Annular detecting instrument for concrete gas seepage coefficient and detecting method

A technology of gas permeation and testing methods, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of complex test procedures, cumbersome experimental operations, laborious loading and unloading, etc., and achieve reliable test results, simple calculation models, and compact equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

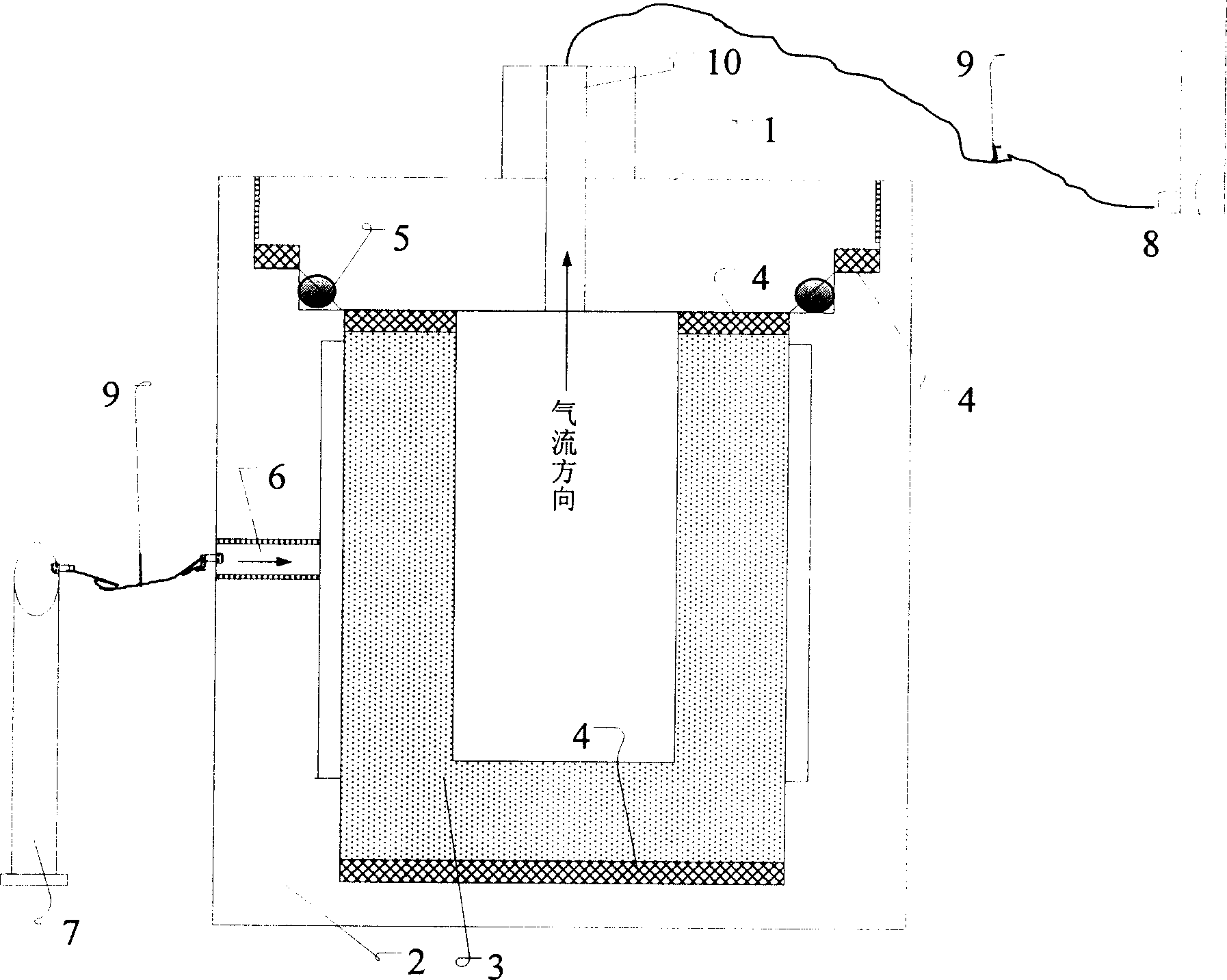

[0029] Embodiment 1: the following parts are pressed figure 1 Those skilled in the art can successfully implement the connection in the manner shown. The cover plate 1 is made of A3 steel material, with a diameter of 220mm on the upper edge and 211mm on the lower edge; the outer shell 2 is made of A3 steel material, with an outer dimension of 236mm in diameter and a total height of 230mm; the size of the tested sample is 200mm in outer diameter, 110mm in inner diameter, The inner cavity is 150mm high and the wall thickness is 45mm; the gasket 4 adopts a 3mm thick vacuum rubber gasket, the gasket 5 adopts an O-shaped rubber gasket of 206×5.30G GB3452.1, and the size of the air inlet 6 is 18mm in diameter; compressed gas The tank 7 is an industrial nitrogen cylinder; the flowmeter 8 is a soap film flowmeter; the hose 9 is a vacuum rubber tube; the hole diameter of the cover plate is 18mm in diameter.

Embodiment 2

[0030] Embodiment 2: test method

[0031] Form the sample according to the mix ratio in Table 1. The specific dimensions are: outer diameter 200mm, inner diameter 110mm, inner cavity height 150mm, wall thickness 45mm.

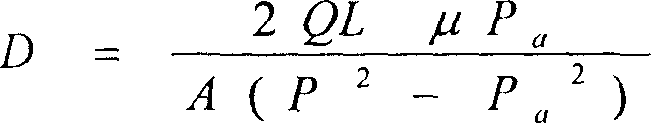

[0032] Dry the above-mentioned concrete samples that have reached the age of 28 days, place them in the casing, tighten the connecting nuts between the casing and the cover plate, open the valve of the compressed gas tank, and feed in N 2 , adjust the air pressure to the specified first pressure value of 0.15MPa, keep the ventilation time in the sample for 20 minutes, start to test the gas flow through the tested sample, and record the flow value; change the test pressure to 0.2MPa and 0.3MPa respectively, Repeat the above test, write down the test values of various conditions, press D = 2 QLμ P a A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com