Multifunctional metallic phase sample inlaying machine

A technology of metallographic samples and mounting machines, which is applied in the preparation of test samples, etc., can solve the problems of high labor intensity and power consumption, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

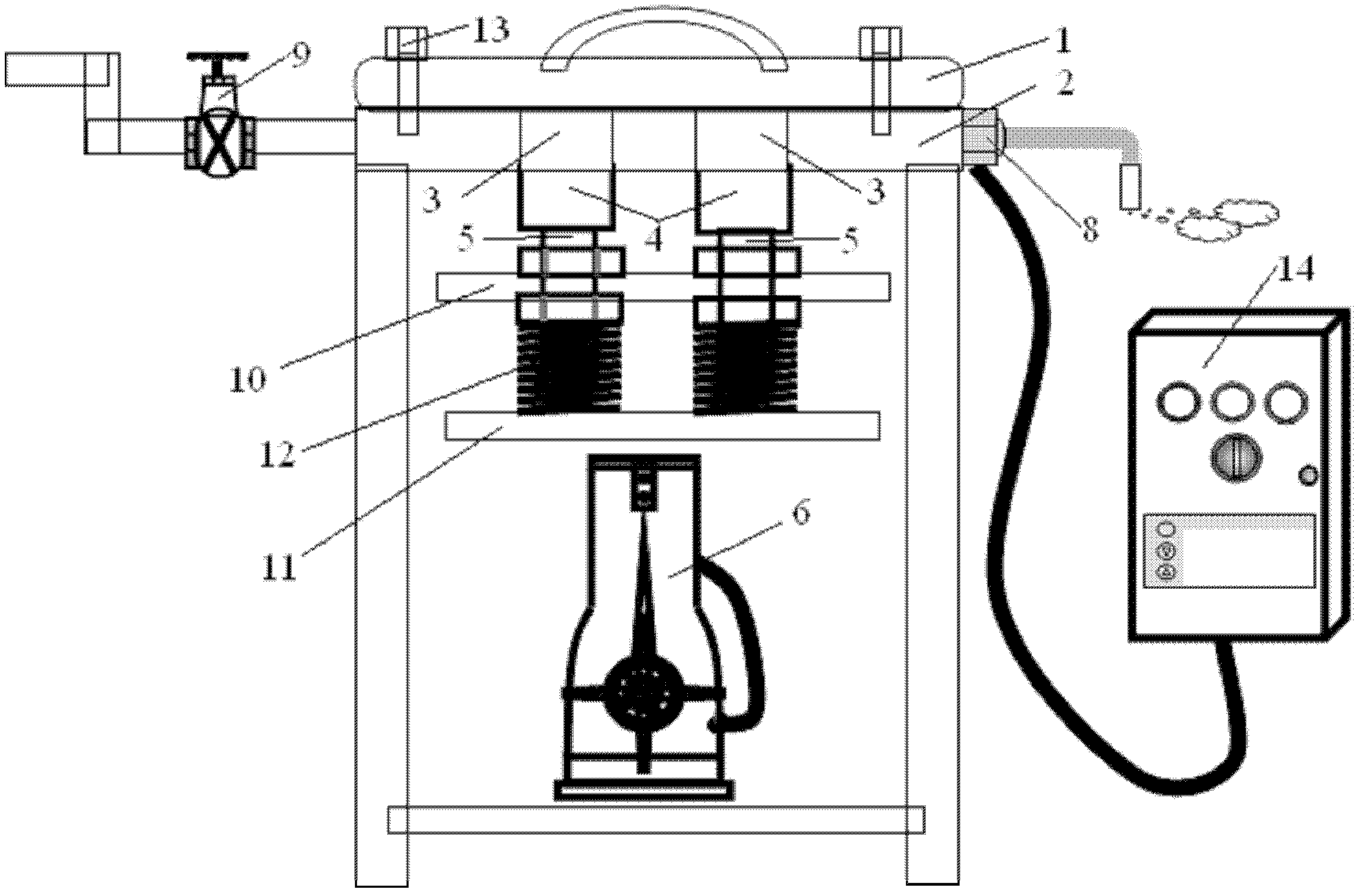

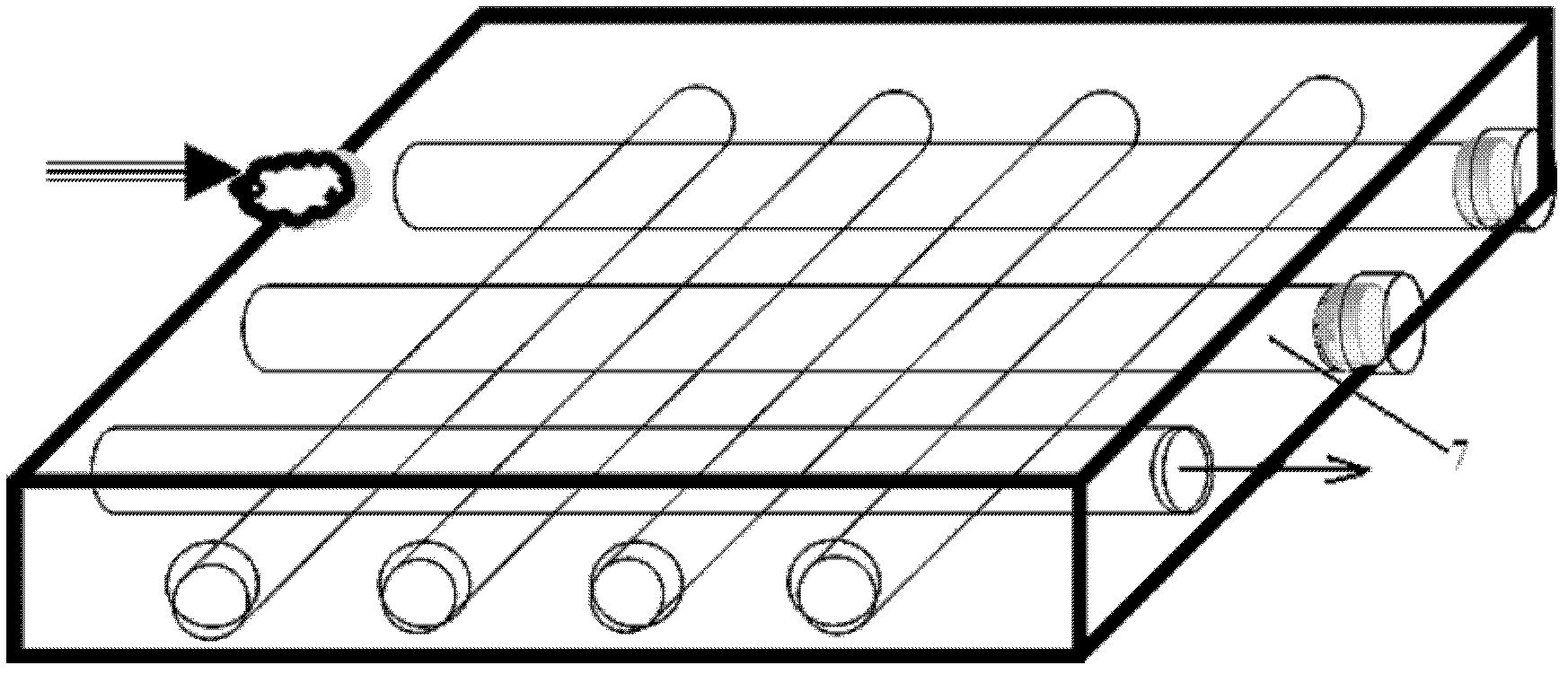

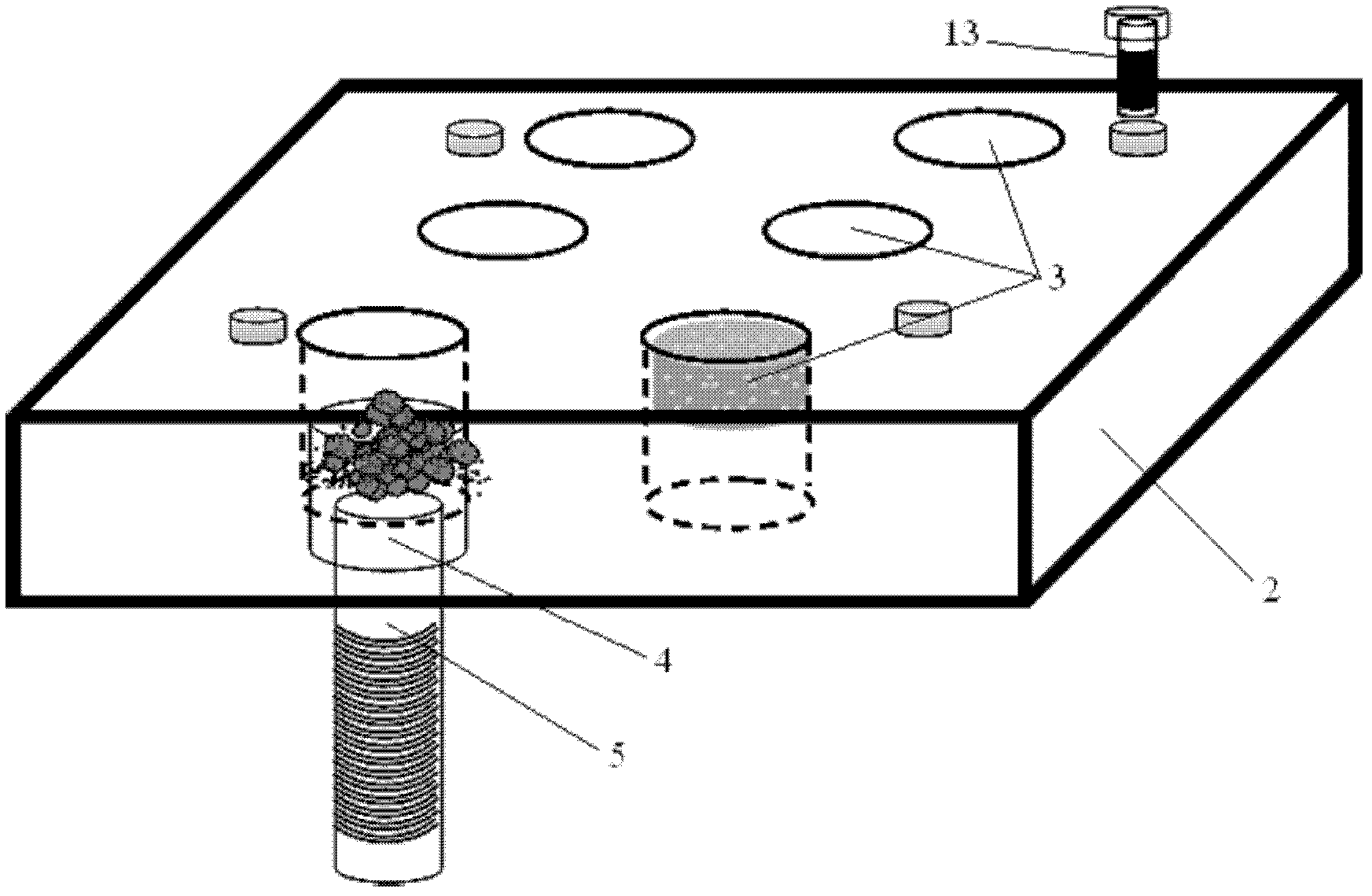

[0007] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment, which includes a gland plate 1, a steel plate mold 2, six mold cavities 3, a plurality of plugs 4, a plurality of adjusting screws 5, a jack 6, a plurality of steam heating pipes 7, a temperature sensor 8, The heating control valve 9, the No. 1 pallet 10 and the temperature control box 14, the gland plate 1 is fixed on the upper surface of the steel plate mold 2, and a plurality of steam heating pipes 7 are arranged in an orthogonal network