Preparation method of ternary cathode material, ternary cathode material prepared through preparation method, lithium-ion battery and electric vehicle

A cathode material, lithium source technology, applied in the field of lithium ion batteries and electric vehicles, can solve the problems of poor particle structure integrity and stability, affecting material processing performance, battery performance, and increased side reactions between materials and electrolytes. Chemical properties, excellent cycle performance, effect of suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

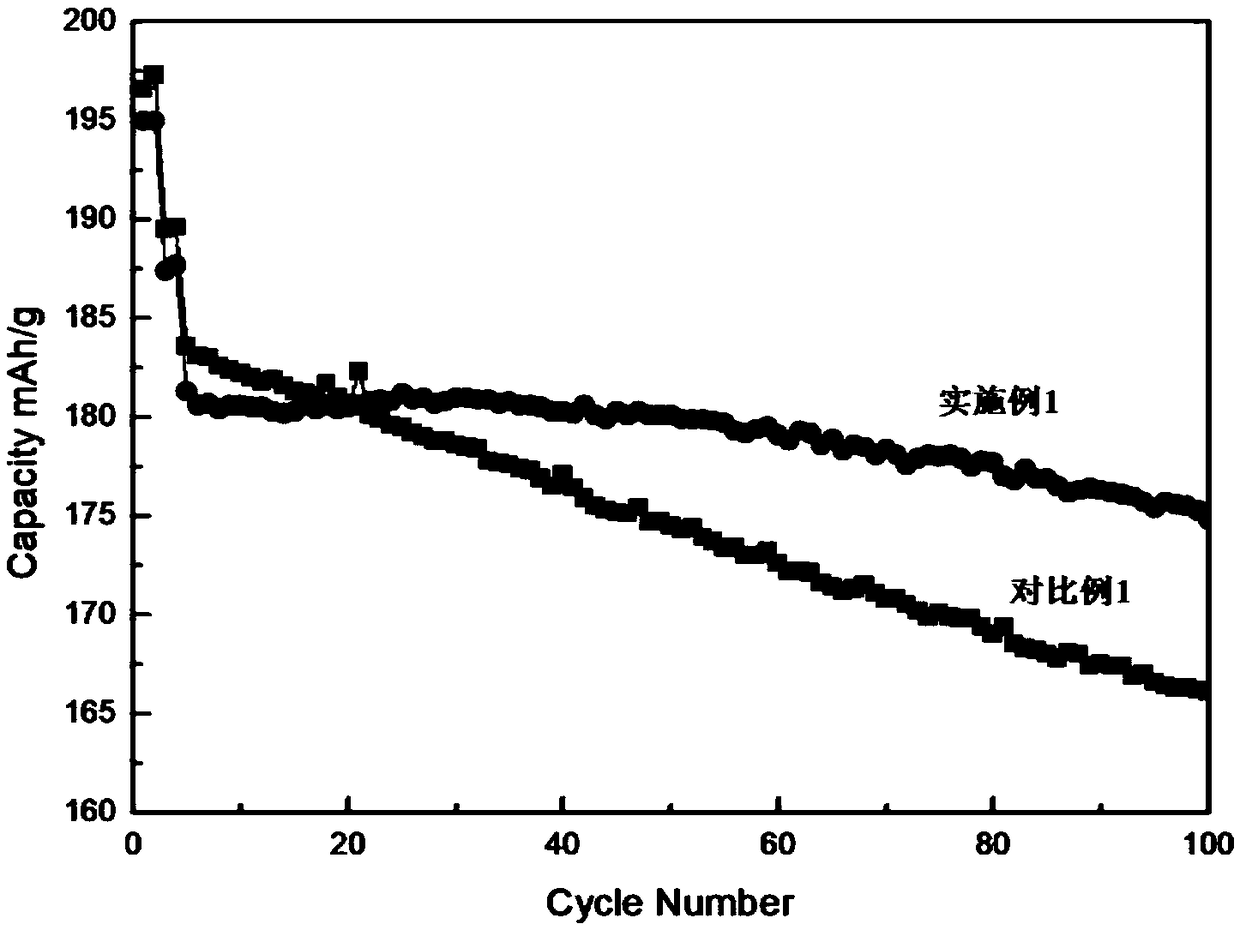

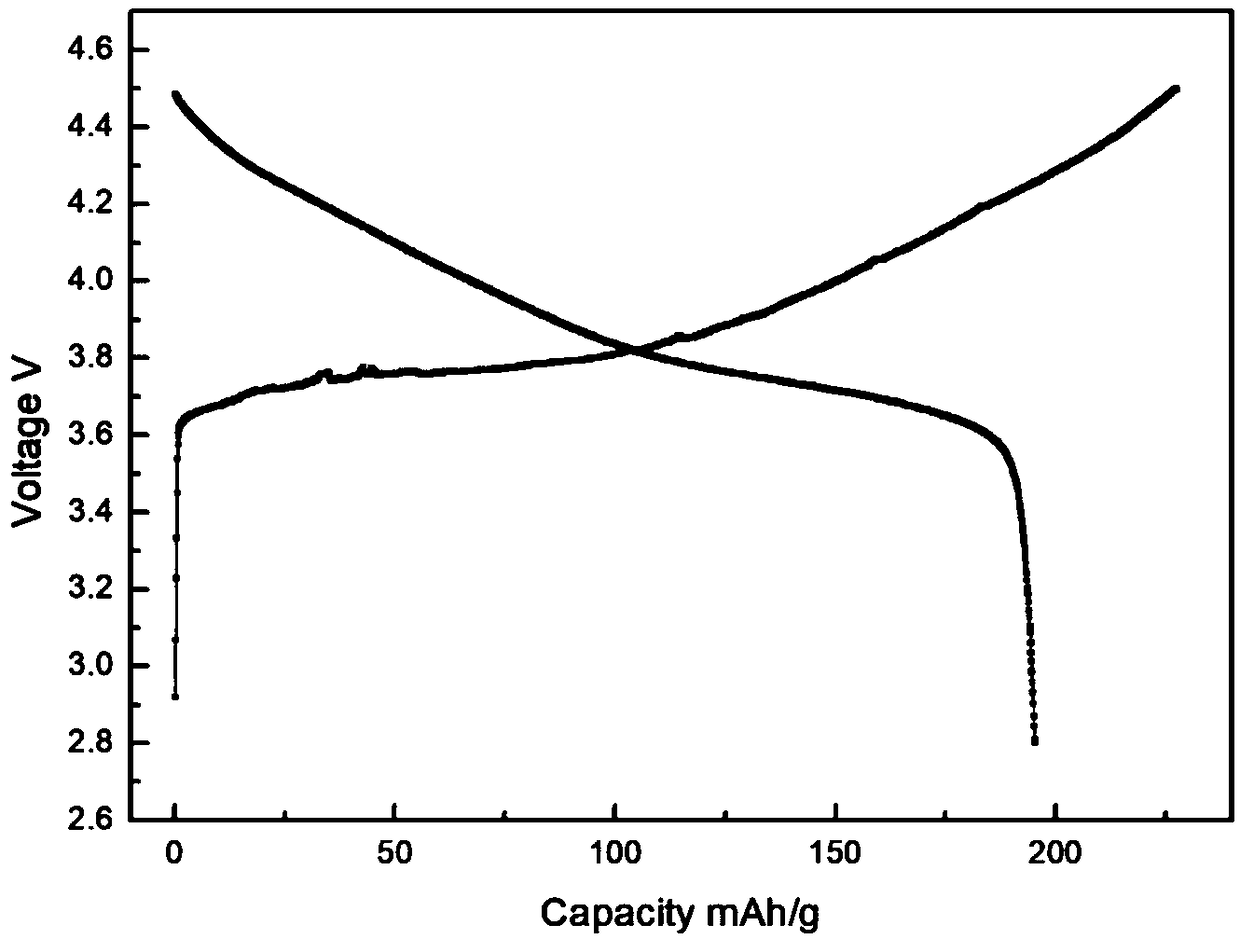

[0051] According to the first aspect of the present invention, a method for preparing a ternary positive electrode material is provided, comprising the following steps: uniformly mixing a ternary precursor, a lithium source, and a flux, and obtaining a quasi-single crystal ternary positive electrode through one-time sintering material; then add the quasi-single crystal ternary positive electrode material into the alumina-titania sol mixed solution, heat and evaporate the solution, and obtain the aluminum-titanium-coated quasi-single crystal ternary positive electrode material through secondary sintering.

[0052] The ternary positive electrode material mentioned here is composed of three chemical components (elements), including but not limited to nickel-cobalt-manganese or nickel-cobalt-aluminum. Exemplary high-nickel NCM materials include NCM333, NCM424, NCM442, NCM523, NCM622 or NCM811 , preferably, the chemical formula of the ternary cathode material is: LiNi 1-x-y co x m...

