Electricity conductive polyaniline carbon nanotube combined electromagnetic shielding composite material and its production method

A carbon nanotube composite and conductive polyaniline technology, which is applied in the field of electromagnetic shielding composite film and its preparation, can solve the problems of low mechanical strength and poor processability of conductive high polymers, and achieve easy large-area film production and improved Mechanical properties and processability, the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

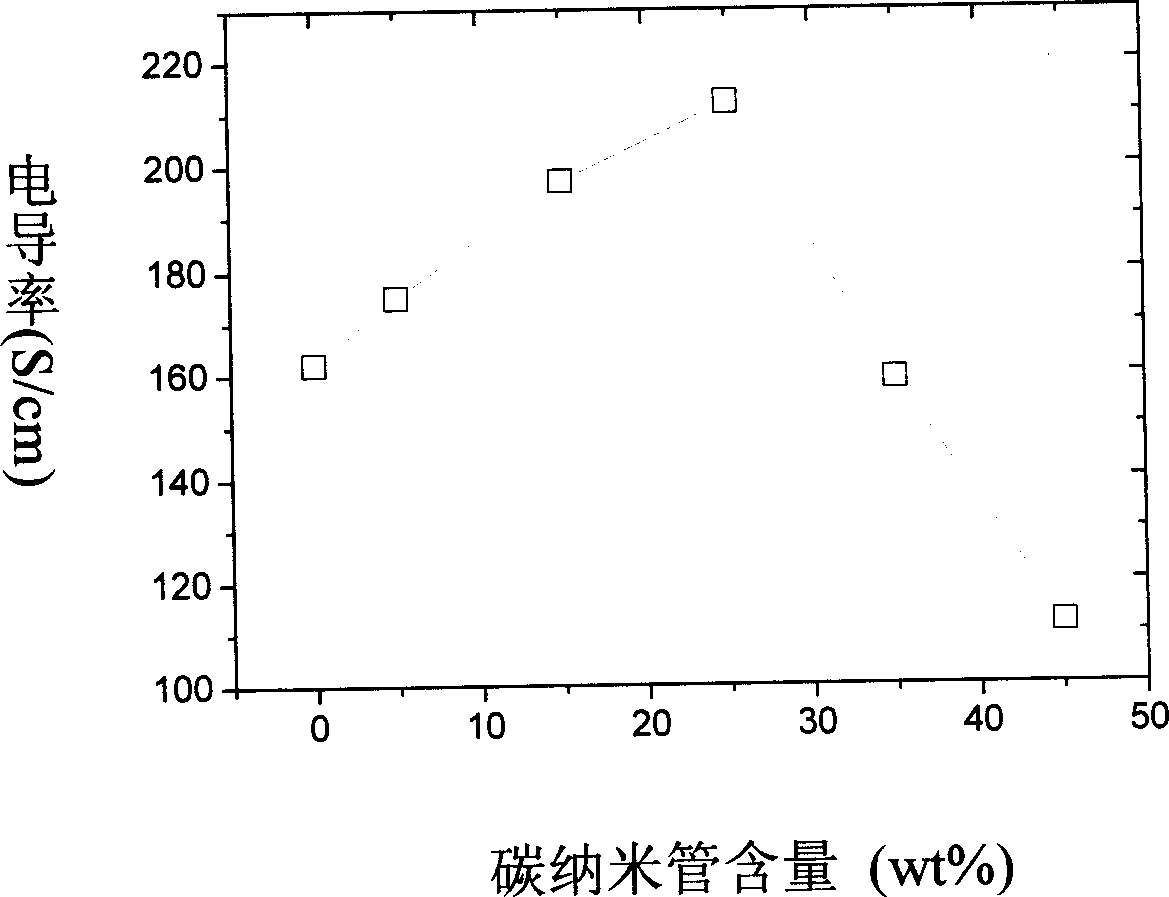

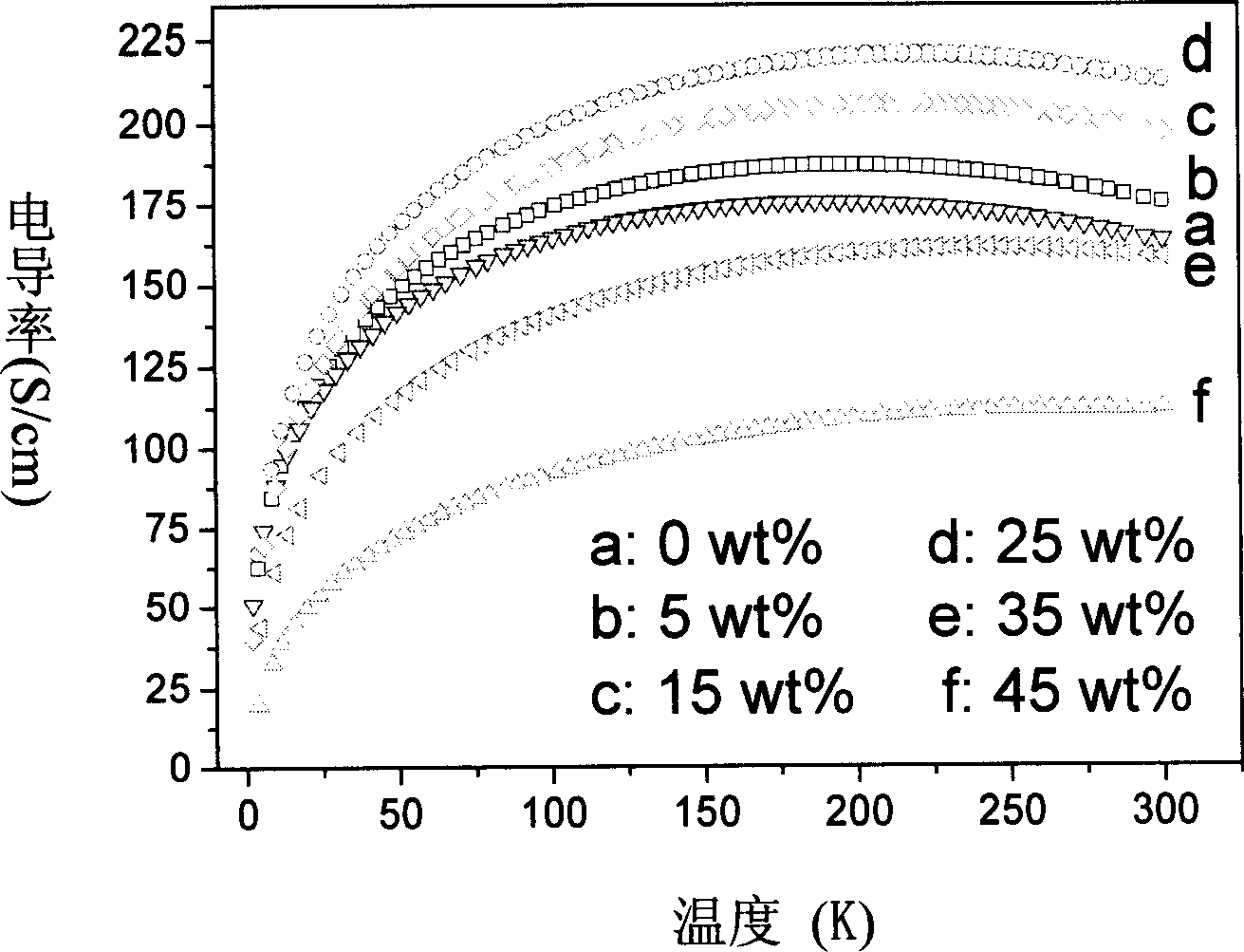

[0025] First adopt ultrasonic method to uniformly disperse carbon nanotube 0.0022g in the chloroform extract solution 0.9g of polyaniline doped with 4-dodecylbenzenesulfonic acid with a concentration of 15wt%, and then mix the above solution with a concentration of 5.1 g of polyaniline-m-cresol solution doped with 85 wt % camphorsulfonic acid was uniformly mixed to form a film-forming solution, and finally the film-forming solution was poured on a glass slide to form a film by volatilization of chloroform.

[0026] Wherein, the mass percent concentration of carbon nanotubes (CNT wt%) is 5 wt%, the electrical conductivity is ~170 S / cm, and the phase transition temperature is 196K.

Embodiment 2

