Ultraviolet curing non-slip elastic floor paint and method

An elastic floor, ultraviolet light technology, applied in coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of difficult processing, unsightly decorative effect, difficult to produce quickly, etc., to increase paint surface friction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

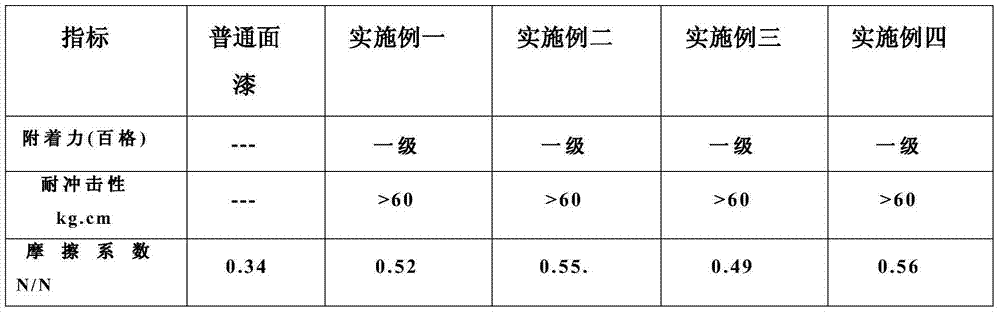

[0012] Embodiment: The present invention provides a specific embodiment of UV-curable anti-skid elastic floor paint, and its components are proportioned by weight according to the following different embodiments, see Table 1 for details:

[0013] Table 1

[0014]

Example 1

Embodiment 2

Embodiment Three

Embodiment Four

15

20

35

40

20

10

10

10

Modified Rosin Resin

15

20

25

20

Active amine

4

5

3

5

1-Hydroxycyclohexylphenylacetone

5

5

2

2

Trimethylolpropane triacrylate

12

5

5

4

Tripropylene glycol diacrylate

15

27

15

13

10

5

2

2

elastic powder

4

3

3

4

[0015] According to the formula in the above-mentioned embodiment, the specific preparation method is as follows: put in order urethane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com