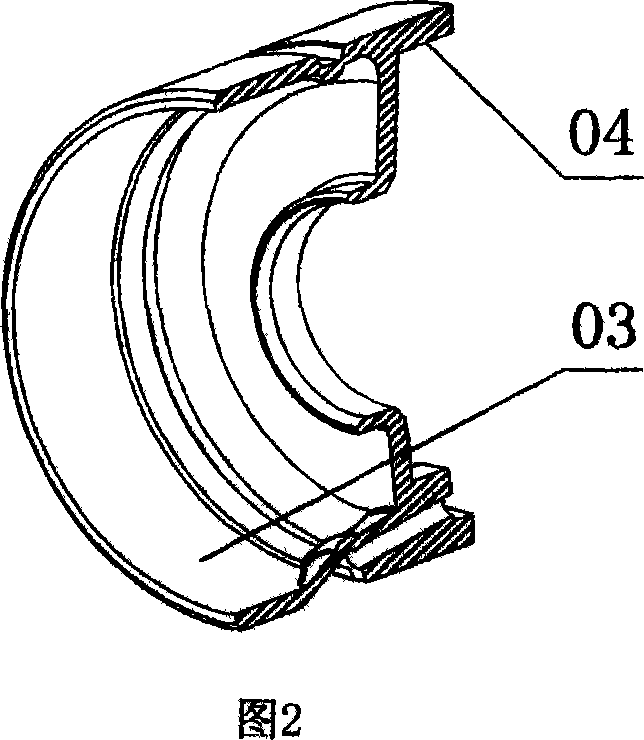

[0014] In the present invention, the bar material and the band saw are cut first, and then the front cavity and the rear cavity with the protruding nose and the core are extruded in the guide cylinder by a warm plastic extrusion process, and then the ring shape is processed by a normal temperature rolling forming process. Oil delivery tank, other dimensions are obtained by machining.

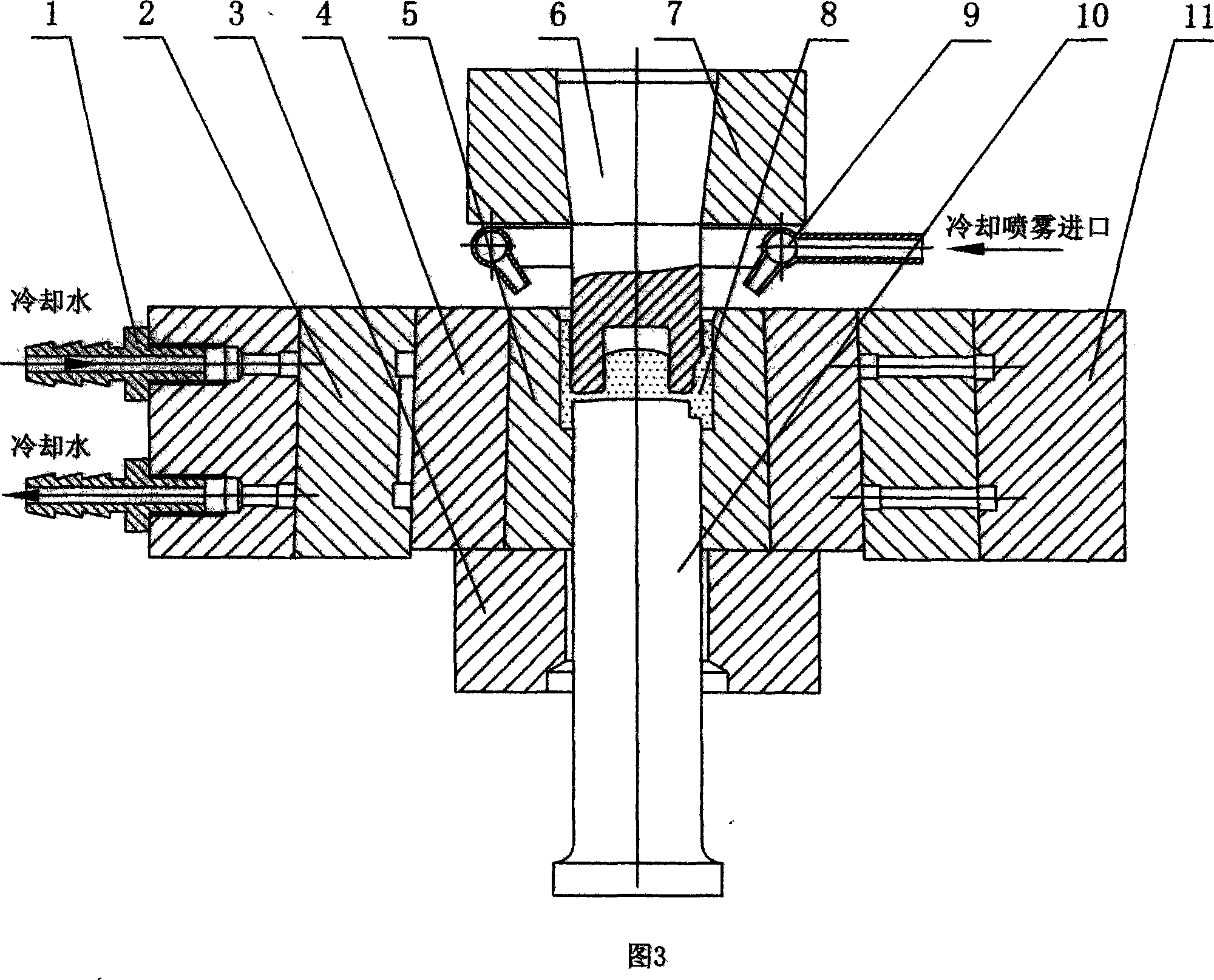

[0015] Referring to Figure 3, there is an annular cooling spray device around the punch of the warm plastic extrusion die, and the water vapor mixed with cooling water and compressed air passes through several nozzles to cool the punch to achieve the best cooling effect. The die adopts a three-layer combined die with pre-tightening force, which can withstand a large unit extrusion force. The concave mold is equipped with an annular cooling channel, through the cooling of circulating water, the mold temperature can be effectively reduced, and the service life and production efficiency of the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com