Heat exchanger with a mixing chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

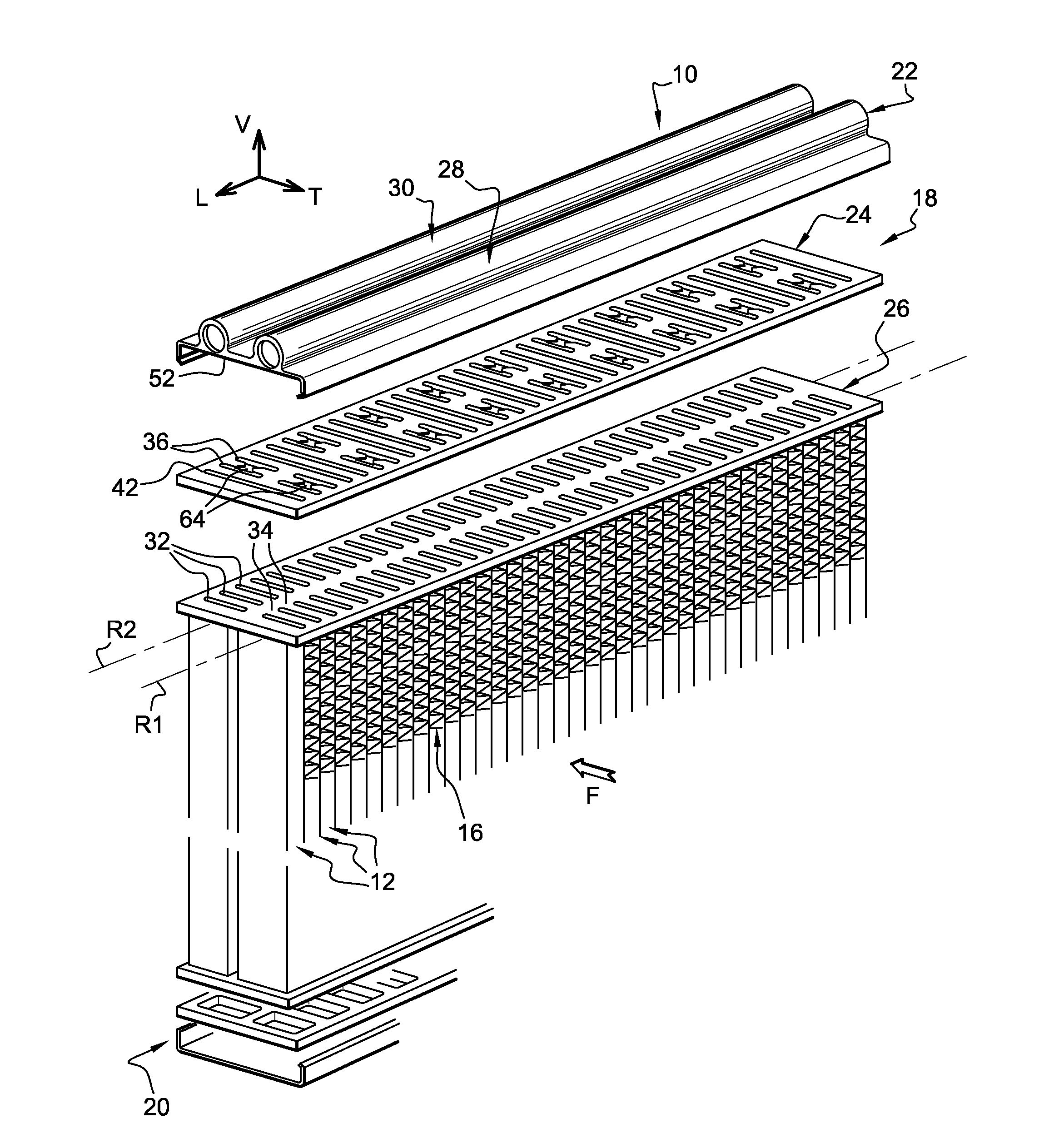

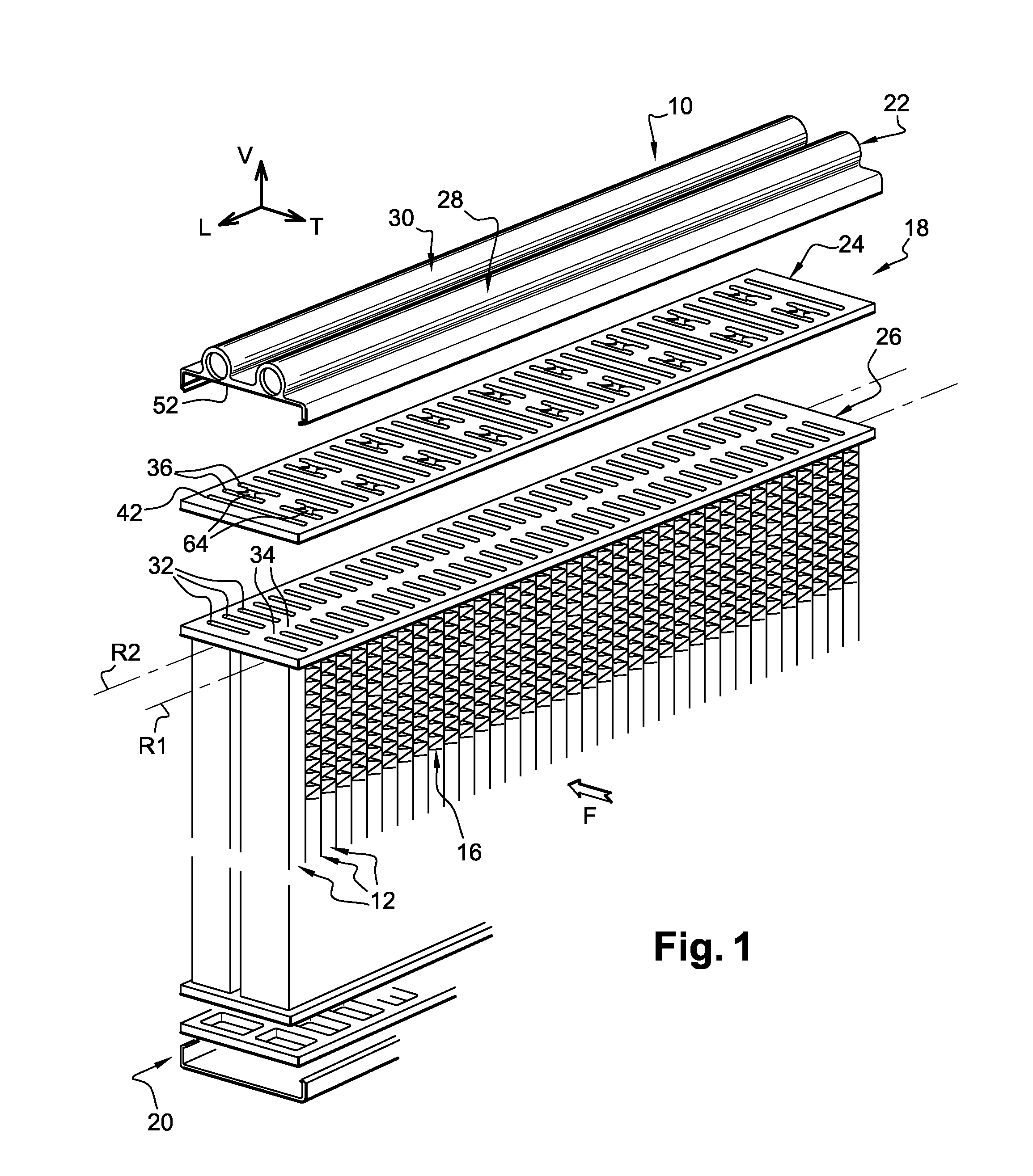

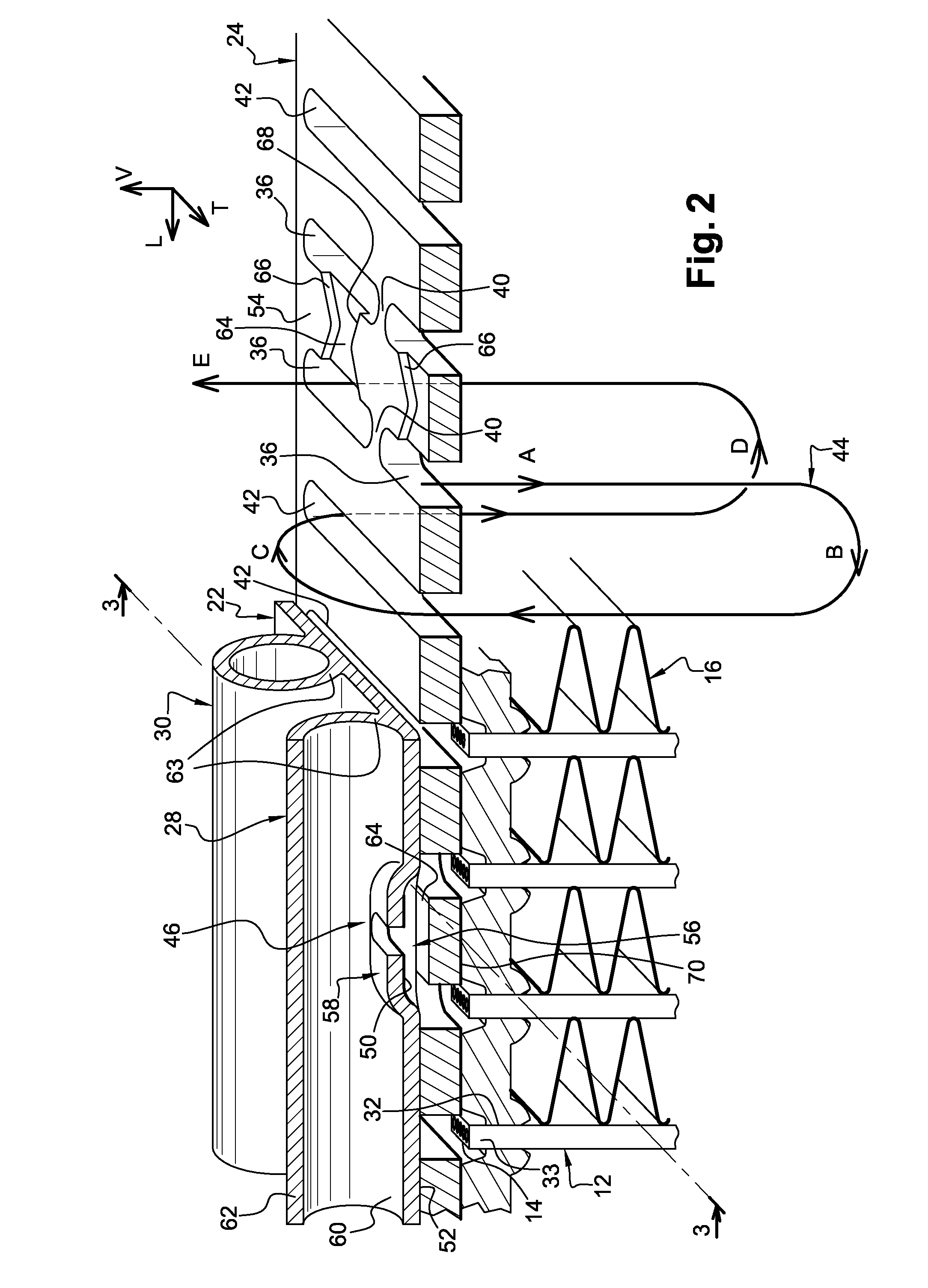

[0030]FIGS. 1 and 2 show an evaporator 10 for a motor vehicle air-conditioning system which is operated with CO2 as refrigerant according to a preferred embodiment of the present invention. This evaporator 10 is designed as a two rows flat-tube evaporator and has a multiplicity of flat tubes 12 arranged along two longitudinal rows R1, R2, a front row R1 on the front side of the evaporator 10 and a rear row R2 on the rear side of the evaporator 10. These flat tubes 12 can be designed as extruded multi-channel flat tubes, which have a multiplicity of flow passages 14. All the flat tubes 12 have the same length along a vertical axis V and the same depth D along a transverse axis T.

[0031]In the following description, for the purpose of better understanding, we will use an orientation along the vertical axis V, the longitudinal axis L, and the transverse axis T, as can be seen on FIG. 1.

[0032]Preferably, the flat tubes 12 are multiport extruded flat tubes.

[0033]Between the individual fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com