Novel wood-burning particle furnace

A technology of burning wood and pellets, which is applied in the direction of combustion method, combustion equipment, fuel supply, etc. It can solve the problems of plate heat exchange heat loss, insufficient combustion, and blockage of the combustion bowl, so as to save operating costs, achieve good heating effect, and thermal efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

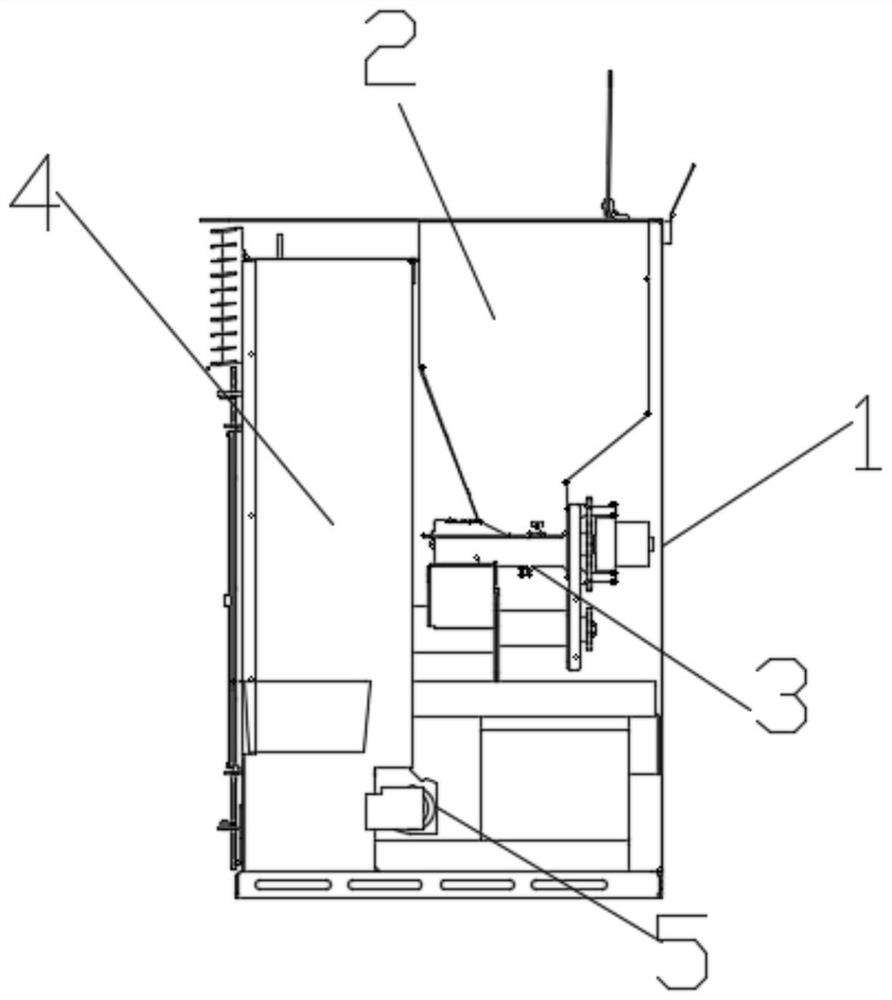

[0044] Such as figure 1 As shown, a new type of wood-burning pellet stove includes a shell 1, a feed port 2, a combustion system 3, a heat converter 4 and an exhaust device 5. The feed port 2 is arranged on the upper end of the shell 1, and the feed port 2 is connected to the combustion The input end of the system 3 and the output end of the combustion system 3 are connected to the input end of the heat converter 4 .

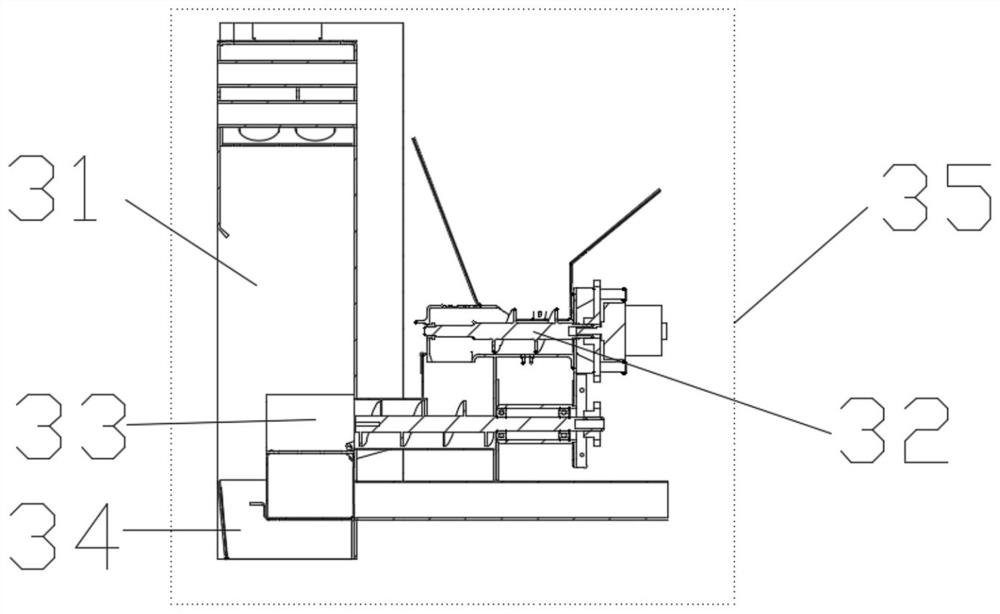

[0045] Such as figure 2 As shown, the combustion system 3 includes a combustion chamber 31, a conveyor 32, a combustion bowl 33, an ash tray 34, and a control system 35. The combustion chamber 31 is arranged on one side of the shell 1, and the input end of the conveyor 32 is connected to the outlet of the feed port 2. The output end of the conveyor 32 is arranged on one side of the combustion chamber 31 to connect with the combustion bowl 33, the combustion bowl 33 is arranged on the inner wall of the combustion chamber 31, the ash tray 34 is arranged directly...

Embodiment 2

[0056] Such as figure 1 As shown, a new type of wood-burning pellet stove includes a shell 1, an inlet 2 for putting fuel into the wood-burning pellet stove, and a combustion system 3 for charging and burning the fuel put into the inlet 2 , a heat exchanger 4 for transferring heat to the cold air in the housing 1 , and an exhaust device 5 for discharging the heated air out of the housing 1 .

[0057] Such as figure 2 As shown, the combustion system 3 includes a combustion chamber 31, a conveyor 32, a combustion bowl 33, an ash tray 34, and a control system 35. The combustion chamber 31 is arranged on one side of the shell 1, and the input end of the conveyor 32 is connected to the outlet of the feed port 2. The output end of the conveyor 32 is arranged on one side of the combustion chamber 31 to connect with the combustion bowl 33, the combustion bowl 33 is arranged on the inner wall of the combustion chamber 31, the ash tray 34 is arranged directly below the combustion bowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com