[0028] First adopt ultrasonic method to uniformly disperse carbon nanotube 0.0072g in the chloroform extract solution 0.9g of polyaniline doped with 4-dodecylbenzenesulfonic acid with a concentration of 15wt%, and then mix the above solution with a concentration of 5.1 g of polyaniline-m-cresol solution doped with 85 wt % camphorsulfonic acid was uniformly mixed to form a film-forming solution, and finally the film-forming solution was poured on a glass slide to form a film by volatilization of chloroform.

[0029] Wherein, the mass percent concentration of carbon nanotubes (CNT wt%) is 15 wt%, the electrical conductivity is ~180 S / cm, and the phase transition temperature is 215K.

Embodiment 3

[0031] First adopt ultrasonic method to uniformly disperse carbon nanotube 0.0137g in the chloroform extract solution 0.9g of polyaniline doped with 4-dodecylbenzenesulfonic acid with a concentration of 15wt%, and then mix the above solution with a concentration of 5.1 g of polyaniline-m-cresol solution doped with 85 wt % camphorsulfonic acid was uniformly mixed to form a film-forming solution, and finally the film-forming solution was poured on a glass slide to form a film by volatilization of chloroform.

[0032]Among them, the mass percentage concentration of carbon nanotubes (CNT wt%) is 25wt%, the electrical conductivity is ~210S / cm, the phase transition temperature is 219K, the mechanical strength is 14.53MPa, the elongation is 6.0243%, and the elastic modulus is 286.39MPa. (See Table 2)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com