Rotary compressor

A technology of rotary compressors and compression mechanisms, which is applied to rotary piston machines, rotary piston pumps, mechanical equipment, etc., and can solve the problems of reducing the amount of refrigerant enclosed and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

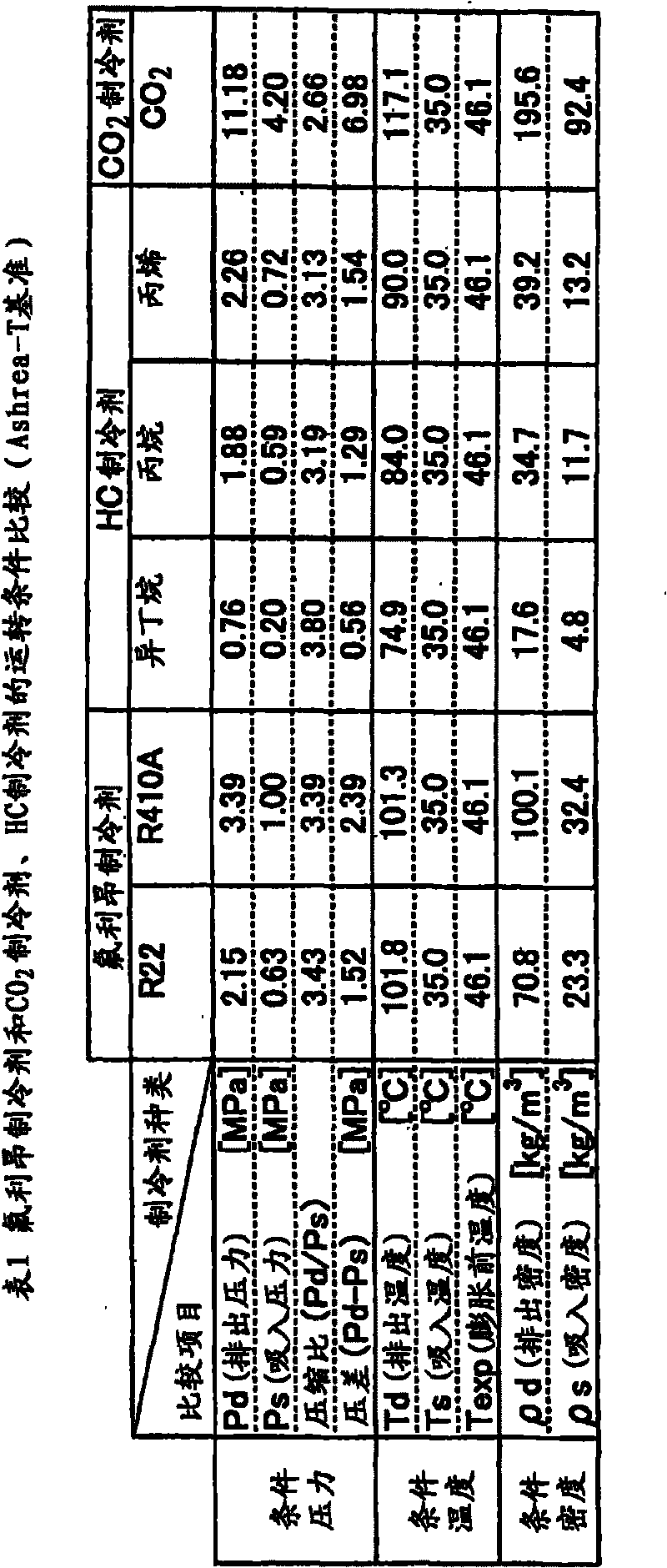

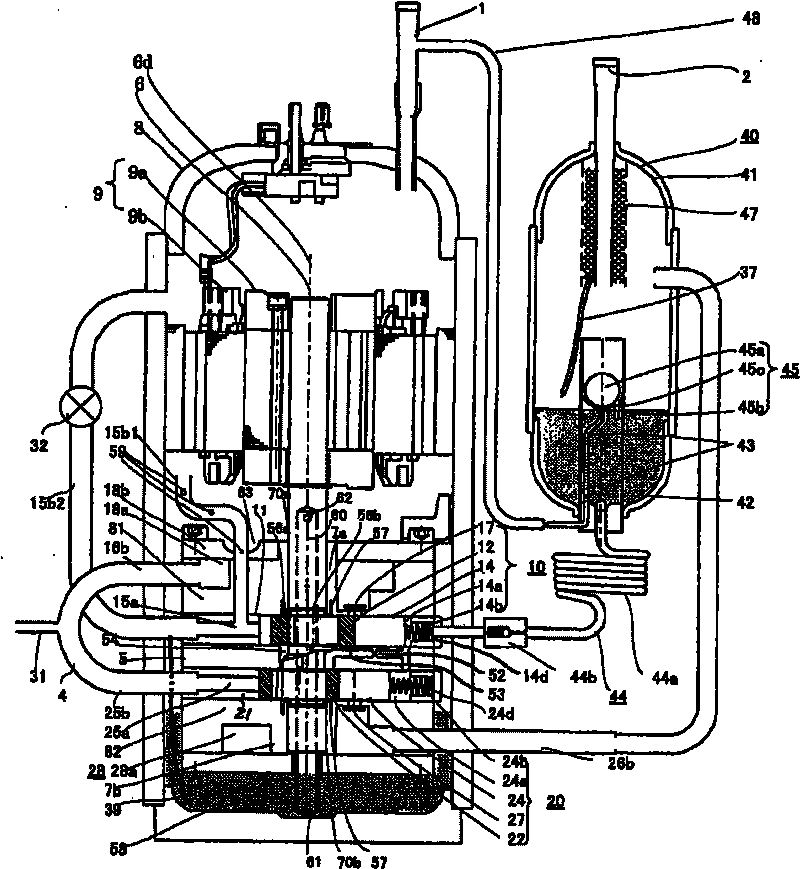

[0030] figure 2 It is an assembly drawing showing the overall structure of the low-pressure shell-type two-stage rotary compressor according to Embodiment 1 of the present invention. The rotary compressor of the present invention includes a hermetic container 8, a motor 9 installed in the hermetic container 8, a crankshaft 6 driven by the motor 9, a long-axis side bearing 7a and a short-axis side bearing 7b supporting both ends of the crankshaft 6, first and The second compression mechanisms 10 and 20 are equipped with an oil separation element 40 outside the sealed container 8 .

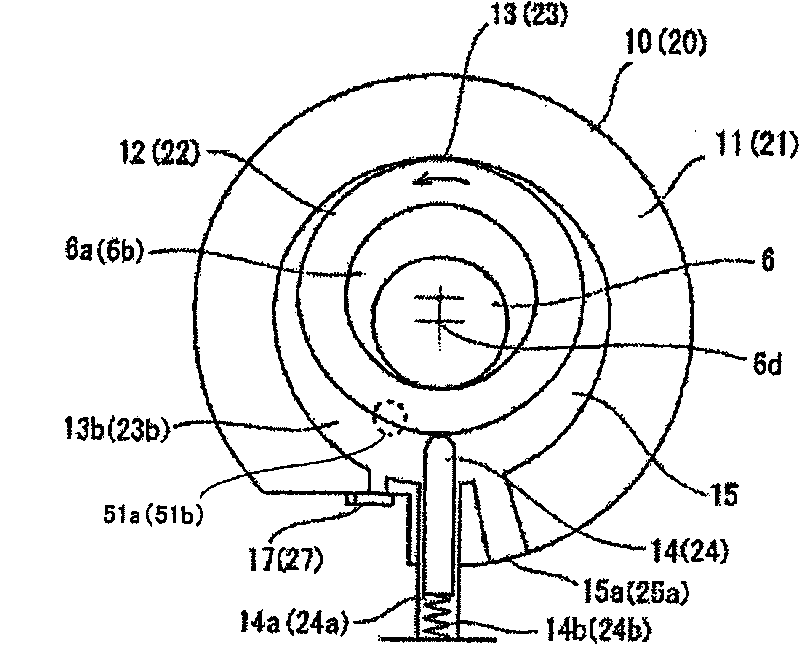

[0031] image 3 yes means figure 2 A cross-sectional view of the structure of the shown low-stage compression mechanism (first compression mechanism). The structure of the high-stage compression mechanism (second compression mechanism) is also the same as that of the low-stage side, and is denoted by reference symbols in parentheses. As the crankshaft 6 rotates around the axis 6d, the cranksha...

Embodiment approach 2

[0056] Figure 8 It is an assembly diagram showing the overall structure of a low-pressure shell-type two-stage rotary compressor according to the second embodiment. The rotary compressor is Figure 1 to Figure 7 The rotary compressor of Embodiment 1 shown is structurally different in that the low-stage