Purple bronze glaze with metallic luster and preparation method thereof

A technology with metallic luster and red copper color, applied in the field of ceramic glaze, can solve the problems of insufficient wear resistance and corrosion resistance of metal glaze, many glaze pinholes, brown eye defects, and high decoration cost, so as to improve the Intrinsic value, pinhole and brown eye defect improvement, effect of solemn artistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

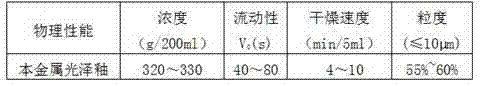

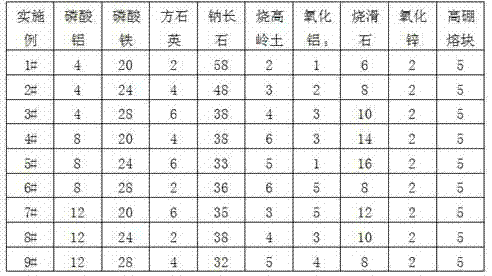

[0017] Embodiments 1-9: The copper-colored metallic luster glaze is prepared by using the following raw materials and methods.

[0018] 1. Raw materials: albite, calcined kaolin, alumina, talc, zinc oxide, boron frit, cristobalite, crystallizer, catalyst, crystallizer, catalyst; of which:

[0019] Crystallization agent: a crystallization agent that forms metallic luster, composed of P-Fe system, does not contain toxic substances such as lead and chromium, preferably iron phosphate;

[0020] Catalyst: A crystallization accelerator that promotes the formation of metallic luster, which can make the glaze layer form a relatively stable spinel crystal structure. It is composed of P-Al system and does not contain toxic substances such as lead and chromium. It is best to use aluminum phosphate;

[0021] Cristobalite: 25wt% to 30wt% with a particle size composition of ≤10μm, 15wt% to 20wt% with a particle size of ≤5μm, and 3wt% to 6wt% with a particle size of ≤2μm.

[0022] The chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com