Camera lens

A camera lens and lens technology, applied in the field of camera lenses, can solve the problems of bulky, bulky, inconvenient operation and carrying of smartphones, and achieve the effects of avoiding process processing, good image quality, and reducing the size of the front end of the lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

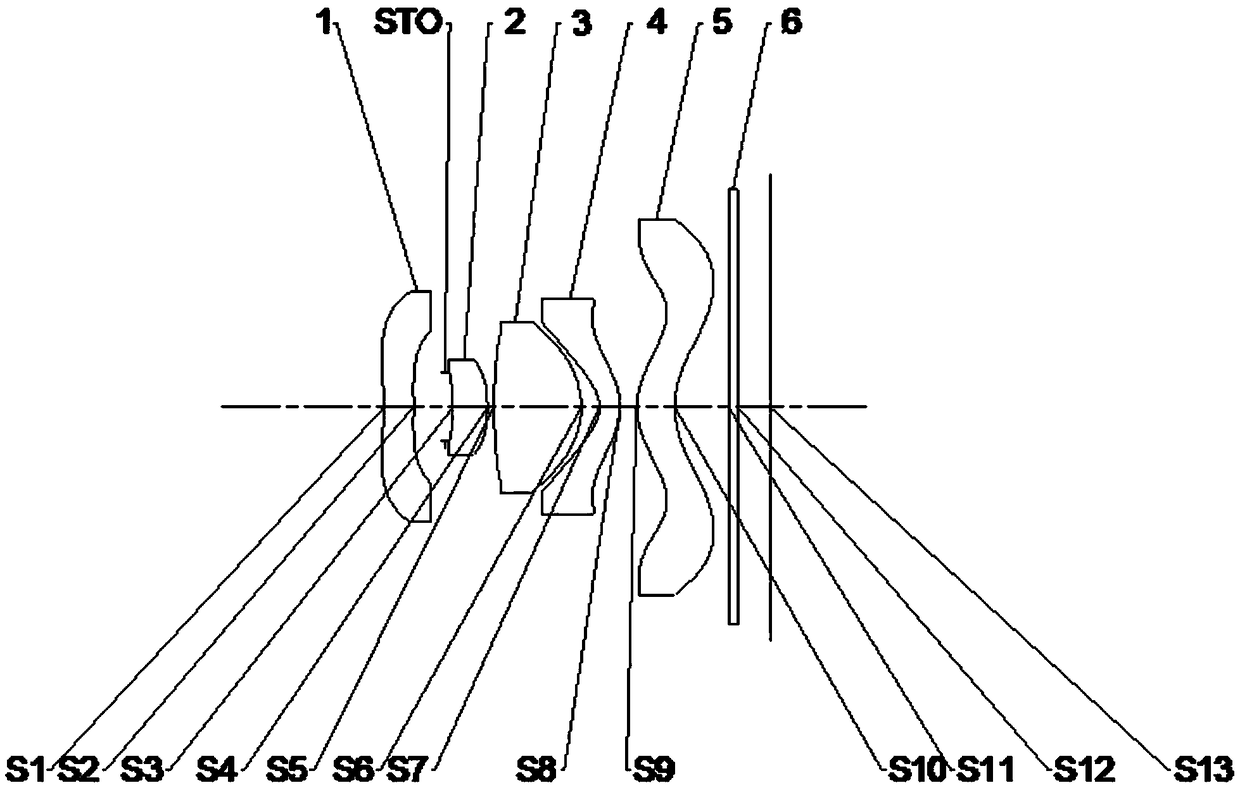

[0074] figure 1 A structural layout diagram of the imaging lens according to Embodiment 1 of the present invention is schematically shown.

[0075] The following table 3 lists the relevant parameters of each lens of this embodiment, including surface type, radius of curvature, thickness, material refractive index and Abbe number and conic coefficient:

[0076]

[0077]

[0078] table 3

[0079] In this embodiment, the data of each lens surface is shown in Table 4 below:

[0080] surface

A4

A6

A8

A10

A12

A14

A16

A18

A20

S1

1.9565E-01

-1.6660E-01

1.5875E-01

-1.0647E-01

4.8292E-02

-1.2398E-02

1.4269E-03

0.0000E+00

0.0000E+00

S2

5.6209E-01

-1.2231E+00

3.4011E+00

-6.7084E+00

8.4874E+00

-5.8076E+00

1.5873E+00

0.0000E+00

0.0000E+00

S3

-1.9438E-01

8.3804E-01

-1.7018E+01

1.7477E+02

-9.4173E+02

2.6020E+03

-3.0299E+03

0.0000E+00

0.0000E+00

S...

Embodiment approach 2

[0085] Figure 6 A structural layout diagram of an imaging lens according to Embodiment 2 of the present invention is schematically shown.

[0086] The following table 5 lists the relevant parameters of each lens of the present embodiment, including surface type, radius of curvature, thickness, material refractive index and Abbe number and conic coefficient:

[0087]

[0088]

[0089] table 5

[0090] In this embodiment, the surface data of each lens is shown in Table 6 below:

[0091] surface

A4

A6

A8

A10

A12

A14

A16

A18

A20

S1

1.2915E-01

-8.0619E-02

5.8970E-02

-3.0984E-02

1.1927E-02

-2.8567E-03

3.4057E-04

0.0000E+00

0.0000E+00

S2

3.3097E-01

-2.5244E-01

-3.0837E-02

1.7008E+00

-4.0405E+00

4.3393E+00

-1.7914E+00

0.0000E+00

0.0000E+00

S3

-3.8298E-01

6.1878E-01

-2.7916E+01

3.7008E+02

-2.8232E+03

1.1053E+04

-1.7688E+04

0.0000E+00

0.0000E+00...

Embodiment approach 3

[0096] Figure 11 A structural layout diagram of an imaging lens according to Embodiment 3 of the present invention is schematically shown.

[0097] The following table 7 lists the relevant parameters of each lens of the present embodiment, including surface type, radius of curvature, thickness, material refractive index and Abbe number, and conic coefficient:

[0098]

[0099]

[0100] Table 7

[0101] In this embodiment, the surface data of each lens is shown in Table 8 below:

[0102] surface

A4

A6

A8

A10

A12

A14

A16

A18

A20

S1

1.4231E-01

-7.3199E-02

7.1901E-02

-6.3202E-02

4.8838E-02

-2.2611E-02

4.8411E-03

0.0000E+00

0.0000E+00

S2

4.7931E-01

1.6630E-01

-4.5455E+00

2.6601E+01

-7.5623E+01

1.1091E+02

-6.5280E+01

0.0000E+00

0.0000E+00

S3

-2.6092E-01

-7.6088E-01

1.3997E+01

-2.7103E+02

2.5612E+03

-1.2026E+04

2.2188E+04

0.0000E+00

0.0000E+0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com