High-efficiency wood chip cutting device capable of processing in cedar growing place

A cutting device and high-efficiency technology, applied in the direction of wood processing equipment, veneer manufacturing, manufacturing tools, etc., can solve the problems of slow felling, transportation and processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

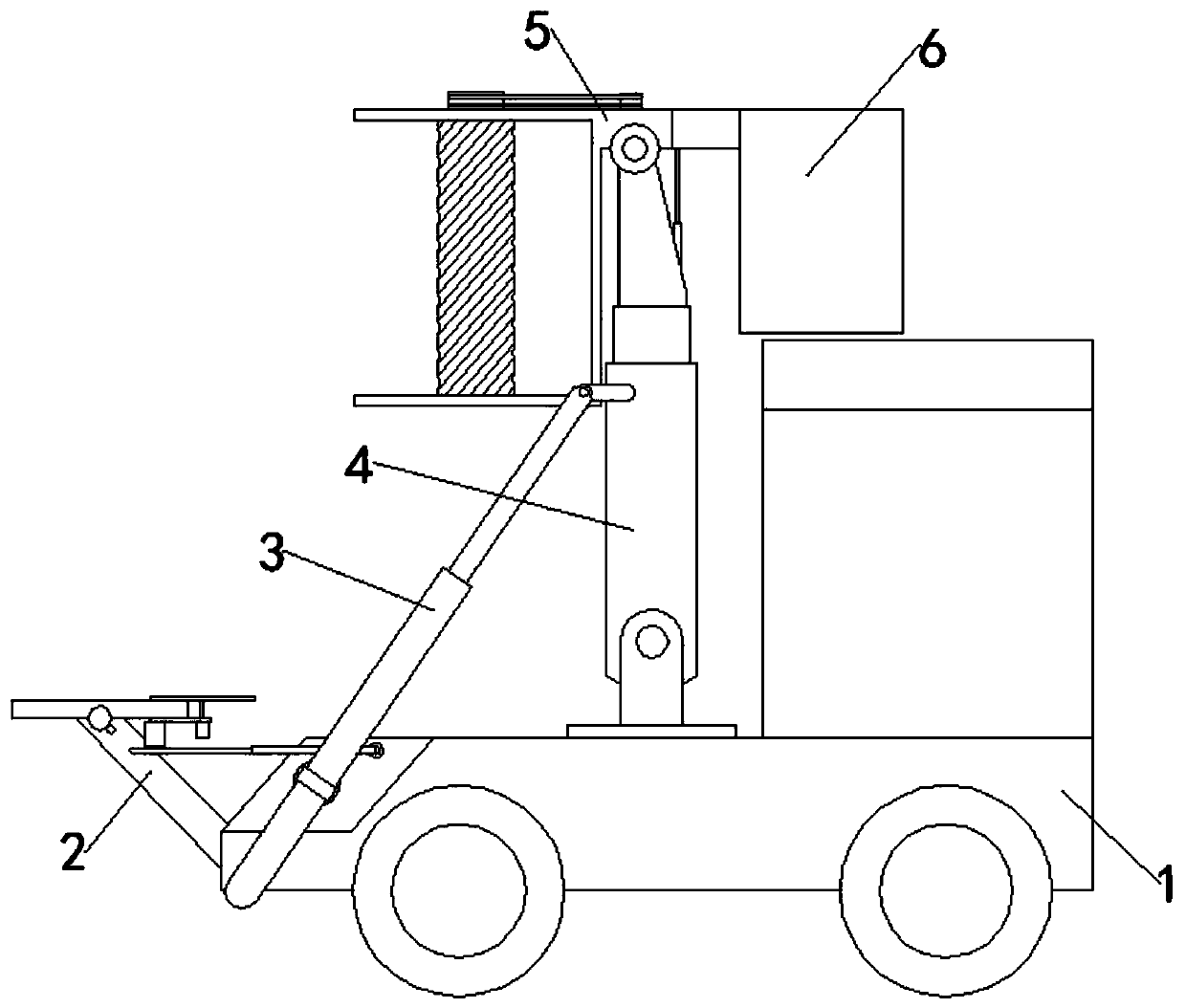

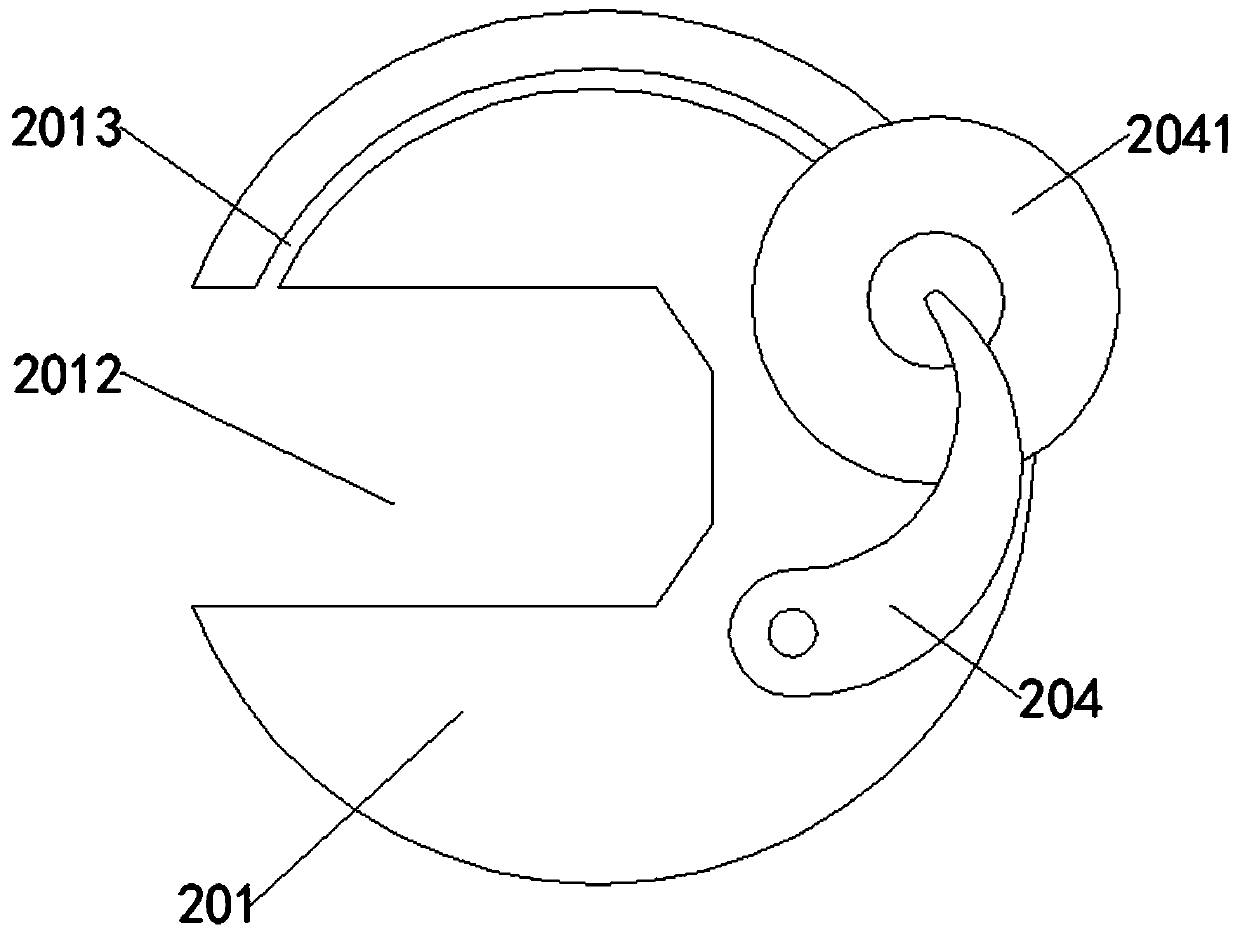

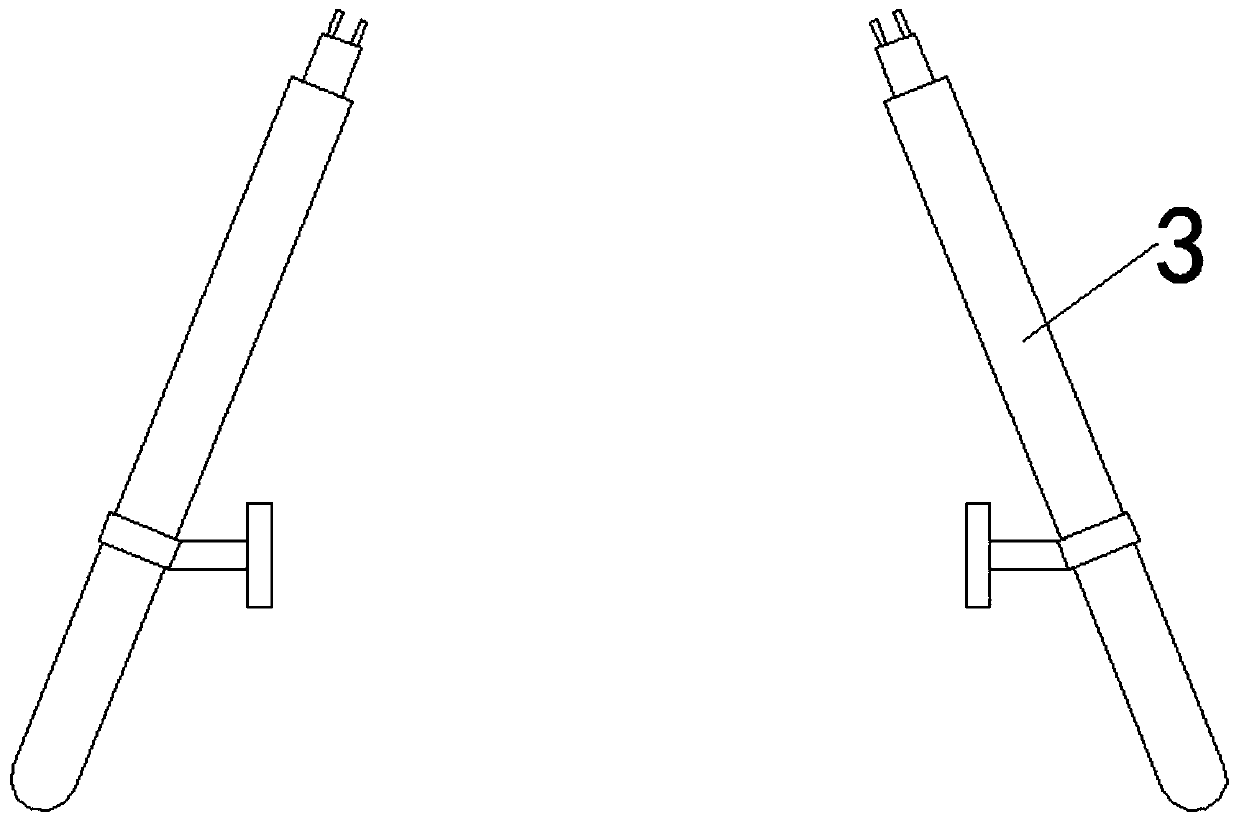

[0029] see Figures 1 to 9, in an embodiment of the present invention, a high-efficiency wood chip cutting device that can be processed in a place where fir trees grow, includes a carrier 1, a cab 101, wheels 102, a bottom bracket 2, a platform 201, a gear 2011, a groove 2012, and a sliding groove 2013 , motor 202, hydraulic rod 203, rotating bracket 204, cutting disc 2041, hydraulic rod 2 3, electric telescopic column 4, platform 2 5, fitting plate 501, elliptical groove 5011, fitting groove 5012, toothed shaft 502, motor 503, Cutting plate 504, guillotine plate 505, oval gear 506, spring 507, guide plate 508, roller 509 and collecting frame 6, carrier 1 right side top is fixedly connected with driver's cab 101, and carrier 1 bottom is connected with wheel 102 around rotation, driving The left side of chamber 101 is rotatably connected with bottom bracket 2, the top of one side of bottom bracket 2 is rotatably connected with platform 201, the bottom of platform 201 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com