Wear-resistant graphene surface modification method

A graphene surface and graphene technology, applied in the field of lubricating materials and wear-resistant graphene surface modification, to achieve the effects of increased wear life, reduced production costs, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

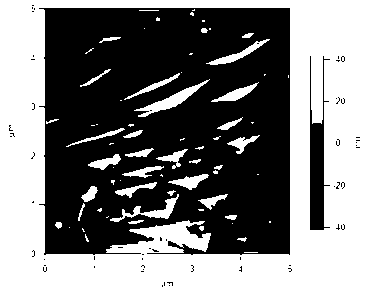

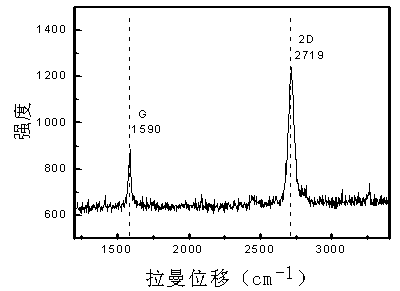

Image

Examples

Embodiment 1

[0044] 1) The preparation of graphene by chemical vapor deposition is divided into the following steps:

[0045] The first step, copper foil surface pretreatment: first put 25μm copper foil into a tube furnace, heat it from room temperature to 1000°C at a heating rate of 10-20°C / min, and keep it for 30 minutes. hydrogen;

[0046] The second step is the process of graphene growth: stop hydrogen, continue to feed methane at 20 sccm, and treat at 1000°C for 10 minutes; stop methane, continue to feed hydrogen at 15 sccm, and cool down to room temperature at a rate of 100°C / min. long graphene;

[0047] The third step is the transfer process of graphene on copper foil: Spin-coat polymethyl methacrylate (PMMA) with a mass concentration of 3% on the surface of copper foil with graphene, dry it at 120°C for 10 minutes, and then Copper foil coated with PMMA was transferred to 5mol / L FeCl 3 Soak in the solution for 2 hours to remove excess copper foil to obtain PMMA / graphene, after 3-...

Embodiment 2

[0056] 1) The preparation of graphene by chemical vapor deposition is divided into the following steps:

[0057] The first step, copper foil surface pretreatment: first put 25μm copper foil into a tube furnace, heat it from room temperature to 1000°C at a heating rate of 10-20°C / min, and keep it for 30 minutes. hydrogen;

[0058] The second step is the process of graphene growth: stop hydrogen, continue to feed methane at 20 sccm, and treat at 1000°C for 10 minutes; stop methane, continue to feed hydrogen at 15 sccm, and cool down to room temperature at a rate of 100°C / min. long graphene;

[0059] The third step is the transfer process of graphene on copper foil: Spin-coat polymethyl methacrylate (PMMA) with a mass concentration of 3% on the surface of copper foil with graphene, dry it at 120°C for 10 minutes, and then Copper foil coated with PMMA was transferred to 5mol / L FeCl 3 Soak in the solution for 2 hours to remove excess copper foil to obtain PMMA / graphene, after 3-...

Embodiment 3

[0069] Friction test conditions:

[0070] The friction test is done on the UMT-2MT friction testing machine, using the ball-on-disk contact mode, the friction load and frequency are 0.1N and 1Hz respectively. The steel ball with a diameter of 3-5mm and a roughness of 0.02-0.06 μm is the contact pair, and the friction adopts Sliding way, the sliding distance is 0.5 cm. The entire rubbing process was done in a room with an ambient temperature of 25°C and a relative humidity of 26%.

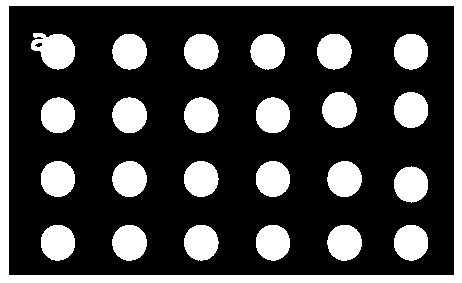

[0071] It can be seen from Figure 4a that the friction coefficient of the graphene with the columnar array structure without metal embedded on the substrate surface is about 0.2, and the friction coefficient increases rapidly after 800 seconds of friction, and the graphene is destroyed.

[0072] Figure 4b shows that the friction coefficient of the graphene embedded in the surface of the metal columnar array structure of the present invention is similar to the former, but the whole friction process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com