Ecological plate and preparation process thereof

A preparation process and technology of ecological board, which is applied in the direction of manufacturing tools, wood layered products, wood processing appliances, etc., can solve the problems of low product defective rate, high ecological board defective rate, ecological board processing raw materials, etc., and achieve reduction Energy consumption, reducing the number of times of hot pressing, and reducing the effect of defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

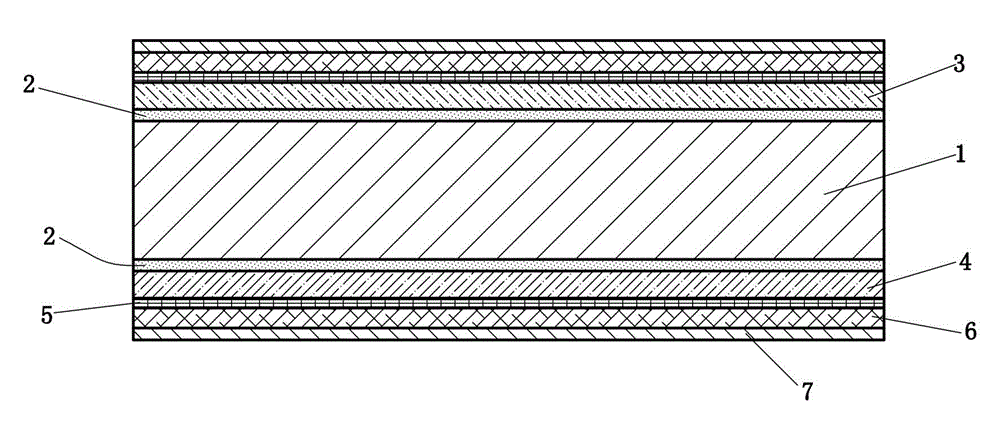

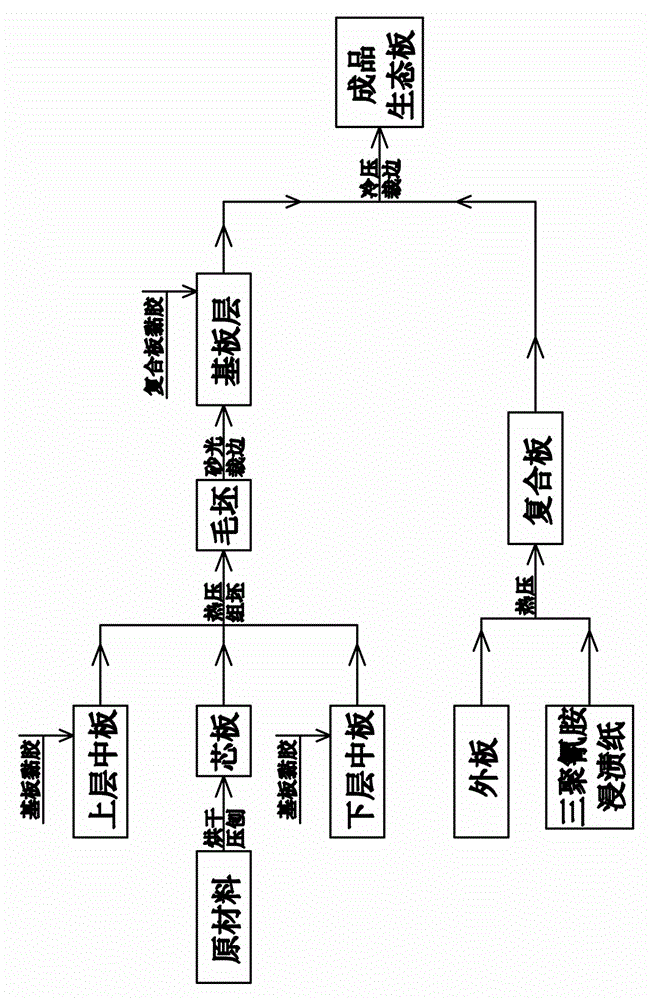

[0025] In this embodiment, the ecological board includes a substrate layer and a composite board. The substrate layer includes a core board 1 and an upper middle board 3 and a lower middle board 4 bonded to the core board through a substrate adhesive layer 2. The composite board includes an outer board 6 and a melamine-impregnated paper 7 attached to one side of the outer board 6, the upper middle board 3 and the lower middle board 4 are bonded to the other side of the outer board 6 through the composite board adhesive layer 5 .

[0026] The outer panel 6 is technical wood.

[0027] Because of national standards or customer order requirements, the thickness of the finished ecological board is a definite value. The thickness of the composite board composed of melamine impregnated paper 7 and the outer board 6 remains unchanged, and the thickness of the substrate layer composite is also unchanged. The ecological board of the present invention is placed on the substrate The uppe...

Embodiment 2

[0033] In this embodiment, the similarities with Embodiment 1 will not be repeated, and the difference is:

[0034] In the production process of the ecological board, in the first step, the duration of hot pressing of the core board, the upper middle board 3 and the lower middle board 4 is 25 minutes, the temperature is 130 degrees Celsius, and the pressure is 1.5 MPa.

[0035] The duration of hot pressing of the outer plate 6 and the melamine-impregnated paper 7 is 10 minutes, the temperature is 140 degrees centigrade, and the pressure is 2 MPa. The outer board 6 is poplar.

[0036] In the second step, the temperature of cold pressing is 30 degrees Celsius, the duration is 30 minutes, and the pressure is 1 MPa.

Embodiment 3

[0038] In this embodiment, the similarities with Embodiment 1 will not be repeated, and the difference is:

[0039] In the preparation process of the ecological board, in the first step, the duration of hot pressing of the core board, the upper middle board 3 and the lower middle board 4 is 15 minutes, the temperature is 115 degrees Celsius, and the pressure is 1.0 MPa.

[0040] The duration of hot pressing of the outer plate 6 and the melamine-impregnated paper 7 is 6 minutes, the temperature is 120 degrees centigrade, and the pressure is 1.4 MPa. The outer board 6 is eucalyptus.

[0041] In the second step, the temperature of cold pressing is 20 degrees Celsius, the duration is 20 minutes, and the pressure is 0.6 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com