Biomass air heater

A hot air blower and biomass technology, applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of poor heating effect, insufficient combustion, inflexible operation, etc., to reduce black smoke and volatile Decomposition, reduction of heat loss, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

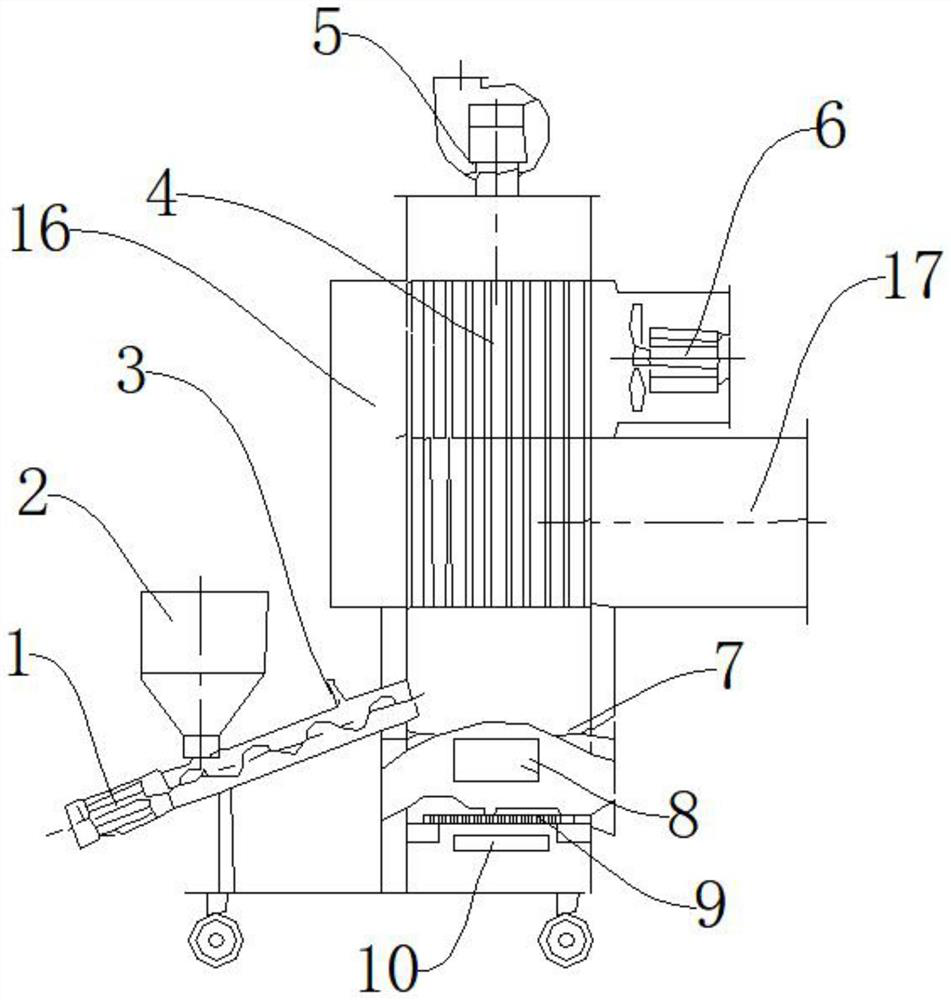

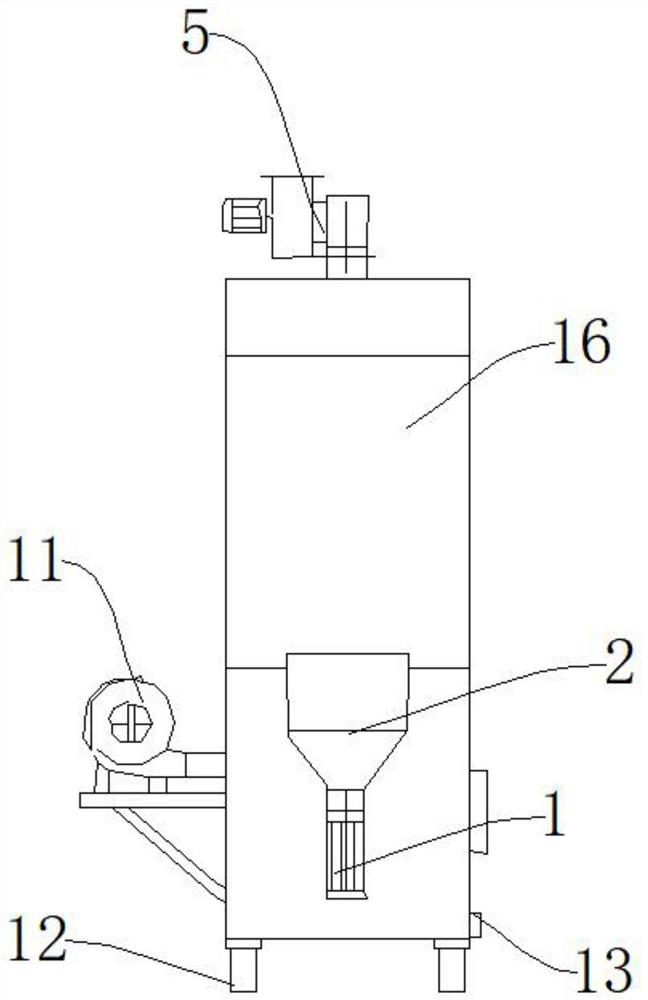

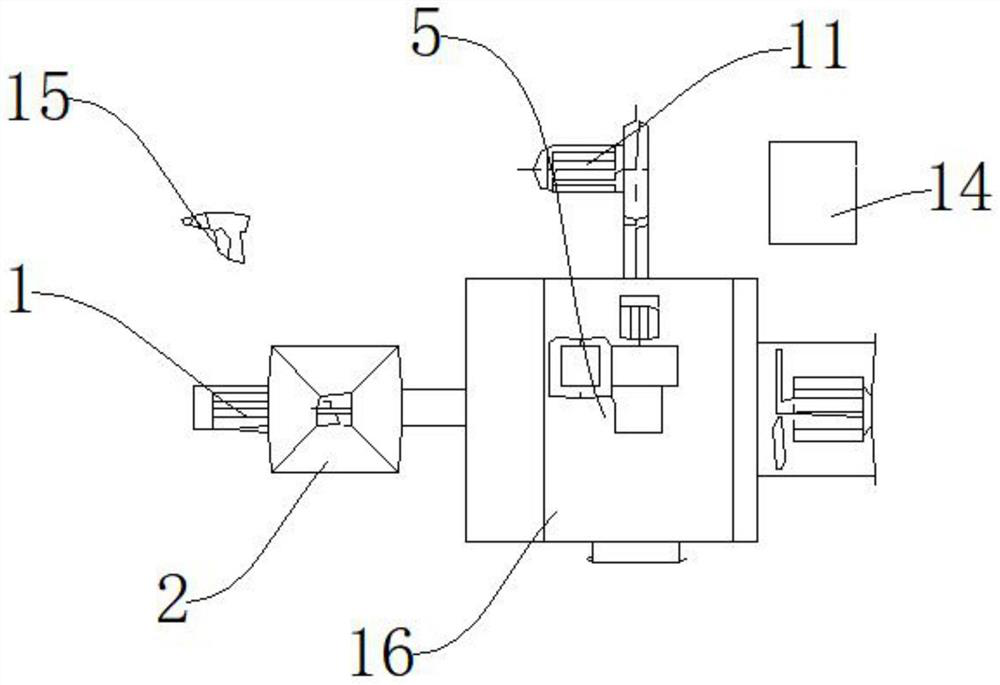

[0031] Such as Figure 1-Figure 3 As shown, a biomass hot air blower includes a screw feeder 1, a hopper 2, a cabinet body 16, and a plate-sheet heat exchanger 4. An induced draft fan 5 is installed at the upper end of the cabinet body 16, and a moving wheel is installed at the lower end of the cabinet body 16. 12. There is an ash outlet 13 on the lower side of the front end of the cabinet body 16, an ignition fan 11 is installed on the rear end of the cabinet body 16, an electric box 14 is installed on one side of the ignition fan 11, and an ignition gun 15 is installed on the other side of the ignition fan 11 , the upper end of the inside of the cabinet 16 is provided with a plate heat exchanger 4, one side of the plate heat exchanger 4 is connected to the outside of the cabinet 16 and correspondingly provided with a blower 6, the lower side of the blower 6 is provided with an air outlet 17, and the plate The lower side of the type heat exchanger 4 is provided with a seconda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com