A kind of surface coating method and equipment

A surface coating and coating technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of high equipment requirements, poor adhesion, complex process, etc., and achieve wide applicability , easy to achieve, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

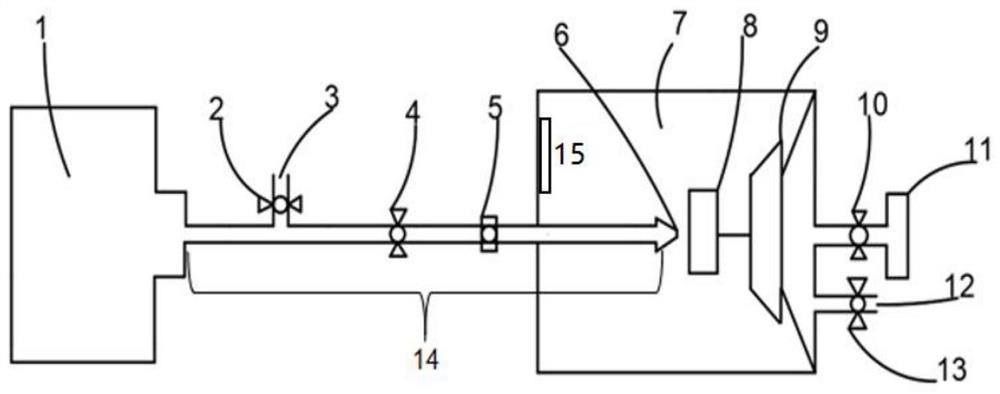

[0043] The nanoparticle aerosol preparation device communicates with the vacuum sample chamber through the critical hole, and the surface coating component and the sample multi-axis linkage platform are installed in the vacuum sample chamber, and the coated sample is placed on the sample multi-axis linkage platform. The nano-aerosol is prepared by the aerosol device, then passes through the critical hole with the airflow, enters the surface coating part, and is coated on the sample of the multi-axis linkage platform of the sample through the nozzle. With the arbitrary movement and rotation of the sample, a thin film with uniform thickness is formed to realize the all-round coating of nanoparticles on the surface of the sample, and then the surface coating is heat-treated by the heat source in the sample cavity.

[0044] Preferably, the nanoparticle aerosol preparation device is one of the nanoparticle preparation devices using gas as a medium, such as an electric spark discharg...

Embodiment 2

[0065] The cube sample is fixed on the multi-axis linkage platform of the vacuum sample chamber, and the sample chamber is evacuated, and the nano-zinc aerosol is prepared by an electric spark discharge device, and nitrogen gas is introduced, and a critical hole with a diameter of 0.02 μm and a diameter of 0.1 μm are used. μm nozzle, adjust the moving speed and rotation speed of the multi-axis linkage platform of the sample, coat the nano-zinc aerosol on the sample through the nozzle, and then heat it to 50°C for 5 minutes by infrared rays to form a uniform and stable 1nm film. The thin film is resistant to seawater and atmospheric corrosion.

Embodiment 3

[0067] The bowl-shaped sample is fixed on the multi-axis linkage platform of the vacuum sample chamber, and the sample chamber is vacuumized, and the nano-alumina aerosol is prepared by an arc discharge device, and argon gas is introduced, and a critical hole with a diameter of 0.1 μm and The nozzle with a diameter of 10 μm adjusts the moving speed and rotation speed of the multi-axis linkage platform of the sample, and the nano-alumina aerosol is coated on the sample through the nozzle, and then heated to 80°C by microwave for 10 minutes to form a uniform thickness of 5nm Film, this film is a good wear-resistant and heat shielding material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com