Liquid Reagent Addition Device with Precise Adjustment

A precision adjustment and functional technology, applied in the direction of liquid distribution, transportation or transfer devices, distribution devices, special distribution devices, etc., can solve the problem of unstable post-sequence process of workload, poor removal effect of non-rare earth impurities, and unstable artificial flow control to improve the effect of impurity removal, improve labor productivity, and avoid local excess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

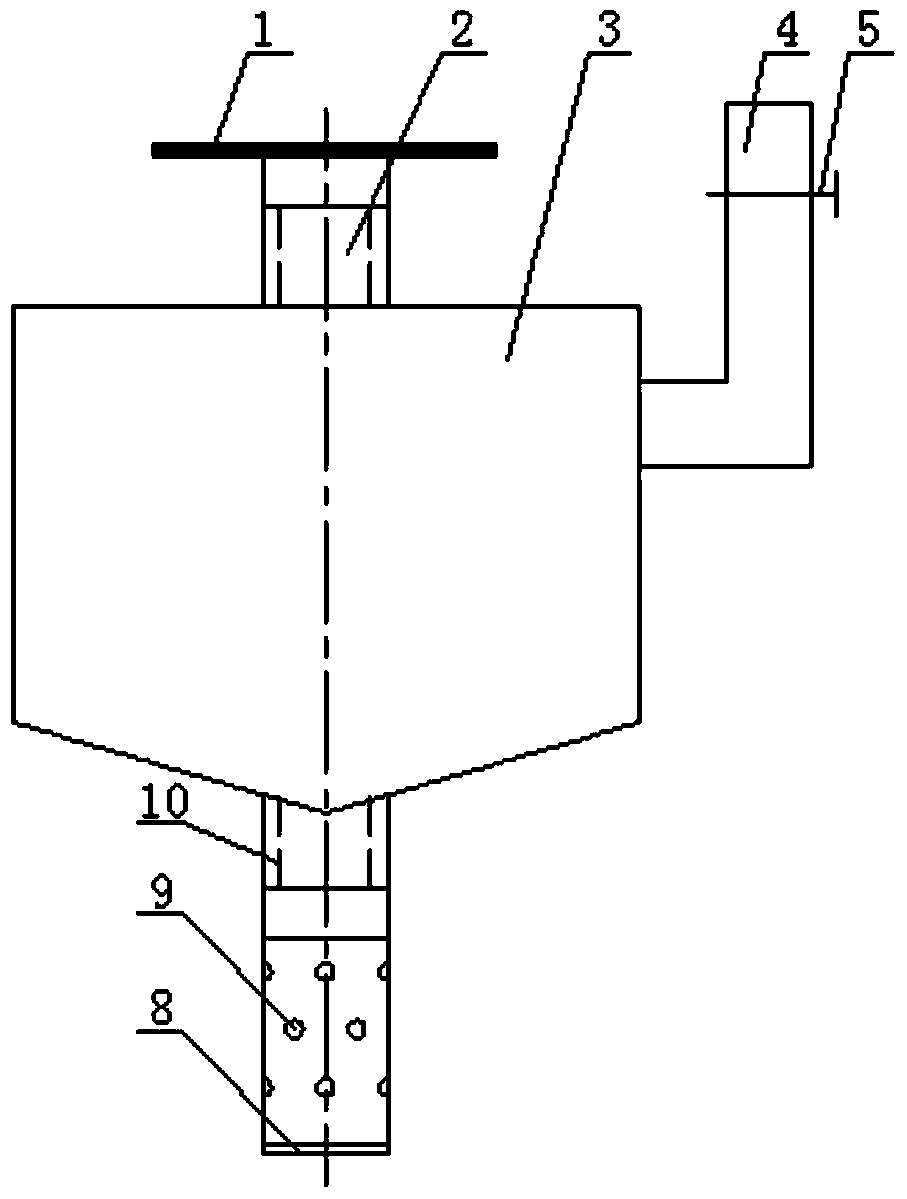

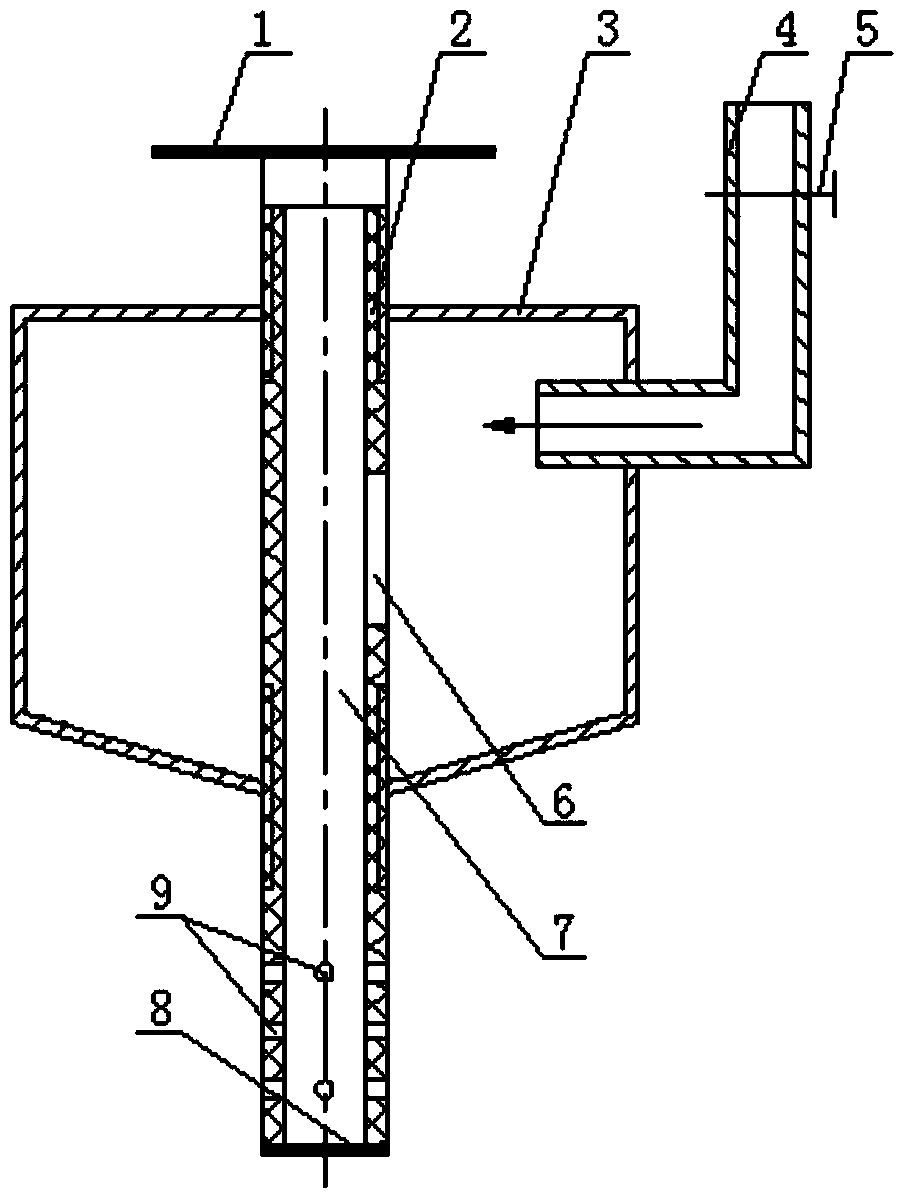

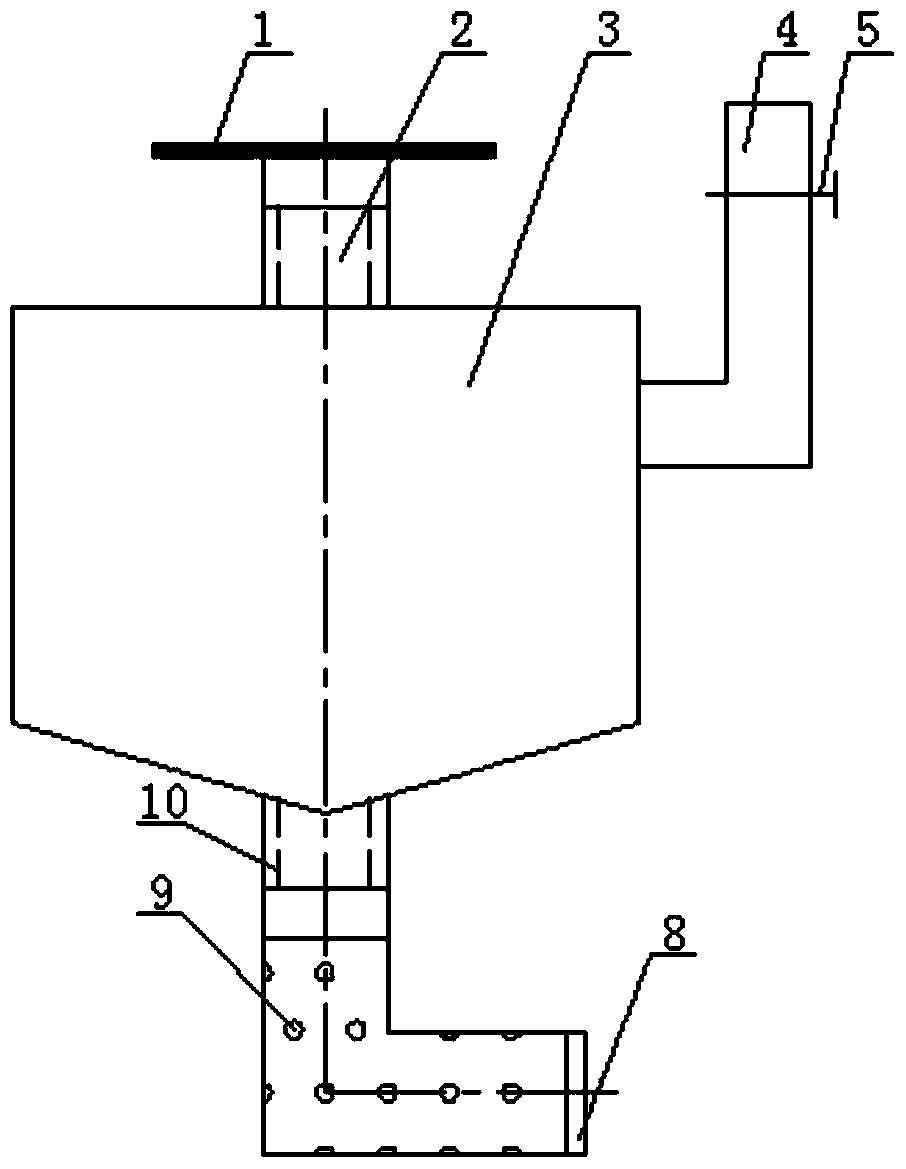

[0021] A liquid reagent adding device with precise adjustment function, including a liquid inlet pipe 4, a valve 5, a handle 1, an adjustable flow meter 3 and a pipe fitting 2, the middle and upper part of the outer surface of the pipe fitting is threaded 10, and the adjustable flow meter box The body is fitted on the outside of the pipe fitting through the coaxial engagement of the thread. The adjustable flowmeter box is a cubic structure (such as: 350mm×350mm×400mm) or a cylindrical structure (such as: Ф350mm). The size specification can be adjusted according to actual needs. Modify selection. The upper part of the adjustable flowmeter box is connected with a liquid inlet pipe, and the liquid level of the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com