Engine braking device and method

An engine braking and engine technology, applied in engine control, engine components, machine/engine, etc., can solve the problems of large size of eddy current retarder, failure of brake action, and failure of hydraulic medium to be updated, and achieve a good market. Foreground, simple control strategy, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

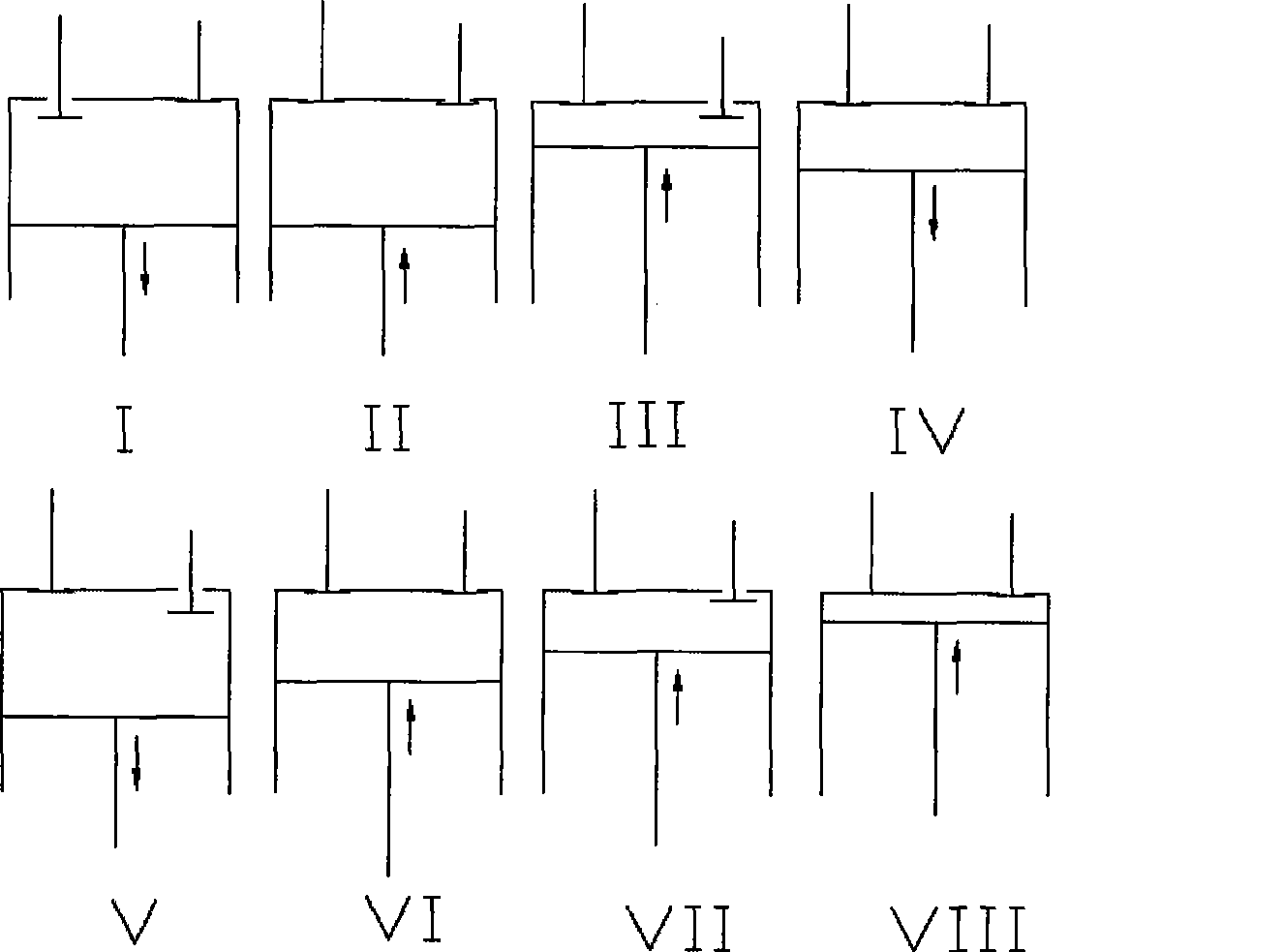

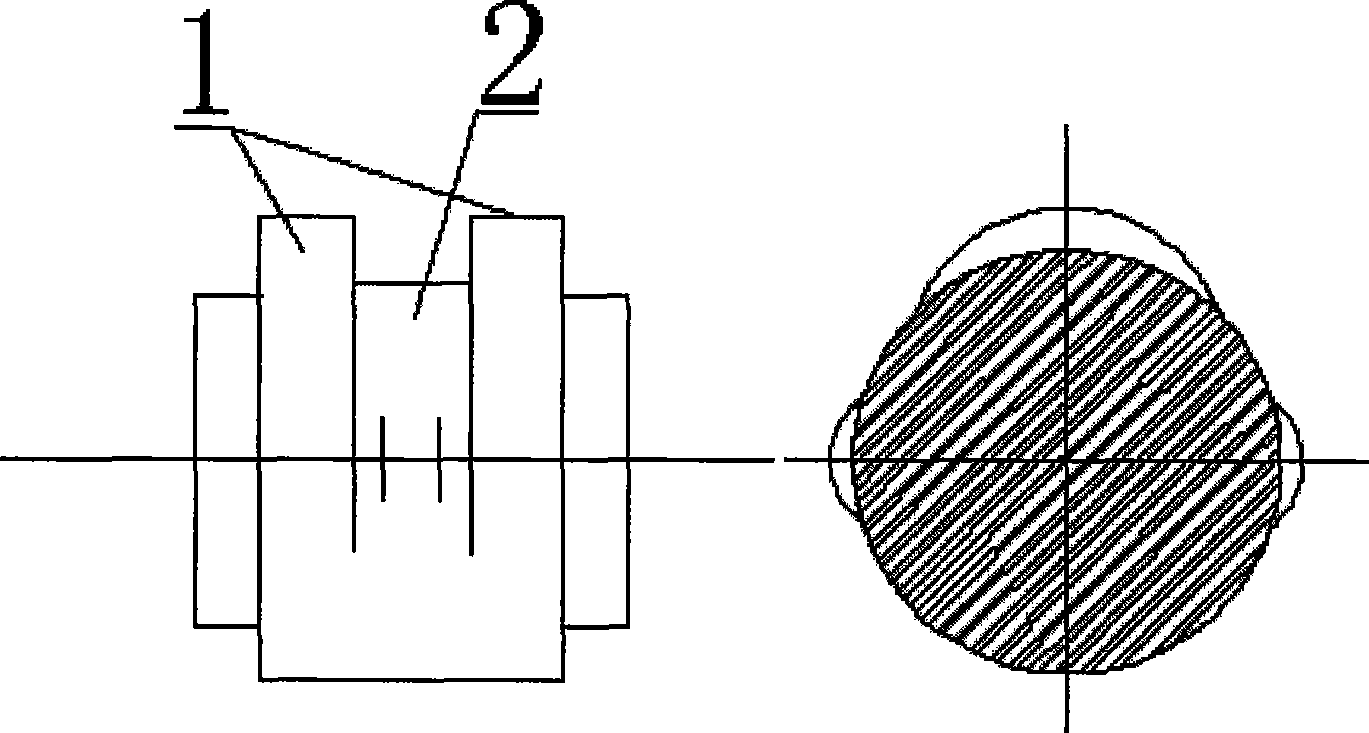

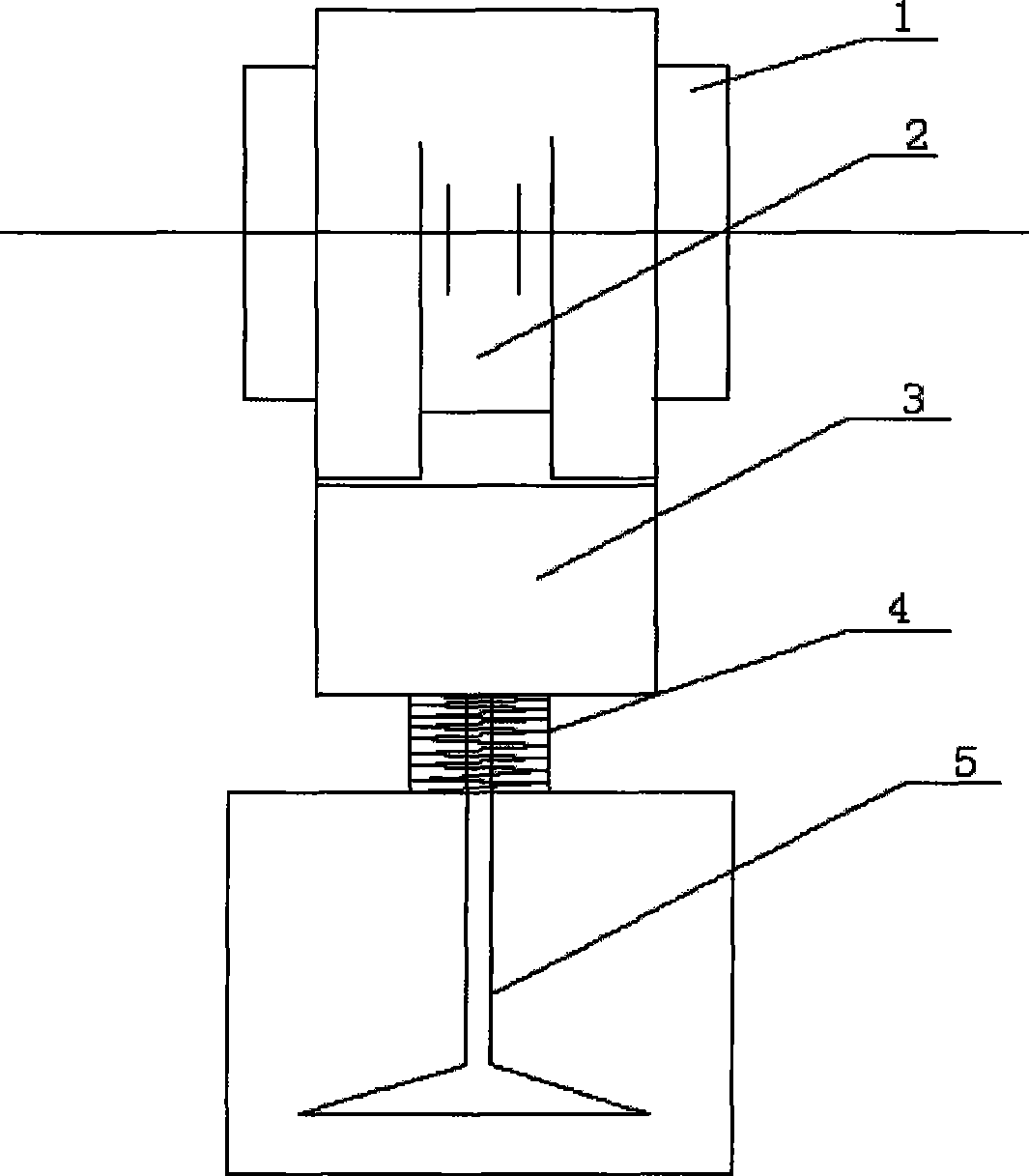

[0030] According to the attached figure 2 , 3 and 5 describe the braking device of the present invention in detail, which is a preferred embodiment among the various implementations of the present invention.

[0031] A device for realizing engine braking according to the present invention includes an engine exhaust valve 5, a valve spring 4, an exhaust cam, and a variable hydraulic tappet mechanism 3, and the variable hydraulic tappet mechanism 3 includes an inner cavity 8 , the outer cavity 9, the pin hole 6 located in the inner cavity and the positioning pin 7 that can move between the inner and outer cavity and insert into the pin hole, wherein the exhaust cam is a double-cam structure, consisting of an outer cam 1 and an inner cam 2, variable The hydraulic tappet mechanism 3 is located between the exhaust valve and the exhaust cam, which can realize the switching between the inner and outer cams. When the engine brake is not needed, the hydraulic system can apply pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com