Disposable anti-slip degradable slippers and manufacturing technique thereof

A production process, one-time technology, applied in footwear, clothing, applications, etc., can solve the problems of non-degradable recycling, endangering health and safety, poor anti-skid performance, etc., to achieve environmental protection, reduce pollution, and good anti-skid effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The plant fiber synthetic material comprises 10% of hairy straws, 70% of reed straws and 20% of straws.

Embodiment 2

[0027] The plant fiber synthetic material comprises 20% of hairy straws, 50% of reed straws and 30% of straws.

Embodiment 3

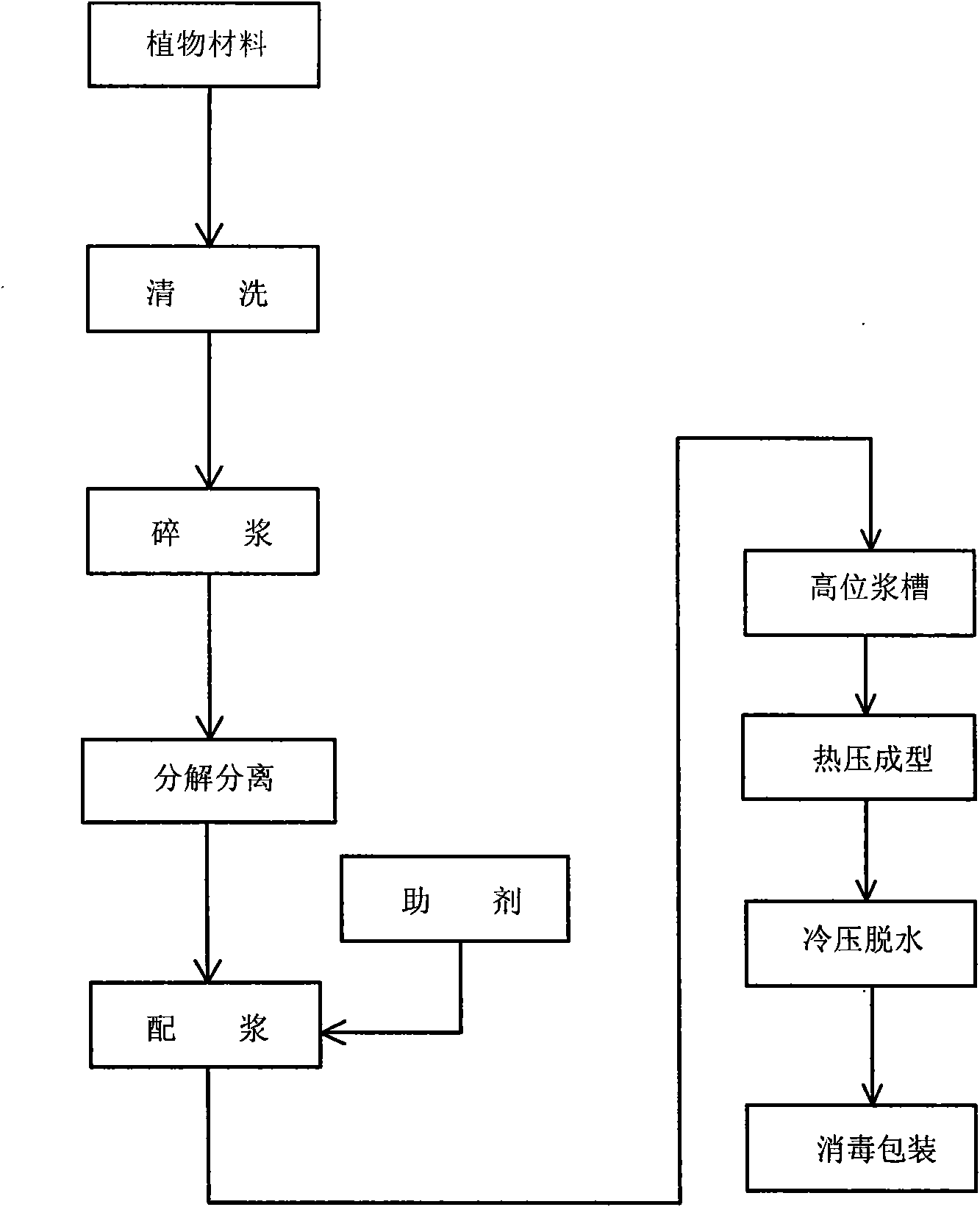

[0029] The plant fiber synthetic material comprises 15% of hairy straws, 60% of reed straws and 25% of straws. The fabrication process, as shown in the figure, includes

[0030] 1) Mixing and cleaning of plant fiber synthetic materials;

[0031] 2) Pulping;

[0032] 3) decomposition and separation;

[0033] 4) mix pulp;

[0034] 5) hot pressing forming;

[0035] 6) Cold press dehydration;

[0036] 7) Sterilized packaging.

[0037] The sole is mainly made of biomaterials synthesized by plant fibers as a raw material and added with auxiliary agents to be molded and manufactured. The sole and the upper are connected to make a disposable non-slip biodegradable slipper.

[0038] The anti-skid sole adopts a concave-convex structure to achieve anti-skid effect. The plant fiber material can not only be degraded and recycled, but also has a certain waterproof function. When the sole is made, its thickness will be increased, so that its service life can reach about one week.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com