High-strength rice gel tailored flour, as well as preparation method and application thereof

A special powder, high-strength technology, applied in the field of special powder for rice products and its preparation, can solve the problems of limited effect and single use, and achieve the effect of improving effect, improving gel toughness and improving rice gel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

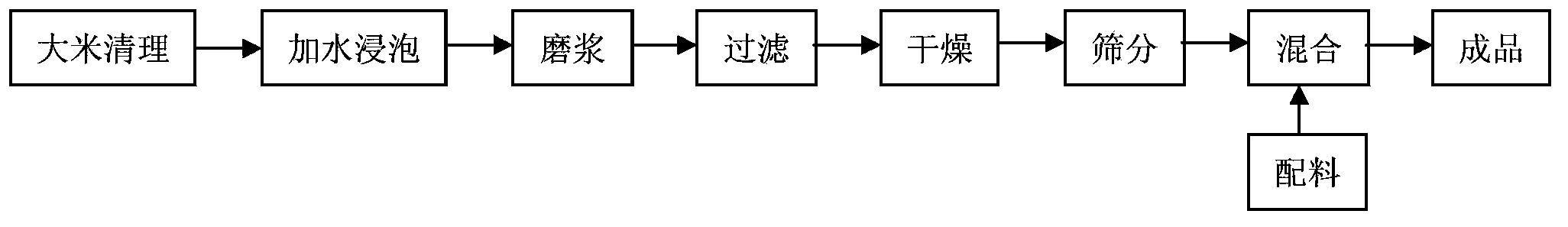

[0068] Embodiment 1: production process example

[0069] Step 1: Take 1000g of indica rice and wash it with tap water to obtain material 1;

[0070] Step 2: Add 1000g of water to material 1, soak at 25°C for 5.5h to obtain material 2;

[0071] Step 3: Refining the material 2, requiring the fineness of the ground pulp to be above 60 mesh, to obtain the material 3;

[0072] Step 4: Dry material 3 at 45°C for 22 hours, pass through an 80-mesh sieve, and obtain powder material 4;

[0073] Step 5: Add 2g of transglutaminase, 10g of gluten protein, 1.5g of calcium lactate, 1g of lysine, 0.5g of threonine and 2g of egg white powder to material 4, and mix evenly to obtain material 5;

[0074] Step 6: Put the material 5 into the retort bag, inject 0.8 mg·L-1 of ozone before sealing, and ventilate for 120 s, then seal to obtain the finished product of high-strength rice gel special powder.

Embodiment 2

[0075] Embodiment 2: the special powder of high-strength rice gel obtained by several formulas

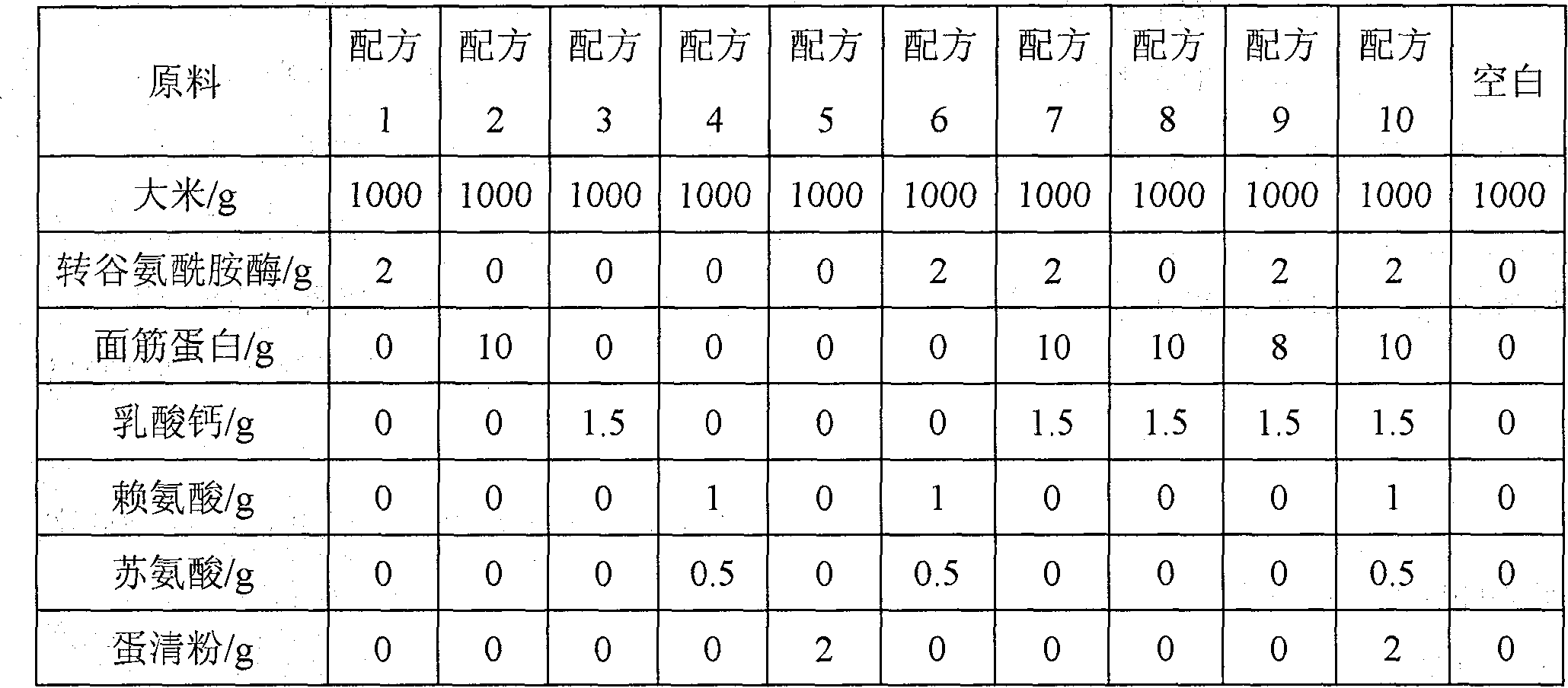

[0076] Lysine and threonine are two essential amino acids with relatively small content in rice protein. The fortification of these two amino acids plays an important role in improving and improving the quality of rice protein. Adopt the method in embodiment 1 to prepare special powder, just change step 5 into several different formulas as described in table 1. The formulation design is shown in Table 1.