Embodiment 1

[0121] A preparation method of a ternary positive electrode material, comprising the following steps:

[0122] (1) Set D50 to 4-5μm Ni 0.6 co 0.2 mn 0.2 (OH) 2 1kg of precursor was heated at 2°C / min to 600°C for 5 hours in an air atmosphere; all pre-calcined precursors, 0.48kg of lithium hydroxide, and 3g of boron oxide were added to a ball milling tank, and ball milled at a speed of 800r / min 4h, obtain pulverized, mixed homogeneous material;

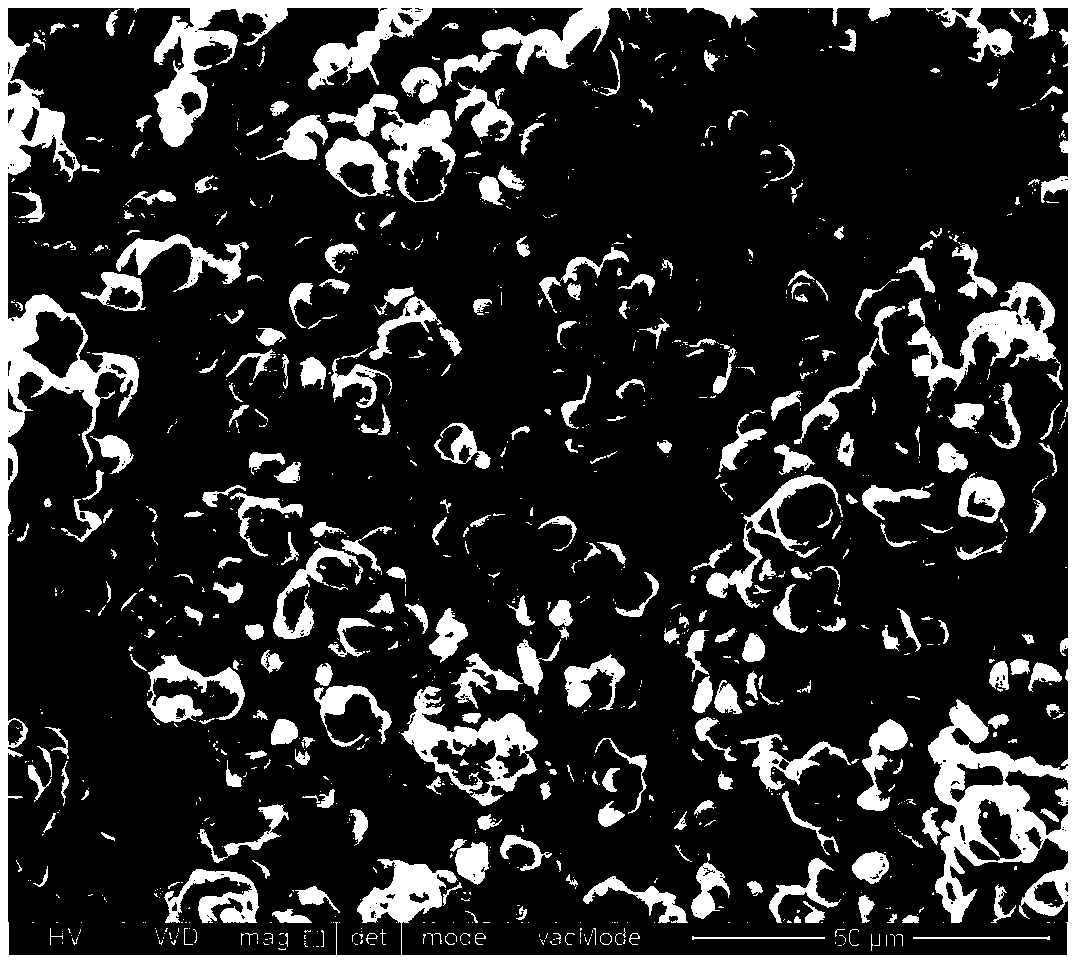

[0123] (2) In an oxidizing atmosphere, heat the mixed material to 500°C at 2°C / min and keep it for 4 hours, then raise it to 920°C at 2°C / min and keep it for 10 hours, then cool it down to 400°C at 1°C / min , and finally cooled with the furnace; after the sintering is completed, the material is mechanically crushed and screened to obtain a ternary cathode material with a similar single crystal morphology;

[0124] (3) Add the above 500g ternary cathode material to 2kg of deionized water at a temperature of 50°C, stir for 20min and t...

Embodiment 2

[0127] A preparation method of a ternary positive electrode material, comprising the following steps:

[0128] (1) Set D50 to 4-5μm Ni 0.7 co 0.2 mn 0.1 (OH) 2 1kg of precursor was heated up to 550°C for 5 hours at 4°C / min in an air atmosphere; all pre-calcined precursors, 0.435kg of lithium hydroxide, and 2.5g of lithium fluoride were added to the ball mill tank, and the speed was 700r / min Ball milling for 4 hours to obtain pulverized and uniformly mixed materials;

[0129] (2) Heat the mixture at 4°C / min to 500°C for 4 hours in an oxidizing atmosphere, then heat at 4°C / min to 860°C for 10 hours, then cool it to 300°C at 1°C / min, and finally Cooling with the furnace; after the sintering is completed, the material is mechanically crushed to obtain a ternary cathode material with a similar single crystal morphology;

[0130] (3) Add 500g of the above-mentioned ternary cathode material to 2.5kg of an aqueous solution with a temperature of 60°C and an ethanol ratio of 5:1, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com