Camshaft bearing structure for engine

A camshaft and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as unfavorable engine weight reduction and engine compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be specifically described below in conjunction with the accompanying drawings.

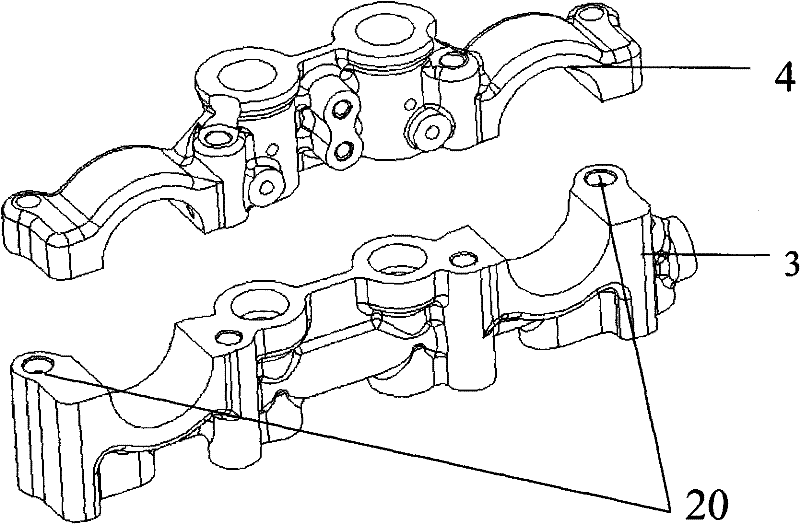

[0029] Such as Figure 5 , 6 As shown, the camshaft bearing assembly consists of a single first camshaft bearing and several identical second camshaft bearings. The lower half bearing of the second camshaft bearing is integrated on the cylinder head 1, and the upper bearing cover 2 of a separate or integral frame type is used. The independent first camshaft bearing is divided into upper and lower bearing caps 4 and 3, and the front end of the cylinder head is provided with a mounting boss. The upper and lower covers of the first camshaft bearing are positioned by two sets of positioning sleeves 5, and the fastening bolts 6 pass through the positioning sleeves. 5. Fasten the upper and lower bearing caps on the cylinder head.

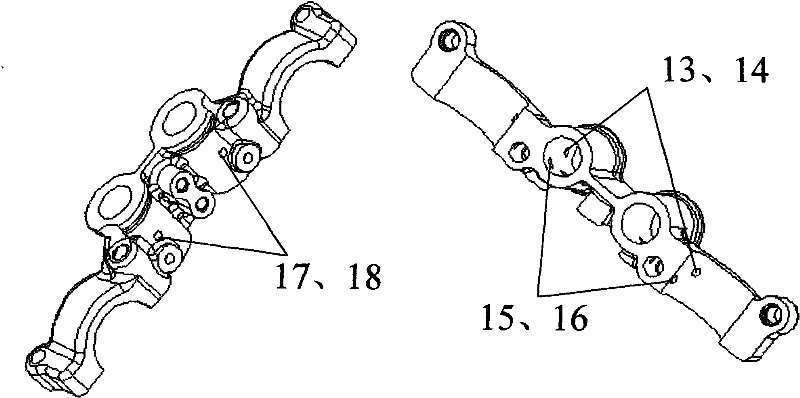

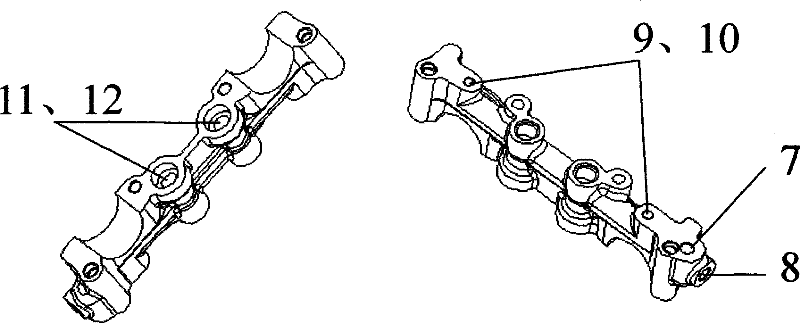

[0030] Such as Figure 2-4 As shown, there are oil passages arranged in the upper and lower covers of the first camshaft bearing, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com