Sewage treatment process of complex biochemistry, coupled physicochemical and removal of heavy metals

A sewage treatment and heavy metal technology, applied in biological sludge treatment, biological organic part treatment, water/sewage multi-stage treatment, etc., can solve the secondary pollution of the ecological environment, high construction and operation costs, and toxic sludge and concentrated water And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

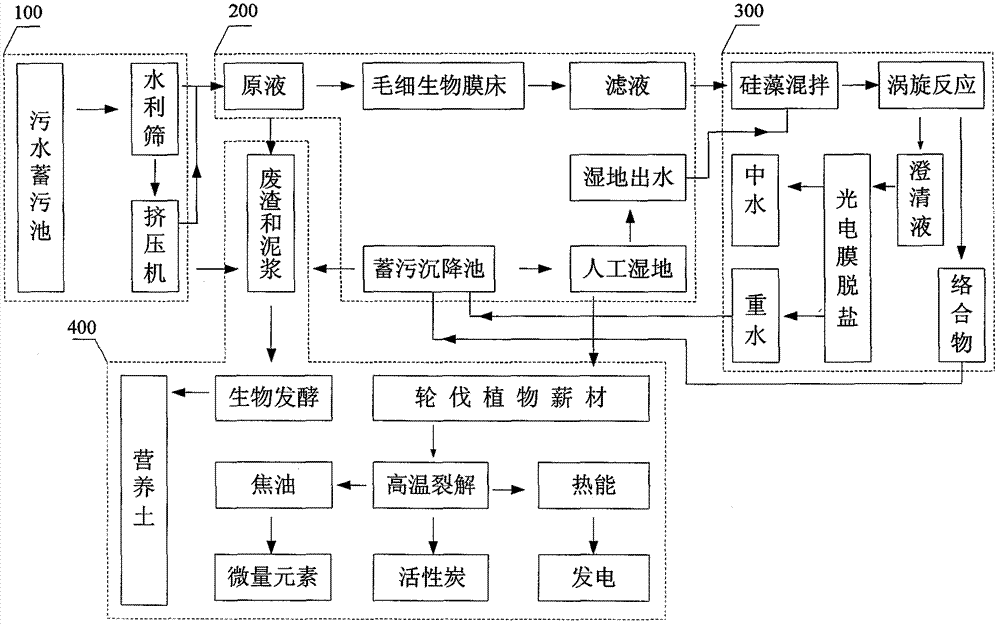

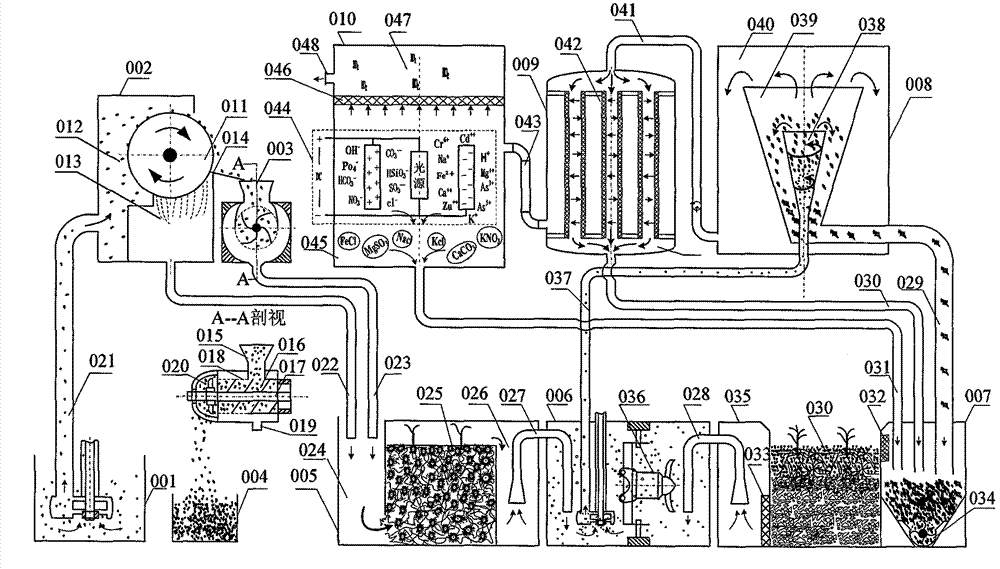

[0014] The above accompanying drawing is one of the embodiments of the present invention. With reference to accompanying drawing, some descriptions are made to this embodiment. figure 1 It is a system process block diagram of the present invention. This is the general framework of the embodiment of the present invention.

[0015] combine figure 1 and figure 2 Gain an understanding of the process and technical system principles of the invention.

[0016] Depend on figure 1 It can be seen that the process and technology of the present invention are generally divided into four major sections.

[0017] 100 is the mechanical solid-liquid separation unit of the present invention, including: 001 sewage storage tank, 021 non-clogging sewage pump and pipeline, 002 hydraulic screen and 003 screw extrusion solid-liquid separator. Larger granular impurities such as sediment, stone, straw, hair, and metal in the sewage in the sewage storage tank are difficult to degrade by microorga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com