Preparation method of flexible force sensitive sensor

A technology of sensor and flexible force, which is applied in the field of flexible force-sensitive sensor of dendritic coaxial nanostructure conductive polyaniline fiber, which can solve the problem of difficult processing and application of polyaniline micro-nano composite fiber for force-sensitive sensor, difficult processing and molding, etc. problem, to achieve the effect of unbreakable, short response time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] This embodiment includes three specific steps of preparing dendritic nanostructured polyaniline coaxial ordered fibers, preparation of a force-sensitive sensor and application of a force-sensitive sensor:

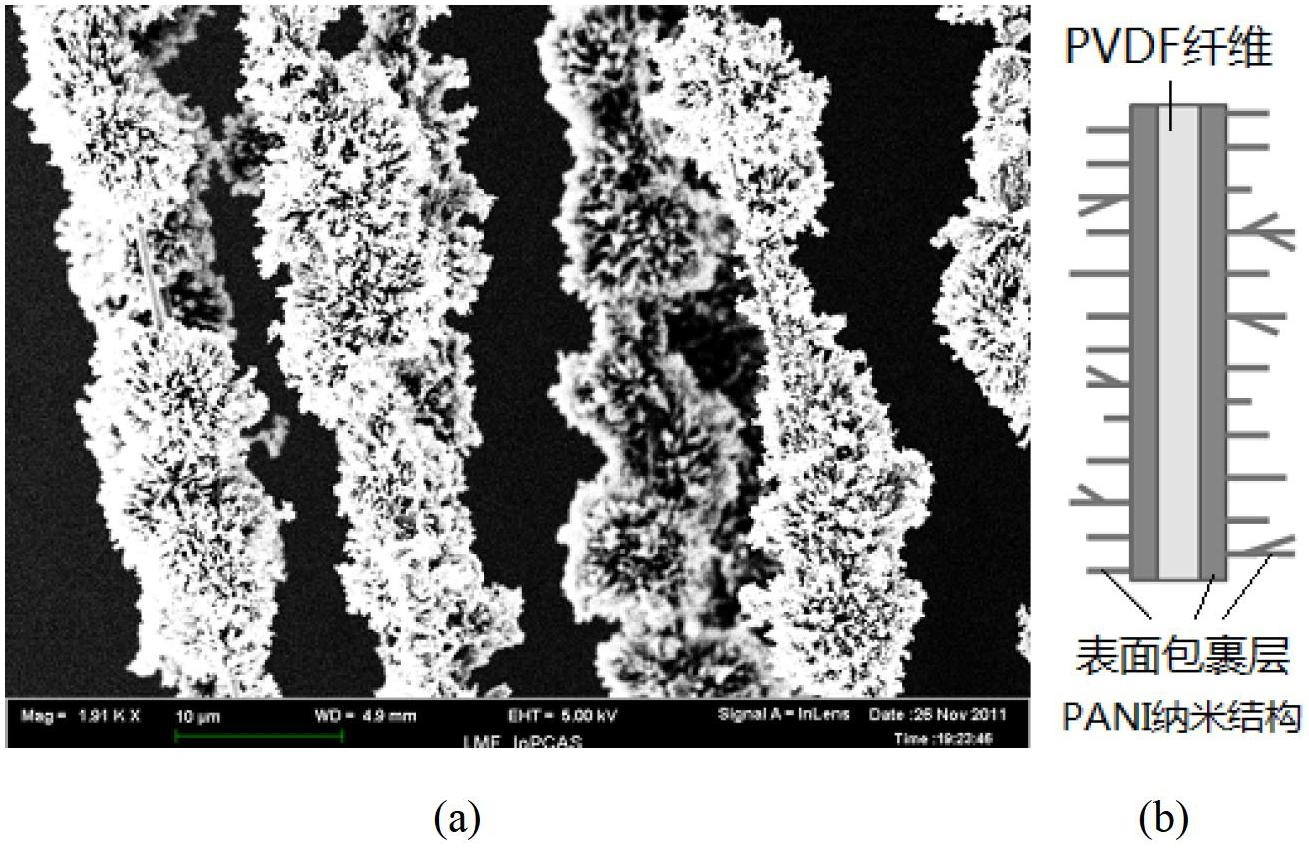

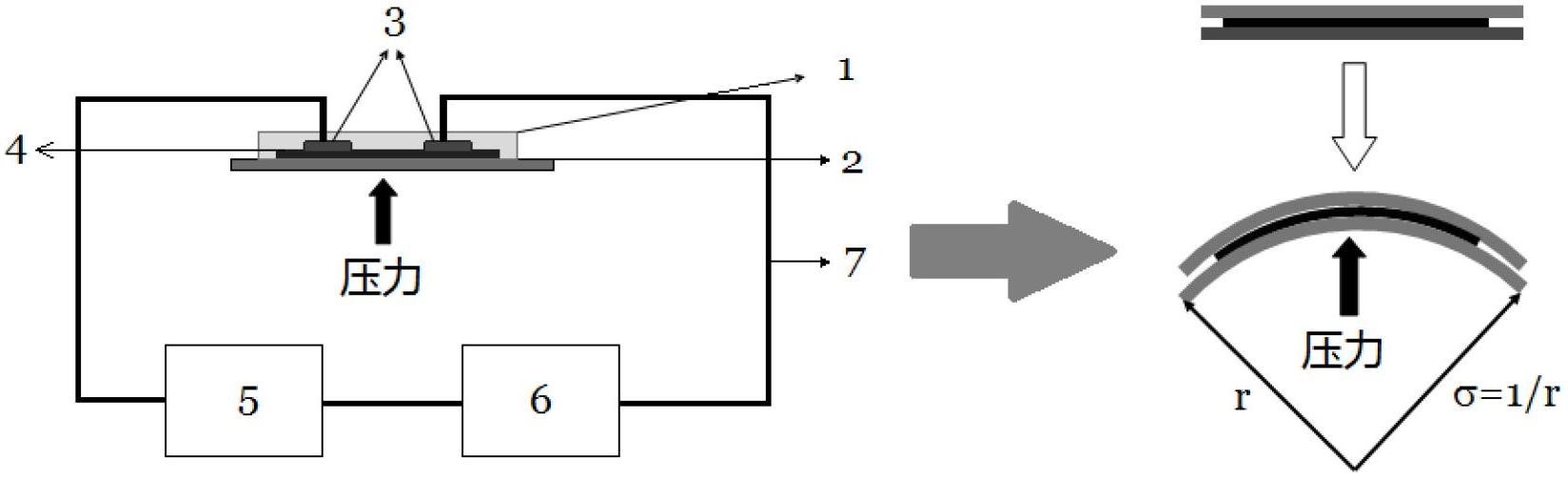

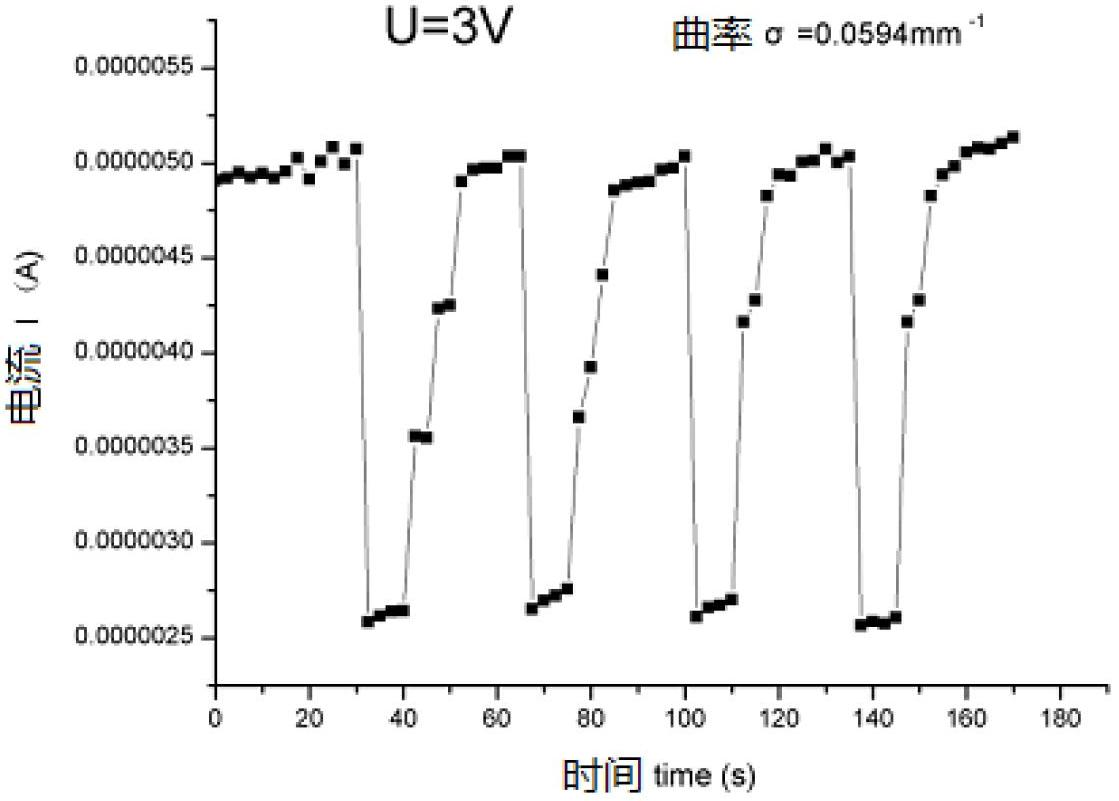

[0018] (1) Preparation of polyaniline coaxial ordered fibers with dendritic nanostructure: Firstly, polyvinylidene fluoride (PVDF) nano ordered fibers were prepared by electrospinning method using a conventional electrospinning device; the prepared mass percentage was 22% PVDF spinning solution, wherein the molecular weight is 250,000 PVDF2.2 grams, 3.8 grams of acetone, 3.8 grams of dimethylformamide, stirred at a constant temperature of 60 ° C for 5 hours to prepare the spinning solution; adjust the emission of the electrospinning device The distance between the pole (needle, inner diameter 0.6 mm) and the receiving pole (steel shaft of the rotating drum) is 10 cm, the spinning voltage is 10 to 14 kV, and the drum speed is 600 rpm; the PVDF nanometer prepared by ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com