Anti-slagging Biomass Composite Fuel for Circulating Fluidized Bed Boiler

A circulating fluidized bed, composite fuel technology, applied in the direction of biofuels, waste fuels, etc., can solve problems such as unfavorable popularization and application, increase the difficulty of industrial production of biomass fuels, increase production costs, etc. The effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

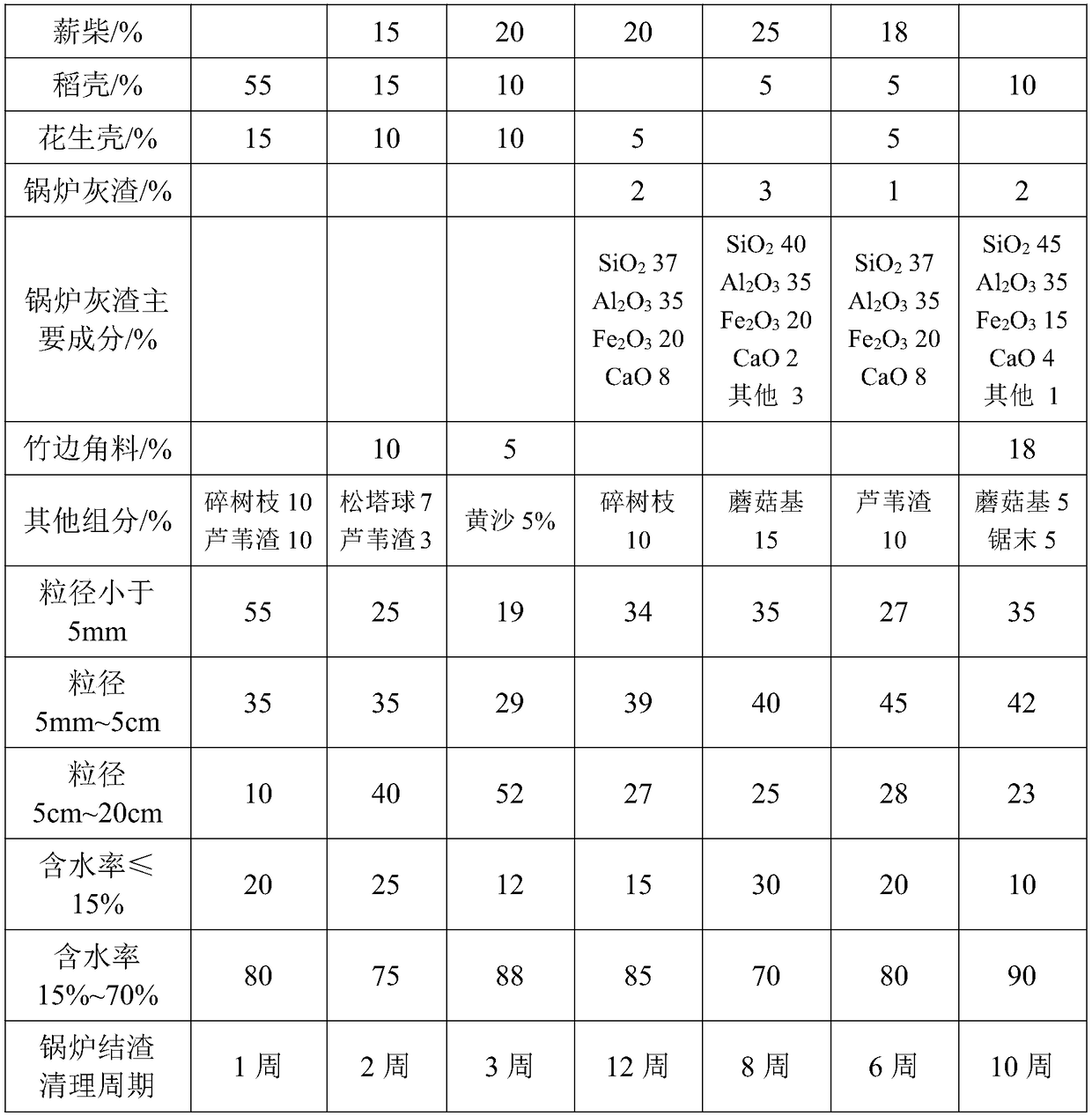

[0034] According to the values given in Tables 1-2, each component is compounded according to moisture content, particle size distribution, and proportion, and is made into biomass fuel through processes such as crushing, screening, and mixing. Due to the addition of 1% to 4% boiler ash and slag, the reasonable proportion, particle size distribution and dry and wet ingredients improve the reaction conditions in the furnace, effectively control the slagging phenomenon, and extend the boiler slagging cleaning cycle to 4 weeks above.

[0035] Table 1

[0036]

[0037]

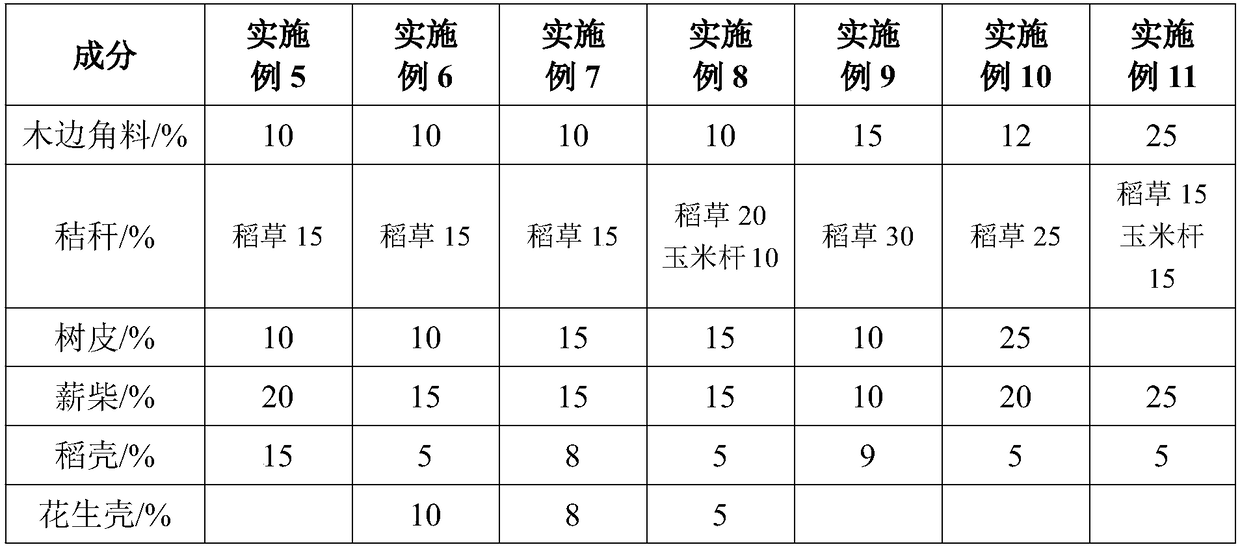

[0038] Table 2

[0039]

[0040]

[0041] Explanation: Blank cells in Table 1 and Table 2 indicate that the corresponding components are not contained; the values in the cells on the right of particle size and moisture content are the comprehensive proportion of biomass fuels falling within the given range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com