inside the steel plate mold 2. There are six transparent mold cavities 3 evenly opened on 2, and each screw plug 4 corresponds to a mold cavity 3 from the lower part of the steel plate mold 2 into the inner cavity of the mold cavity 3, and each screw plug 4 is correspondingly fixed on an adjusting screw 5, the lower ends of all adjustment screws 5 are fixed on the No. 1 pallet 10, and the No. 1 pallet 10 is fixed on the upper surfa...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that it also includes No. 2 pallet 11 and a plurality of adjustment springs 12, No. 2 pallet 11 is located between the hydraulic tappet of jack 6 and No. 1 pallet 10 Between, a plurality of adjustment springs 12 are located between the No. 2 pallet 11 and the No. 1 pallet 10, the upper ends of the plurality of adjustment springs 12 are respectively fixed on the lower surface of the No. 1 pallet 10, and the lower ends of the plurality of adjustment springs 12 are respectively It is fixed on the upper surface of No. 2 pallet 11. Other components and connections are the same as those in Embodiment 1.

[0010] A plurality of adjustment springs 12 are compressed after the force applied by the jack, and a plurality of adjustment springs 12 release potential energy in the later stage of coal sample forming, so as to ensure that t...

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that it further includes four fixing screws 13 , and the four fixing screws 13 are distributed at the four corners of the gland plate 1 . Other components and connections are the same as those in Embodiment 1.

[0012] The four fixing screws 13 are used to fix the gland plate 1 to ensure the realization of the required pressure of the coal material and ensure that the gland plate 1 does not deform under high temperature and high pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com