Ultrahigh-precision multilayer film thickness drift error calibration method

A technology of drift error and calibration method, applied in the direction of testing optical properties, etc., can solve problems such as the boundary of difficult film thickness calculation, the inability to measure thickness error, and the accuracy cannot reach resolution, etc., to achieve small influence of instrument conditions and high characterization accuracy , highly controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

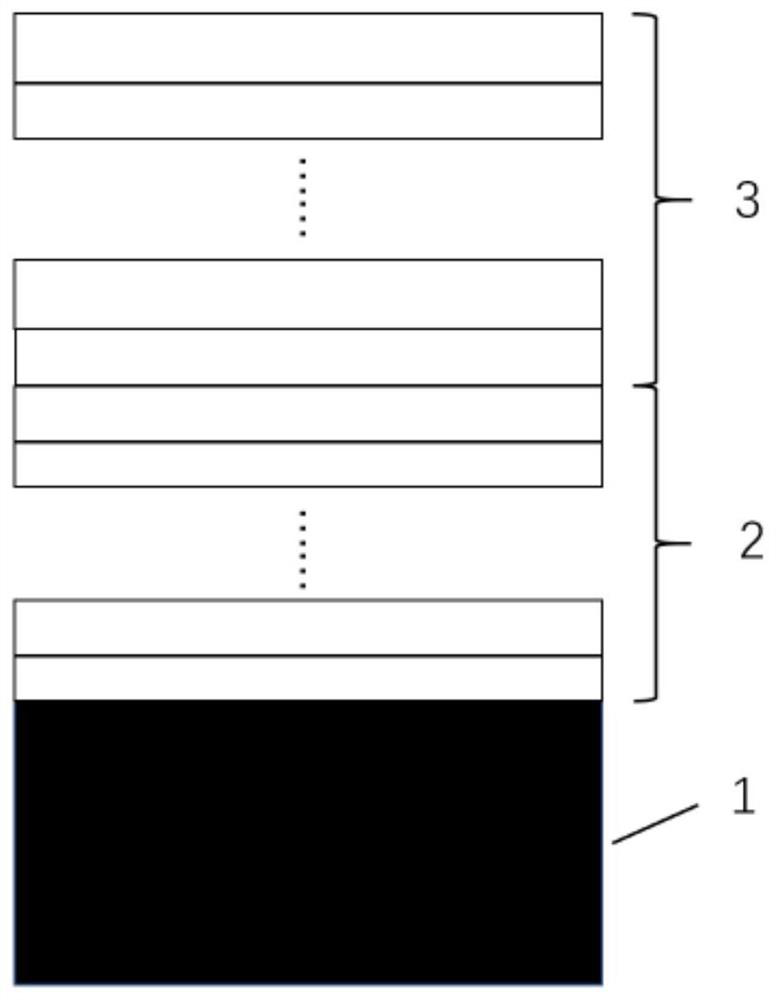

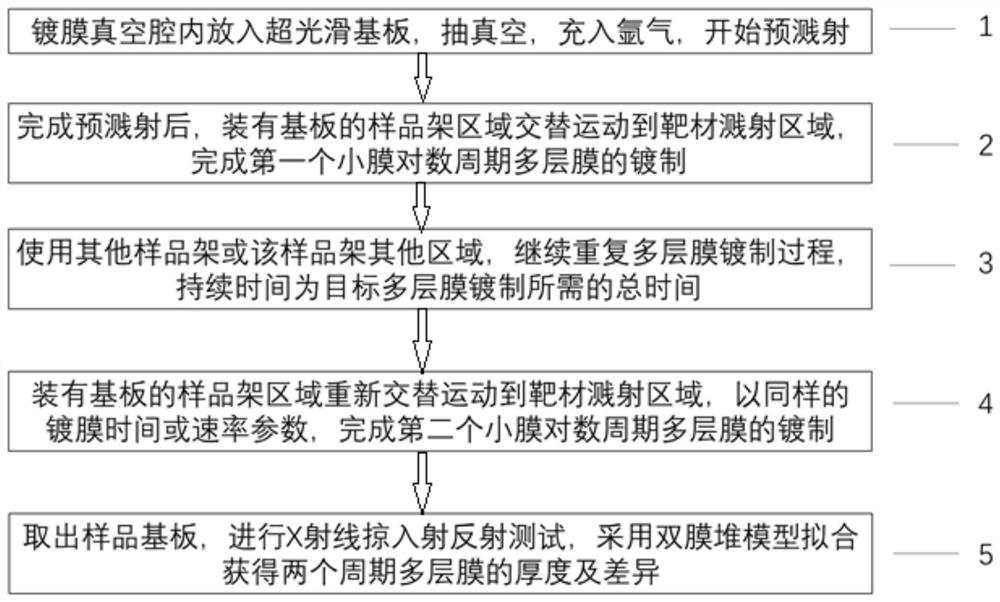

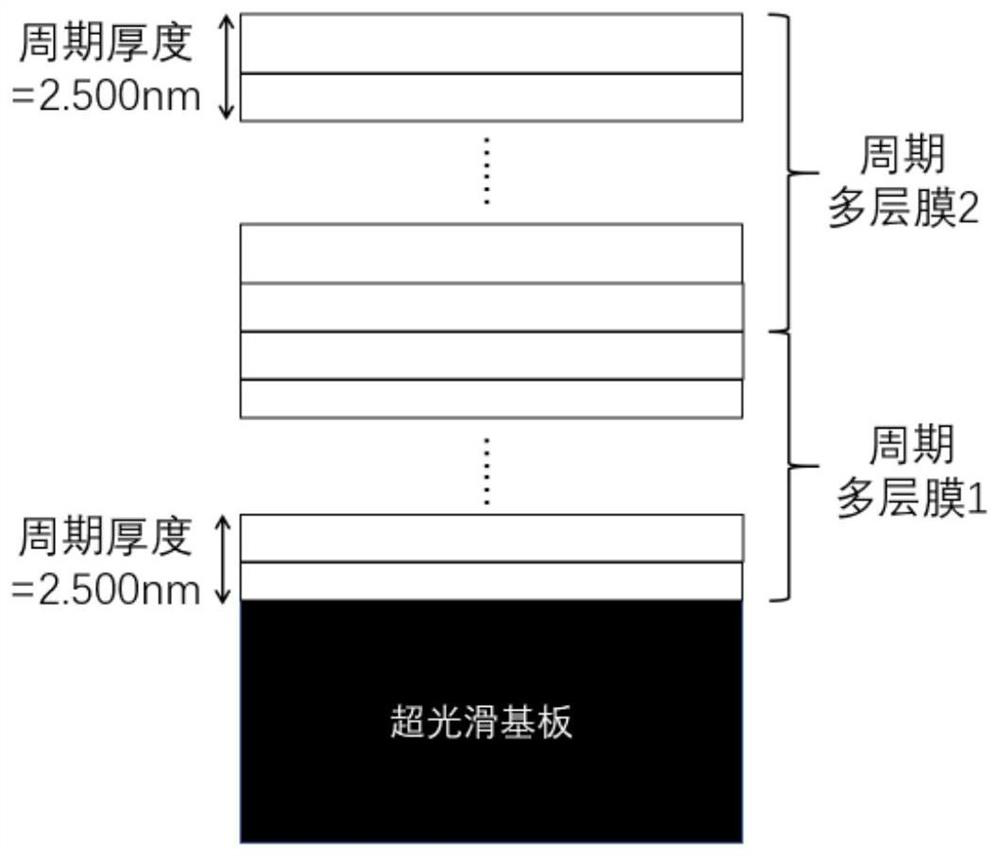

[0037] In this embodiment, the target period multilayer film is palladium / boron carbide, the period thickness is 2.5nm, the total number of film pairs of the finished multilayer film is 150 pairs, and the length of the multilayer film reflector for the synchrotron radiation light source monochromator is generally 300mm. It takes 25-30 hours to complete the plating of this large-scale palladium / boron carbide multilayer film mirror by using magnetron sputtering technology. During the long-term sputtering process, due to the change of the voltage and current of the palladium and boron carbide target guns, and the change of the depth of the etching ring on the target surface, the film deposition rate will drift slightly, and the general drift range is 1% to 5%. about. According to calculations, in order to obtain high reflectivity of the multi-layer film, the thickness drift range of all film layers in the structure cannot exceed 2%, corresponding to an absolute thickness drift va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com