Minimum quantity lubrication supply system capable of automatically regulating oil mist quantity for machine tool processing

An automatic adjustment and micro-lubrication technology, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of polluting the working environment and ecological environment, poor cooling and lubrication effect, and high cost, so as to reduce workload and ensure Lubrication effect, effect of reducing the influence of centrifugal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

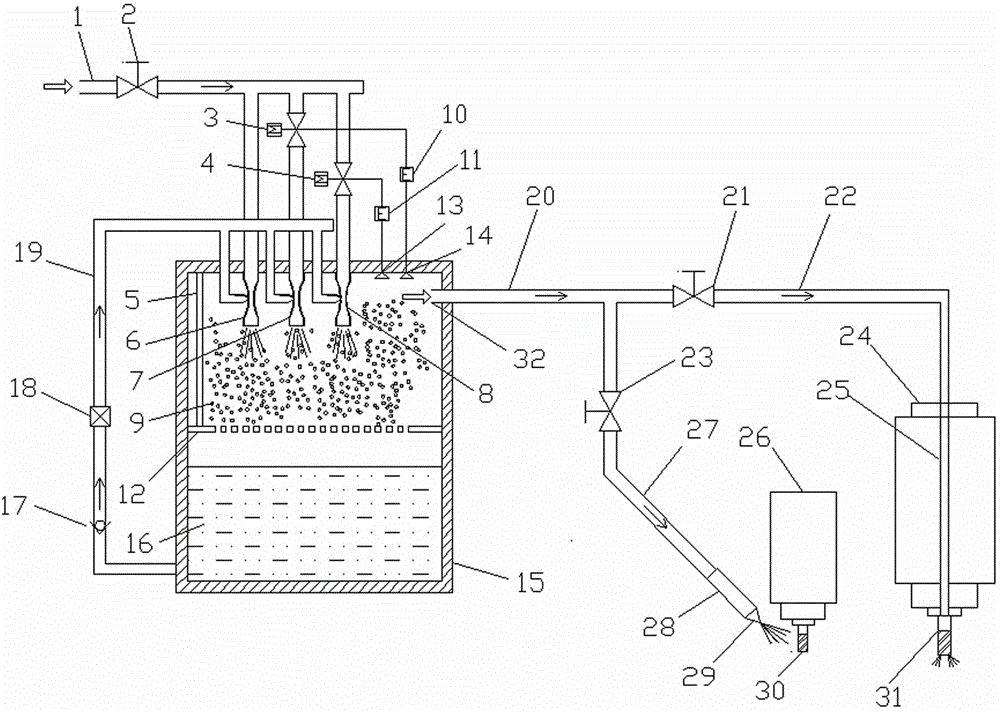

[0023] For the convenience of those skilled in the art to understand, below in conjunction with embodiment and appended figure 1 To further illustrate the present invention, the content mentioned in the embodiment is not to limit the present invention.

[0024] See figure 1 , a minimum quantity lubrication supply system capable of automatically adjusting the amount of oil mist for machine tool processing, comprising a gas delivery switch 2, at least one solenoid valve, a check valve 17, a flow control valve 18 and an atomization chamber 15 containing cutting oil 16, At least two Venturi atomizing nozzles are provided on the top inner wall of the atomizing chamber 15;

[0025] The gas delivery switch 2 and a Venturi atomization nozzle are sequentially connected through the gas delivery pipe 1; the gas delivery switch 2 and at least one solenoid valve are respectively connected with at least one Venturi atomization nozzle through the gas delivery pipe 1 in sequence;

[0026] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com