discharge muffler 18, the low-stage discharge valve 17, and the intermediate connecting portion are provided in the intermediate plate 5, and the oil separator 90 is provided in the The internal space 28b of the high-level discharge muffler container 28 in the airtight container 8 also serves as the structure of the high-level discharge muffler, so the oil supply path of the high-pressure lubricating oil separated by the oil separator 90 is different. Other configurations are the same as those in Embodiment 1, and therefore description thereof will be omitted.

[0057] That is, the intermediate plate 5 is composed of upper and lower two laminated plates, that is, a first inte...

Embodiment approach 3

[0066] Figure 9 It is an assembly drawing showing the overall structure of the low-pressure shell-type single-stage rotary compressor according to the second embodiment. The difference in structure from the rotary compressor of Embodiment 2 is that it is a single-stage rotary compressor composed of one compression mechanism, and the bottom shell of the hermetic container 8 is configured to double as a high-pressure container 41 for an oil separator and The structure of the discharge muffler 18 is such that, in the container 41 , a swirling flow generation rotating body 64 functioning as an oil separation member is provided at the lower end of the crankshaft 6 , and an oil pump rotating body 61 is attached as an oil supply member. Other configurations are the same as those in Embodiment 2, and description thereof will be omitted. Here, the single-stage compression mechanism itself is associated with Figure 3-5 The compression mechanism of Embodiment 1 shown is the same, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com