[0077] Table 1 formula design table

[0078]

[0079] Note: The blank is the rice flour made only with raw rice without adding any ingredients.

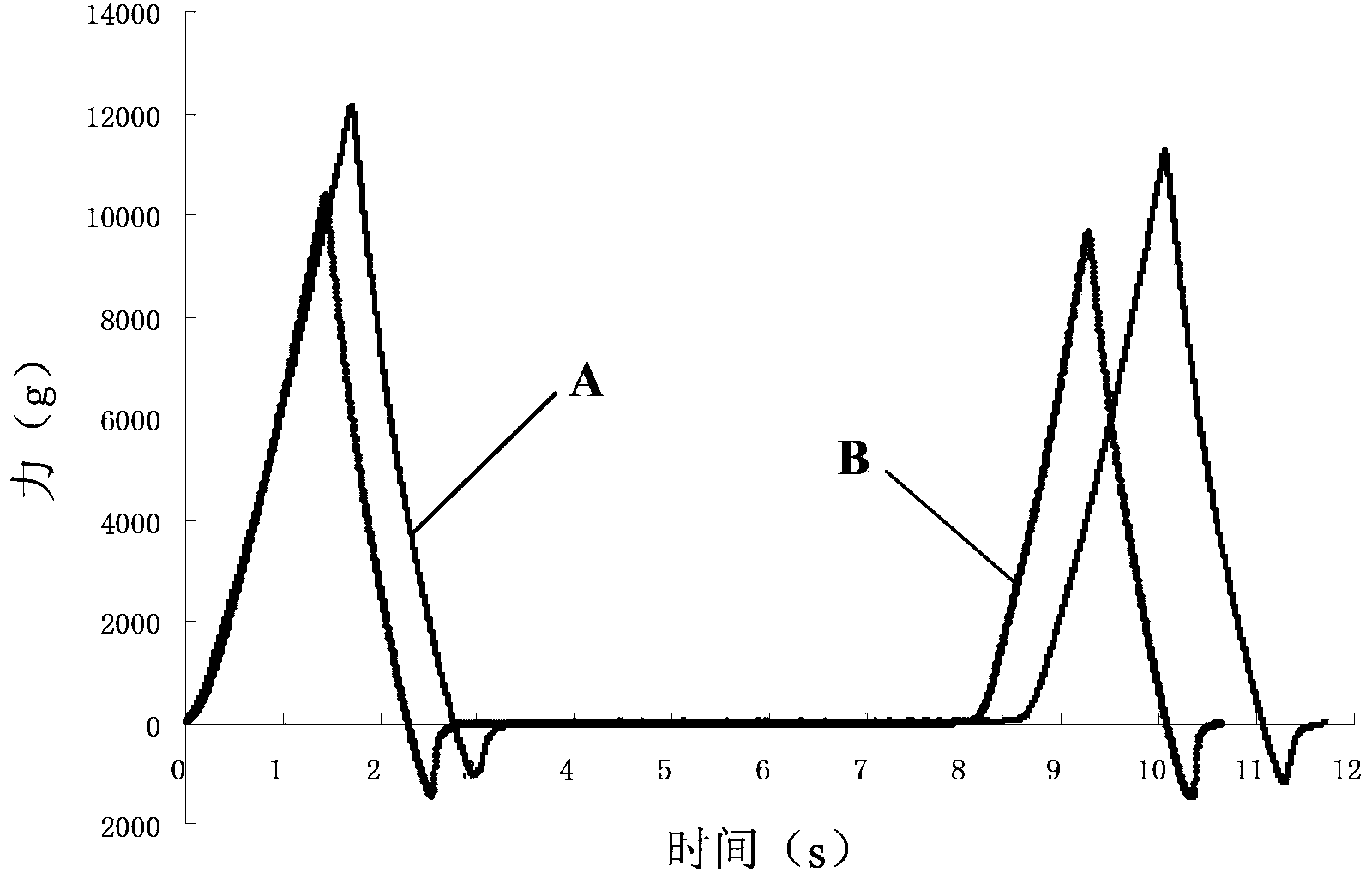

[0080] Add 1200g of water to special powders with different formulas, stir them evenly, spread them into a certain thickness in a flat container, heat slowly for 10 minutes, steam at 100°C for 5 minutes after reaching 70°C, and cool to get rice gel . A texture analyzer (product of Stable Micro Systems, UK) was used to measure the...

Embodiment 3

[0082] Embodiment 3: Oxidation-treated high-strength rice gel special powder

[0083] Adopt the method among the embodiment 1 to prepare two parts of special powders, wherein a part is not processed through ozone, then prepare rice gel with two parts of special powders respectively by the method among the embodiment 2. The texture of the rice gel prepared by this method was measured by a texture analyzer (product of StableMicro Systems, UK), and the results are shown in Table 3. It can be seen from Table 3 that the oxidation treatment moderately increases the strength and elasticity of the rice gel.

[0084] Table 3 Oxidation / non-oxidation treated rice gel texture parameters

[0085]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com